Chris Hamilton

.

January 30, 2019

.

C10 Builders Guide

Chris Hamilton

.

January 30, 2019

.

C10 Builders Guide

Outfitting a Vintage C10 with a Wilwood Big Brake System

There’s a lot of things we like about vintage trucks: timeless styling, mechanical simplicity, and mystic nostalgia. But braking performance isn’t one of them. Though they were fine for country road speeds and farm truck utility, the binders on these old trucks don’t meet the expectations of today’s enthusiasts.

Luckily for us, Wilwood Engineering offers complete, high-end braking options for historic trucks. After discussing our goals with the company, Wilwood recommended their 2.5” drop ProSpindles (P/N 831-14202), AERO6 Big Brake Front kit (P/N 140-15305), and AERO4 Big Brake rear kit (P/N 140-10941) for our 1977 C10 pickup. Besides giving us upgraded braking ability, the big brake kits fill our 20” wheel package nicely.

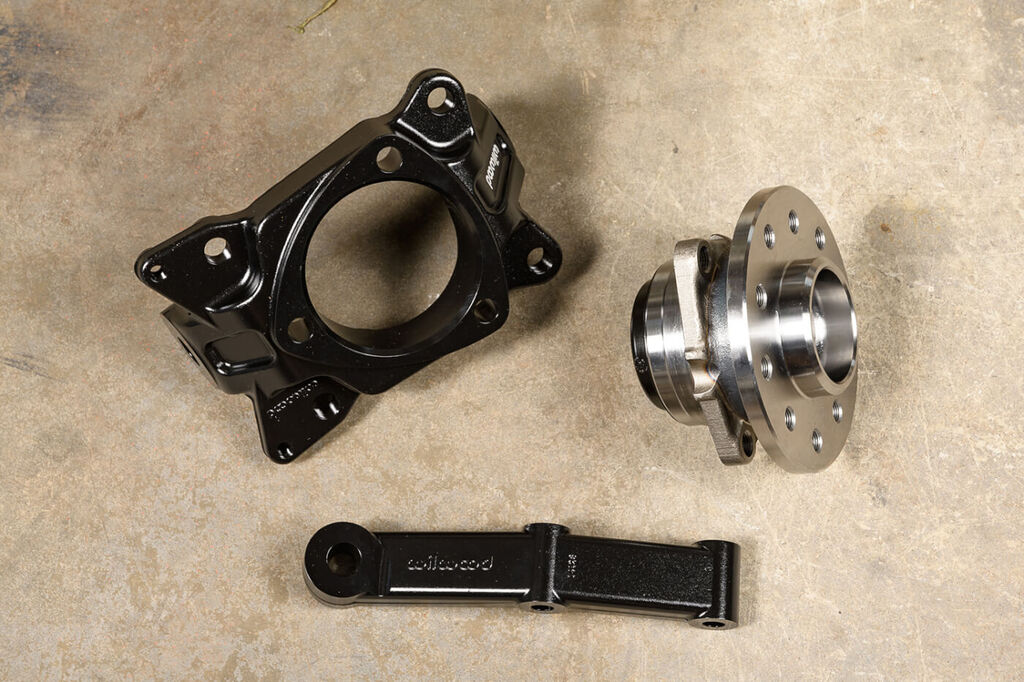

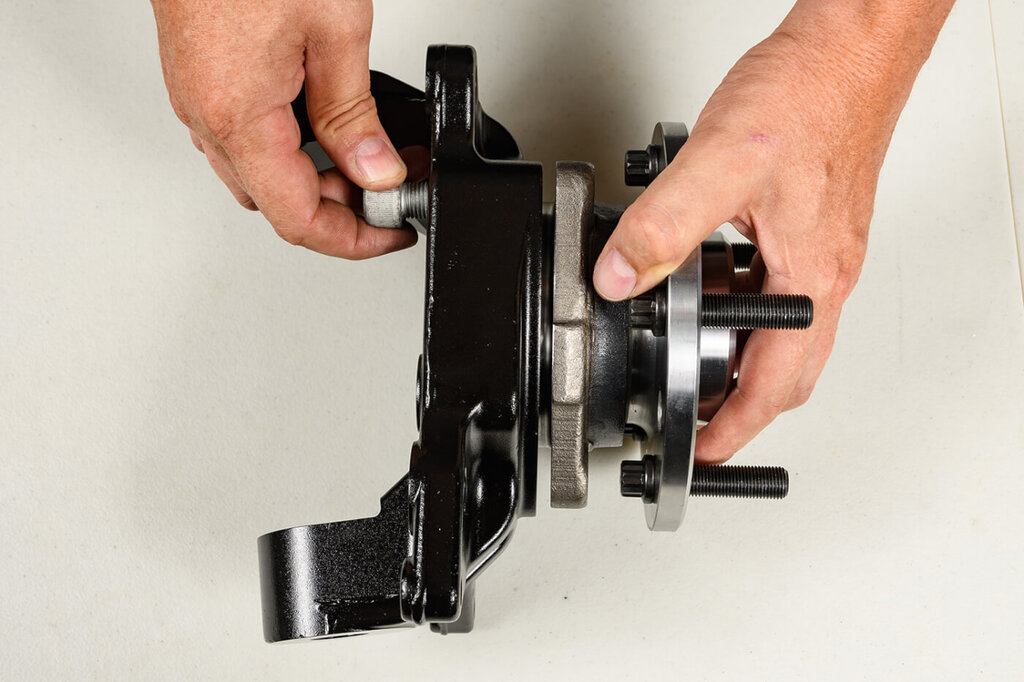

Like all of Wilwood’s components, the ProSpindles are works of art. The kit includes a pair of forged aluminum spindles, steering arms, and bolt-in hubs. The ProSpindles work with Wilwood’s disc brake kits and provide a 2.50” drop for a more aggressive stance without affecting steering geometry. The hub is drilled for both 5 x 4.75” and 5 x 5.00” wheel bolt circles. They’re covered in a durable black e-coat for long-lasting good looks.

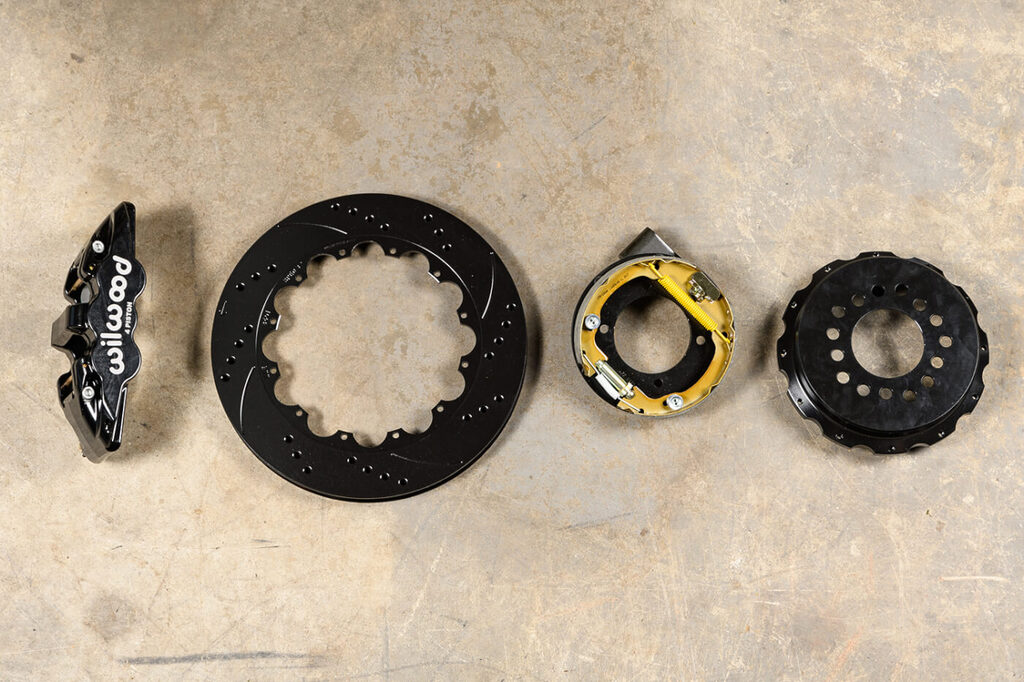

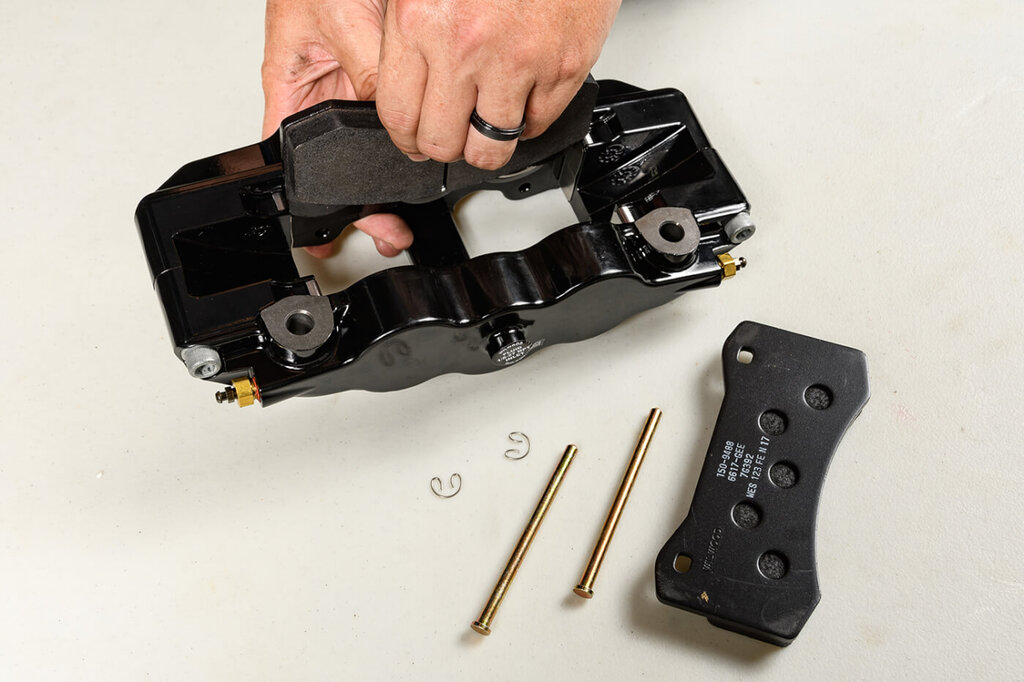

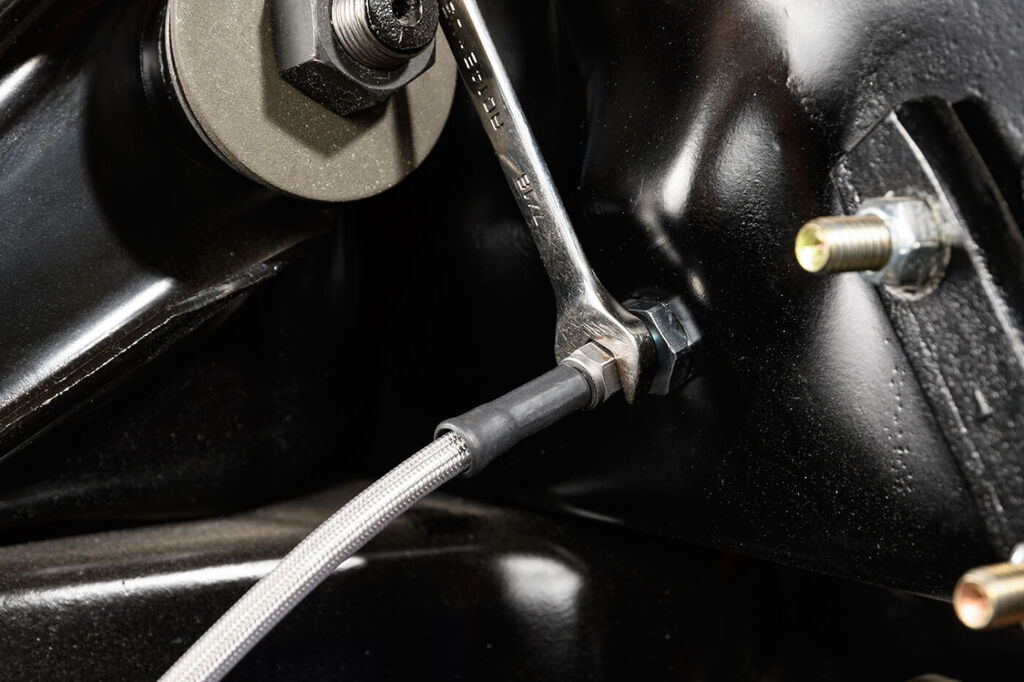

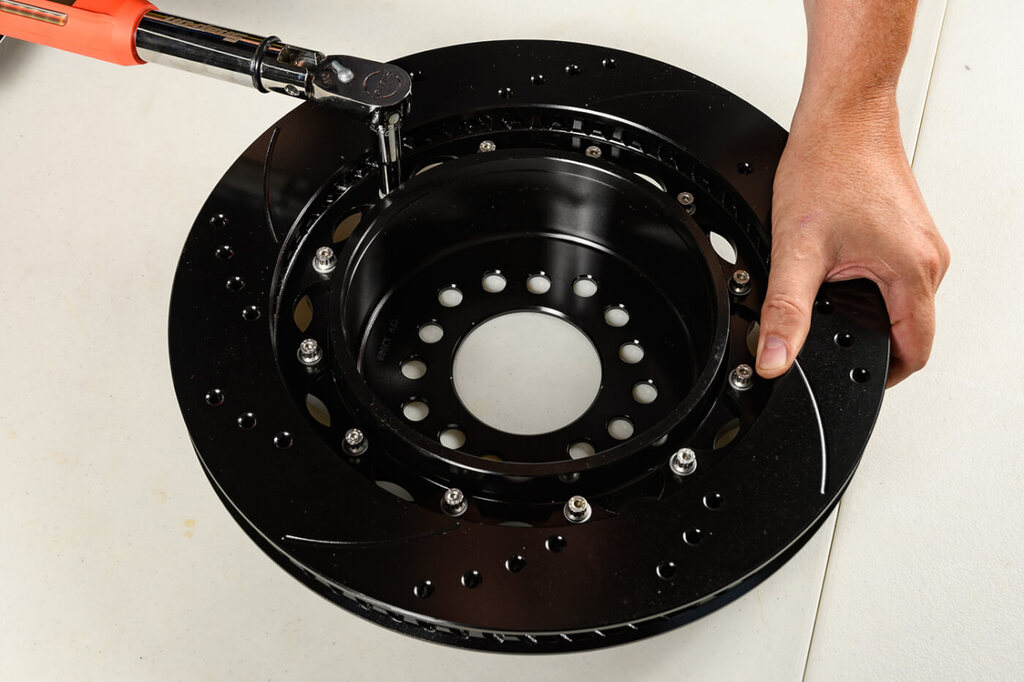

Wilwood’s Big Brake Front kit includes AERO6 calipers and 14” rotors that are designed for heavy trucks with big diameter wheels like our 1977 C10. Even though the AERO6 Big Brake kit is compatible with most OEM master cylinders, we opted for Wilwood’s aluminum tandem master and proportioning valve.

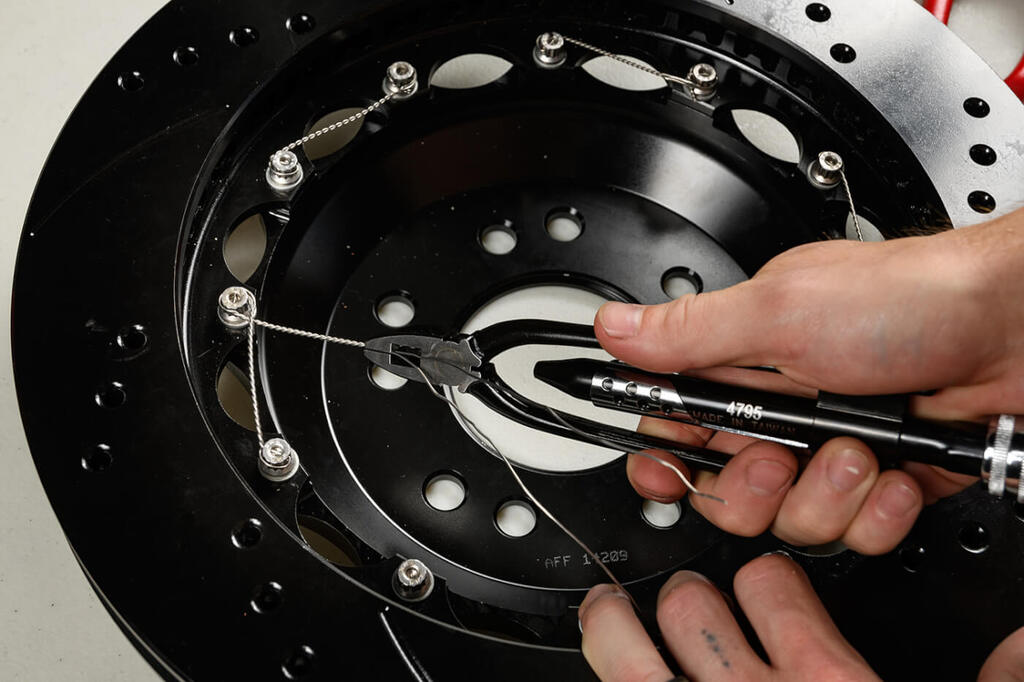

The rear setup consists of Wilwood’s AERO4 calipers and 14” rotors. The calipers share the look of a 6-piston piece but feature four pistons for proper brake force proportion between the front and rear. The integrated parking brake system is hidden neatly inside the rotor hat. Slick!

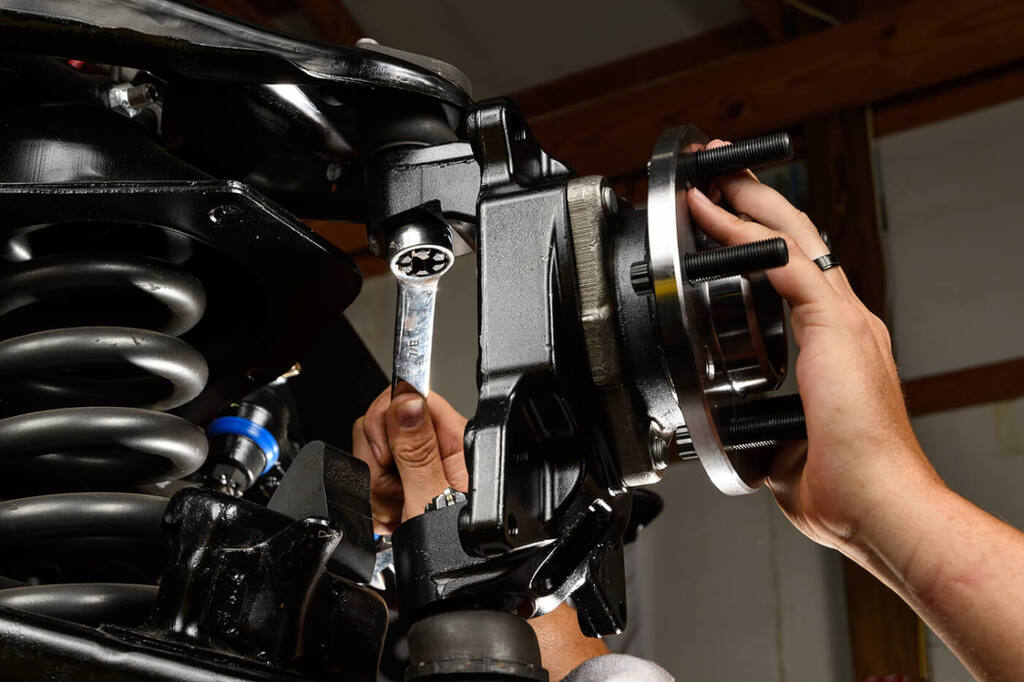

Besides improving the looks and braking performance of our C10, the Wilwood spindle and brake combination saved a whopping 34 pounds of unspring weight at each front corner! We’ll have to install the master cylinder and proportioning valve when our cab is mounted, but we were really impressed by the overall quality and fitment of the Wilwood AERO6 and AERO4 kits. It’s clear that a lot of thought went into the components, and the detailed instructions kept us out of trouble. Everything fit beautifully, and the black e-coat the components (especially the rotors) was a nice touch. We can’t wait to get our truck back together and give these brakes a workout!

Source:

Wilwood Engineering

4700 Calle Bolero

Camarillo, CA 93012

(805) 388-1188

How has Wilwood Engineering grown since its inception?

Wilwood Engineering began as a small, family-owned business when Bill Wood founded it in 1977. Initially, it focused on crafting brake systems designed specifically for racing. Over the years, their commitment to quality and innovation allowed them to carve out a significant niche in the high-performance aftermarket and racing brakes sectors.

From these humble beginnings, Wilwood Engineering dramatically expanded its reach. They are now a leading name in high-performance braking systems, recognized by car enthusiasts and professionals alike. This growth wasn’t just about increasing their product range but also about continuously improving their existing offerings to meet the rigorous demands of the racing community.

Their evolution is marked by a relentless pursuit of excellence and a robust innovation pipeline. By consistently introducing new technologies and refining their brake systems, Wilwood has maintained its position at the forefront of the industry. Today, their products are synonymous with reliability and performance, making them a preferred choice for both amateur and professional racers.

Through strategic growth and a commitment to quality, Wilwood Engineering has transformed from a niche player into a dominant force in high-performance braking systems.

What is the history of Wilwood Engineering?

Wilwood Engineering’s journey began in a modest garage behind the home of founder Bill Wood in Camarillo, California. Bill’s passion for designing brake systems for hot rods gradually evolved from a hobby into a full-fledged business. Established in 1977, the company has remained a family-owned and operated venture, deeply rooted in the heart of the high-performance aftermarket sector specializing in racing brakes.

From its humble origins, Wilwood Engineering steadily ascended to prominence, eventually becoming a household name in high-performance braking systems. Renowned for their dedication to quality and innovation, the company has earned a stellar reputation over the decades. Not just hobbyists, but top-tier racing teams and professional motorsports organizations consistently vouch for Wilwood’s superior disc brakes. This widespread acclaim underscores the brand’s commitment to engineering excellence and its pivotal role in the competitive world of racing.

With each passing year, Wilwood Engineering continues to build on its rich legacy, cementing its status as an industry leader renowned for performance and reliability.

What was the motivation behind the founding of Wilwood Engineering?

Bill Wood’s journey into the world of high-performance brake systems began in a small garage located behind his house in Camarillo, California. His passion for designing brake systems for hot rods wasn’t just a pastime; it was a full-fledged hobby that he cherished. This drive and enthusiasm eventually spurred him to turn his hobby into a full-time enterprise.

In 1977, recognizing a gap in the market for race-proven brake systems, Bill officially established his business. The core motivation was clear: to deliver highly effective and reliable braking solutions for the performance and racing communities. With a commitment to quality and a penchant for innovation, this family-owned business quickly carved out a reputable niche in the high-performance braking industry.

From its humble beginnings, the company has grown substantially, gaining recognition as a top name in the market. The dedication to producing the best disc brakes available today continues to fuel the company’s mission, ensuring that the original motivation behind its founding still drives operations and innovations.

Where is Wilwood Engineering headquartered?

Wilwood Engineering is based in Camarillo, California, where they specialize in creating high-performance disc brake systems.

What is the legacy and expertise of Speedway Motors in the automotive industry?

Since its inception in 1952, Speedway Motors has become a trusted partner for auto enthusiasts and racers alike. Collaborating with top-tier brands, they have continuously facilitated the journey of building remarkable cars that captivate both in terms of style and performance.

With over seven decades in the industry, Speedway Motors has amassed a wealth of knowledge and experience. This long-standing presence has allowed them to refine their offerings and ensure every product meets the highest standards. Their expertise spans across three generations, epitomizing a deep-rooted commitment to quality.

Speedway Motors’ collaboration with industry-leading brands like Wilwood has further solidified their reputation. These partnerships are not just about providing products but fostering a network of support that helps enthusiasts achieve their automotive dreams. Whether you’re seeking top-notch brakes or specialized components, their extensive catalog is designed to cater to both style and performance-centric needs.

What sets Speedway Motors apart is their unwavering dedication to helping customers build their projects right the first time. Each product is carefully selected and supported by expert advice, ensuring that every purchase contributes to a successful build. This commitment to customer satisfaction is evident in their comprehensive product support and affordable pricing.

Speedway Motors stands by the quality of their offerings. The products available are not only high performing but also backed by generations of automotive wisdom. This assurance means that when you buy from them, you can trust that you are getting components that will deliver exceptional results on the road or the track.

In summary, Speedway Motors’ legacy in the automotive industry is marked by a rich history, strong partnerships, and an unwavering focus on quality and expertise. Their enduring presence and customer-first approach make them a cornerstone for anyone passionate about building and refining their automotive projects.

How does Wilwood Engineering collaborate with Speedway Motors to serve auto enthusiasts and racers?

Since 1952, a trusted partnership has flourished between Wilwood Engineering and Speedway Motors, bringing auto enthusiasts and racers unparalleled access to high-performance braking solutions. This dynamic collaboration ensures that whether your passion lies in enhancing your vehicle’s style or boosting its performance, you have the support and the products you need.

Every product born from this partnership is backed by three generations of automotive know-how:

Wilwood Engineering and Speedway Motors cater to a broad spectrum of automotive interests:

This collaboration goes beyond mere product provision:

By combining high-quality products with exceptional customer support, Wilwood Engineering and Speedway Motors create an empowering environment for car builders of all levels. Whether you’re enhancing your vehicle’s style or its performance, this partnership is dedicated to helping you achieve success.

How does Speedway Motors support its customers in building their cars with Wilwood Brakes products?

For over half a century, Speedway Motors has been a trusted partner for car enthusiasts and racers alike. They provide a comprehensive support system that goes beyond merely offering the Wilwood Brakes products you need.

Firstly, Speedway Motors leverages three generations of automotive expertise to guide you through every step of the car-building process. Their seasoned team is available to offer personalized recommendations and troubleshoot any issues you might encounter, ensuring you get the most out of your Wilwood Brakes products.

By collaborating with top brands like Wilwood, Speedway Motors ensures that you receive only the highest quality components. These products are meticulously vetted to meet stringent performance and safety standards, so you can trust that you’re installing nothing but the best.

Their extensive inventory of Wilwood Brakes components covers everything from calipers and rotors to complete braking systems. This variety allows you to find precisely what you need to match your performance goals and style preferences.

Speedway Motors also provides a wealth of resources to aid you in your build. Detailed tutorials, installation guides, and how-to videos simplify the process, making it easier for both novice builders and seasoned pros to get the job done right the first time.

Lastly, their customer service is second to none, committed to ensuring your complete satisfaction. Whether you need help selecting the right part or have questions about installation, their support team is there to assist you every step of the way.

In summary, Speedway Motors supports its customers by offering expert guidance, high-quality components, an extensive product range, valuable resources, and exceptional customer service. All of this ensures that your car-building experience with Wilwood Brakes products is smooth and successful.

How does Speedway Motors ensure the quality and affordability of Wilwood Brakes parts?

Speedway Motors has stringent quality control measures in place. Each Wilwood Brakes part undergoes meticulous inspection to ensure it meets top-tier standards. By partnering directly with reputable manufacturers like Wilwood, they can guarantee the integrity and performance of every brake component they offer.

Speedway Motors leverages bulk purchasing and strong industry relationships to keep costs down. This allows them to pass on savings directly to customers, ensuring that high-quality Wilwood Brakes parts are available at competitive prices. They are committed to providing value without compromising quality.

The selection process at Speedway Motors is thorough. Their team of automotive experts carefully curates their inventory, focusing only on parts that meet strict performance criteria. This expertise ensures that customers receive products that are both reliable and cost-effective.

By combining these strategies, Speedway Motors ensures that every Wilwood Brakes part delivers exceptional performance at an affordable price.

What makes Wilwood’s calipers stand out in the market?

Wilwood’s Big Brake Front kit includes AERO6 calipers and 14” rotors that are designed for heavy trucks with big diameter wheels like our 1977 C10. Even though the AERO6 Big Brake kit is compatible with most OEM master cylinders, we opted for Wilwood’s aluminum tandem master and proportioning valve. The rear setup consists of Wilwood’s AERO4 calipers and 14” rotors. The calipers share the look of a 6-piston piece but feature four pistons for proper brake force proportion between the front and rear.

Wilwood’s innovative calipers are some of the most rugged, reliable racing brake components available on the market today. This innovation is showcased in their AERO6 and AERO4 calipers, both designed to provide exceptional performance and durability. The AERO6 calipers are particularly noteworthy, offering superior braking power ideal for heavy trucks, while the AERO4 calipers ensure balanced braking force for optimal performance.

By integrating these advanced features, Wilwood continues to lead the market in high-performance braking solutions, making their calipers a top choice for both racing enthusiasts and everyday drivers seeking unmatched quality and reliability.

What are the benefits of using Wilwood brakes for racing and high-performance applications?

Wilwood Engineering offers complete, high-end braking options for historic trucks. After discussing our goals with the company, Wilwood recommended their 2.5” drop ProSpindles (P/N 831-14202), AERO6 Big Brake Front kit (P/N 140-15305), and AERO4 Big Brake rear kit (P/N 140-10941) for our 1977 C10 pickup. Besides giving us upgraded braking ability, the big brake kits fill our 20” wheel package nicely.

Wilwood has developed advanced rim and disc brakes for all kinds of applications requiring superior performance and durability. These high-performance braking systems are not only robust but also versatile, making them suitable for various high-performance needs.

Even though the AERO6 Big Brake kit is compatible with most OEM master cylinders, we opted for Wilwood’saluminum tandem master and proportioning valve.

Wilwood offers the optimal mix of performance, reliability, and ease of use, making it a great choice for even novice racing enthusiasts. Their user-friendly systems ensure that even those new to high-performance racing can master them effectively.

Besides improving the looks and braking performance of our C10, the Wilwood spindle and brake combination saved a whopping 34 pounds of unsprung weight at each front corner!

Wilwood takes pride in being the leader in rotor technology, offering not only high-performance brakes but an easy-to-master system. The core of the company remains focused on customer service and support. By working closely with racers and enthusiasts, Wilwood has become synonymous with quality.

Their brakes are used at every level of motorsports in the world, proving their reliability and trustworthiness. The quality of Wilwood products is measured not only by how they perform in competition but also by how they perform under real-world conditions.

The 14-inch rotors and four-piston rear calipers are a great match for the front brakes, and really set our truck apart from the crowd.

Products that exceed customer expectations are rewarded with exceptional customer feedback. This extensive use in global motorsports shows that Wilwood brakes are designed to perform under the most demanding conditions, ensuring both safety and excellence.

By seamlessly integrating Wilwood’s advanced technology, usability, and proven track record, our 1977 C10 pickup now boasts a braking system that stands out both in performance and appearance.

How does Wilwood Engineering maintain its quality and innovation in brake systems?

“Everything fit beautifully, and the black e-coat on the components (especially the rotors) was a nice touch. We can’t wait to get our truck back together and give these brakes a workout! … It’s clear that a lot of thought went into the components, and the detailed instructions kept us out of trouble.”

Wilwood Engineering, founded in 1977, has built a reputation for excellence on the pillars of integrity, quality, and design. The company specializes in the rapid development of custom-engineered brake systems, combining off-the-shelf and custom components to meet diverse needs.

Built on a philosophy of quality over quantity, Wilwood has become the most trusted name in high-performance braking systems. This commitment to quality is evident not only in their innovative calipers but also in their meticulous attention to detail, which ensures that even novice racing enthusiasts can easily master their systems.

The company’s history is rooted in a desire to create better brake products. Bill Wood, frustrated with the unreliable brakes on his hot rod, decided to craft superior ones. From these humble beginnings, Wilwood has grown into a recognized leader in brake technology, continuously developing advanced rim and disc brakes for various applications.

What sets Wilwood apart is their focus on customer service and support. By working closely with racers and enthusiasts, they ensure their products meet real-world demands. Their brakes are used at every level of motorsports, and the quality is measured by how well they perform both in competition and everyday conditions.

Wilwood’s dedication to innovation and customer satisfaction is reflected in their products, which consistently exceed expectations and garner exceptional feedback.

“Everything fit beautifully, and the black e-coat on the components (especially the rotors) was a nice touch. We can’t wait to get our truck back together and give these brakes a workout! … It’s clear that a lot of thought went into the components, and the detailed instructions kept us out of trouble.”

From the initial design to the final product, Wilwood’s attention to detail and commitment to quality ensure that you are getting the best braking system on the market. With Wilwood, you can rest easy knowing you have the brakes that countless racers already count on.

What kind of brake systems does Wilwood Engineering design and manufacture?

Luckily for us, Wilwood Engineering offers complete, high-end braking options for historic trucks. Wilwood Engineering has been designing and manufacturing high-performance disc brake systems since 1977. They specialize in the rapid development of custom-engineered brake systems, combining both off-the-shelf and custom components to meet diverse needs.

After discussing our goals with the company, Wilwood recommended their 2.5” drop ProSpindles (P/N 831-14202), AERO6 Big Brake Front kit (P/N 140-15305), and AERO4 Big Brake rear kit (P/N 140-10941) for our 1977 C10 pickup. This recommendation demonstrates their expertise in providing tailored solutions that enhance performance and maintain the authenticity of historic vehicles.

By leveraging their extensive experience and innovative approach, Wilwood ensures that each braking system not only meets but exceeds expectations, making them a top choice for custom and high-performance applications.

How does Wilwood Engineering ensure the performance and durability of its products?

Like all of Wilwood’s components, the ProSpindles are works of art. The kit includes a pair of forged aluminum spindles, steering arms, and bolt-in hubs. The ProSpindles work with Wilwood’s disc brake kits and provide a 2.50” drop for a more aggressive stance without affecting steering geometry. The hub is drilled for both 5 x 4.75” and 5 x 5.00” wheel bolt circles. They’re covered in a durable black e-coat for long-lasting good looks.

It’s clear that a lot of thought went into the components, and the detailed instructions kept us out of trouble. Everything fit beautifully, and the black e-coat the components (especially the rotors) was a nice touch.

Wilwood’s commitment to performance and durability shines through every product they create. By continuously developing advanced rim and disc brakes, they ensure superior performance across various applications. This dedication to innovation is evident in the ProSpindles’ design, merging advanced technology with user-friendly features.

Wilwood doesn’t just stop at creating high-performance components; they strive to offer an optimal mix of reliability and ease of use. This makes their products a great choice for novice racing enthusiasts and seasoned pros alike. The ProSpindles’ seamless compatibility with Wilwood’s disc brake kits exemplifies this philosophy, providing a user-friendly experience without compromising on performance.

Customer feedback plays a crucial role in Wilwood’s quality assurance. By working closely with racers and enthusiasts, they continually refine their products to meet and exceed expectations. This customer-centric approach ensures that their components perform flawlessly not only in competitive motorsports but also under real-world conditions.

The leadership in rotor technology underscores Wilwood’s focus on innovation. Their products aren’t just high-performance; they’re designed to be mastered easily, making them accessible to all levels of racing enthusiasts. This blend of cutting-edge technology and practical usability is a hallmark of Wilwood’s engineering excellence.

In summary, Wilwood’s dedication to continuous improvement, customer satisfaction, and technological leadership ensures that every product, including the ProSpindles, meets the highest standards of performance and durability. This holistic approach to engineering is why their components are trusted at every level of motorsports worldwide.

What kind of support does Wilwood Engineering offer to racers and enthusiasts?

Luckily for us, Wilwood Engineering offers complete, high-end braking options for historic trucks. After discussing our goals with the company, Wilwood recommended their 2.5” drop ProSpindles (P/N 831-14202), AERO6 Big Brake Front kit (P/N 140-15305), and AERO4 Big Brake rear kit (P/N 140-10941) for our 1977 C10 pickup. Besides giving us upgraded braking ability, the big brake kits fill our 20” wheel package nicely.

The core of Wilwood Engineering remains focused on customer service and support. By working closely with racers and enthusiasts, Wilwood has become synonymous with quality. Their dedication to understanding customer needs and providing tailored solutions sets them apart in the industry. This commitment was evident in our experience, as they patiently listened to our requirements and offered the best possible recommendations for our project.

Whether you are a seasoned racer or an automotive enthusiast, Wilwood’s hands-on approach ensures you receive not only top-notch products but also unparalleled support throughout your journey.

What role does Wilwood Engineering play in the high-performance aftermarket and racing brakes market?

Luckily for us, Wilwood Engineering offers complete, high-end braking options for historic trucks. After discussing our goals with the company, Wilwood recommended their 2.5” drop ProSpindles (P/N 831-14202), AERO6 Big Brake Front kit (P/N 140-15305), and AERO4 Big Brake rear kit (P/N 140-10941) for our 1977 C10 pickup. Besides giving us upgraded braking ability, the big brake kits fill our 20” wheel package nicely.

Wilwood Engineering, a family-owned business founded by Bill Wood in 1977, has been at the forefront of the high-performance aftermarket and racing brakes market for decades. From its humble beginnings, Wilwood has grown to become the most recognized name in high-performance braking systems. Their dedication to quality and innovation is evident in every product, and they are known for offering the best disc brakes on the market today.

By integrating advanced technology and race-proven designs, Wilwood ensures that their braking systems not only enhance safety but also deliver superior performance. This commitment to excellence has cemented their reputation among enthusiasts and professionals alike, making them a go-to choice for high-performance braking solutions.

What kind of reputation does Wilwood Engineering have?**

Wilwood Engineering is renowned for offering some of the best disc brakes available today.

What is the company’s commitment to quality and innovation?**

The company is dedicated to producing high-quality and innovative braking systems.

What type of company is Wilwood Engineering?**

Wilwood Engineering is a family-owned and operated business.

What is the market position of Wilwood Engineering?**

Wilwood Engineering is a leading name in the high-performance aftermarket and racing brakes market.

When was Wilwood Engineering founded?**

Wilwood Engineering was established in 1977.

How do customers and racing teams perceive Wilwood Engineering’s products?

“Luckily for us, Wilwood Engineering offers complete, high-end braking options for historic trucks. After discussing our goals with the company, Wilwood recommended their 2.5” drop ProSpindles (P/N 831-14202), AERO6 Big Brake Front kit (P/N 140-15305), and AERO4 Big Brake rear kit (P/N 140-10941) for our 1977 C10 pickup. Besides giving us upgraded braking ability, the big brake kits fill our 20” wheel package nicely. It’s clear that a lot of thought went into the components, and the detailed instructions kept us out of trouble. Everything fit beautifully, and the black e-coat the components (especially the rotors) was a nice touch.”

Wilwood has built a reputation as the most trusted name in high-performance braking systems and components since its inception in 1977. The company’s mission has always been to develop superior products that exceed customer expectations, a goal they consistently achieve.

This combination of personal experience and widespread acclaim makes it clear that Wilwood products are designed not only with precision and care but also with the end-user in mind. Whether you’re upgrading a classic truck or competing at the highest levels of motorsport, Wilwood’s commitment to quality and performance ensures you’re getting top-tier braking solutions.

What is the significance of customer service and support for Wilwood Engineering?

There’s a lot of things we like about vintage trucks: timeless styling, mechanical simplicity, and mystic nostalgia. But braking performance isn’t one of them. Though they were fine for country road speeds and farm truck utility, the binders on these old trucks don’t meet the expectations of today’s enthusiasts.

Luckily for us, Wilwood Engineering offers complete, high-end braking options for historic trucks. After discussing our goals with the company, Wilwood recommended their 2.5” drop ProSpindles (P/N 831-14202), AERO6 Big Brake Front kit (P/N 140-15305), and AERO4 Big Brake rear kit (P/N 140-10941) for our 1977 C10 pickup. Besides giving us upgraded braking ability, the big brake kits fill our 20” wheel package nicely.

It’s clear that a lot of thought went into the components, and the detailed instructions kept us out of trouble. Everything fit beautifully, and the black e-coat the components (especially the rotors) was a nice touch. We can’t wait to get our truck back together and give these brakes a workout!

The core of Wilwood’s operations remains focused on customer service and support. By working closely with racers and enthusiasts, Wilwood has become synonymous with quality. Their brakes are used at every level of motorsports around the world, ensuring they meet the high standards of performance and reliability.

Products that exceed customer expectations are rewarded with exceptional feedback. This feedback loop is crucial, as it helps Wilwood continually refine their offerings to better serve their customers. The quality of Wilwoodproducts is measured not only by how they perform in competition but also by how they perform under real-world conditions.

Incorporating customer feedback into their product development process, Wilwood ensures that their brakes deliver exceptional performance both on the track and on the road. This dedication to quality and customer satisfaction is evident in every component, from the ProSpindles to the AERO6 and AERO4 Big Brake kits.

By focusing on customer service and support, Wilwood not only meets but often exceeds the expectations of modern enthusiasts. This commitment to excellence is what makes their products stand out, whether you’re upgrading a vintage truck or competing in a high-stakes race.

Share Link