Chris Hamilton

.

August 11, 2021

.

Department

Chris Hamilton

.

August 11, 2021

.

Department

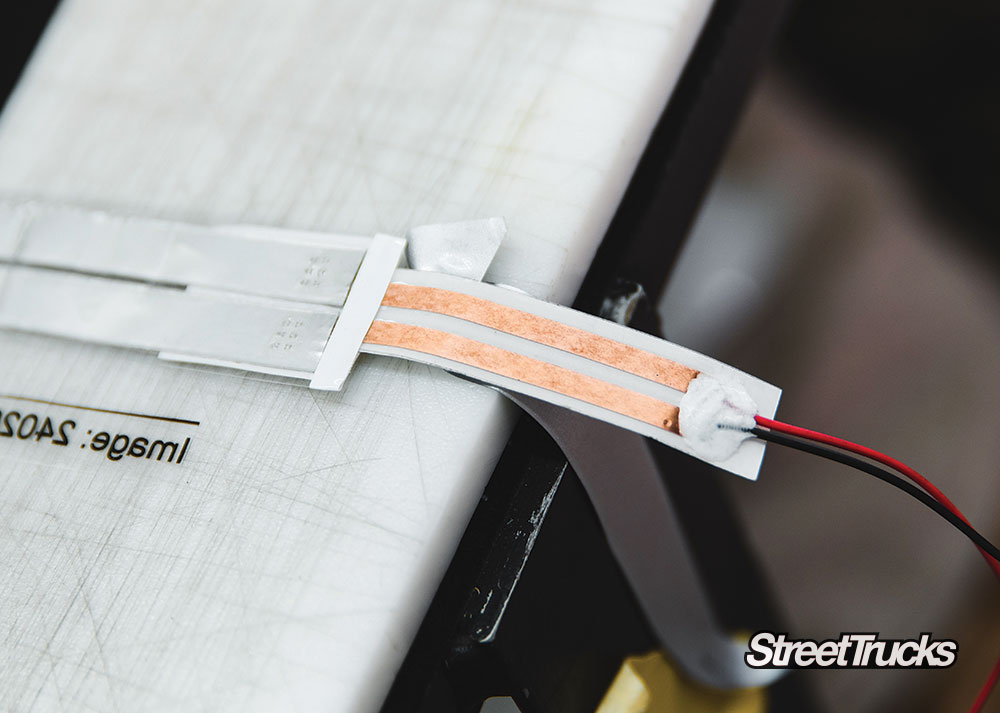

If you remember from the last issue, we dropped off our 1998 GMC Sierra known as Project Artemis to the amazing minds at Glarb Wrapped and Tate Designs for an overhaul of epic proportions. A combination of a killer design, high quality prints and one of the best installers in the game is all that it took to transform this basic bagged Bowtie into a motorized masterpiece we can’t wait to take to shows. Not only is the design eye-catching and hypnotizing, but it also incorporates LED panels underneath the wrap that light up at the push of a button. Now the name of the truck can be seen at night, which will definitely stand out in the crowd.

Ryan Sandoval from Glarb Wrapped sent his files to We Print Wraps, and within a few weeks we were watching them install a high-quality material that will last as long as paint. With a design this intricate, Ryan only trusted one crew to lead with the install. Tate designs in Ft. Lauderdale, Florida, was proud to participate and happily lead the charge. Tape measures went flying and numbers were being calculated in their heads faster than we could take photos, but there’s a method to their madness that you can only appreciate if you just sit back and watch the process. We were able to hang out with them for the entire week as they sanded, stripped and wrapped the entire truck from bumper to bumper. Their work is amazing, and from what we know it’s second to none. We have a whole new respect for this particular industry, and before you drop your deposit at your favorite paint shop, just give this method of metal masking another look. Check out the steps it takes to prepare these wraps and line them up correctly.

Share Link