Mike Self

.

September 14, 2022

.

Blood Sweat and Gears

Mike Self

.

September 14, 2022

.

Blood Sweat and Gears

It’s crazy to think that the LS engine is now about a quarter century old, but here we are toward the tail end of its mass production. With the Gen V now in full swing and taking over every new GM engine compartment that once housed an LS, are the LS’s days as a viable swap option numbered? We certainly don’t think so, and it seems that you don’t either!

Whether you’re starting out with a daily friendly 4.8L LR4 or going HAM with a 7.0L LS7, it’s hard to make a wrong decision when swapping or modding an LS-based engine. So, we’ve compiled the top 10 questions we’ve been asked about them and offer you some simple answers to hopefully enlighten and entertain.

LS engines, like most engines, are pretty reliable as long as they’ve been properly maintained, and they’re even pretty decent when somewhat neglected! They are inherently strong, partly due to their main cap and head designs, which is why it’s not uncommon to see engines with 300,000-plus miles on them with only regular maintenance. Used, high-mileage LS-based engines are seeing large amounts of boost with very minor modifications and usually survive quite a while. So, in our opinion, yes, they’re reliable!

It should come as no surprise that the chief engineers of the LS were not only skilled engine designers, but lifelong gearheads as well. Ed Koerner and Tom Stephens came up with the general architecture of the LS, with design team members Alan Hayman, Jim Mazzola, Ron Sperry, Bill Compton, Brian Kaminski, Jon Lewis, Stan Turek, Don Weiderhold, and Dave Wandel contributing their expertise to one of the world’s most beloved engine platforms.

If we’re including all derivatives, the various displacements that have been available over the years include 4.3L (yup, a V-6 variant released in 2014), 4.8L, 5.3L, 5.7L, 6.0L, 6.2L, 6.6L, and 7.0L engines. Each of these has been refined through multiple iterations and differed depending on the application.

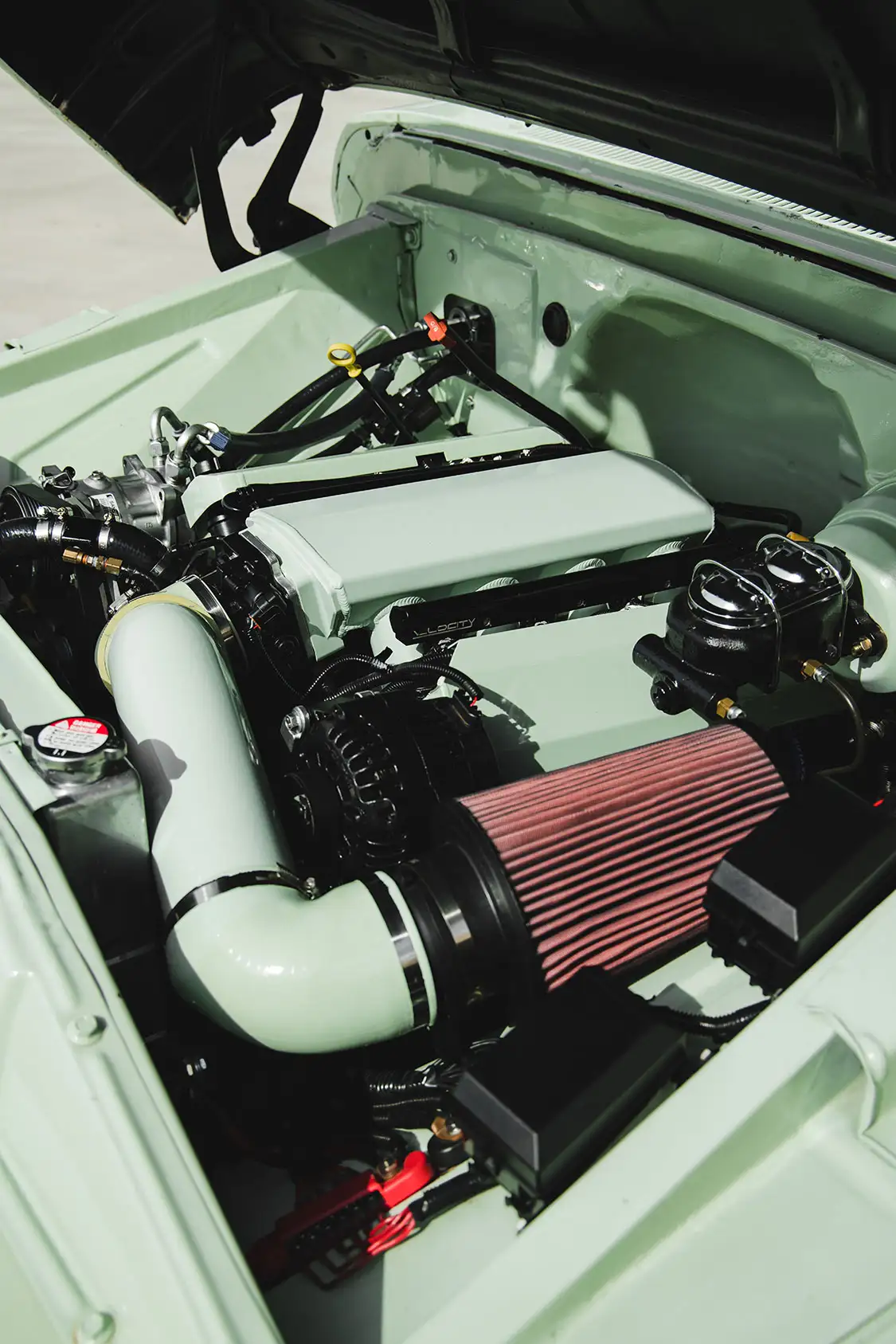

We’re of the mindset that EFI is a better option 99% of the time, but if you’re swapping an LS into a classic truck and want to keep things as simple as possible, a carbureted setup may indeed be a good choice. You’ll need an aftermarket intake manifold designed for a carb, the carb itself, and an electronic ignition controller (LS-based engines don’t have a spot for a distributor and still require an ignition source for the coils). You could install a front-mounted distributor if you really wanted to, or any other multitude of things for that matter, but that’s a lot of trouble to go through to ditch the reliability of EFI. In the end, you’ll have to run your own numbers and see if this is the right move for you.

If we’re talking about any LS engine ever directly offered by GM, the winner is the long-discontinued LSX454R, conservatively rated at 770 horsepower and 612 lb-ft of torque. The most powerful LS in a production vehicle is in the upcoming 2023 Cadillac Escalade V, a 6.2-liter pushing 682 horsepower and 653 lb-ft of torque!

Technically, you can use just about any transmission with the use of an adapter, but luckily the list of options is long, most requiring only minor modifications. Have an old Powerglide or manual 3-speed? Yup, those’ll work with the proper spacers and hardware. So will that Turbo 350 in your uncle’s shed, or even that T-5 5-speed in that Astro at the wrecking yard. There are generally multiple options to achieve any given combination.

The 4L65E and 4L80E automatics are popular choices since they are more robust than the 700R4/4L60E and are made to bolt right on to LS engines. That being said, plenty of folks have used “weaker” transmissions with success when coupled with a consistently light foot. On the manual side, T56s are the usual fare, but some opt for the beefier Tremec TKO-series transmissions.

Of course, the more power and torque your engine have, the stouter you want to go. That’s where the 4L80E and 4L85E really start looking like a good idea!

We thought this question would be a bit more complicated to answer, but as it turns out it’s pretty straightforward! Every LS engine that came out of a passenger car had/has an aluminum block, but trucks and SUVs usually received an iron block. Notable exceptions are the LS2-equipped SSR and Trailblazer SS, and L76-equipped Silverados and Sierras from 2007-2009 (the Avalanche kept the L76 through the 2013 model year).

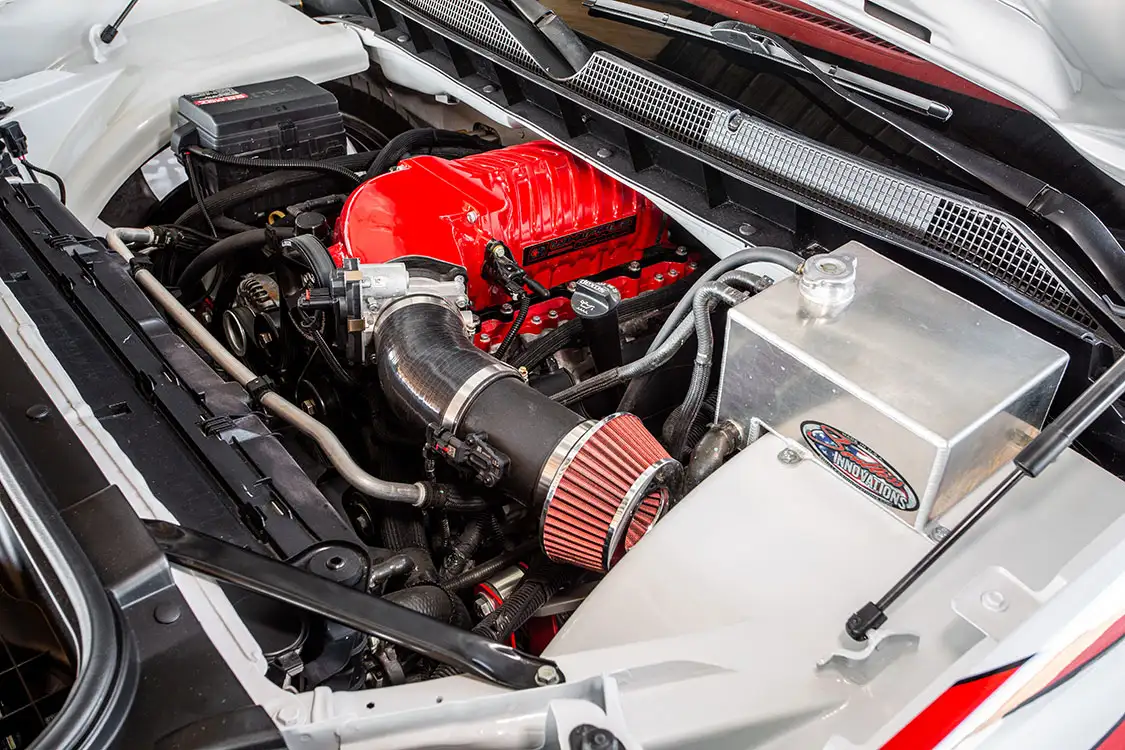

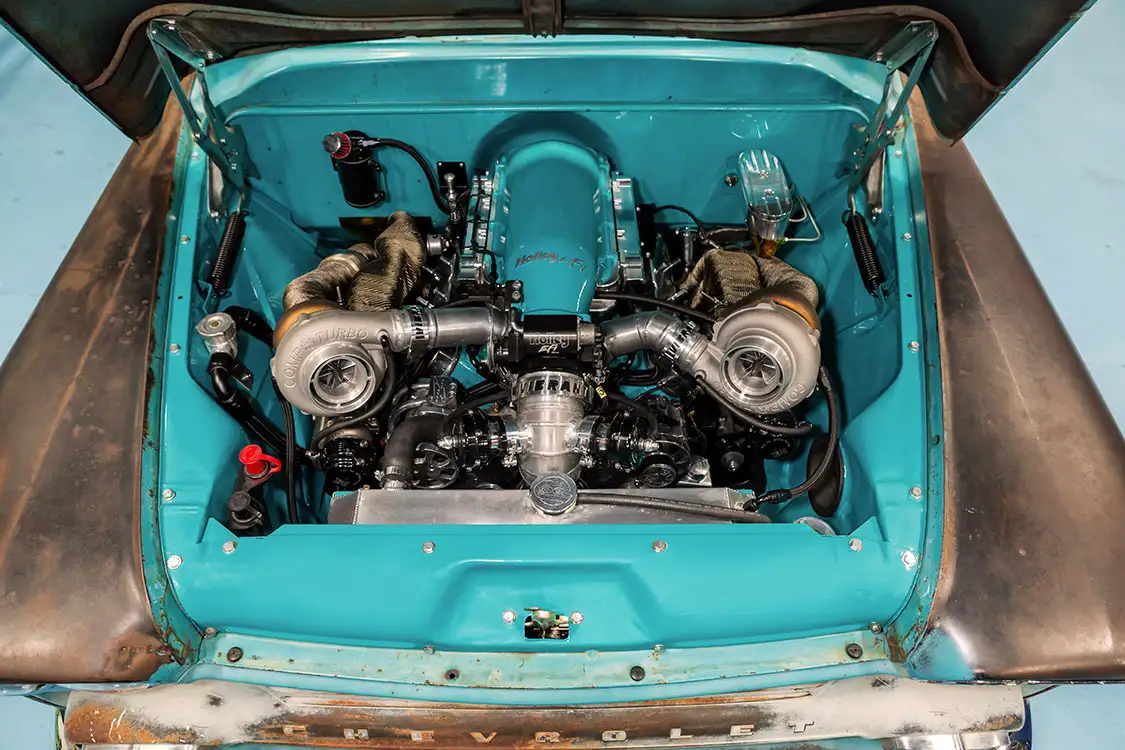

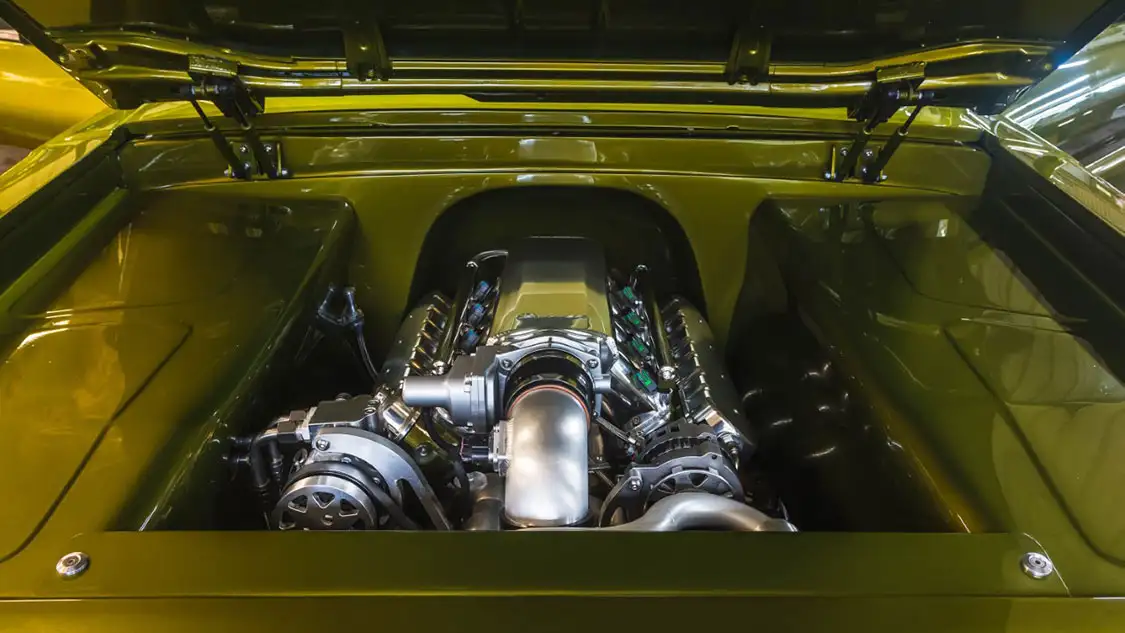

Both 5.3L and 6.0L engines are the most popular for turbocharging since they are widely available and can support up to 1,000 horsepower with proper preparation, but we’ve pretty much seen every iteration of the LS receive boost by now, and both cathedral port and rectangular port heads flow very well under pressure. From backyard “eBay” turbo setups to high-dollar twin-charged dream builds, anything goes when it comes to forced induction on an LS!

The key is to upgrade as much as possible before you go crazy. Oil pumps and timing chains are common failure points, so swapping out the originals for

If money isn’t an object, why not look into factory boosted options such as the LSA, LS9, or even a Gen V LT5 (yeah, we know, but LTs are the future of the small-block, are they not)?

The engine we all know and love was first introduced in 1997 in the C5 Corvette in 345-horsepower 5.7L LS1 form, and as the 270-horsepower 5.3L LM7 in the 1999 Silverado/Sierra. Both engines would receive refinements and improvements over their life cycles, resulting in more power across the board.

Well, that depends! If shopping new, you can’t beat buying an LS through any of Chevrolet Performance’s authorized retailers, but LS-based crate engines are also available from aftermarket companies such as Edelbrock.

If you’re in the market for a good used engine and want to build it yourself, your local Pick-N-Pull type place is likely the cheapest but may result in a dud unless you can inspect the engine thoroughly before buying. It may be in your best interest to purchase any available warranty on the long block.

We’ve had decent luck with used engine resellers as they can usually provide a video of the engine running and will often offer a reasonable warranty. You’ll pay more up front but will receive better service than the pull-it-yourself route.

Lastly, there’s Craigslist, Facebook Marketplace, and any of the other person-to-person websites and apps that sell everything under the sun. At a bare minimum, you’ll want to try to check the compression and the condition of the oil if possible.

How has the E-Rod program evolved over time?

When LS-swaps gained traction among automotive enthusiasts, an innovative program known as the E-Rod was introduced to meet the rising demand for emissions-compliant engines. Initially, the program featured engines like the 5.3-liter variants. These early versions were designed to be integrated into modern vehicles while adhering to stringent emissions regulations, making them legal even in states with tough standards like California.

The shift from the initial 5.3-liter engines to the more powerful LS3s and LSAs demonstrates the program’s growth in both engine options and performance potential. This evolution reflects a commitment to providing enthusiasts with versatile, high-performance engines that respect environmental regulations.

What is the COPO program and its engines designed for?

COPO Program Engines: Engineered for the Track

The Central Office Production Order (COPO) program is renowned for engineering top-notch racing engines. Designed explicitly for high-performance track use, COPO engines are synonymous with power and speed. This program allows for the creation of bespoke engines tailored to racing enthusiasts’ needs.

Investing in a COPO engine, despite the substantial cost, equips you with a robust, race-ready machine. With its 7.0-liter displacement and 427 cubic inches of pure power, it is a favorite among racing aficionados looking to make a mark on the track.

These engines are not just designed for peak performance; they are crafted to deliver a seamless experience during competitive racing, thanks to their precision engineering and high-quality components.

What types of engines were initially offered in the E-Rod program?

When aftermarket engine swaps became increasingly popular for vehicle enthusiasts seeking enhanced performance without sacrificing compliance with emission regulations, an innovator in performance parts introduced the E-Rod program. This initiative aimed to provide engines and drivetrain packages that could be legally swapped into various vehicles while meeting stringent emission standards, even in states known for their rigorous requirements, like California.

In the early stages of the E-Rod program, the selection primarily included 5.3-liter engines. These engines quickly became a go-to option for those looking to upgrade their vehicles without falling afoul of emission regulations.

However, the program didn’t stop there. It evolved to include more powerful options such as the E-Rod LS3 and LSA engines, providing greater performance capabilities while maintaining emission compliance.

By continually expanding and refining their offerings, the E-Rod program catered to the needs of automotive enthusiasts who demanded both performance upgrades and legal compliance.

What is the purpose of the E-Rod program?

The E-Rod program was created to provide a solution for car enthusiasts who wanted to perform engine swaps while still adhering to strict emissions regulations. Essentially, it offers a range of engine and drivetrain packages that can be installed in various vehicles. These packages are carefully designed to ensure that, if the installation guidelines are followed, the modified vehicles will meet stringent emissions standards, even in states with tough regulations like California.

By opting for an E-Rod package, you can enjoy the benefits of improved performance while staying environmentally responsible and legally compliant.

What is the horsepower and torque rating of the LS376/515 crate engine?

The LS376/515 crate engine delivers an impressive 533 horsepower and offers a torque rating of 477 lb-ft. This powerful performance makes it a top choice for enthusiasts seeking enhanced power and responsiveness.

What components are included in the LS376/515 crate engine assembly?

The LS376/515 crate engine features a variety of high-performance components designed to enhance its power and efficiency. Here’s what’s included:

These components work together to deliver a potent and reliable crate engine suitable for various high-performance applications.

What are the features of the LSX-454 and LSX-454R aftermarket engines?

If you’re diving into the world of high-performance engines, the LSX-454 and LSX-454R are two aftermarket powerhouses that stand out.

Both engines pack big-block power and significant displacement within a compact framework, making them perfect for any LS engine swap project. While the LSX-454R is geared towards racing with its higher rev limit and greater horsepower, the LSX-454 is a more balanced option, providing a blend of power and usability for various driving conditions.

Choose the LSX-454R if you’re aiming for peak performance on the track, or opt for the LSX-454 if you want a powerful yet street-appropriate engine transformation.

How Much Does an LS Engine Swap Cost?

Answering, “How much does an LS engine swap cost?” largely depends on your specific goals and budget. Here’s a detailed breakdown to help you understand the various components and their associated costs.

If you aren’t performing the swap yourself, labor costs can add significantly to the overall expense. Professional installation can range from $1,000 to $5,000 or more, depending on complexity and location.

In summary, a basic LS engine swap can start at around $2,500 if you’re doing it yourself with used parts. However, a fully optimized build performed by professionals with all new components can easily exceed $20,000.

Understanding these variables helps you plan effectively, ensuring your LS swap project stays within your budget while meeting your performance expectations.

Which LS Engine is Considered the Best?

When it comes to the best LS engine, enthusiasts have a tough choice. Each offers unique advantages that cater to different needs.

The LS7 stands out for its revolutionary engineering. Known for impressive horsepower and torque, this naturally aspirated engine is ideal for those prioritizing performance and reliability. Its advanced design makes it a top contender for high-performance builds.

On the other hand, the LS9 offers jaw-dropping power, thanks to its supercharged setup. With its robust design, this engine excels in sheer output, making it perfect for those who need maximum horsepower and torque. It’s a dream come true for drag racing and extreme performance applications.

Ultimately, the best LS engine is the one that fits your specific needs and budget. If you need cutting-edge innovation and consistent performance, the LS7 is hard to beat. If raw power and supercharged might are what you’re after, the LS9 is a fantastic choice.

In the end, choosing the best LS engine boils down to matching your desires with what you can afford. Both engines offer stellar performance; it’s up to you to decide which attributes matter most for your project.

What Distinguishes the LS376/515 Crate Engine from the LS3 Engine?

The LS376/515 crate engine elevates the standard LS3 engine by incorporating several high-performance components. Here’s what sets it apart:

All these modifications combine to give the LS376/515 an impressive output of 533 horsepower and 477 lb-ft of torque, significantly surpassing the capabilities of the base LS3 engine.

What makes the LS7 engine in the Camaro Z28 special?

The LS7 engine, a 7.0-liter, 427-cubic-inch powerhouse, makes the Camaro Z28 truly remarkable.

Considerations for Modification: While the LS7 has the potential for further modifications, such as converting it to a wet sump, it is often best appreciated in its original state due to its finely tuned engineering.

In essence, the LS7 engine’s blend of high horsepower, substantial stroke capacity, and track-focused design make it a standout feature in the Camaro Z28, keeping it revered among automotive enthusiasts.

What Makes the LS9 Engine Unique?

The LS9 engine stands out due to several high-performance enhancements that set it apart from other engines.

In summary, the LS9 engine’s uniqueness lies in its combination of groundbreaking supercharging, robust construction, advanced components, and precise craftsmanship, enabling record-setting performance.

What advancements were introduced with the LS7 engine?

The LS7 engine introduced several significant advancements that set it apart from previous models. This 7.0-liter (427 cubic inches) powerhouse was specifically engineered for high-performance vehicles, featuring a unique 4.000-inch stroke that maximized its capabilities.

These advancements collectively made the LS7 a standout in the realm of high-performance engines, offering a blend of innovative design and cutting-edge materials.

Can You Swap an LS Engine into Any Car?

Absolutely! The LS engine family is incredibly versatile, making it a popular choice for engine swaps. Here are a few reasons why:

In summary, with the right parts and some mechanical know-how, you can swap an LS engine into almost any vehicle, turning a standard ride into something extraordinary.

What are the key features of the LSX376-B15 engine?

The LSX376-B15 engine is designed for superior performance, particularly for those pushing the limits with boost. Here are its standout features:

With these features, the LSX376-B15 stands out as a powerful and durable choice for those looking to maximize their vehicle’s performance.

What is the LSX376-B8 Crate Engine Designed For?

The LSX376-B8 crate engine is tailor-made for racing enthusiasts looking to enhance their vehicle with forced induction. This engine uses a robust Bowtie standard-deck block and integrates 9.0:1 forged pistons, making it particularly conducive to accommodating a supercharger or turbocharger.

By focusing on these specific attributes, the LSX376-B8 crate engine offers a durable and efficient solution for racers looking to get more power out of their engines while maintaining affordability.

What are the features of the LSA engine?

The LSA engine, with its 6.2-liter (376ci) displacement, stands out for several key features that enhance its performance. Let’s delve into what makes this engine unique:

In summary, the LSA engine distinguishes itself through a combination of advanced cooling systems, robust main caps, and a potent supercharger, making it a formidable choice for high-performance applications.

What are the key features of the LS1 engine?

The LS1 engine represents a significant milestone in V-8 performance engineering. Here are the standout features that define this powerplant:

While maintaining the classic single cam pushrod V-8 design, the LS1 underwent extensive modifications. The basic architecture was retained, but critical updates were implemented for enhanced performance and reliability.

One of the major changes was the introduction of a deep-skirt block, which added rigidity and strength to the engine. This design helps to improve the structural integrity and reduce vibrations.

The LS1 moved away from the problematic Opti-Spark system to a more reliable coil-near-plug arrangement. This change enhanced the ignition system’s efficiency and durability.

In a bid to reduce weight, the engine blocks are made from cast aluminum with iron sleeves. This not only makes the engine lighter but also helps improve fuel efficiency and overall vehicle performance.

The LS1 boasts a displacement of 5.7 liters or 346 cubic inches, which is very close to the traditional 350 cubic inch engines it replaced. This new displacement offers comparable power and torque, making it an excellent successor.

Initially debuting in the 1997 Corvette, the LS1 was later incorporated into the Camaro lineup by 1998, marking its widespread adoption and success in high-performance vehicles.

These key features collectively contribute to the LS1 engine’s reputation for exceptional performance and innovation.

What Cars Use LS Engines?

The LS engine, originally developed for the Chevrolet Corvette, has powered a variety of high-performance vehicles across several General Motors (GM) brands. Here are some of the models that feature the revered LS engine:

The LS engine also finds its way into a plethora of GM performance cars, making it a popular choice for those looking to boost their ride’s capabilities.

The versatility and adaptability of the LS engine make it a popular choice across a wide range of vehicles, offering impressive power and performance wherever it is featured.

What are the main similarities across LS engines?

LS engines share a variety of engineering characteristics that underscore their performance and versatility. Here’s a detailed look at the main similarities:

Additionally, the LS engines share common bolt patterns for various components such as:

These shared features highlight the modular nature of LS engines, facilitating ease of maintenance, performance upgrades, and parts interchangeability.

What is the history and development of the LS1 engine?

In the early 1990s, the automotive industry faced growing pressures to meet stringent emissions requirements and Corporate Average Fuel Economy (CAFE) standards, as well as the evolving demands for higher performance. At that time, the Gen II LT1 and LT4 engines were leading the charge in performance cars, but they were becoming outdated. Recognizing the need for innovation, engineers embarked on designing a new V-8 engine in 1993 which would eventually be known as the LS1.

Replicating the success of the original small-block engine was no easy feat. The team retained the fundamental architecture of a single cam pushrod V-8, but nearly every other aspect was reimagined. From the deep-skirt block design to a revised firing order, the LS1 was crafted with modernity in mind. One significant upgrade was the introduction of a coil-near-plug ignition system, which replaced the less reliable Opti-Spark system.

To address the issue of weight, the new engine featured blocks made of cast aluminum with iron sleeves. This not only contributed to performance efficiency but also helped in meeting the ever-critical weight reduction goals. The LS1 engine had a displacement of 5.7 liters, equating to 346 cubic inches—remarkably close to the 350 cubic inch engines it aimed to replace.

The LS1 made its debut in the 1997 Corvette, setting a new standard for performance. By 1998, it was powering the Camaro, and by 1999, various iterations, including those with iron blocks and different displacements, began appearing in trucks and SUVs. Over its 18 years of production, the LS platform saw numerous variants tailored for diverse applications. Importantly for automotive enthusiasts, these variations maintained a high degree of parts interchangeability, further cementing the LS1’s legacy in the hot rodding community.

In summary, the LS1 engine stands as a testament to innovative engineering, adapting an old concept to meet modern standards while offering exceptional performance and versatility.

What is the LSX376-B15 engine designed to handle?

The LSX376-B15 engine is meticulously engineered to handle high levels of stress and power. With its robust, all-forged rotating assembly, this powerhouse can support impressive boost pressures of up to 15 pounds. Designed for enthusiasts who demand durability and reliability, this engine is well-suited for applications requiring substantial force and endurance.

What Makes the LC9 5.3-Liter Engine So Common?

The LC9 5.3-liter engine has earned its status as one of the most prevalent engines largely due to a combination of its design and widespread use.

The LC9’s design versatility and consistent updates with modern fuel management systems make it a common choice in various vehicle models. Its robust performance and fuel efficiency have made it a go-to option for many automakers, thereby contributing to its ubiquity.

What are the key features of the LS2 engine?

The LS2 engine, a significant upgrade in the LS family, boasts several key enhancements and features:

The LS2 engine distinguishes itself with its increased displacement, improved components, and versatility across various high-performance applications. Its design enhancements and compatibility with various cylinder heads make it a favorite for performance enthusiasts and a robust option for upgrades.

What Improvements Were Made in the LS6 Engine?

The LS6 engine, an evolution of the LS1, introduced several key enhancements aimed at boosting performance and reliability. Here are the major upgrades:

These refinements not only provided the LS6 engine with greater horsepower but also enhanced its durability and overall performance.

What are the specifications of various LS and Vortec engines?

Understanding the specifications of various LS and Vortec engines can provide valuable insights for performance enthusiasts and engineering aficionados. Below, we’ll delve into the key details of popular LS and Vortec engines, outlining their displacement, dimensions, horsepower, torque, and compression ratios.

These specifications highlight the diverse range and capabilities of LS and Vortec engines, from smaller 4.8-liter models to the mighty 7.0-liter LS7. Whether you’re seeking raw horsepower, a balanced torque curve, or a specific compression ratio, there’s likely an LS or Vortec engine that fits your needs.

What is the difference between a Vortec and an LS engine?

At first glance, Vortec and LS engines may seem interchangeable, but they serve distinct roles within their respective applications.

In summary, while LS and Vortec engines share some similarities, they cater to different performance needs and vehicle categories. Understanding these nuances can help in choosing the right engine for your specific requirements.

What are the differences between LS and Vortec engines?

When comparing LS and Vortec engines, several key distinctions stand out. Below are the primary differences:

In sum, while Vortec and LS engines share many similarities, including parts interchangeability, their differences in material, displacement, and intended use set them apart. This makes each type suitable for different kinds of automotive projects and performance goals.

What are the characteristics of the L9H 6.2-liter engine?

The L9H 6.2-liter engine stands out for its impressive performance and modern technology. Let’s delve into its key features:

In summary, the L9H 6.2-liter engine is characterized by its aluminum construction, variable valve timing, significant displacement, and application in high-performance vehicles. These attributes make it a notable engine in its category, combining power with modern advancements.

What are the features of the LQ9 6.0-liter engine?

The LQ9 6.0-liter engine, predominantly found in heavy-duty trucks like 3/4- and 1-ton models, offers a range of notable features making it a popular choice for high-performance applications. Here’s a breakdown of its key attributes:

With its robust construction and adaptability, the LQ9 6.0-liter engine remains a versatile choice for those looking to maximize power and performance.

What are the characteristics of the LQ4 4.8-liter engine?

The LQ4 4.8-liter engine is known for being the smallest displacement version in its series. Here are some notable features and characteristics:

From an external perspective, distinguishing the 4.8-liter variant from its 5.3-liter counterpart is nearly impossible due to their similar design. Despite its smaller size, the LQ4 engine offers robust performance and durability, making it a popular choice for various applications.

What is the LS4 Engine and Where is it Used?

The LS4 engine is a relatively rare powerplant, featuring a 5.3-liter V8 configuration crafted from aluminum. Unlike its more common iron counterparts, this engine offers a lighter alternative, enhancing performance in specific vehicle models.

The LS4 engine is predominantly found in front-wheel-drive vehicles. Notable examples include the Pontiac Grand Prix GXP and Chevrolet Impala. These models utilize the LS4 for its blend of power and reduced weight, which complements their design and performance needs.

In summary, if you’re looking for a powerful, lightweight engine for front-wheel-drive applications or specific transaxle setups, the LS4 is an excellent option. However, for most other types of engine swaps, its distinct mounting configuration may pose a challenge.

What Are the Differences in LS7 Heads?

Port Design and Airflow: LS7 heads are distinguished by their rectangular ports, which are wider and shorter than those found in L92 or LS3 heads. The 12-degree design facilitates a straight-through airflow path, significantly influencing performance.

CNC-Ported from Factory: A unique feature of LS7 heads is that they come CNC-ported straight from the factory. This precision machining enhances airflow efficiency and combustion chamber consistency, leading to better performance.

Intake Ports and Valves: The intake ports on LS7 heads measure 270cc, accommodating a higher volume of air. Additionally, they are equipped with titanium intake valves and sodium-filled exhaust valves, innovations that were almost unheard of in pushrod V-8 engines prior to the LS7.

Horsepower Capabilities: The LS7 heads can support over 600 hp in a naturally aspirated setup. This is partly due to their large valves, which require a bore of at least 4.125 inches.

Compatibility: These heads are designed to work exclusively with LS7 intake manifolds or aftermarket equivalents. This specificity ensures that the entire intake system operates optimally.

In summary, the LS7 heads stand out for their rectangular port design, factory CNC-porting, advanced valve materials, significant horsepower capabilities, and specific intake manifold requirements. These features collectively contribute to their superior performance in high-powered engines.

What are the differences in LS cylinder heads?

The LS engine family features a variety of cylinder heads, each with unique characteristics tailored to specific engine models. Here’s a breakdown of the types and their compatibility:

By understanding these differences, you can choose the right LS cylinder head to match both your engine’s specifications and performance goals.

What Pistons Do LS Engines Use?

LS engines are known for using specific types of pistons that cater to their performance needs. Here’s a breakdown of the types of pistons used in these engines:

Understanding these variations in piston design and attachment methods is crucial for anyone working with or upgrading LS engines.

What are the differences in LS crankshafts?

LS crankshafts vary significantly, and understanding these differences is crucial for engine performance and customization. Let’s break down the key distinctions:

By understanding these differences, you can make informed decisions on the best LS crankshaft for your engine’s needs. Whether prioritizing strength, stroke, or compatibility, these details ensure optimal performance and reliability.

What are LS rectangular port heads?

Simply put, these are a type of cylinder head used in certain high-performance General Motors (GM) engines. They differentiate themselves primarily through the shape and design of their intake ports—rectangular rather than the more traditional cathedral shape.

Each version of the LS rectangular port heads comes with its own unique specifications, mainly in terms of valve material and combustion chamber size:

Different types of valves are employed depending on the specific application:

In summary, LS rectangular port heads are a specialized type of cylinder head known for their excellent airflow characteristics and application versatility. They are a favorite in performance circles for their ability to significantly enhance engine performance, especially when combined with the right components and tuning.

What are LS cathedral port heads?

LS cathedral port heads are a type of cylinder head found in various General Motors (GM) engines, particularly within the LS series. These heads are distinguished by the unique, cathedral-like shape of their intake ports, which impacts airflow characteristics and engine performance.

These heads are versatile and can work with several intake manifolds, including the LS1, LS6, and LS2, as well as Vortec intakes from cathedral port-headed variants.

Understanding these variations can help in selecting the right heads for your specific engine build, whether it’s for enhanced compression, scavenging in junkyards, or pairing with specific valve covers and bolt configurations.

Are all LS connecting rods the same?

Absolutely, not all LS connecting rods are the same. While many LS rods are interchangeable and generally made from powdered metal, there are notable exceptions. For instance, LS9 and LS7 rods are distinct—they’re forged from titanium and specifically designed to work only with LS7 and LS9 pistons.

In conclusion, while many LS connecting rods share similarities, certain engines like the LS7 and LS9 feature unique components that aren’t interchangeable with standard LS rods. Always check the specific requirements of your engine to ensure you select the correct rods and accompanying parts.

What Does LS Stand for in Engines?

When discussing engines, particularly in the context of performance and modification, the term “LS” often comes up. However, there’s some ambiguity about what “LS” actually stands for.

Several other theories and myths have circulated over the years. Some enthusiasts suggest LS stands for “long stroke,” while others speculate it might be initials of someone significant in the engine’s development. However, these claims lack substantial evidence.

In reality, LS doesn’t have a grand meaning or backstory. It’s simply a way for manufacturers like GM to categorize and distinguish this series of engines from other types. So, while “Luxury Sport” might align with trim level naming conventions, it’s not the definitive answer when it comes to engines.

What are the main characteristics of the LS3 engine?

If we’re including all derivatives, the various displacements that have been available over the years include 4.3L (yup, a V-6 variant released in 2014), 4.8L, 5.3L, 5.7L, 6.0L, 6.2L, 6.6L, and 7.0L engines. Each of these has been refined through multiple iterations and differed depending on the application.

The LS3 engine, a standout in the LS family, hit the market in 2008 with its debut in the C6 Corvette. Here are some key characteristics:

This detailed breakdown not only highlights the versatility of the LS engine family but also showcases the specific enhancements and applications that make the LS3 a notable member.

How has the LS7 engine impacted the automotive performance landscape?

The LS7 engine marked a revolutionary moment in automotive performance history. Introduced in the mid-2000s, it was a game-changer, bringing supercar-level horsepower to production cars on a scale previously unseen.

Before the advent of the LS7, achieving 500 horsepower in a production car was a rarity. The LS7 made this benchmark more accessible, enabling a broader range of enthusiasts to experience high-performance driving. This engine’s influence was so significant that it pushed other manufacturers, such as Dodge with the Hellcat and Fordwith the Shelby Mustang, to up their performance game.

The LS7 was a marvel of engineering. Its large displacement, combined with advanced cylinder heads and lightweight titanium valvetrain components, allowed it to rev up to 7,000 RPM—a remarkable feat for a naturally aspirated engine. Hand-built with precision, the LS7 utilized deck-plate boring and honing, setting new standards for manufacturing excellence.

Unlike many of its contemporaries that rely on superchargers to achieve high horsepower, the LS7 delivered pure, unadulterated power. The absence of any forced induction components meant no extra weight or complications from intercooling circuits. This high-revving, naturally aspirated engine provided an experience that was as raw as it was exhilarating, a characteristic rarely matched by its competitors.

Even 15 years after its debut, the LS7 remains a benchmark in naturally aspirated performance. Its influence is evident in how manufacturers design and build high-performance engines today. The LS7 set a high bar, pushing the industry towards more innovative solutions and advanced engineering techniques.

In summary, the LS7 engine didn’t just raise the bar; it redefined what was possible in automotive performance. It inspired other manufacturers to pursue greater horsepower and efficiency, making high-performance engines more accessible and setting new standards that continue to shape the industry. This engine’s impact is still felt today, underscoring its status as a landmark achievement in automotive history.

What makes the LS3 engine a popular choice for LS swaps?

The LS3 engine has skyrocketed in popularity for LS swaps due to its impressive balance of performance, affordability, and ease of integration. For starters, this engine delivers a robust 430 horsepower straight out of the box. Achieving similar power from a classic small-block engine would typically require significantly more investment, often exceeding the LS3’s average price of under $8,000.

Additionally, as the popularity of LS swaps continues to rise, the aftermarket industry has responded by producing a plethora of compatible parts that make the entire process smoother and more cost-efficient. From engine mounts to wiring harnesses, these components are becoming increasingly accessible and budget-friendly.

In summary, the LS3 engine is a favored option for LS swaps because it combines high power output with cost efficiency and widespread support from an ever-growing aftermarket ecosystem.

What unique features and performance characteristics does the LS7 engine have?

The LS7 engine stands out due to its remarkable engineering and exceptional performance traits. Let’s delve into what sets this powerhouse apart:

The LS7 engine is meticulously assembled by hand, ensuring superior quality control and attention to detail. This level of craftsmanship is rare in production engines and contributes to its stellar performance.

Drawing inspiration from competitive racing, the LS7 incorporates advanced technologies. Key among these is the deck-plate boring and honing of the unique cylinder block, enhancing the engine’s structural integrity and efficiency.

With a large displacement, the LS7 can process a significant amount of air. Its cavernous cylinder heads, combined with featherweight titanium valvetrain components, enable it to rev up to an impressive 7,000 RPM. This high-revving capability is essential for delivering substantial horsepower.

Unlike supercharged engines, which come with additional weight and complexity, the LS7 is naturally aspirated. This means it delivers pure, unadulterated horsepower without the parasitic losses associated with driving a supercharger.

Even after fifteen years since its debut, the LS7’s naturally aspirated output remains unmatched by many modern engines, including the 6.2L LT1 of the C8 Corvette. This enduring performance standard highlights the engine’s design excellence.

The LS7 engine was not only central to the Corvette Z06 but also featured in the 427 Edition convertible in 2013, marking the end of an era for the C6 generation. This special edition further cemented its legacy as a benchmark of naturally aspirated performance.

In summary, the LS7 engine combines hand-built precision, racing-derived technology, and a high-displacement design to deliver unrivaled naturally aspirated horsepower. Its legacy continues to influence and inspire, making it a truly iconic engine in automotive history.

How did the LS9 engine influence the performance car market and aftermarket?

The introduction of the LS9 engine marked a turning point in the performance car market, setting new benchmarks for power and speed. Initially equipped in high-performance sports cars, this engine pushed the envelope of what was possible for production vehicles.

In sum, the LS9 engine didn’t just influence the performance car market—it redefined it, setting new standards and spawning a robust aftermarket that continues to thrive.

Why is the LS3 engine considered the modern equivalent of the classic 350 small-block?

The LS3 engine is often hailed as the modern counterpart to the iconic 350 small-block for several compelling reasons.

First, its performance is immediately impressive—offering 430 horsepower straight out of the box. Achieving such power with a traditional small-block would typically cost significantly more. The LS3’s affordability, often priced below $8,000, makes it a highly attractive option for enthusiasts looking for the best bang for their buck.

The engine’s popularity is burgeoning, not just in its original vehicles but as a crate engine for LS swaps. Much like the classic 350 small-block became a go-to for custom builds, the LS3 is becoming a favorite for modern modifications. Its versatility and broad application spectrum make it a natural successor.

While the original 350 small-block set the standard in its time, the LS3 incorporates modern technological advancements. Improved fuel efficiency, better emissions control, and enhanced reliability are just a few of the improvements. Car enthusiasts and builders find these features incredibly appealing, further solidifying its status as a contemporary equivalent.

Moreover, the components needed for a successful LS3 swap are becoming increasingly accessible and affordable. This mirrors the pattern seen with the classic 350 small-block, where a wide availability of parts made it easier to modify and maintain.

In summary, the LS3 engine embodies the legacy of the classic 350 small-block by offering exceptional value, widespread use in custom builds, technological advancements, and readily available replacement parts. All these elements combine to make the LS3 a modern benchmark in the world of performance engines.

Why is the LS1 engine considered a revolutionary performance engine?

The LS1 engine stands out as a revolutionary force in the automotive world for several compelling reasons:

The engineering behind the LS1 engine set new benchmarks in the industry. This compact, all-aluminum V-8 was designed with overhead-valve technology, a stark contrast to the complex, space-consuming multiple-overhead-cam engines that were the norm. The LS1’s design enabled it to deliver remarkable performance, with unparalleled breathing efficiency that allowed for higher revolutions per minute (RPM) than previous pushrod V-8 engines.

One of the LS1’s key innovations was its optimized pushrod design, which contributed to its smaller size and lighter weight. This not only made it easier to fit into a variety of vehicles but also enhanced the engine’s power-to-weight ratio. Such efficiency in both space and weight allowed for better vehicle handling and performance dynamics.

The LS1 engine quickly garnered the support of the aftermarket performance community. Its adaptability and modification potential made it a favorite among car enthusiasts and tuners. Whether being tweaked for increased horsepower, torque, or fuel efficiency, the LS1 proved to be a versatile platform that could meet a wide range of performance needs.

Beyond its technical merits, the LS1 had a significant cultural impact. It represented a bold move in automotive engineering, challenging existing norms and showcasing the potential of pushrod technology in a modern context. The engine’s enduring popularity and continued relevance in current performance trends underscore its revolutionary status.

Nearly 25 years after its introduction, the LS1 engine remains a cornerstone of performance engineering. Its blend of innovation, efficiency, and adaptability has ensured its place in automotive history. The ripple effect of its introduction can still be felt today, influencing engine design and performance standards across the industry.

In summary, the LS1 engine revolutionized the performance world by combining cutting-edge engineering with versatile design, earning it a well-deserved reputation as a game-changer in automotive history.

Why is the LS7 engine considered the best LS engine ever?

In the realm of high-performance engines, the LS7 stands out profoundly. Its influence and lasting legacy have cemented it as the pinnacle of LS engine design. But what exactly makes the LS7 so extraordinary?

Before the LS7, very few production cars could boast a horsepower level exceeding 500. This engine changed the game by democratizing supercar-level performance. Its introduction in the Corvette Z06 made such power accessible and set new standards in the automotive industry.

The LS7’s engineering distinguishes it from other engines. Key features include:

Unlike many of its competitors, such as the supercharged engines found in the Camaro ZL1, Hellcats, and Shelby Mustangs, the LS7 achieves stellar performance without forced induction. This lack of a supercharger reduces weight and eliminates the power consumption that superchargers demand. The result is pure, unadulterated horsepower that revs to an exceptional 7,000 rpm.

Despite being over 15 years old, the LS7’s prowess remains unmatched. Even the advanced 6.2L LT1 engine of the modern Corvette falls short in naturally aspirated output compared to the LS7. Its continued prominence speaks volumes about its groundbreaking design and performance capabilities.

Aside from the Z06, the LS7 found its way into noteworthy vehicles, including the 427 Edition convertible, a commemorative model celebrating the end of the C6 generation. This versatility further solidified its status as a cornerstone of high-performance engineering.

In a landscape crowded with powerful engines, the LS7 remains a true benchmark of naturally aspirated performance. Its combination of revolutionary design, advanced engineering, and enduring legacy justifies why it is considered the best LS engine ever produced.

What are the performance capabilities of the LS9 engine?

Performance Capabilities of the LS9 Engine

The LS9 engine stands out with remarkable performance metrics. This powerhouse, previously the zenith of General Motors’ production engines, delivers a breathtaking 638 horsepower. When installed in the C6 Corvette ZR1, it propelled the car to incredible speeds, rocketing through the quarter-mile in just over 11 seconds and reaching a top speed of 205 mph.

Central to the LS9’s performance is its 2.3L Eaton TVS supercharger, a feature that aggressively force-feeds air into the engine. This system ensures that the engine operates at its peak efficiency, providing an adrenaline-fueled driving experience with its high-pitched shriek at wide-open throttle.

Beyond its initial application in high-performance vehicles, the LS9 found a second life as a Chevrolet Performancecrate engine. Enthusiasts and builders swiftly adopted it for use in Pro Touring and restomod projects, recognizing its unparalleled factory-engineered capabilities. Despite being sold out, the engine remains a highly coveted component for those looking to maximize performance in classic builds.

Engineered with the aggressive flair often lacking in OE manufacturer offerings, the LS9 brought a level of performance that seemed almost unattainable just a few years prior. Its combination of brute force and precision engineering marked a high point in the evolution of LS engines.

In summary, the LS9 engine is a testament to high-performance engineering, with its formidable horsepower, supercharged excellence, and versatility making it a legendary choice for speed enthusiasts and builders alike.

What engineering and cultural significance does the LS1 engine hold?

The LS1 engine is a landmark in automotive history, altering both engineering standards and cultural perceptions. Initially released nearly 25 years ago, it represented a major shift for engine design and performance expectations.

Compact and Efficient Design

One of the most revolutionary aspects of the LS1 was its compact, all-aluminum construction. Unlike the bulky multiple-overhead-cam (DOHC) engines that were gaining popularity, the LS1 utilized a pushrod design. This choice was unconventional at the time but offered several advantages:

High-Performance Capabilities

The LS1 did more than just look good on paper; it delivered unparalleled performance. It was designed to “breathe” better than its predecessors, allowing it to rev higher and produce more power. This combination of compactness and capability made it a versatile engine.

Shifting Perceptions

When the LS1 hit the market, it defied conventional wisdom about engine design. Overhead-valve engines were often considered outdated, but the LS1 proved that modern pushrod engines could be both innovative and efficient. This changed the way enthusiasts and critics alike viewed engine architecture.

Aftermarket Support

The LS1 quickly garnered the support of the aftermarket performance community. The engine became a favorite for tuners and hobbyists, sparking a wave of modifications and custom builds. This grassroots support solidified its status as a cultural icon.

Lasting Relevance

Even decades after its introduction, the LS1 remains relevant. Advances in technology and evolving performance trends have done little to diminish its standing. Its fundamental design principles have aged exceptionally well, continuing to influence new engine designs and aftermarket modifications.

In summary, the LS1 engine’s ingenious engineering and sweeping cultural impact make it a cornerstone of modern automotive history. From its space-efficient design to its lasting influence, the LS1 has fundamentally redefined what a high-performance engine can be.

What are the benefits of the L92, L9H, and L94 truck engines for LS swaps?

When considering an LS swap, the L92, L9H, and L94 truck engines present compelling options for several reasons:

Truck-based 6.2L engines like the L92, L9H, and L94 are significantly more affordable compared to their high-performance counterparts, such as the LS3 from sports cars. Salvage yards often offer these engines at a fraction of the price, making them a budget-friendly choice for engine swaps.

These truck engines primarily share the same foundation as the LS3. Specifically, the L92 was the first aluminum-block 6.2L LS variant, setting a precedent for performance and durability. They are receptive to similar enhancements like camshaft swaps and supercharger installations, which can boost their power output significantly. The L9H and L94 even feature robust fuel systems designed for FlexFuel, facilitating performance gains. For instance, the E85 fuel system used in the L9H and L94 models is capable of supporting up to around 700 horsepower.

One of the key advantages of these engines is their adaptive fuel capabilities. The L9H, equipped for FlexFuel E85, and the L94, featuring Active Fuel Management for cylinder deactivation, offer both performance and efficiency improvements over older engine models. This allows for a more versatile and environmentally friendly setup without sacrificing potency.

The L92, L9H, and L94 share many components with the more expensive LS3, providing a broad range of aftermarket parts and compatibility. This includes the ability to swap the truck-specific induction systems for performance-enhancing alternatives like superchargers. Removing the stock truck intake manifold and replacing it with a performance intake or supercharger is a straightforward upgrade that further amplifies engine output.

These engines are engineered for rugged use in full-size trucks and SUVs, meaning they come with enhanced durability. Their robust construction ensures they can handle the strains of performance modifications and rigorous use, which is a valuable trait for any engine undergoing a swap.

In sum, the L92, L9H, and L94 engines stand out for their affordability, upgrade potential, advanced fuel systems, and robust engineering. Their availability and cost-effectiveness make them attractive candidates for LS swaps, offering high performance without the high price.

What makes the LS376/525 engine stand out in terms of performance potential?

The LS376/525 engine stands out in the crowded world of performance engines thanks to its remarkable blend of power and simplicity.

At the heart of the LS376/525’s performance is a specialized camshaft. This key component boosts the engine’s output to an impressive 525 horsepower. The remarkable aspect? It’s achieved without the need for head porting, stroker assemblies, or forced induction. The camshaft’s 0.526-inch lift, along with precise timing of 226/236 degrees duration and a 110-degree lobe separation angle, paired with matching valve springs, elevates the engine’s capabilities.

The camshaft doesn’t work alone—it makes the most of the deep-breathing, high-flow cylinder heads inherent to the LS engine family. This synergy is crucial, as effective airflow management is a cornerstone of LS engine performance, ensuring that all available power potential is efficiently harnessed.

When considering the cost-to-performance ratio, the LS376/525 emerges as a top contender. Its straightforward design means that significant horsepower gains are achieved without complex modifications. For enthusiasts looking to get the most bang for their buck in restomod or Pro Touring builds, this engine offers unparalleled value. It’s so cost-effective that even some engine builders recommend it over custom-built engines due to the long-term savings and performance benefits.

In summary, the LS376/525 engine’s blend of simplicity, raw power, and cost-efficiency make it a standout choice for any performance build.

What are the applications and benefits of the LSA engine as a crate engine?

Applications and Benefits of the LSA Engine as a Crate Engine

The LSA engine, renowned for its impressive power and torque, finds versatile applications both as an original fitment and a crate engine. Here are some common use cases:

Exceptional Power and Torque

Superior Low-End Performance

Versatility

Reliability and Availability

By opting for the LSA engine, builders and enthusiasts alike gain access to a powerhouse that combines high horsepower, immediate low-end torque, and reliable performance—making it an excellent choice for a range of automotive applications.

Why is the LS2 engine considered versatile and adaptable?

The LS2 engine, introduced in 2005, exemplifies versatility and adaptability through several key features:

The LS2 engine stands out for its remarkable blend of power, compatibility, and upgrade potential, making it a benchmark in automotive versatility and performance.

What are the performance characteristics of the LS2 engine?

Performance Characteristics of the LS2 Engine

Introduced in 2005, the LS2 engine set a new standard with its innovative design and impressive performance. As the first of the Gen IV small-block engines, it brought several enhancements that made it a significant upgrade over its predecessor, the LS1.

One of the key characteristics of the LS2 is its larger 6.0L displacement, achieved through a 4.000-inch bore. This increased its engine size from the LS1’s 346 cubic inches to 364 cubic inches. This expansion allowed the LS2 to produce a notable 400 horsepower and 400 lb-ft of torque, setting a new performance benchmark for the time.

The LS2 engine carried over the “cathedral”-style cylinder head design from the previously limited LS6 engine but omitted the LS6’s sodium-filled valves. A significant factor contributing to the LS2’s increased power is its high compression ratio of 10.9:1. This high compression ratio played a crucial role in boosting the LS2’s output by 50 horsepower over the LS1.

Another standout feature of the LS2 engine is its versatility. This engine wasn’t limited to a single vehicle type; it powered various high-performance vehicles, including SUVs and retro roadster pickups. The engine’s flexibility was further highlighted by its compatibility with cylinder heads from multiple other engines, such as the LS1, LS6, LS3, and L92. This interchangeability made the LS2 a popular choice for performance enhancements and modifications.

The LS2 also exhibited excellent performance when subjected to upgrades. It responded exceptionally well to ported heads and forced induction, making it a favorite among enthusiasts looking to extract even more power. Its adaptability and robust design allowed for significant performance gains through aftermarket modifications.

In summary, the LS2 engine is celebrated for its combination of increased displacement, innovative cylinder head design, high compression ratio, and remarkable adaptability. These characteristics not only delivered impressive stock performance but also provided a versatile platform for further enhancements. This combination solidified the LS2’s reputation as a high-performance engine in the automotive world.

Which LS engines are considered the most influential and why?

Approaching its 25th anniversary, the LS engine has firmly cemented itself as a pivotal force in the automotive world. While each LS engine has its own merits, a select few have distinguished themselves through remarkable performance, cultural impact, and profound influence on car enthusiasts.

Certain LS engines have risen above the rest due to their unique blend of power, innovation, and community impact. Here, we dive into the top engines that have left an indelible mark on the automotive scene.

The LS1 was revolutionary when it debuted, bringing all-aluminum construction to mass-produced V8 engines. This engine set a new standard for performance and reliability, making it a favorite for swaps and custom builds.

Known for its enhanced breathing capabilities and increased power output, the LS6 found its home in high-performance vehicles. Its role in motorsports cemented its reputation as a powerhouse.

With improvements in displacement and power, the LS2 became synonymous with mid-2000s performance. It balanced everyday drivability with impressive horsepower, making it a versatile option for enthusiasts.

The LS3 is often celebrated for its exceptional balance of performance and affordability. Its availability in performance-oriented vehicles and crate engine form made it accessible to a wide audience.

Boasting a massive displacement and impressive redline, the LS7 is a track-focused beast. Its hand-built nature and superior components make it a legend among gearheads.

This supercharged marvel took performance to the extreme, becoming a benchmark for power and torque. Its advanced engineering showcased the potential of forced induction within the LS family.

While not as glamorous as their aluminum counterparts, the LQ4 and LQ9 offer robustness ideal for high-boost applications. Their durability has earned them a dedicated following in the off-road and drag racing communities.

Blending supercharging with everyday usability, the LSA brought high horsepower to more accessible platforms. It bridged the gap between casual enthusiasts and hardcore performance seekers.

Representing the future of the LS lineup, the LT1 introduced advanced technologies like direct injection and variable valve timing. It stands as a testament to the continuous evolution of the LS platform.

Specific dry sump configurations, most notably used in high-performance and racing applications, improved oiling systems under extreme conditions, ensuring engines perform at their peak.

The influence of these engines extends far beyond their technical specifications. They have become the backbone of countless builds, from street machines to race cars. Their reliability, tunability, and outright performance inspire a deep sense of community and passion among car enthusiasts.

By recognizing the top LS engines, we not only celebrate remarkable engineering but also honor the cultural wave they have driven in the automotive world. Whether you’re a weekend warrior or a seasoned racer, these engines symbolize the relentless pursuit of performance and innovation.

How has the LS engine architecture evolved over time?

As we approach the 25th anniversary of the LS engine, it’s a prime moment to reflect on how this groundbreaking engine family has evolved and made its mark on the automotive world.

The journey began with the introduction of the 5.7L LS1, setting off a legacy that encompasses a wide array of engine displacements—from 4.8L to 7.0L. Initially crafted to serve trucks, these engines were soon recognized for their versatile capabilities, including compatibility with E85 fuel and advanced cylinder-deactivation technology.

Over time, the LS engines proliferated into more than two dozen production variants. Not only did this include the standard models, but also high-performance crate engine options built specifically for racing. The architecture’s adaptability allowed for enhancements that catered both to everyday utility and high-octane competition.

Despite the differences in output and application, all LS engines share essential design elements that have contributed to their enduring relevance. Key among these is the efficient airflow capability, which allows the engines to process air with remarkable effectiveness. This feature enables the LS engines to generate considerable torque for truck applications and impressive revs for performance vehicles.

The legacy of the LS engine is cemented by its robustness and durability. Its design allows it to not only perform consistently under heavy loads but also compete with more complex engine designs. This blend of reliability and high performance has made the LS engine an enduring favorite among automotive enthusiasts and professionals alike.

As we celebrate this milestone, it’s clear that the LS engine’s impressive blend of durability, adaptability, and performance will continue to influence the automotive landscape for years to come.

How do the LM7 and LY6 engines respond to turbocharging and other modifications?

When it comes to budget-friendly performance boosts, the LM7 5.3L and LY6 6.0L engines stand out as prime candidates. These iron-block engines, originally found in countless Chevy and GMC light-duty trucks, have garnered a cult following among performance enthusiasts, particularly for their remarkable adaptability to turbocharging.

The iron block construction of the LM7 and LY6 engines makes them particularly suited for forced induction. They can handle high levels of boost without significant modifications, an appealing feature for anyone looking to maximize performance on a budget. It’s not uncommon to hear success stories of these engines achieving astonishing horsepower figures—ranging from 600 to 800 hp—when paired with affordable turbochargers.

Despite what you might expect, these engines hold up exceptionally well under the strain of turbocharging. Many builders report that even stock versions, with their cast pistons and factory crankcases, can withstand the intense pressure that turbocharging brings. This robust nature allows them to serve as a reliable backbone for high-boost street and strip applications.

For those with a bit more to spend, upgrading the rotating assembly can yield even more impressive results. Components such as forged pistons and crankshafts add durability and increase the engine’s capacity for higher boost levels. However, even without these upgrades, the LM7 and LY6 engines offer a commendable balance between performance and affordability.

The widespread adoption of these engines in the performance community isn’t just about their capability. It’s also about the spirit of innovation and resourcefulness they inspire. Finding affordable ways to achieve significant speed gains is a core principle of hot rodding, and these engines embody that ethos perfectly.

In summary, the LM7 and LY6 engines respond exceptionally well to turbocharging and other modifications, making them ideal for budget-conscious builders looking to achieve high performance without breaking the bank.

Why are the LM7 and LY6 engines popular for budget performance builds?

The LM7 5.3L and LY6 6.0L engines have carved out a niche among budget-conscious performance enthusiasts for several compelling reasons.

Originally designed for light-duty trucks and SUVs, these iron-block engines are built to endure heavy use. They were the backbone of countless 1/2-ton pickups, offering robustness and longevity. This inherent durability makes them perfect candidates for performance upgrades without needing extensive internal modifications.

One of the main attractions is their availability at a low cost. Often found in junkyards or as surplus units, the price point can be incredibly affordable. This low initial investment allows builders to allocate more budget towards upgrades and tuning.

The stout iron block design of the LM7 and LY6 can handle significant increases in power, especially with forced induction setups like turbocharging. Even without expensive enhancements to the rotating assembly, these engines have been known to handle boost levels that are typically seen as extreme, often achieving 600-800 horsepower with relatively modest investment.

The community around these engines is another factor in their popularity. Builders have developed numerous cost-effective solutions and shared them widely, fostering a culture of innovation and ingenuity. This collective knowledge base makes it easier for newcomers to achieve impressive results without breaking the bank.

In addition to their stock capabilities, the aftermarket support for these engines is extensive. High-performance parts are readily available, and there are numerous guides and kits for popular swaps and upgrades, making the process more straightforward and less intimidating for hobbyists.

For many, the appeal of these engines lies in their embodiment of the hot rodding ethos: getting the most performance for the least amount of money. They’ve become symbols of what can be achieved when creativity meets engineering.

With their combination of reliability, affordability, and adaptability to performance enhancements, the LM7 and LY6 engines are perfect platforms for budget performance builds, making them beloved choices among enthusiasts.

How do the L92, L9H, and L94 engines compare to the LS3 in terms of affordability and performance?

Understanding the nuances between the L92, L9H, L94, and LS3 engines can help inform your decision when it comes to choosing an engine for your next project.

For those aiming to maximize performance without spending a premium, the L92, L9H, and L94 engines are smart choices. They offer many of the same capabilities as the LS3 but come at a much more reasonable cost, especially when sourced from salvage yards. Plus, their adaptability to various modifications makes them highly versatile for a range of automotive projects.

How does a camshaft upgrade affect the performance of the LS376/525 engine?

A camshaft upgrade dramatically transforms the LS376/525 engine, unlocking its full potential with astounding simplicity. Essentially, this engine functions as an enhanced version of the LS3, chiefly due to the specialized camshaft it employs.

The camshaft is pivotal in augmenting the engine’s horsepower. When upgraded, it propels the LS376/525 from a standard LS3 engine to a powerhouse producing 525 horsepower. No other major modifications—such as head porting, stroker rotating assemblies, or forced induction—are required.

The primary effect is a significant increase in horsepower—95 hp more than the standard LS3. This is achieved without altering the engine’s natural aspiration, making it an ideal choice for restomod and Pro Touring builds that prioritize high-revving power. The enhanced camshaft allows the engine to deliver more power efficiently, maintaining its reliability and longevity.

In summary, upgrading the camshaft in the LS376/525 engine profoundly boosts its performance, proving that sometimes, less is indeed more. This single component leverages existing engine capabilities to achieve greater power and efficiency, transforming a robust engine into a high-performing beast.

How does the LSA engine deliver its power and torque?

The LSA engine delivers its impressive power and torque through a combination of advanced engineering and forced induction. Central to this setup is its 1.9L Eaton TVS-type supercharger, which directly addresses the low-end torque limitations commonly found in naturally aspirated LS engines.

In summary, the LSA engine’s power and torque are delivered through its supercharged system, precise boost management, and efficient design, resulting in a high-performance engine renowned for its responsiveness and strength.

What are the key components and features of the LSX376-B15 engine?

Key Components and Features of the LSX376-B15 Engine

The LSX376-B15 is meticulously designed to excel under boosted conditions, offering a robust foundation and customizable options for serious performance enthusiasts.

What makes the LSX376-B15 engine ideal for supercharging and turbocharging?

Why the LSX376-B15 Engine Excels for Supercharging and Turbocharging

The core strength of the LSX376-B15 engine lies in its cast-iron cylinder block. This material choice ensures durability and can withstand the immense pressure generated by supercharging and turbocharging systems. Designed specifically for enthusiasts who seek significant power gains, this engine is engineered to handle up to 15 pounds of boost effortlessly.

Interestingly, the LSX376-B15 is delivered as a long-block assembly without an intake manifold or induction system. This design choice isn’t a shortfall but a strategic advantage. By excluding these components, the cost is kept lower—often around $9,200. This allows users to add their own preferred blower or custom turbo induction system, maximizing performance and customization options.

Built with a forged crankshaft and pistons, the LSX376-B15 further bolsters its capability to endure higher boost levels. These forged internals are crucial for maintaining engine integrity under demanding conditions. Additionally, it features six-bolt LSX-LS3 rectangular-port cylinder heads. These specialized heads provide substantial head-clamping strength, essential for high-boost engines, especially those frequently used in track environments.

Another standout feature is the hydraulic roller camshaft. Designed with a broad, 121-degree lobe separation angle, it is particularly suited for forced induction applications. This specification helps in optimizing both performance and durability, making the engine ready for high boost pressures right out of the box.

In summary, the LSX376-B15 engine combines robust construction, cost-efficient design, and specialized components to deliver an ideal platform for supercharging and turbocharging setups. Whether on the track or for high-performance street use, this engine is built to excel.

What criteria were used to rank the top 10 LS engines?

When it comes to evaluating LS engines, it’s not just about sheer horsepower. We’ve considered multiple factors to determine which ones deserve to be in the top 10.

By looking at these elements—performance, cultural influence, and community effect—we’ve ranked the top LS engines not just as powerhouses, but as pivotal pieces of automotive art that have captured the hearts of enthusiasts worldwide.

What is the history and significance of the LS engine family?

The engine we all know and love was first introduced in 1997 in the C5 Corvette in 345-horsepower 5.7L LS1 form, and as the 270-horsepower 5.3L LM7 in the 1999 Silverado/Sierra. Both engines would receive refinements and improvements over their life cycles, resulting in more power across the board.

Approaching its 25th anniversary, the LS engine family has become a cornerstone in automotive performance history. It all began with the 5.7L LS1, but soon expanded to an impressive range of displacements, spanning from 4.8L (293 ci) to the formidable 7.0L (427 ci). This variety catered to an array of applications, from trucks with E85 capability and cylinder-deactivation technology to high-performance sports cars.

The LS engines share core design elements that made them revolutionary at their inception and continue to keep them relevant today. These engines are not only robust and durable but also excel in their capability to process air, significantly enhancing their performance range. This is why they generate impressive torque for truck applications and rev like no other pushrod engine when it comes to high-performance scenarios, often outperforming more complex multi-cam engines on the dyno.

Beyond technical specifications, the LS engine has left an indelible mark on automotive culture and the enthusiast community. Its adaptability and performance have made it a favorite for both street and track, influencing countless builds and aftermarket innovations. From the base truck engines to the supercharged LS9, each variant has contributed to the LS legacy in unique ways.

Given the vast number of LS engine variants, determining the best involves more than just horsepower ratings. Factors like performance, cultural influence, and impact on the enthusiast community play crucial roles. While opinions may vary, it’s this rich diversity and adaptability that make the LS engine family truly exceptional.

In summary, while all LS engines are remarkable, some stand out for their exceptional performance and cultural significance. We look forward to your thoughts on this enduring engine family.

What are some key features that make the LS engine durable and high-performing?

LS engines, like most engines, are pretty reliable as long as they’ve been properly maintained, and they’re even pretty decent when somewhat neglected! They are inherently strong, partly due to their main cap and head designs, which is why it’s not uncommon to see engines with 300,000-plus miles on them with only regular maintenance.

What sets the LS engine apart, though, are a few key features that contribute to its durability and high performance:

In essence, the LS engine’s combination of reliability, inherent strength, and advanced design elements makes it a standout choice for both everyday driving and high-performance applications.

How does the LS376/525 showcase the LS engine’s performance potential?

The LS376/525 crate engine epitomizes the remarkable flexibility and performance potential synonymous with the LS engine family. This engine showcases its prowess through clever engineering adjustments rather than drastic overhauls.

Central to the LS376/525’s performance leap is a strategic modification of the camshaft. By integrating a racing-inspired “ASA” roller cam, the LS376/525 extracts an additional 95 horsepower from the familiar LS3 architecture. This shift offers 525 horsepower, demonstrating how precise camshaft enhancements can elevate an engine’s capabilities without major alterations such as head porting or induction boosts.

What sets this engine apart is its ability to deliver impressive power while maintaining simplicity. The focus is on optimal utilization of the LS3’s deep-breathing cylinder heads, proving once again that a well-designed camshaft is pivotal in unleashing the engine’s true potential.

Particularly appealing for restomod and Pro Touring enthusiasts, the LS376/525 offers naturally aspirated power in a package that’s easy to retrofit. It provides significant value by delivering high performance without the need for costly custom builds, making it a more economical choice for those seeking robust power gains.

For those looking to balance cost and performance, the LS376/525 is a compelling option. Engine builders often recommend it as a smart alternative to custom engines, highlighting its feasibility for enthusiasts wanting the best performance-per-dollar ratio.

In summary, the LS376/525 is a testament to the untapped performance potential of the LS engine series, achieving remarkable results through thoughtful engineering rather than extensive modifications.

Why is the LS9 engine referred to as the “King of the Hill”?

The LS9 engine earned the nickname “King of the Hill” due to its impressive power and performance capabilities, especially within its production context. Initially found in the C6 Corvette ZR1, this engine delivered a striking 638 horsepower, setting a new benchmark for General Motors’ production engines at the time. With its distinctive roar, it was a formidable force on the road and racetrack alike.

The LS9 achieved its power supremacy thanks to a 2.3L Eaton TVS supercharger, allowing the Corvette ZR1 to break the quarter-mile barrier in just over 11 seconds, reaching speeds up to 205 mph. This capability marked it as a titan in the performance domain, offering a blend of brute force and engineering precision.

Its exclusivity only fueled its legend. After serving its primary purpose, the LS9 was offered as a crate engine, quickly becoming a favorite among enthusiasts involved in Pro Touring and restomod projects. However, these engines were soon sold out, making any remaining units highly sought after by collectors and builders aiming to capture the zenith of factory-engineered LS performance.

Beyond its specifications, the LS9 represented an audacious leap in automotive innovation, showcasing what was possible in terms of power from an original equipment manufacturer. Despite its relatively short production life, it remains a symbol of peak LS performance, embodying the spirit of pushing boundaries in engine design and application. This combination of power, innovation, and exclusivity cements the LS9’s status as the true “King of the Hill.”

How have the LM7 and LY6 engines become popular choices for budget-friendly performance builds?

The LM7 5.3L and LY6 6.0L engines have captured the hearts of performance enthusiasts, emerging as popular choices for cost-effective builds. Here’s why they’ve become staples in the DIY tuning community.

Initially powering countless Chevy and GMC trucks, these engines earned a reputation for being robust and reliable. Their iron blocks provided a solid foundation that withstood the rigorous demands of daily driving in light-duty vehicles.

Their design makes them particularly suited for forced induction. Despite lacking the pricier components found in high-end racing engines, these iron-block powerplants excel under pressure. Enthusiasts often opt for turbocharging, taking advantage of their capacity to handle significant boost levels. Even when combined with budget-friendly turbo systems, they can produce impressive power outputs between 600 to 800 horsepower.

A major draw for the LM7 and LY6 engines is their availability at low prices, often found in junkyards across the country. This provides a unique opportunity for builders on a budget to experiment and push performance boundaries without a hefty investment.