TIM ROPER

.

April 15, 2023

.

Department

TIM ROPER

.

April 15, 2023

.

Department

Jason Thomas has always been an automotive and motorcycle enthusiast. Being a helicopter mechanic, it is hard for someone of his nature to keep his hands off classic cars and motorcycles. Back in 2015, Jason was working on a 1965 Ford T-Bird. He had done all the leg work of a basic restoration, including motor rebuild, new interior, fresh chrome, and paint. Then one Friday at a local car show in Arlington, Texas, a gentleman offered Jason too much money to refuse for the car. By the next day, the car was on a trailer and he had a stack of cash in his hands.

This left Jason with a dilemma: What should he get his hands on next? Jason really had no preference, but in less than one week he found and brought home the 1955 Chevy 3100 you see before your eyes—just a little more on the original, unrestored side. Jason really had no intentions of restoring the truck to what it is now; he just wanted a beater to mess around with. But as we all know, a die-hard car guy combined with an obsession for detail and perfection cannot leave anything alone.

Once the truck was in Jason’s garage and stripped down to the bare elements, the snowball started rolling. Beginning with the stock frame, Jason ordered up a Porterbuilt stage 3 front and rear suspension. Initially, he sourced a local shop to install the suspension but as time went on, he realized they were not up to the task. This is when he enlisted his good friend and former coworker Jerry Sanderlin to take over and help with the build. Jerry installed the Porterbuilt kit after he fully boxed the stock chassis with everything masterfully TIG-welded in.

Once the chassis was beefed up, Jason installed the rest of the Porterbuilt front and rear suspension components as well as the McGaughy’s 13-inch front disc brakes. To get the truck at just the right stance, laying rockers while at all the shows as well as the perfect ride height while cruising, an Air Lift Performance 3P system was installed. RideTech HQ shocks complement the Air Lift kit to smooth out the ride. Of course, all the front and rear suspension components were powdercoated to Jason’s liking.

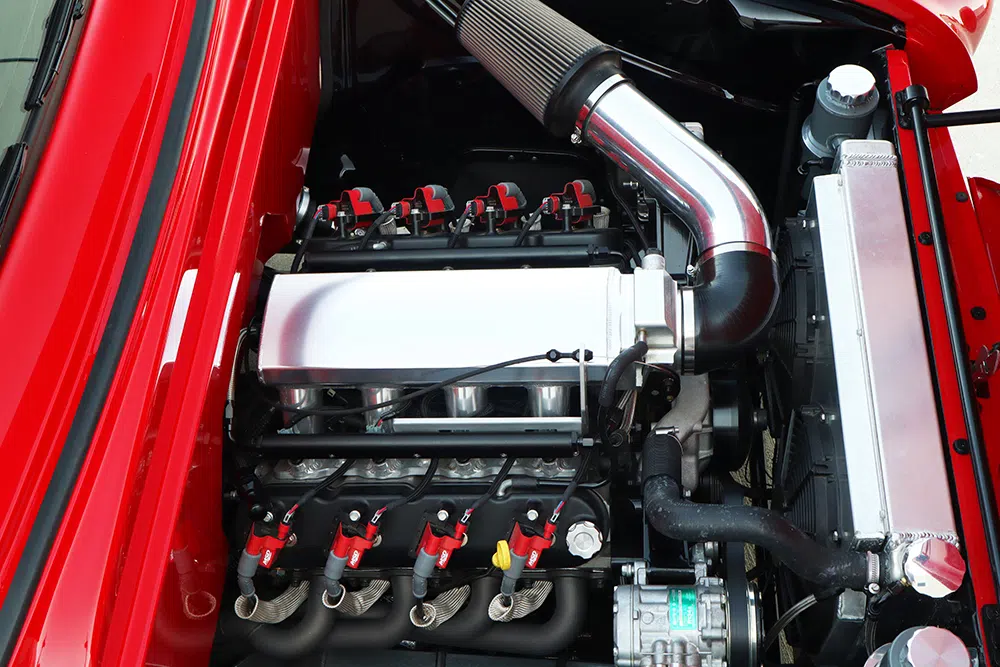

Once the chassis was ironed out, Jason started thinking about what powerplant to use. With all the available options, none other than a Chevy LQ9 was found to fit in the engine bay. Lacking the ability to leave anything alone, Jason called up Pro Touring Texas in Justin, Texas, to make the LQ just a little better. Once the engine was in Pro Touring Texas’ hands, they stuffed a 408 stroker kit in the block with all the goodies, including a Callies crankshaft, Callies connecting rods, and Diamond pistons. Up top, the engine has a set of milled GM 823 heads with a Brian Tooley Racing camshaft opening and closing the valves with .624/.595 lift and 239/254 duration, respectively. Mixing the air and fuel is a Summit Racing intake manifold and 102mm throttle body with MSD coil packs firing the spark plugs. Holley valve covers and accessory brackets sprucing things up. Holding everything together is none other than ARP fasteners and a Griffin radiator to keep everything cool. After the engine was assembled, it was dyno’d with a more than respectable 452 hp and 475 lb-ft of torque.

With the engine complete, Jason went back to Jerry Sanderlin and had him fabricate a full custom mandrel-bent 3-inch exhaust system including the headers. Again, Jerry TIG-welded everything together, and once that was complete the entire exhaust system with Magnaflow race mufflers was ceramic-coated in titanium color. A Boyd’s fuel tank normally used for ’67-’72 C10s fits perfectly between the frame rails to hold the fuel.

For the transmission, Jason chose a GM 4L80E built by Larry’s Speed Shop in Ft. Worth, Texas. Larry’s put all the heavy-duty goodies in the transmission and then installed a new Circle D converter with a 2,600-rpm stall. A Derale heat exchanger cools the transmission and is tucked away behind the front bumper. Transferring all the power from the engine and transmission to the rearend assembly is the original 1955 driveshaft with the necessary yokes to match the transmission and rearend. Speaking of rearends, Jason utilized the common Ford Explorer 8.8. The 8.8 was narrowed but still uses factory Ford 31 spline axles with a Track lock differential and 3.73 gearing. The factory style rear brakes were also used but upgraded to drilled, slotted, and zinc-coated aftermarket rotors with new pads. A E-Stopp electric parking brake holds the truck in place when actuated.

Moving on to the shell of the truck, Jason was looking to clean things up a bit and put the perfect wrapper on the outside. Again, with the help of Mr. Sanderlin, the firewall was smoothed, the cowl was smoothed, all the minor rust repaired, and the framework for the raised bed floor was fabricated. Jason and Jerry also installed the No Limit Engineering hood flip kit as the original hood hinges did not locate the hood in a clean consistent manner to Jason’s liking. In addition, a Brothers one-piece electric window kit was installed to give a cleaner appearance, and Altman bear claw latches were installed for safety and smoother door latching.

Once all the metalwork was complete, Jason took the truck over to Jag Custom Paint and Body in Alvarado, Texas. At Jag, a custom mix of red from Sherwin Williams was applied with four coats of clear on top. Jag also painted the frame of the truck in a metallic gray, which adds some nice contrast. Once the paint dried, Jason had Nicks Custom Detailing in Bedford, Texas, sand the clear to 3,000 and then buff to a deep mirror finish. Once that was complete, Nick applied a ceramic coating to protect the perfection. With the truck painted, Jason and Jerry fabricated the wood floor in the bed and applied stain and sealer. Jerry also fabricated the pneumatic lift system, which raises the bed floor to expose the detailed chassis and suspension underneath.

With everything starting to come together, it was time to start thinking about the interior. Jason then sent the truck to PG Upholstery in Haltom City, Texas. At PG, they custom made the door panels, kick panels, center console, lower dash panel, as well as the subwoofer box and panels behind the seats. Speaking of seats, C6 corvette seats were installed with custom brackets and are fully functioning. With everything in the interior ready for upholstery, PG covered it all with a tasteful mix of black leather and vinyl, including the smoothed dash, and then installed the Kenwood double DIN head unit.

The ear massage comes from Focal Components and a JL Audio 10-inch subwoofer all powered by a JL amplifier. Topping off the beautiful dash is a Dakota Digital HDX instrument cluster with all the necessary information to monitor the systems of the truck. To keep the cabin cool, a Vintage Air A/C system was installed and is operated with a Dakota Digital A/C controller. Restomod Air Membrane was applied to all the interior panels to help control heat and vibration for the added comfort while on the road. Jason fabricated his own A/C lines which were hidden to keep the engine bay tidy.

With the truck complete it was time for Jason to put on the final touch with just the right rolling stock. With thousands of options in the wheel market, 18×7 and 18×9 American Racing Burnouts were chosen. Jason did not stop there though; if you look closely, the “windows” of the insides of the wheels are tastefully painted the same metallic gray as the chassis. Once that touch was added, the wheels were then wrapped in Michelin Pilots with 225/50/18s up front and 285/40/18s out back, filling the wheelwells perfectly.

Since its completion, Jason has cruised the truck around town and attended few truck shows where the 3100 has received multiple awards, including a most recent Builder’s Choice Top 10 pick at the 11th annual Goodguys Spring Lone Star Nationals. We are confident that this truck will be a top award winner at any show and definitely an attention getter while cruising the back roads of Texas, which Jason plans to do a lot. So, what do you think? Divine intervention with the sale of the T-Bird? We would say so.

Share Link