Mark Barbee

.

December 30, 2018

.

C10 Builders Guide

Mark Barbee

.

December 30, 2018

.

C10 Builders Guide

Every C-10 nut needs a diesel, right? Well, this nut does. I have had the privilege of owning many 1960-66 C-10 trucks in my life. Some of you guys might remember my ’63 C-10 that won Best Custom Truck at SEMA 2007 and went on to be made into a real Hot Wheels toy.

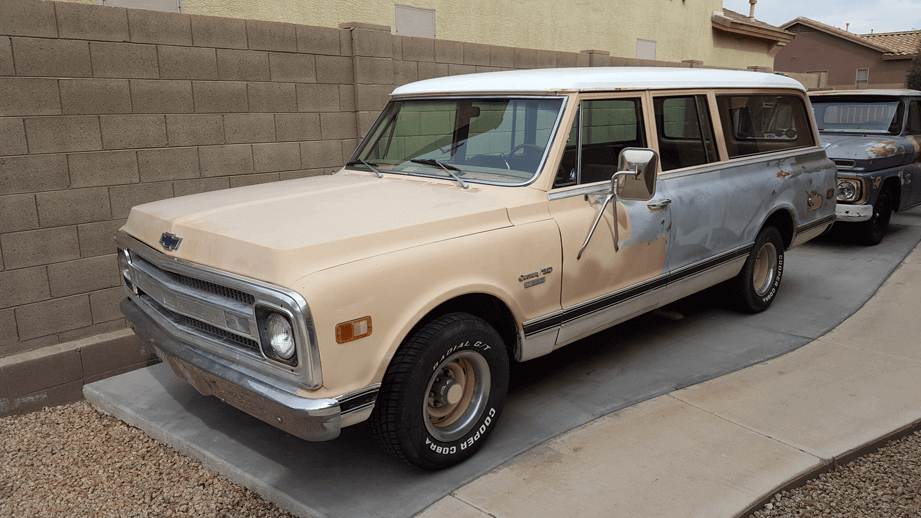

I decided that I wanted something a little different, so my friends and I started searching the web. We came across a running three-door ’69 2WD Suburban located about an hour away. A couple of friends and I headed over to check out the truck, and I ended up buying it on the spot for $3,000. I even drove it home without any issues.

I’ve never owned a 1967-72 C-10 before, and when my wife and daughters first saw the Suburban, the first thing they said was, “What are you going to do with that?” I told them that I wasn’t completely sure, but that I had a vague idea of what I wanted.

I parked the truck in my side yard for a few months where it became a playground for my girls. My wife would send me pictures of my daughters acting like they were driving it, putting the dog on the seat, and just having a good time. Seeing my girls enjoy the Suburban so much while it was just sitting there cemented a few ideas that I had about the truck’s future. We could take the truck on long family road trips and use it as a tow vehicle.

First things first, I needed to research costs, because I didn’t have an unlimited budget. I replayed the C10talk.com episode where the hosts discussed LS swaps. They said the average LS swap costs $10-15K, all included. I immediately decided that a Cummins was in the Suburban’s future. I certainly didn’t have an LS-sized budget! I got to work looking for donor vehicles that had a mostly mechanical diesel motor.

Sources:

Mark Barbee

GotCPR on Instagram

Jason Bowman

Big10Garage on Instagram

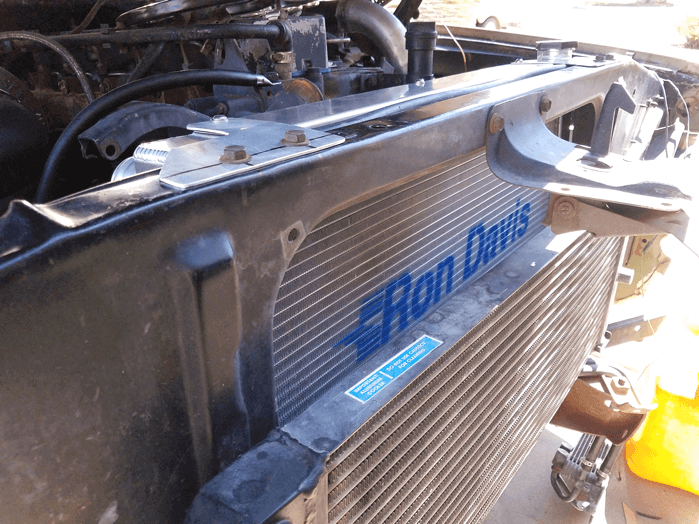

Ron Davis Radiators

Rondavisradiators.com

Airaid

Airaid.com

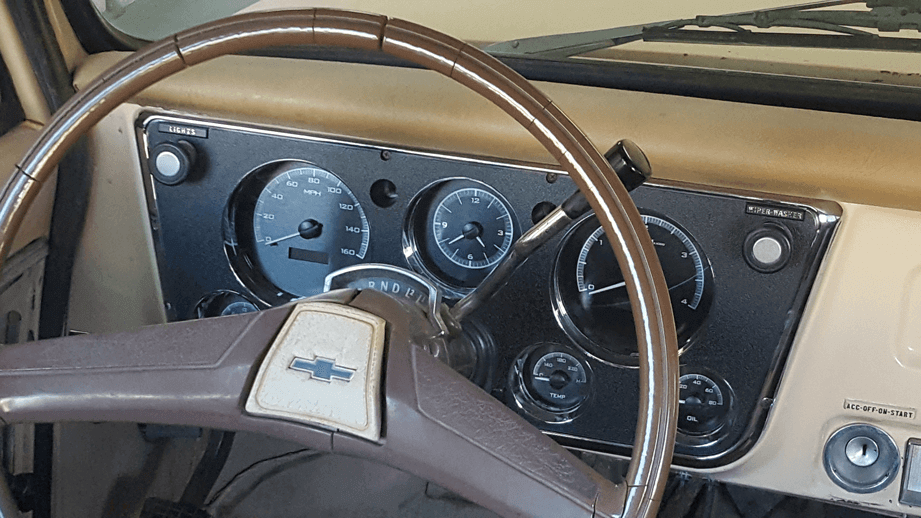

Dakota Digital

Dakotadigital.com

Royal Purple

Royalpurpleconsumer.com

How did Drew Barber’s profession influence the construction of his vehicle?

Drew Barber, a skilled fabricator with extensive experience at Avalanche Engineering, has made a name for himself crafting robust buggies like the Sniper and Assassin. His professional expertise profoundly shaped the construction of his personal vehicle, a custom-built Suburban designed for family adventures.

While Drew’s day-to-day role involves creating buggies capable of tackling extreme terrains, his family truck needed different specifications. Prioritizing space and comfort for his wife, child, and dog, Drew sought to build a vehicle perfect for long off-road excursions into the remote parts of southwest Colorado.

Drew’s fabrication skills were pivotal from the start. He specifically chose a ’92-’00 Suburban body style and located a suitable candidate—a bright yellow former school vehicle. This choice held particular significance, as Drew had a penchant for yellow rigs.

One core advantage of Drew’s expertise was his ability to improve upon his old vehicle’s specifications. Wanting the power of a Cummins diesel and enhanced comfort, he meticulously selected each aftermarket part. Drew’s professional background allowed him to take precise measurements and integrate components seamlessly.

Given his specialization in constructing frames and chassis, Drew felt compelled to design a custom chassis for his new Suburban. Using 6x2x11/48-inch rectangular tubing, he built a frame specifically tailored to the vehicle’s requirements, ensuring durability and performance in rugged environments.

By applying his professional knowledge, Drew not only constructed a high-performing, comfortable exploration vehicle but also demonstrated how his career in fabrication directly influenced the design and functionality of this family truck.

What were the main features and specifications of Drew Barber’s custom-built chassis?

Drew Barber embarked on his ambitious project with a clear vision in mind: a robust and customized chassis for his ’92-’00 body style Suburban. Here are the core features and specifications that make Drew’s chassis exceptional:

In summary, Drew Barber’s custom-built chassis stands out with its meticulously chosen materials, powerful engine with boosted capabilities, and expertly measured and fitted components. This blend of precision engineering and practical ingenuity showcases Drew’s commitment to creating a high-performance, durable vehicle.

What modifications were made to the suspension system of Drew Barber’s Suburban?

Drew Barber’s Suburban underwent several key changes to its suspension system to enhance both performance and handling. These modifications include:

These updates collectively contribute to a more robust and capable suspension system, ideal for tackling various driving conditions.

What type of tires and wheels are used on Drew Barber’s Suburban?

Drew Barber’s Suburban features robust, all-terrain tires measuring 37×12.50-17. These tires are specifically designed for superior traction and durability across various off-road conditions. The tires are paired with high-quality bead lock wheels from Walker Evans, known for their strength and reliability during demanding off-road adventures.

Key Features:

These components are chosen to ensure optimal off-road performance and stability while maintaining a rugged look.

What type of axles are used in Drew Barber’s Suburban, and what are their specifications?

Drew Barber’s Suburban is equipped with robust axles designed for superior performance.

These axles, paired with the specified gear ratios and air lockers, ensure enhanced traction and durability, making the vehicle well-suited for both off-road adventures and heavy-duty use.

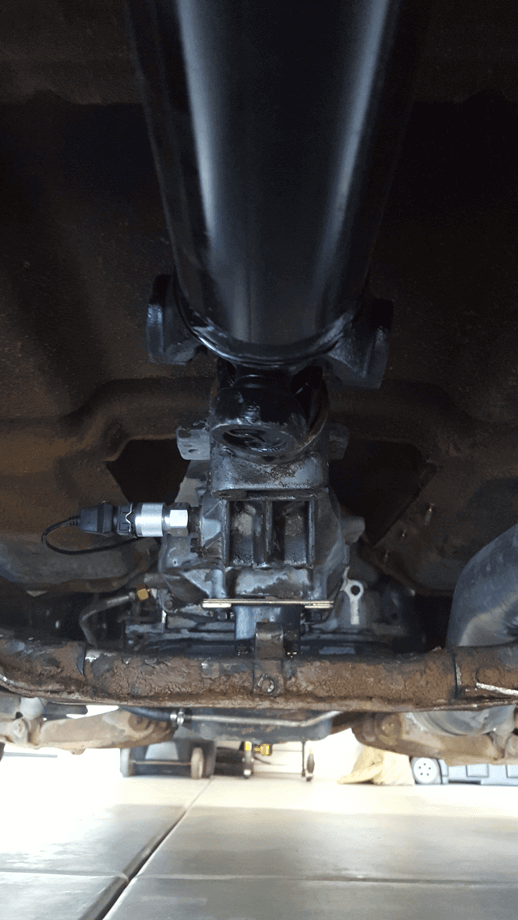

What Type of Transfer Case is Installed in Drew Barber’s Suburban?

Drew Barber’s Suburban comes equipped with a robust NP205 transfer case. This model is renowned for its durability and reliability, making it a popular choice for off-road enthusiasts and heavy-duty applications.

In summary, Drew’s Suburban features the NP205 transfer case, a testament to its robust construction and proven reliability.

What is the estimated torque output of Drew Barber’s modified Suburban?

Drew Barber’s modified Suburban generates an estimated torque output of around 1,000 lb-ft. Although he hasn’t had it officially dyno-tested, he confidently assesses this impressive figure. Yes, you read that right—approximately 1,000 lb-ft of torque.

Why did Drew Barber decide to build a new camping rig?

Drew Barber’s motivation to build a new camping rig stemmed from a blend of necessity and ambition. After years of rigorous use, Drew’s ’87 Chevy Suburban, which featured a Cummins engine and a five-speed manual transmission, had begun to show signs of wear. The vehicle was increasingly unreliable, requiring constant maintenance to stay functional.

Recognizing the limitations of his aging truck, Drew sought not just a replacement but an upgrade. He aimed for a new camping rig that would offer enhanced power and greater comfort. His previous experience with a Cummins diesel engine left him impressed, yet he envisioned improvements that would cater to both performance and convenience.

For Drew, the project was an opportunity to refine his camping experiences. He intended to incorporate modern features that would withstand the demands of off-road adventures while providing a more enjoyable and dependable journey.

Who is Drew Barber and what is his profession?

Drew Barber is a fabricator known for his craftsmanship in the off-road vehicle industry. He thrives in solitude, often retreating with his truck for extended periods. Drew’s professional expertise lies in creating renowned off-road buggies, showcasing his skills through well-known models like the Sniper, Assassin, and the BFG Karnivore. Working with Avalanche Engineering, Drew has established himself as a key figure in building exceptional and durable off-road machines.

What modifications did Drew Barber make to the engine of his new Suburban?

What kind of vehicle did Drew Barber originally own and modify?

Every C-10 nut needs a diesel, right? Well, this nut does. I have had the privilege of owning many 1960-66 C-10 trucks in my life. Some of you guys might remember my ’63 C-10 that won Best Custom Truck at SEMA 2007 and went on to be made into a real Hot Wheels toy.

Before diving into this project, I originally had an ’87 Chevy Suburban. It wasn’t just any Suburban; it had a Cummins engine and a five-speed manual swapped in it. Over the years, though, that truck took a lot of abuse. It was definitely getting ragged around the edges, and I knew it was time for a new ultimate camping rig.

I decided that I wanted something a little different, so my friends and I started searching the web. We came across a running three-door ’69 2WD Suburban located about an hour away. A couple of friends and I headed over to check out the truck, and I ended up buying it on the spot for $3,000. I even drove it home without any issues.

The plan was clear: take the lessons learned from my old ’87 Chevy Suburban and build something even better. This new project would be the ultimate blend of classic looks and modern power.

What future modifications are planned for the diesel vehicle project?

Engine Enhancements

We’ll meticulously install plumbing and wiring systems to ensure peak engine performance. Additionally, a custom exhaust system will be crafted to enhance efficiency and power output.

Structural Reinforcements

The vehicle’s chassis will undergo comprehensive reinforcement to handle increased torque and stress, ensuring durability and longevity on the road.

Drivetrain and Interior Upgrades

Expect significant improvements to the drivetrain to boost overall capability and performance. Inside, the interior will be upgraded to maintain comfort and functionality for extended use.

These modifications aim to ensure that our diesel vehicle remains robust and reliable for many years to come.

What are the goals for the Doomsday Diesel Suburban build?

The Doomsday Diesel Suburban aims to blend practicality and toughness into a singular vehicle that stands out for its adaptability and resilience. Here’s what this ambitious project seeks to achieve:

This build is all about creating a vehicle that’s ready for anything—be it a quick getaway or navigating a chaotic cityscape.

What is the project focus for building a diesel vehicle in the article?

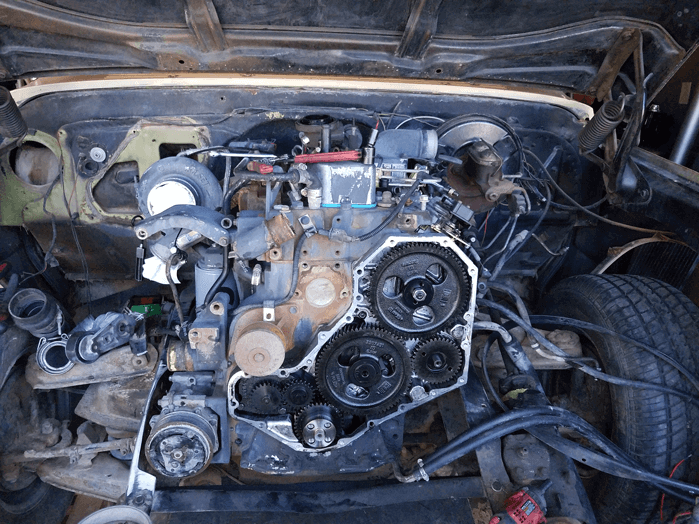

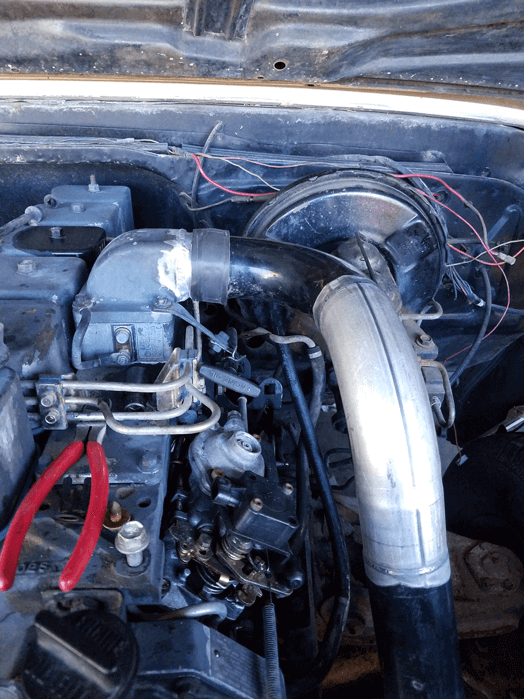

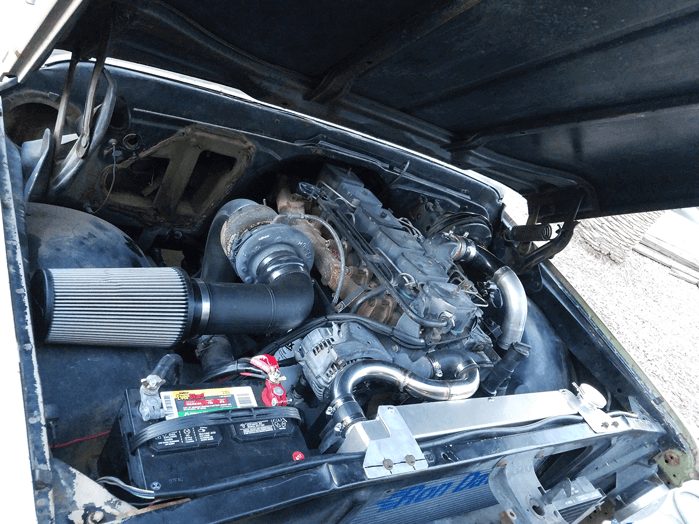

Diesel Engine Swap! 5.9-l Cummins in a 69 C10 Suburban

Every C-10 nut needs a diesel, right? Well, this nut does. I have had the privilege of owning many 1960-66 C-10 trucks in my life. Some of you guys might remember my ’63 C-10 that won Best Custom Truck at SEMA 2007 and went on to be made into a real Hot Wheels toy.

I decided that I wanted something a little different, so my friends and I started searching the web. We came across a running three-door ’69 2WD Suburban located about an hour away. A couple of friends and I headed over to check out the truck, and I ended up buying it on the spot for $3,000. I even drove it home without any issues.

The idea was to create a truck that wasn’t just another showpiece but a functional marvel of versatility and endurance. I envisioned a vehicle that could double as a family road trip machine and a robust tow vehicle, much like a getaway car and urban-assault vehicle rolled into one. The dream was to craft a Suburban with all-terrain capability, a significant fuel range, and enough space to accommodate the whole family on those long adventures.

I’ve never owned a 1967-72 C-10 before, and when my wife and daughters first saw the Suburban, the first thing they said was, “What are you going to do with that?” I told them that I wasn’t completely sure, but that I had a vague idea of what I wanted.

I parked the truck in my side yard for a few months where it became a playground for my girls. My wife would send me pictures of my daughters acting like they were driving it, putting the dog on the seat, and just having a good time. Seeing my girls enjoy the Suburban so much while it was just sitting there cemented a few ideas that I had about the truck’s future. We could take the truck on long family road trips and use it as a tow vehicle.

First things first, I needed to research costs, because I didn’t have an unlimited budget. I replayed the C10talk.comepisode where the hosts discussed LS swaps. They said the average LS swap costs $10-15K, all included. I immediately decided that a Cummins was in the Suburban’s future. I certainly didn’t have an LS-sized budget! I got to work looking for donor vehicles that had a mostly mechanical diesel motor.

The journey wasn’t just about the swap itself but about transforming this classic into a reliable beast that could cover significant mileage while carrying a small squad — in this case, my family. It was about blending practicality with passion, ensuring the Suburban wasn’t only a nod to the past but a step into a versatile future.

What qualities are being prioritized in the vehicle’s design?

The design emphasizes adaptability, robustness, and fuel efficiency, ensuring it can handle diverse and challenging environments.

What are the key features and capabilities of the vehicle?

It boasts off-road capabilities, a substantial fuel range of 1,000 miles, and sufficient space to accommodate a small team of survivors, making it versatile for various scenarios.

What is the primary purpose or concept of the vehicle?

The vehicle is designed to function both as an escape vehicle and a resilient urban assault vehicle, combining practicality with tactical capabilities.

What components were required to connect the Cummins engine to the GM transmission?

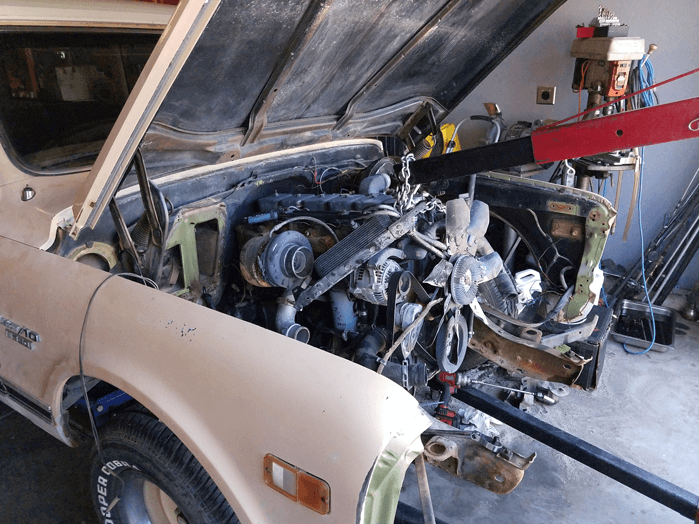

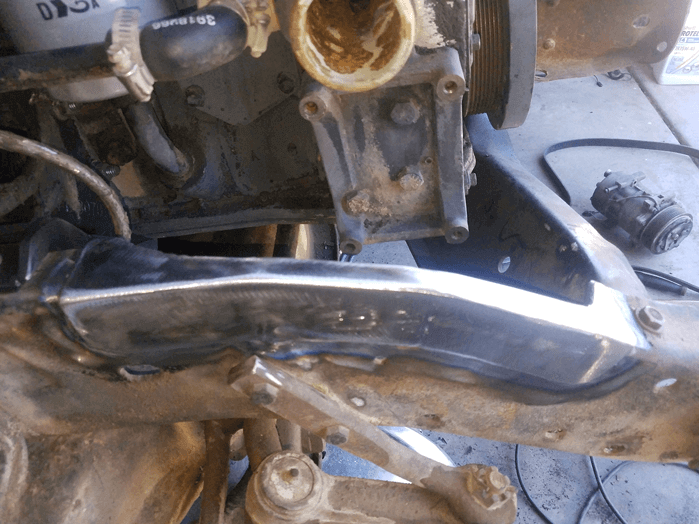

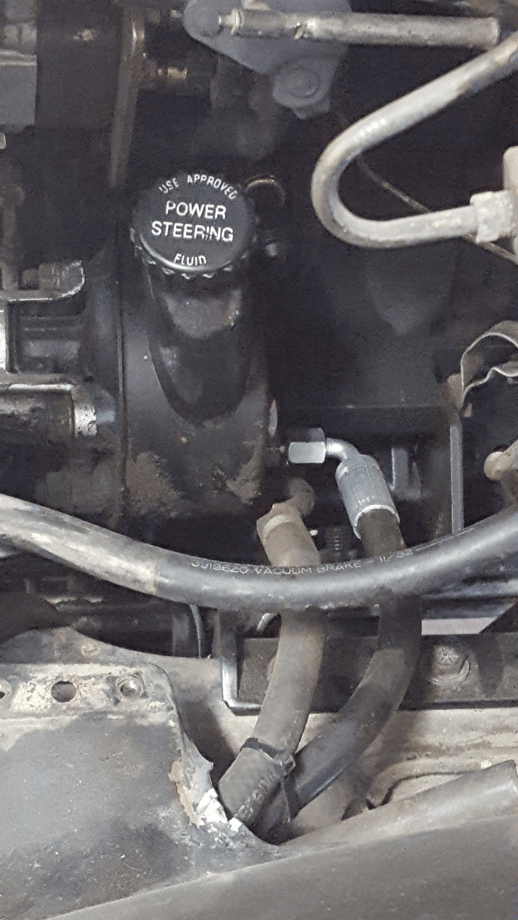

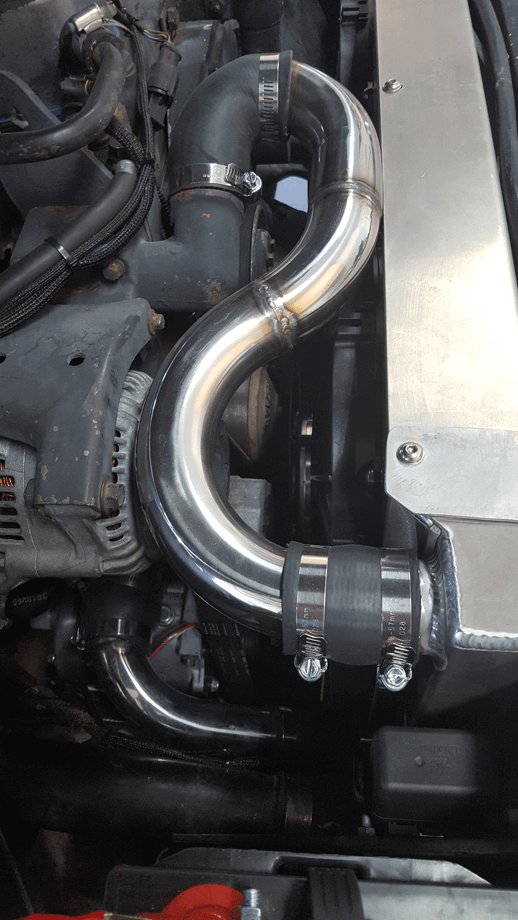

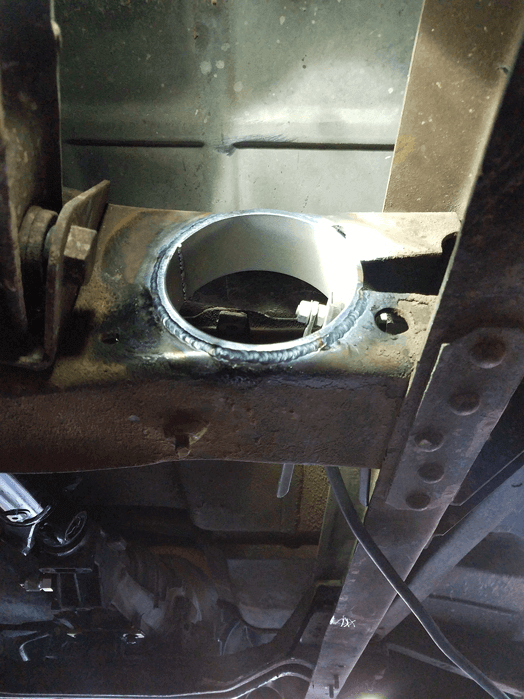

The Dodge A518 transmission aligned perfectly with the factory Chevy transmission cross member. Jason used the Turbo 400 mount between the Dodge transmission and Chevy cross member’s existing holes. We wanted to use as many factory parts as available, so Jason sourced a high hump Chevy transmission cover that worked perfectly. A custom driveshaft was made to mate the Dodge A518 transmission to the stock Chevy differential.

To adapt the Cummins engine seamlessly to the GM setup, a few key components were essential. We utilized a billet-aluminum adapter plate to ensure a solid connection. Additionally, an SFI-approved steel flexplate was incorporated, allowing the Cummins to be securely bolted to the existing setup. These components were crucial in facilitating the integration of the engine and transmission, ensuring both performance and reliability.

This meticulous selection of parts ensured that the integration was not only functional but also optimized for durability, maintaining the integrity of both the engine and transmission systems.

What type of transmission is being used with the Cummins engine?

The transmission paired with the Cummins engine is a heavy-duty GM 4L80E, which features four speeds and is automatic.

How is the engine physically connected to the transmission?

The engine is directly attached to the transmission using the adapter components, ensuring a secure fit.

What adapter components are needed to connect a Cummins engine to a GM transmission?

To facilitate the connection between a Cummins engine and a GM transmission, a billet-aluminum adapter plate along with a steel flexplate that meets SFI standards are essential components.

What future modifications are planned for the Suburban after the engine swap?

After the engine swap, several key modifications are planned for the Suburban to ensure its longevity and performance.

These modifications aim to extend the vehicle’s lifespan and maintain optimal performance on the road for years to come.

How is the 5.9L Cummins engine being integrated into the 1991 Suburban?

To integrate the 5.9L Cummins engine into the 1991 Suburban efficiently, a methodical approach is underway:

By following these steps, the team aims to merge the power of the Cummins engine with the rugged reliability of the Suburban, achieving a seamless and high-performance conversion.

What modifications are planned for the Suburban to enhance its survivability?

To enhance the Suburban’s longevity and resilience, several key modifications are planned. First, the chassis will get a significant reinforcement, which will provide a stronger foundation and better support the vehicle’s structure under stress.

Next, the drivetrain will receive a comprehensive upgrade. This includes robust components that ensure smooth and reliable power transmission, critical for tough driving conditions and long journeys.

Additionally, the interior will be upgraded for durability and comfort. These enhancements not only contribute to a longer lifespan but also improve the overall driving experience, making the Suburban ready for many more miles on the road.

How will the vehicle be prepared for potential apocalyptic scenarios?

When gearing up a vehicle for potential apocalyptic scenarios, the focus is on creating a machine that embodies versatility, endurance, and efficiency—qualities essential for navigating a world in chaos.

Attention to these details guarantees that the vehicle not only serves as a reliable mode of transportation but also acts as a mobile fortress in any survival scenario. Whether evading danger or embarking on a supply run, this apocalyptic-ready vehicle is designed to keep you moving forward, come what may.

What is the purpose of the Doomsday Diesel project?

The Doomsday Diesel project aims to craft a vehicle that embodies versatility, endurance, and fuel efficiency, drawing on the robust capabilities of diesel engines. This project envisions a multipurpose truck designed to function as both a reliable escape vehicle and an adaptable urban operation unit. Equipped to handle challenging terrains, the vehicle is engineered to cover extensive distances with a fuel range of 1,000 miles, while providing ample space for a team of passengers and their gear.

How is the transmission issue addressed in the Cummins engine swap?

The Dodge A518 transmission aligned perfectly with the factory Chevy transmission cross member. Jason used the Turbo 400 mount between the Dodge transmission and Chevy cross member’s existing holes. We wanted to use as many factory parts as available, so Jason sourced a high hump Chevy transmission cover that worked perfectly. A custom driveshaft was made to mate the Dodge A518 transmission to the stock Chevy differential.

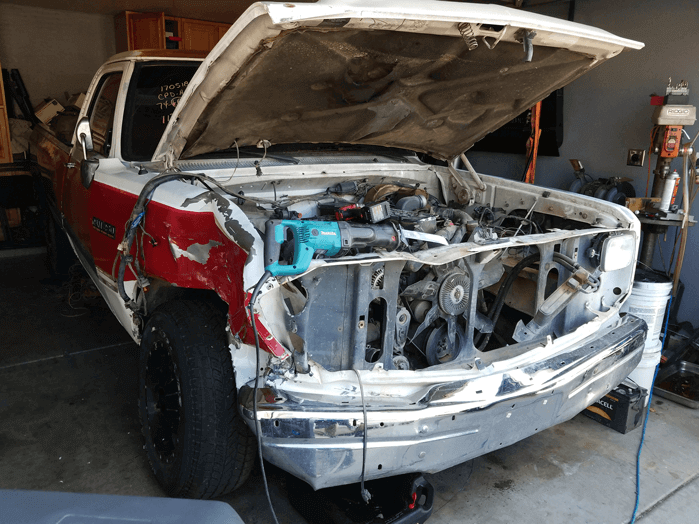

But the journey didn’t end there. The absence of a compatible transmission initially posed a significant challenge. Fortunately, inspiration struck from the ’91 Suburban parked in the driveway, which housed a heavy-duty 4L80E four-speed automatic transmission. Using a precision-engineered billet-aluminum adapter plate and an SFI-approved steel flexplate, the Cummins engine was seamlessly connected to the 4L80E.

Jason took constant measurements throughout the swap. Just because the engine and transmission looked good and fit didn’t mean everything else would fit down the road. He had to keep in mind that the plan was to keep everything factory. By ensuring each component was meticulously aligned and compatible, he preserved the integrity of the original setup while achieving a high-performance upgrade.

How is the engine directly connected to the transmission?

The engine is directly attached to the transmission using the adapter plate and flexplate, ensuring a secure fit.

What specific components are needed to connect the engine to the transmission?

A billet-aluminum adapter plate and a steel flexplate are necessary to connect the engine to the transmission.

What transmission is used for the swap?

The transmission used for the swap is a heavy-duty 4L80E four-speed automatic from a ’91 Suburban.

What are the goals for the vehicle’s performance and capabilities?

Seeing my girls enjoy the Suburban so much while it was just sitting there cemented a few ideas that I had about the truck’s future. We could take the truck on long family road trips and use it as a tow vehicle.

But this truck is destined for more than just family fun. Imagine a vehicle that can truly go the distance—I’m talking about a 1,000-mile fuel range. This kind of capability ensures we can explore without the constant worry of refueling, making it perfect for those cross-country adventures.

Moreover, the Suburban isn’t just about leisure; it’s built to handle any challenge thrown its way. With all-terrain capability, we can venture off the beaten path and explore rugged landscapes with confidence. This truck offers the durability and versatility that make it an ideal companion for both everyday use and unexpected situations.

And let’s not forget the space—ample room to accommodate a small squad or all the gear we might need for our travels. Whether it’s a family trip or an impromptu camping weekend, the Suburban is ready to adapt, ensuring comfort and utility for every journey.

What is the vehicle’s capacity for occupants or cargo?

The interior is spacious enough to accommodate a small group of people, suggesting ample room for either passengers or cargo.

What are the key performance features?

It boasts capabilities for navigating rough terrain and can travel 1,000 miles on a single tank, highlighting its efficiency and rugged performance.

What is the primary purpose of the vehicle?

The vehicle is designed to serve dual functions: as both an escape vehicle and a tactical urban vehicle.

Share Link