MIKE MCGLOTHLIN

.

December 30, 2020

.

c10

MIKE MCGLOTHLIN

.

December 30, 2020

.

c10

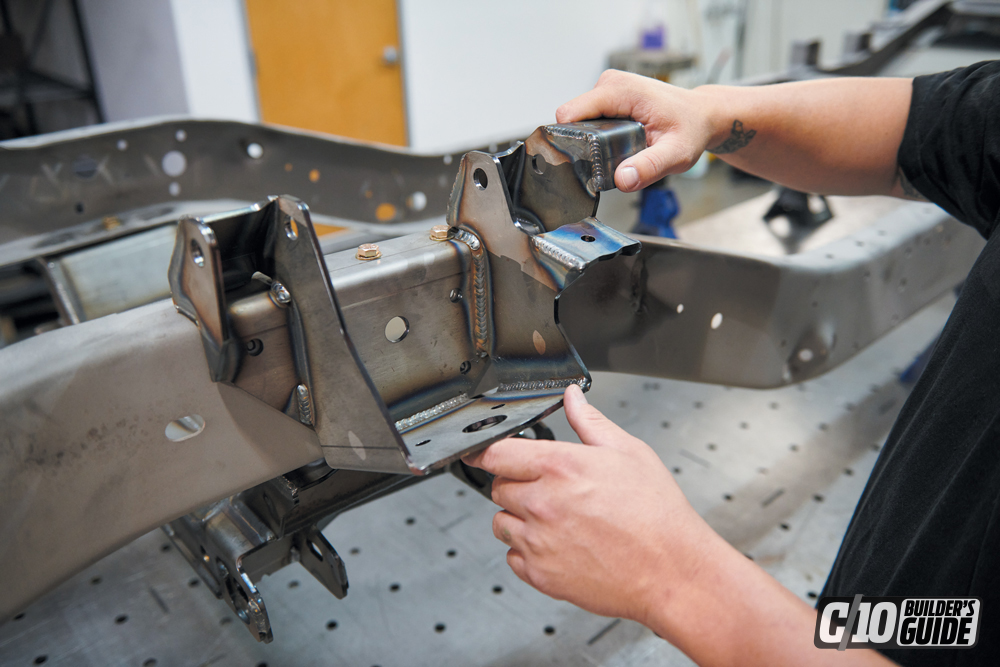

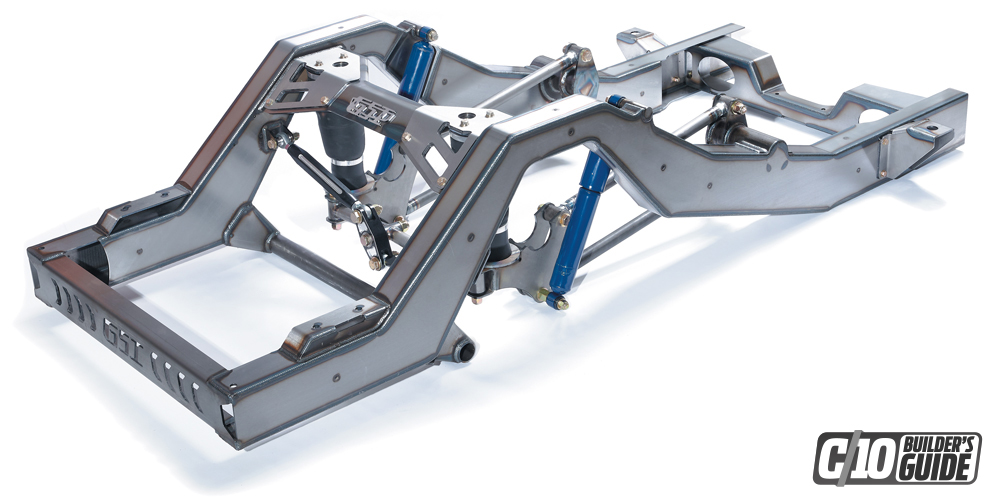

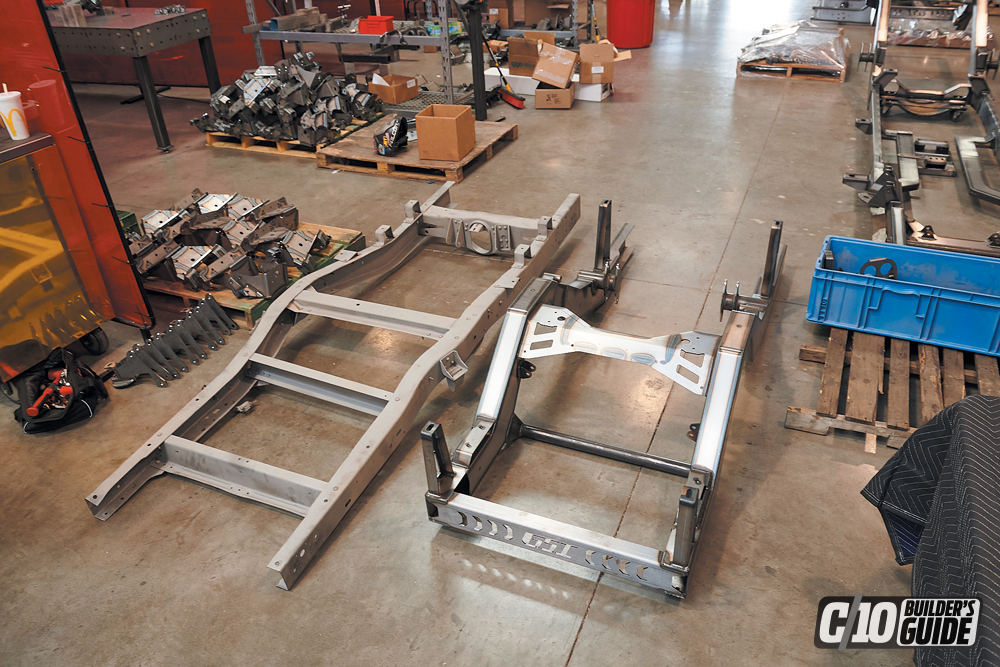

So, you bought an old C10 and you just don’t love the stance? Let me guess—you want it “hammered on the ground, but still enjoyable to drive.” Confidence and driveability in your air suspension are what you need. If you’re looking to put air ride suspension on a classic ’63-’87 C10 but want to make sure you are satisfied after all the time and money spent to get there, consider this GSI Machine and Fabrication C10 frontend suspension kit.

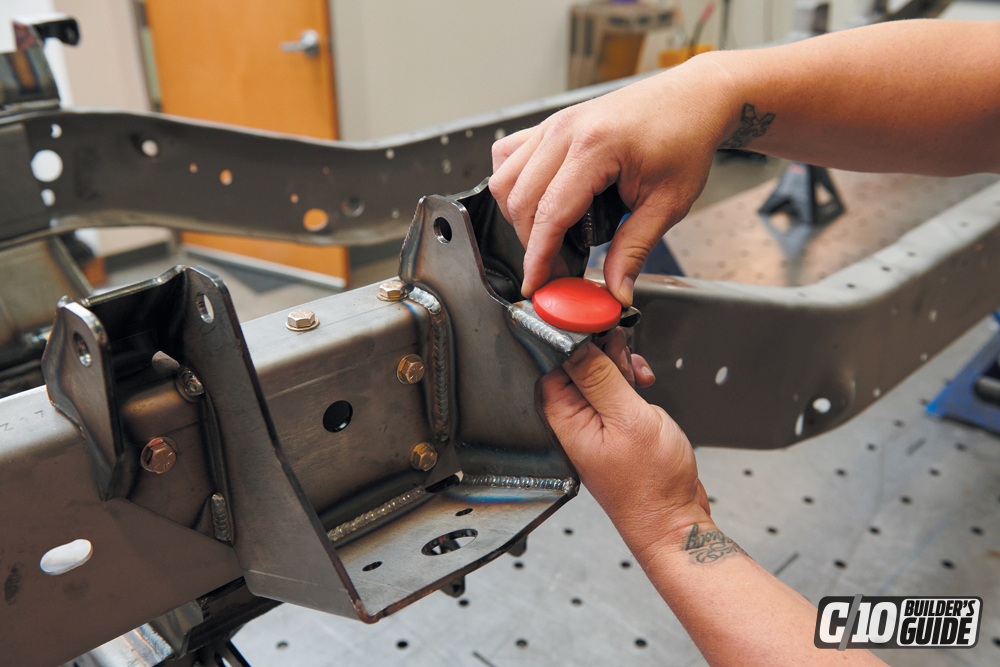

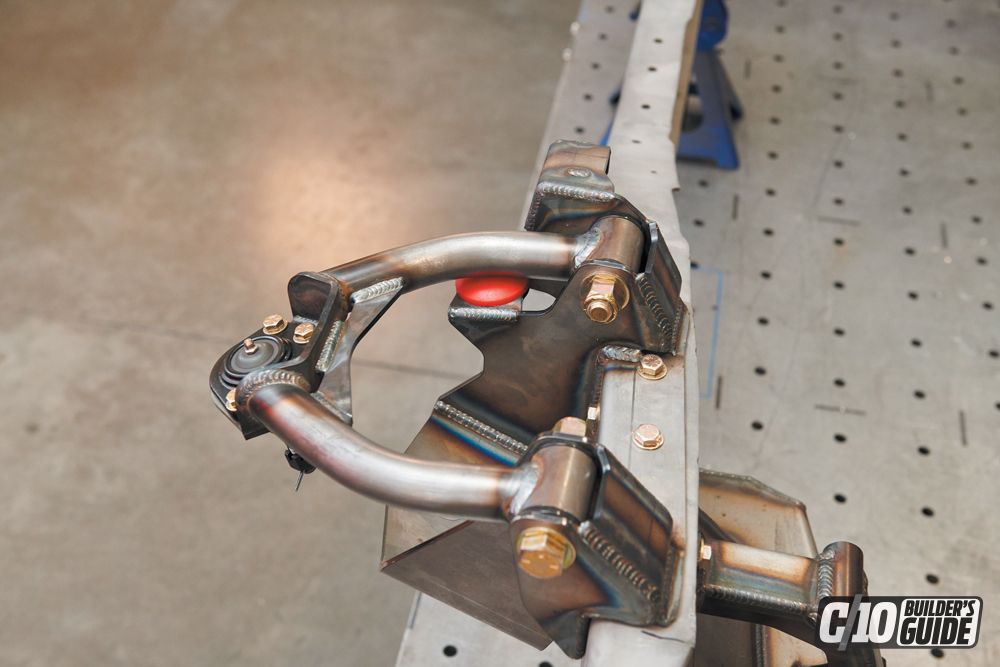

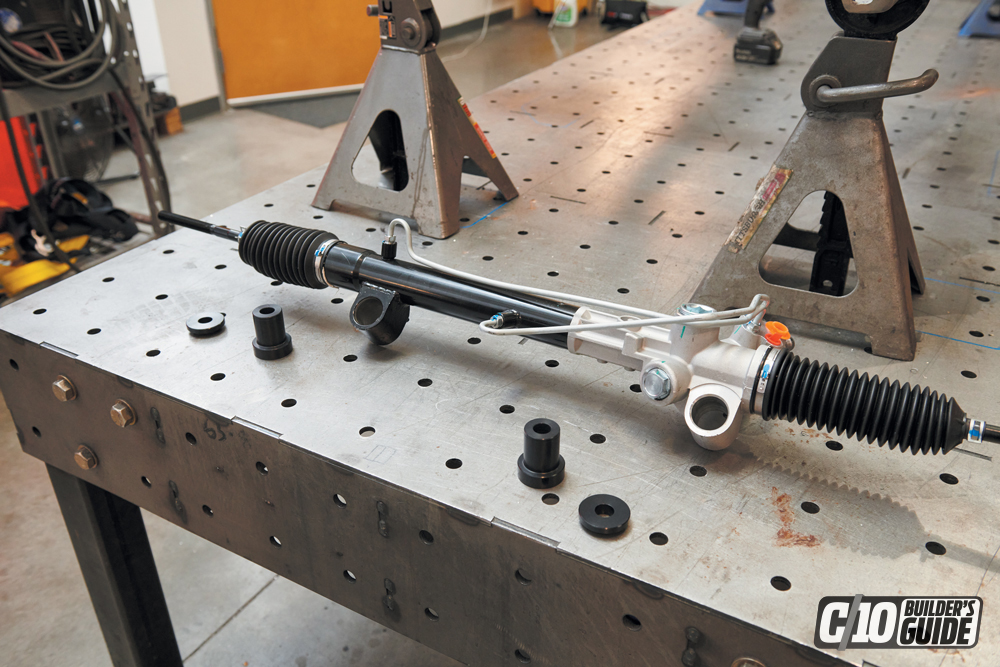

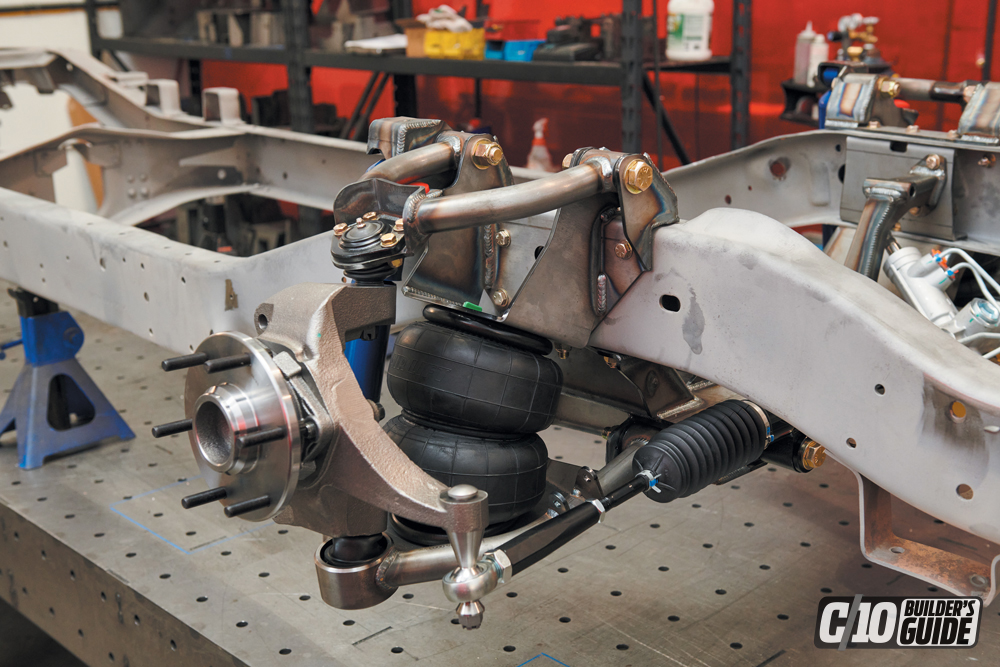

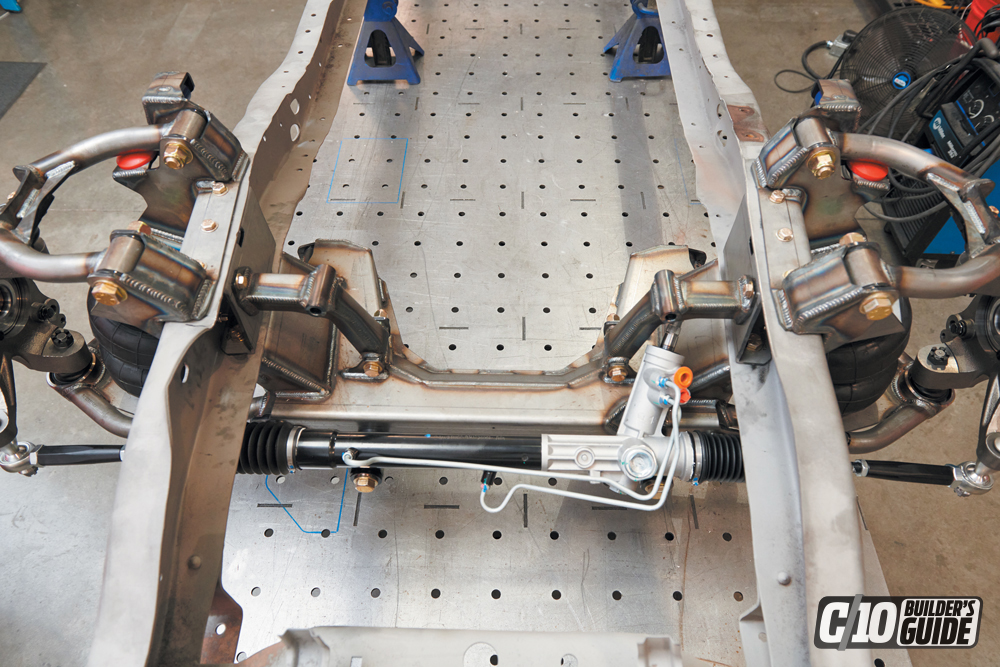

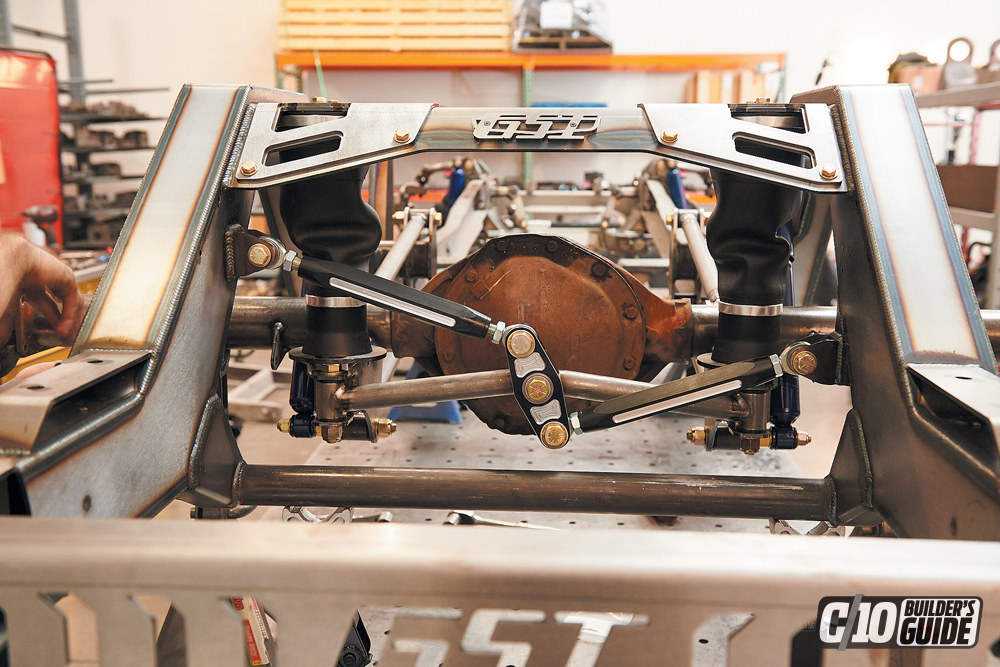

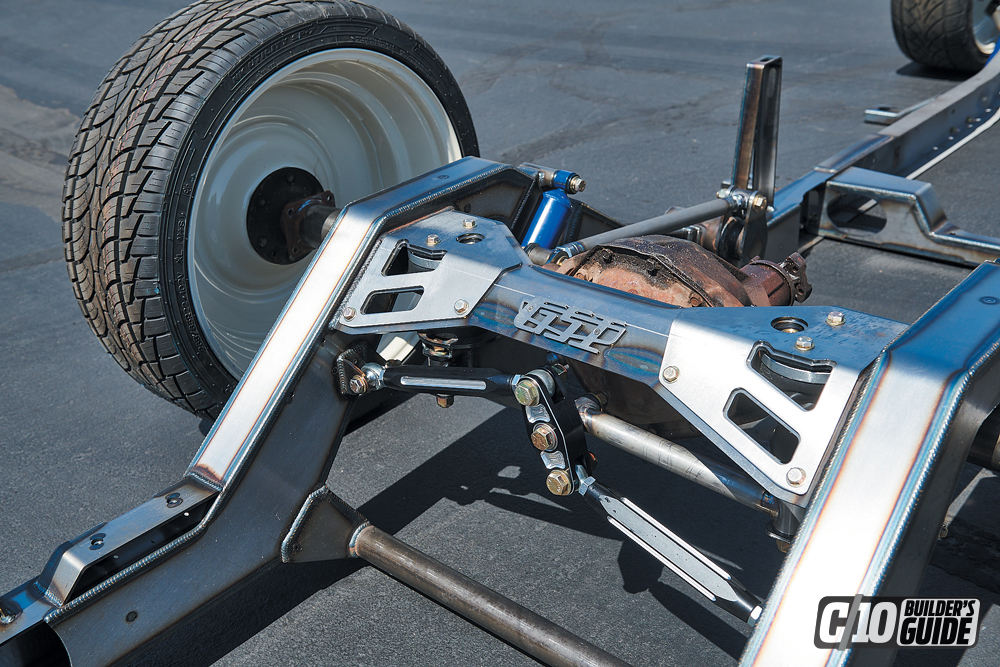

This superior geometry specifically designed for a stock C10 chassis with airbags, this kit accepts large-diameter wheels and tires up to 31 inches tall. This kit narrows the track width, making wheel options greater, and brings the cross-member and lower control arm pivots up out of the way so your frame rails lay flat on the ground when aired out. This system also upgrades the steering to a power rack-and-pinion unit and utilizes disc brake spindles, which are all supplied by GSI when you order the complete kit.

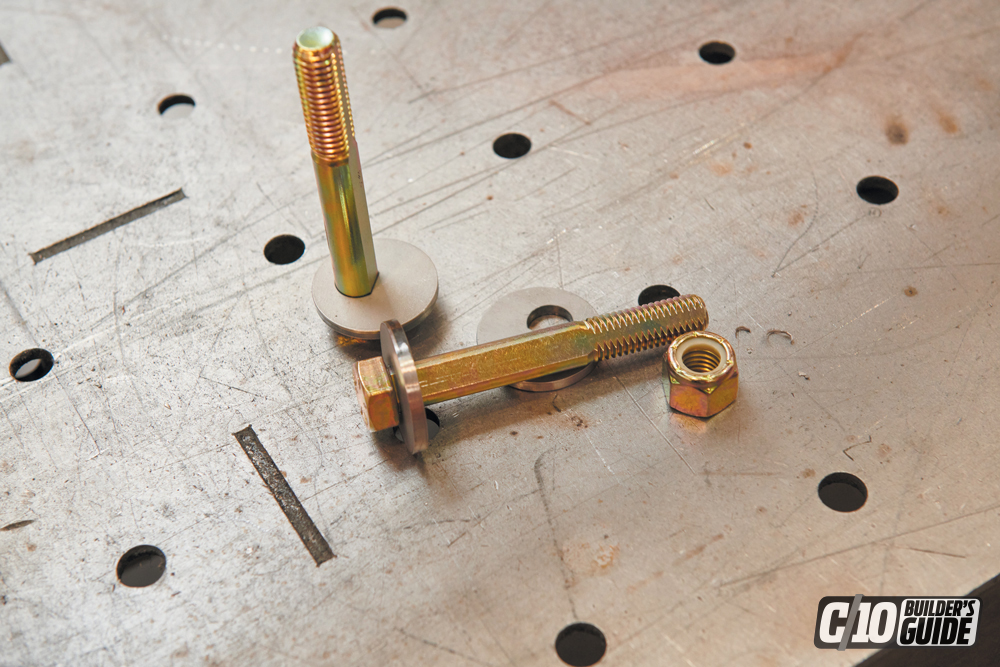

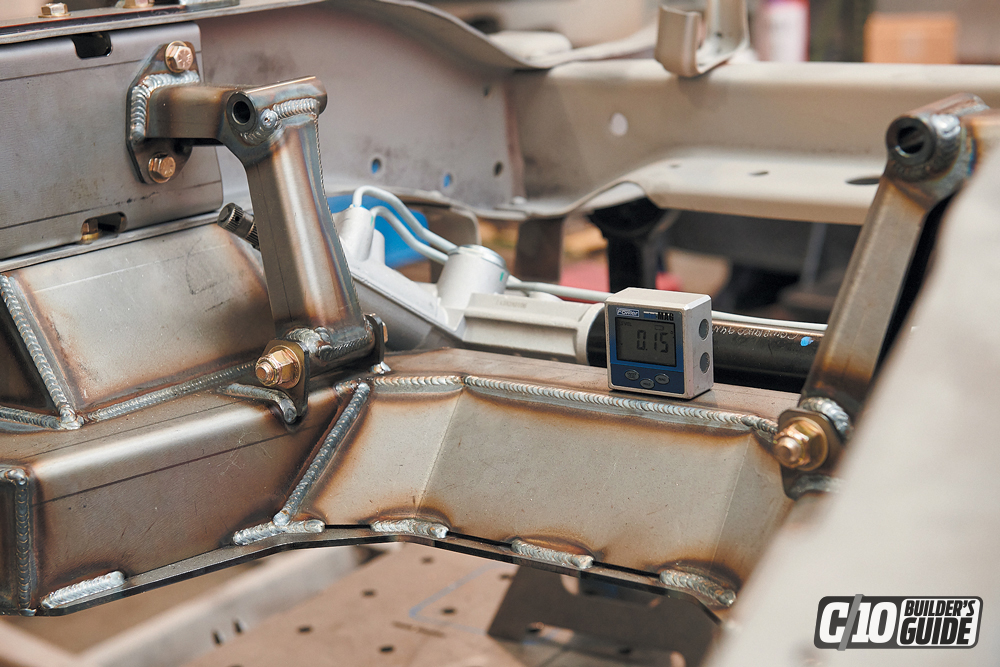

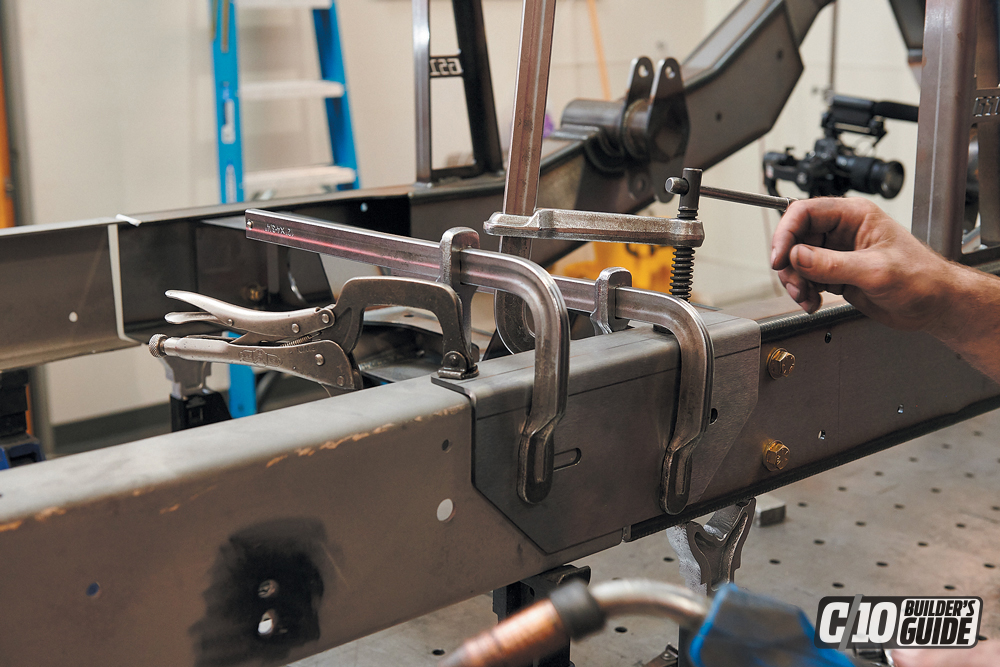

We grabbed a longbed ’64 stock chassis, stripped it down to its bare bones and had it sandblasted by Matador Powder Coating in Mesa, Arizona. When we got the frame back, we brought it to our fab shop and set it on the frame table. This install can be done without the use of specialty tools. You will need a press for the ball joints and bushings, but otherwise a floor jack, sockets, ratchets, wrenches, a couple of jack stands and a drill will get it done.

Share Link