Chris Hamilton

.

April 20, 2021

.

America

Chris Hamilton

.

April 20, 2021

.

America

For 2020’s “Best Of” awards, we’re bringing in a new category that will create a bit of fun competition between all the great parts manufacturers in our industry. There are no special favors made or additional money spent to take this title. To get noticed, a company just needs to make a massive impact on the printed articles we run throughout the year.

When the majority of the trucks we feature in print have the same brand of upgrades, and our tech articles keep repeating the same name, it’s almost impossible not to think of one name first when choosing a winner for the Street Trucks Manufacturer of the Year award. The company that we consistently wrote into stories and tech pieces for 2020 is one we all know. The crew is motivated by the idea that experiences are best made behind the wheel. That’s why we chose QA1 to take this year’s top honor.

No matter what you drive, QA1 just wants you to #goDRIVEit!

Founded in 1993, QA1 is an industry leader in performance shocks, suspension components, composite driveshafts, rod ends, spherical bearings and related accessories for the motorsports and industrial markets. The company has more than 100,000 square feet of office and manufacturing space in Lakeville, Minnesota. QA1 believes that vehicles were meant to be driven. From bolt-on products that get you behind the wheel faster and experienced technicians available to help increase your 60-foot times with confidence, everything it does is designed to get you out on the road!

The number one priority at QA1 is quality, which is why the company’s manufacturing system is certified to the ISO 9001 standard. QA1’s products are designed, built and tested to ensure consistent quality, ultimate reliability and unbeatable performance. QA1 follows strict processes, uses precision machinery and inspects all of its products to ensure the quality meets the standards.

Recently, QA1 moved to a brand-new facility located just two miles away from QA1’s previous location. Providing more than 100,000 square feet of manufacturing, office and distribution space, the new building allows QA1 to continue adding to its long line of American-made products, all under one roof.

“We are excited to provide this new facility to everyone at Team QA1,” says Melissa Scoles, president of QA1. “The investment and move shows our commitment to our employees, our customers and our community. We are proud of what we’ve built in Lakeville and are excited to continue making quality American-made products here for years to come. The new facility provides space for more equipment, inventory and innovation, while providing modern workspaces for our team to be more comfortable and efficient.”

Carbon Fiber Driveshaft Testing

QA1’s carbon fiber driveshaft testing meets or exceeds SFI specification 43.1. Not only are the finished carbon fiber driveshafts tested, but the materials used to make them are tested throughout the process as well including tension, compression, shear, three-point bend and surface roughness. Harmonic testing is done to determine the natural frequency of the driveshaft, and a modal analysis is performed to ensure the composite driveshaft meets the applications’ requirements for NVH (noise, vibration and harshness).

QA1’s carbon fiber driveshaft testing meets or exceeds SFI specification 43.1. Not only are the finished carbon fiber driveshafts tested, but the materials used to make them are tested throughout the process as well including tension, compression, shear, three-point bend and surface roughness. Harmonic testing is done to determine the natural frequency of the driveshaft, and a modal analysis is performed to ensure the composite driveshaft meets the applications’ requirements for NVH (noise, vibration and harshness).

QA1 Quality Policy

QA1 is committed to providing quality rod ends, spherical bearings, shock absorbers and related products, fabricated suspension components, composite products and OEM custom components. This is accomplished through teamwork, data analysis, continuous improvement and communication throughout QA1.

QA1 is committed to providing quality rod ends, spherical bearings, shock absorbers and related products, fabricated suspension components, composite products and OEM custom components. This is accomplished through teamwork, data analysis, continuous improvement and communication throughout QA1.

Test Fit and Track Tested

Many of QA1’s employees are racers or automotive enthusiasts themselves and understand your needs and goals. They know that dyno testing, computer evaluations and endurance tests are only valuable if they can also result in real world performance. Every product is test fit, track tested and driver or racer approved before it begins production.

Many of QA1’s employees are racers or automotive enthusiasts themselves and understand your needs and goals. They know that dyno testing, computer evaluations and endurance tests are only valuable if they can also result in real world performance. Every product is test fit, track tested and driver or racer approved before it begins production.

Complete Coilover Conversion Systems for Squarebody Trucks

These engineered-from-scratch rear suspension systems for squarebody trucks are extremely well designed for the do-it-yourselfer. Now Chevy truck owners can add modern performance to a pickup that was designed for utilitarian use. QA1 engineered this unique bolt-in torque arm system design that maximizes performance without the inherent binding issues of other four-link systems.

These engineered-from-scratch rear suspension systems for squarebody trucks are extremely well designed for the do-it-yourselfer. Now Chevy truck owners can add modern performance to a pickup that was designed for utilitarian use. QA1 engineered this unique bolt-in torque arm system design that maximizes performance without the inherent binding issues of other four-link systems.

The major benefit of the torque arm design is that each component is designed to perform one function. This provides superior control over suspension movement, resulting in a smooth ride and great handling characteristics. With 4 to 7 inches of adjustment, dialing in the stance is easy with this QA1 adjustable coilover system.

Front and Rear QA1 Coilover Conversion ’65-’72 Ford F-100s

Ditch your twin I-beam front suspension for a completely new frontend that has been engineered to make your truck handle great, with the ride height adjustability to dial in the perfect stance. This front system is narrower than a Crown Vic and offers you fitment of larger wheels and tires. After installation, this system saves 150 pounds of weight and provides 3 to 7 inches of drop, depending on whether stock or drop spindles are used. The system includes upper and lower control arms, upper and lower crossmembers, adjustable coilover shocks and springs, rack-and-pinion steering and spindles.

Ditch your twin I-beam front suspension for a completely new frontend that has been engineered to make your truck handle great, with the ride height adjustability to dial in the perfect stance. This front system is narrower than a Crown Vic and offers you fitment of larger wheels and tires. After installation, this system saves 150 pounds of weight and provides 3 to 7 inches of drop, depending on whether stock or drop spindles are used. The system includes upper and lower control arms, upper and lower crossmembers, adjustable coilover shocks and springs, rack-and-pinion steering and spindles.

For the F-100 rear coilover conversion system, QA1 engineered a unique torque arm design that offers unprecedented adjustability with the Panhard bar, torque arm, trailing arms, bracket mounts and shocks.

Do You Race? If You Win, QA1 Pays!

QA1 is proud to participate in several contingency programs to support, recognize and award top performers during the racing season who are using QA1 products. Racers who utilize QA1 products to outperform the competition will be eligible for a contingency payment or certificate. QA1 is committed to helping racers compete at the highest level.

QA1 is proud to participate in several contingency programs to support, recognize and award top performers during the racing season who are using QA1 products. Racers who utilize QA1 products to outperform the competition will be eligible for a contingency payment or certificate. QA1 is committed to helping racers compete at the highest level.

QA1 MOD Shocks and More Honored with 5 Awards at SEMA

QA1 has received multiple national awards for their products including five awards for new products during the 2018 SEMA Show in Las Vegas. Each year, around 3,000 of the most innovative and cutting-edge products are entered into SEMA’s New Product Showcase. What an honor to win these categories.

QA1 has received multiple national awards for their products including five awards for new products during the 2018 SEMA Show in Las Vegas. Each year, around 3,000 of the most innovative and cutting-edge products are entered into SEMA’s New Product Showcase. What an honor to win these categories.

Best Engineered New Product, Runner-Up – MOD Series Shock

Best New Product in Performance–Racing, Runner-Up – MOD Series Shock And Carbon Fiber Sway Bars

Global Media Award – F-100 Suspension System

Global Media Award – GM Carbon Fiber Driveshafts

1988-1998 C1500 Coilover Conversion Systems

QA1’s bolt-on front and rear systems for ’88-’98 OBS Chevy trucks can not only lower your C1500 to the perfect stance. But you’ll also be able to handle those corners and curves like a sports car.

These kits are designed to easily bolt on big suspension performance that integrate control arms. With QA1 coilover shocks. These systems offer control arm weight savings of 25 pounds per side over stock, plus up to 7 degrees of caster and a range of +2 to -3 camber. The Level 2 system is great for street performance, while the Level 3 is the perfect match for OBS owners with competition in mind while still allowing adjustability to cruise to the track in comfort.

Picture this: 24×15-inch polished Intro Billets and QA1 coilovers on a midnight black ’93 Ford Lightning. Bet you never thought you would hear those specs, did you?

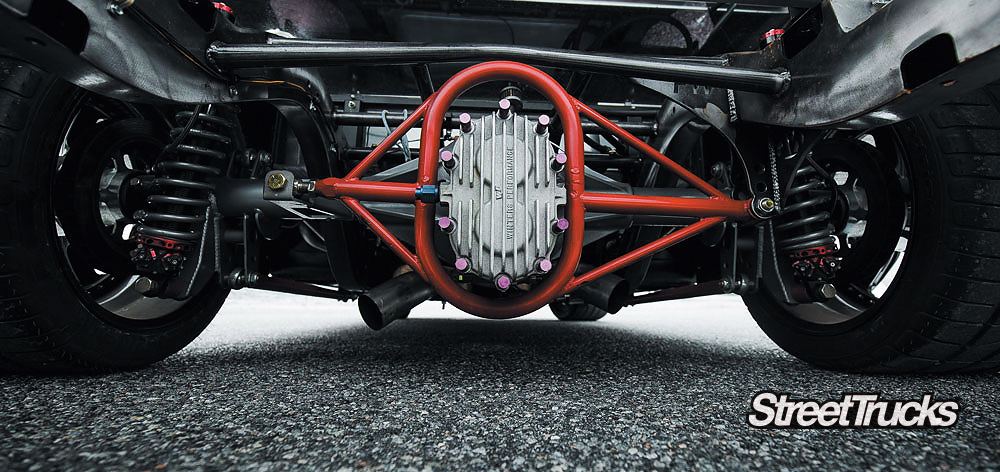

Outfitted with beefy sway bars, QA1 adjustable coils and a Winters Performance quick-change rear, this ’68 Ford F-100 is coming to life. A set of Forgeline GF3 wheels were spec’d out and 18×12 three-piece wheels soon sat at each corner with BF Goodrich measured at 300/30ZR18 keeping things planted.

Outfitted with beefy sway bars, QA1 adjustable coils and a Winters Performance quick-change rear, this ’68 Ford F-100 is coming to life. A set of Forgeline GF3 wheels were spec’d out and 18×12 three-piece wheels soon sat at each corner with BF Goodrich measured at 300/30ZR18 keeping things planted.

This ’01 Dodge 2500 Pickup is running a set of QA1 coilovers on a four-link rear suspension setup

This ’01 Dodge 2500 Pickup is running a set of QA1 coilovers on a four-link rear suspension setup

QA1

800-721-7761

www.QA1.net

9574 217th Street

West Lakeville, MN 55044

Share Link