Mike Alexander

.

May 25, 2020

.

Features

Mike Alexander

.

May 25, 2020

.

Features

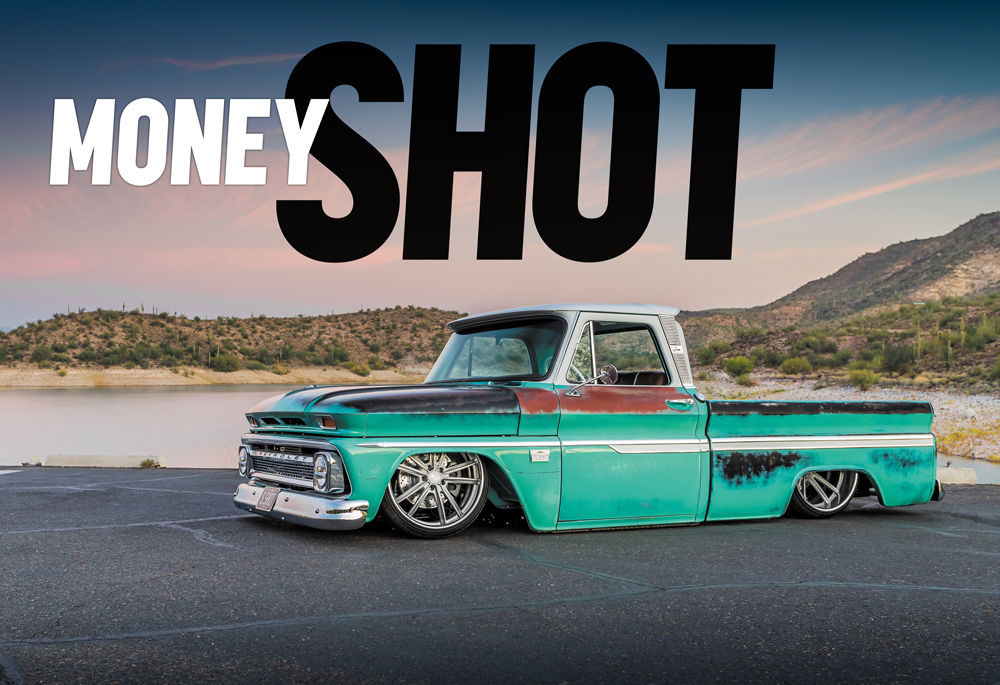

WHEN IT comes to a winning formula, there’s just something about a perfectly slammed C10 sporting the right wheel/tire combo, a gorgeous patina finish and that diesel chugga chugga. Wait, what? That’s right folks. Morgan Youngberg’s 1966 Chevy C10 may look like “just another patina C10” at first glance, but that’s where judging a book by its cover will get you into trouble.

Yes, when you hear this super clean C10 fire up, there’s something creepin’ under the hood. Morgan wanted to do something a little different, and although a nice classically clean exterior presents itself, below the surface is much, much more. But let’s back up a bit here. Morgan had been on the hunt for a nice C10 build for a bit. He knew he wanted to start with a really clean and solid body, as a nice patina finish was what he had in mind for the exterior look of his perfect cruiser. Being from “the C10 Mecca” in Arizona right off, Morgan made the right choice and teamed up with Metalox Fab and Johny’s Garage to be on the hunt as well as to take part in bringing his vision to life.

The perfect specimen was located, and the team quickly put their heads together for a game plan. A budget and timeline were set, and the build was planned to make a big debut for the upcoming SEMA Show, so time was definitely something the crew had to keep a close watch on and not go too crazy with wild exterior mods. The build was quickly picked up for a booth spot, so the team really had to shine. The first phone call was to Porterbuilt Fab to get her planted a bit closer to Mother Earth. The Porterbuilt front and rear drop-members were paired with the PB frame stiffener to complete the C10 chassis and suspension in a reliable and quick manner. But first, the couple of frame and body mods that were decided to be a must on Morgan’s must-have list were a shortbed conversion and big back window. The longbed being cut down required the factory chassis being shortened as well before the completion of Porterbuilt upgrades.

Moving along quickly as the crew only had about five months total build time, the wild card here was the engine choice. Morgan opted for a 2.8L Cummins diesel crate engine to really stir things up a bit on the build, and it definitely did the trick! Morgan wanted a nice cruiser that would be reliable, but he didn’t just want another run-of-the-mill LS-swapped C10. So Metalox and Johny’s Garage tackled the task of mating the 2.8L with the C10 chassis and all of the wiring and necessary kinks that go with such a task. Being so well versed with C10s, this was still quite a feat in the time period, but Money Shot was definitely in good hands.

The foundation was dialed and with a set of 22-inch US Mags the stance really played out nicely, exactly as Morgan had envisioned. Drivetrain and plumbing were moving right along, and the exterior would be cleaned up/restored by Auto Renew. So, the last big piece of the puzzle was creating a nice interior cabin to complement the rest. A beautiful TMI Interior bench seat, door panels and cladding really filled the interior quarters nicely. Rounded out with Dakota Digital gauges and a killer JL Audio system from Connect Audio and the creature comforts of a daily cruiser were in place. Last but not least, United Pacific lighting was updated throughout as the Metalox Money Shot C10 was chosen to represent United Pacific in their SEMA booth. If you ask us, they really made a great selection. Money Shot may have come together quickly, but she was dialed and made quite an impression. We can’t wait to see more from this talented crew, and we know there’s plenty more to come!

[divider]BUILD SPECS[/divider]

OWNER

MORGAN YOUNGBERG

1966 Chevy C10

Peoria, Arizona C10 Club

CHASSIS & SUSPENSION

WHEEL & TIRES

POWERTRAIN & BRAKES

EXTERIOR & PAINT

INTERIOR & SOUND

INTERIOR & STEREO

Share Link