CHRIS TOBIN

.

August 14, 2020

.

Features

CHRIS TOBIN

.

August 14, 2020

.

Features

AS THE SAYING GOES, YOU SHOULD NEVER JUDGE A BOOK BY ITS COVER. The same could be said about Ryan Milliken’s ’14 Ram. Viewed from the front, the truck looks like a mild custom streetdriven ride, but when you look further back, the drag slicks and parachutes give away the real purpose of this stock-looking pickup. As the owner of Hardway Performance, Ryan wanted to campaign a drag truck. The new truck would come to be known as Mini-Wheat since it was Buckwheat’s little brother with just as much power in a smaller, lighter package.

Milliken started with a Hemi-powered standard cab short-bed ’14 Ram 1500 that ran and drove fine but needed some Cummins grunt under the hood to make him happy. The new Ram went under the knife as soon as he got it back to his shop in Navarre, Florida. He and his crew stripped the truck down to the bare body and chassis, removing the engine and interior, except for the door panels. Then they shipped it to Fleece Performance Engineering in Brownsburg, Indiana.

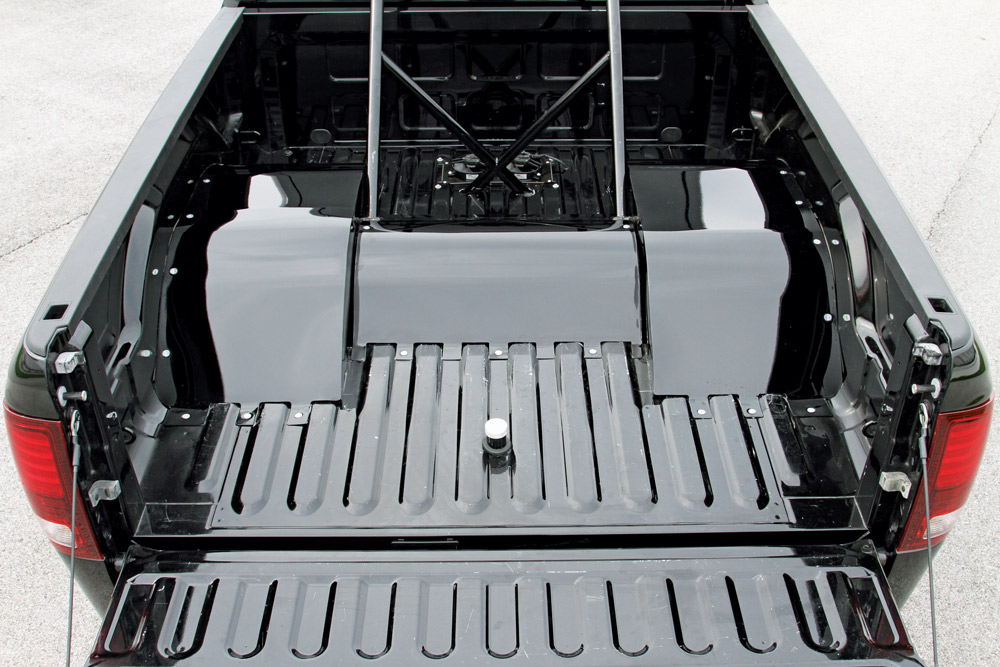

With Milliken’s 1,500-hp goal in mind, Fleece focused attention on the truck’s back, chopping off the rear section of the frame. Chris Alston’s Chassisworks components and custom-fabricated pieces were used to build a Pro Street-style adjustable 4-link suspension with Competition Suspension adjustable coil-over shocks. The links and shocks support a Strange Engineering Pro- Race 9.5-inch fabricated rearend housing. On the track, Milliken uses a set of Hoosier 34.5/17-16 drag slicks wrapped around 16×16-inch Weld Racing SFI 15.3 rated AlumaStar PRO double beadlock wheels.

The factory front suspension configuration was retained, but enhanced with a set of Belltech 2-inch lowering springs and a pair of double-adjustable Competition Suspension shocks. It rolls on a set of factory five-spoke 20×9- inch wheels with 255/55R20 NT05 Nitto tires.

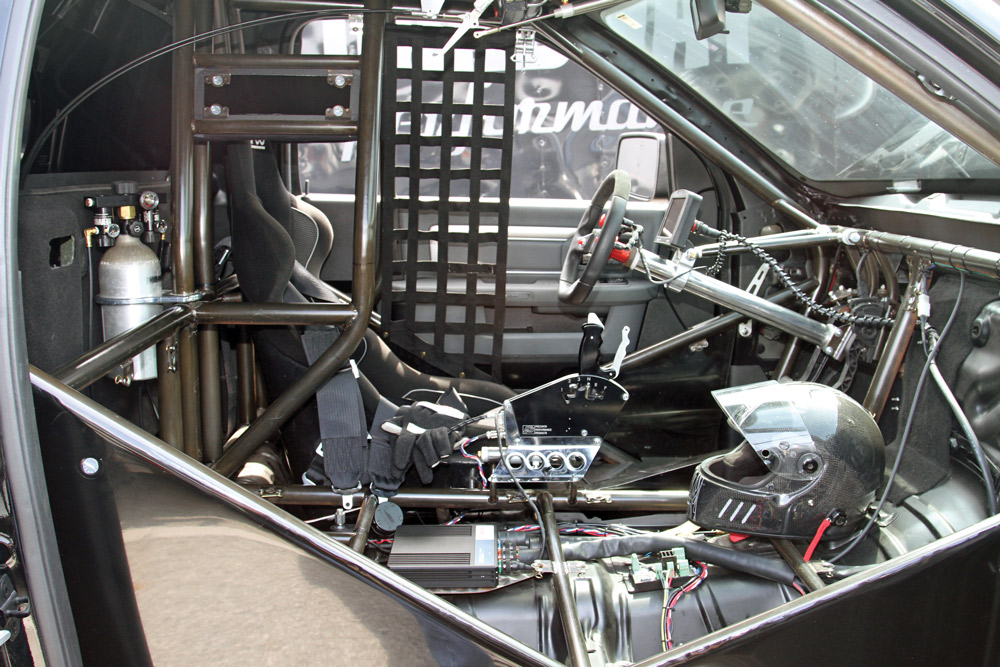

With a gutted cab, Fleece built a safety cage that features a maze of intricately cut tubes, which are notched and welded together.

Everything vital to the driver is anchored to the cage, including the pedals, steering column and shifter. Additionally, the Sparco Pro 2000 racing seat and five-point safety harness is firmly attached to the cage to keep Milliken safe and secure during his runs down the strip. The roll cage is built from chrome-moly tubing for ultimate strength with minimal weight, and the main structure anchors directly to the truck frame. Rather than installing a ton of individual gauges to monitor the truck’s vitals, Milliken chose to go with the Bosch DDU 7 motorsport display to keep all vitals condensed to a single screen.

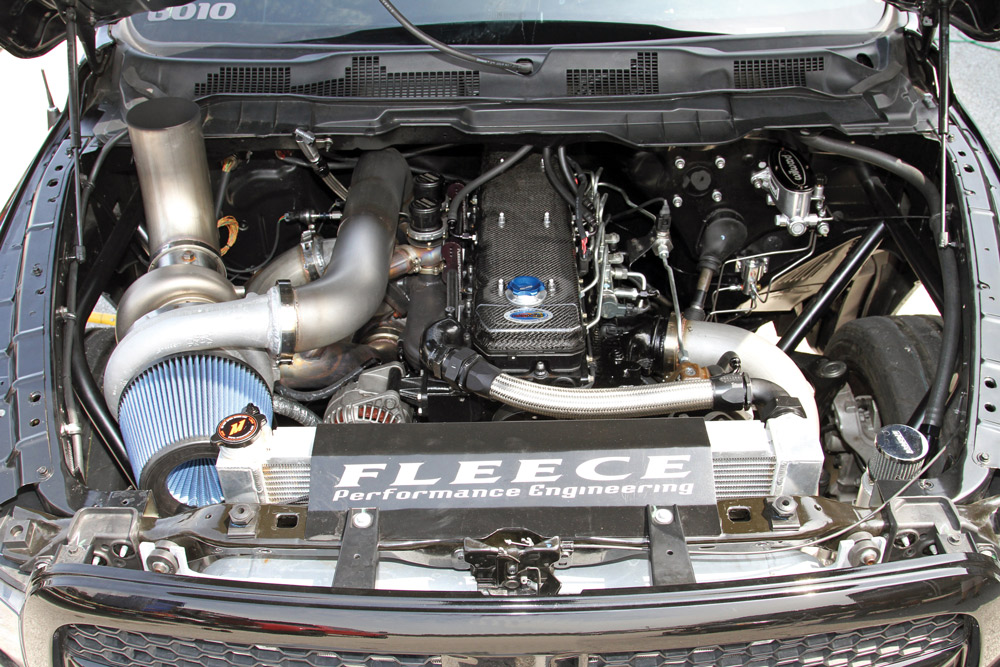

Lifting the factory steel hood reveals the Fleece Performance Engineeringbuilt Cummins engine in all its tire-shredding glory. The crew at Fleece started with a 2007 Cummins block, with a 4.125-inch bore, and a factory Cummins crankshaft swinging R&R rods through a 4.88-inch stroke to arrive at 6.4L of displacement. The short-block is topped with a Cummins cylinder head that the crew at Fleece ported and polished after milling off the intake shelf to replace it with a Banks Power side draft intake manifold.

“AS OF OUR PRESS DEADLINE, MILLIKEN HAD MADE ONLY A FEW FULL ¼-MILE PASSES WITH THE TRUCK AFTER OUR PHOTO SHOOT AND HAS CROSSED THE LINE AT NINE SECONDS FLAT.”

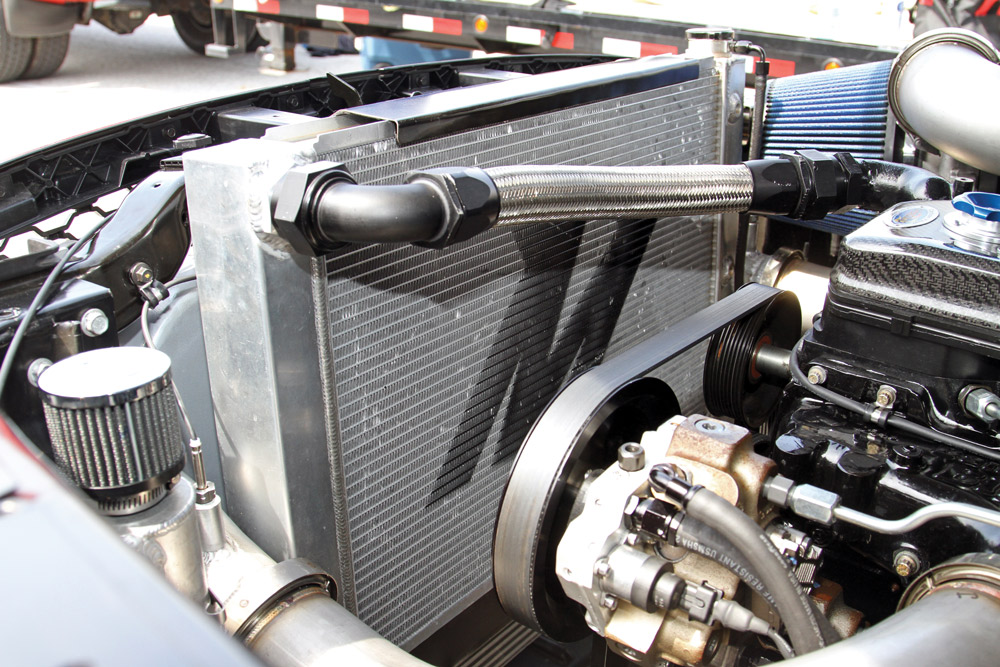

To get the compound turbos spinning, spent gasses are fed from the Steed Speed 24V T6 manifold to the Garrett GTX5533R turbo, then carried over to the Garrett GTX S480/96 turbo and expelled through a short hood stack. The manifold also holds a pair of highflow Turbosmart Comp-Gate 40-hp highpressure wastegates that divert exhaust gasses around the manifold turbocharger directly to the primary charger when needed. Fleece Performance built all of the custom stainless steel plumbing and piping for the turbo system. After the intake charge is compressed once again, it’s channeled through a Mishimoto air-to-air intercooler mounted in front of the Mishimoto aluminum radiator. Then, after the charge air is cooled, it’s routed to the Banks intake and into the modified Cummins head.

A Sun Coast SFI rated billet flex plate was used to link the Cummins engine to the Dodge 47RE transmission through a 2,600- rpm stall Sun Coast triple disc billet torque converter. While the 47RE case is factory, the rest of the transmission has been given a thorough upgrade to put the power to the ground through each gear as the truck flies down the track. The transmission is linked to the Strange Pro-Race 9.5-inch fabricated rearend through a carbon fiber driveshaft from Precision Shaft Technologies.

As of our press deadline, Milliken had made only a few full ¼-mile passes with the truck after our photo shoot and has crossed the line at nine seconds flat. We can also report that he has made a dyno pull of 1,450 hp while maxing out the torque reading at 2,000 lbs-ft when he made some tuning passes. If you happen to attend any diesel event, keep an eye on both Milliken and Mini- Wheat as they blast down the track.

[divider]TRUCK SPECS[/divider]

OWNER

Ryan Milliken 2014 Ram 1500

Navarre, FL

ENGINE

SUSPENSION

WHEELS & TIRES

BODY & PAINT

INTERIOR/STEREO

Share Link