Chris Hamilton

.

June 29, 2020

.

America

Chris Hamilton

.

June 29, 2020

.

America

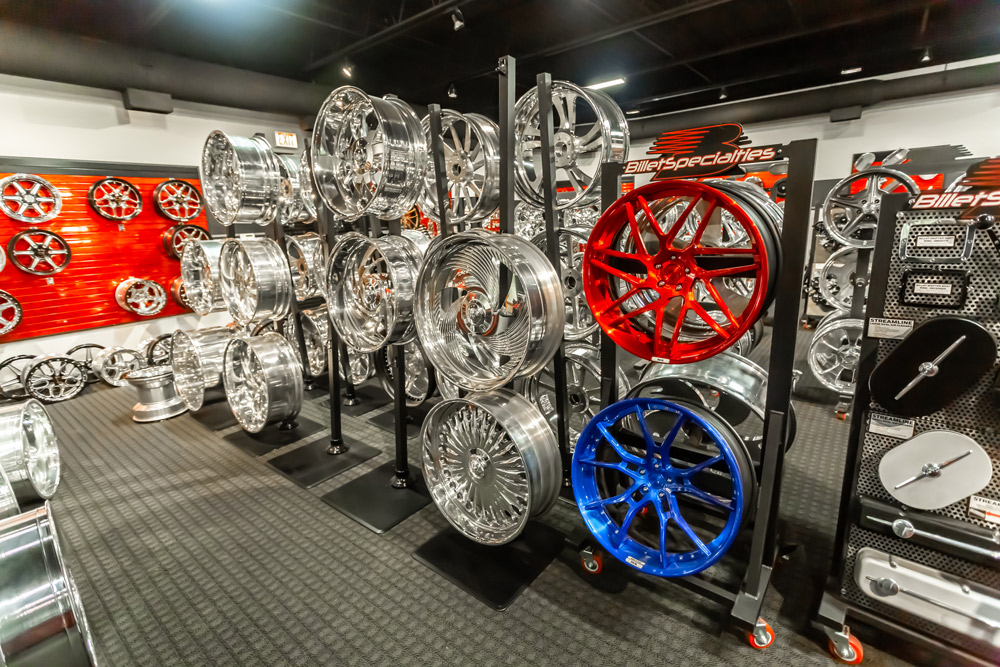

In 1985, Billet Specialties began producing accessories never before seen in the street rod industry. The attention to detail, fit and finish was unprecedented. “History Re-defined by Styling” is the company’s motto, and the crew there sticks to it by developing wheels that define hot rodding and vintage style. Making their designs available in a wide array of sizes, widths and custom backspacing ensures your set will be the perfect fit on your truck.

The Billet Specialties Original Equipment Series line of wheels beefs up the look and size of the past while allowing clearance for big performance modern braking systems. The Legends Series offers three styles that look great on muscle cars, street rods and classic trucks; these styles have set trends in the hot rod world at an entry-level price. The blend of multiple surfaces coming together to create dramatic features in these wheels are produced from millions of lines of machining code executed on state-of-the-art CNC machines. The soft, flowing detail of each spoke is a telltale sign that Billet Specialties products are much more than the ordinary straight-cut billet wheel. The attention to detail pays off in styling that screams excellence. The products are custom built just for you and available in a wide range of diameters, from 17 to 26 inches.

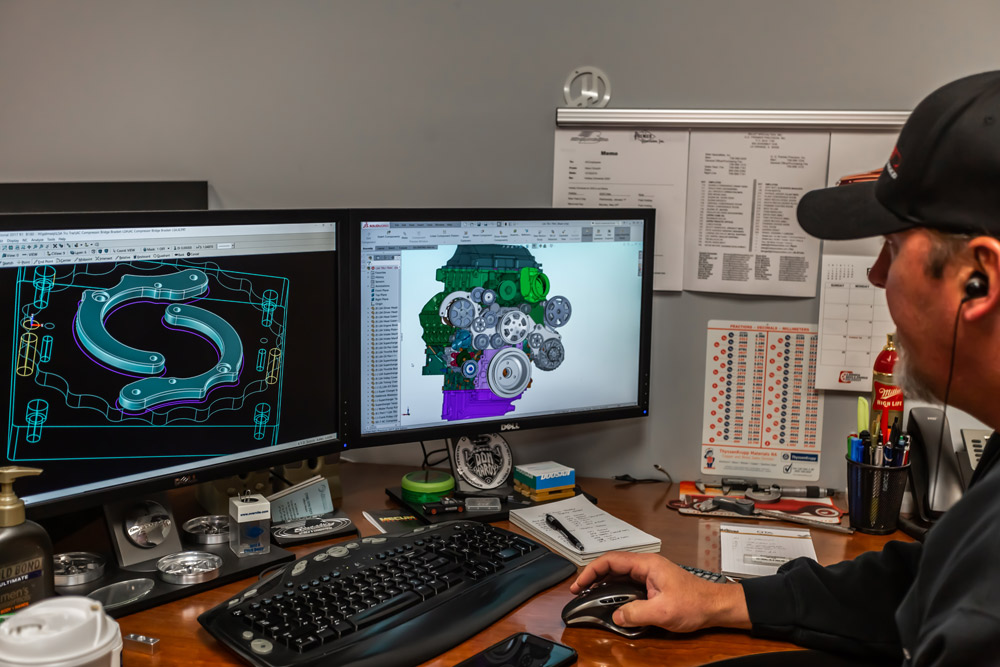

After setting trends in the custom wheel industry for over 30 years, Billet Specialties launched additional product lines, including their polished aluminum valve covers and their all billet Tru Trac serpentine system. Guaranteed to draw attention to your engine compartment and available in short and tall heights, Billet Specialties valve covers are produced from a high-grade aluminum that is polished to their high standards, and each design is CNC machined in the USA. Let us help you get a sense of how impressive this operation is by taking you on a behind the scenes tour at their La Grange, Illinois, factory.

Share Link