Chris Hamilton

.

April 30, 2020

.

C10 Builders Guide

Chris Hamilton

.

April 30, 2020

.

C10 Builders Guide

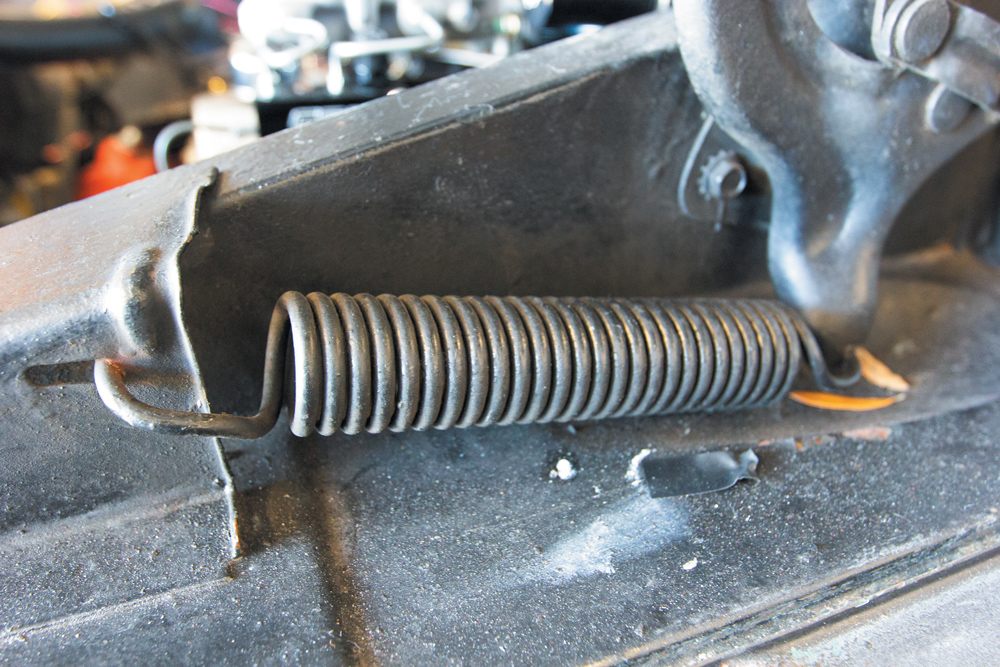

WHAT’S WORSE THAN EVENLY LIFTING A 55-year-old steel hood with the factory installed hood hinges? Having one fall on your hand while you’re working on the engine. I’m sure you’ve been there a time or two as well. These spring-style hinges are never smooth and sometimes cause your hood to open one side at a time. Dousing them with WD-40 is always a viable option, but if you plan to open your hood at truck shows or cruise nights, we recommend replacing them and never questioning their reliability again.

Eddie Motorsports manufactures billet aluminum hood hinges for most models of Chevrolet and Ford muscle cars as well as some trucks. The hinges are CNC machined from solid chunks of 6061-T6 billet aluminum in the USA at the company’s Southern California facility. The hinges utilize a stainless-steel nitrogen-filled strut in place of the inferior stock compression springs to actuate the hood. The hinges use high quality sealed ball bearings at all pivot points for an ultra-smooth and reliable operation. Available with a raw machined look like we chose, a bright polished finish or a wide variety of anodized and Fusioncoated colors. They’re designed as direct fit, “bolt on” units that utilize the stock mounting holes with elongated slots for ease of gap adjustment. Let’s see how easy they are to install!

Share Link