SCOTT NELSON

.

February 17, 2021

.

America

SCOTT NELSON

.

February 17, 2021

.

America

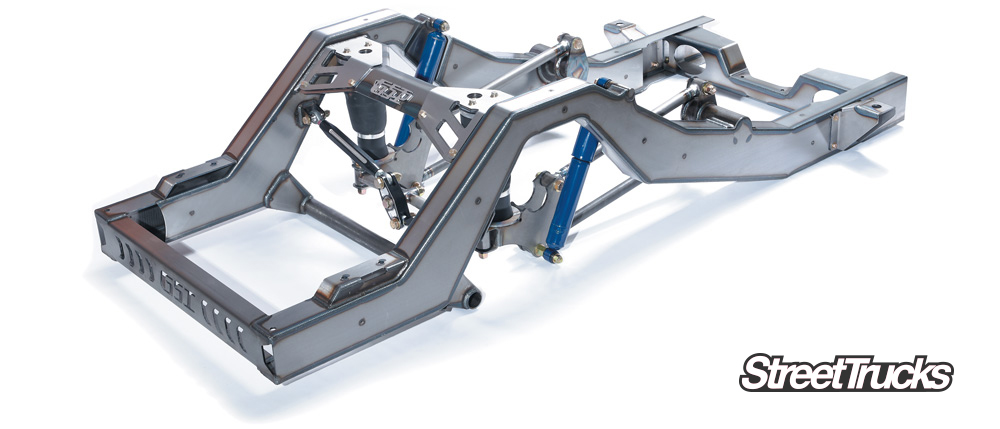

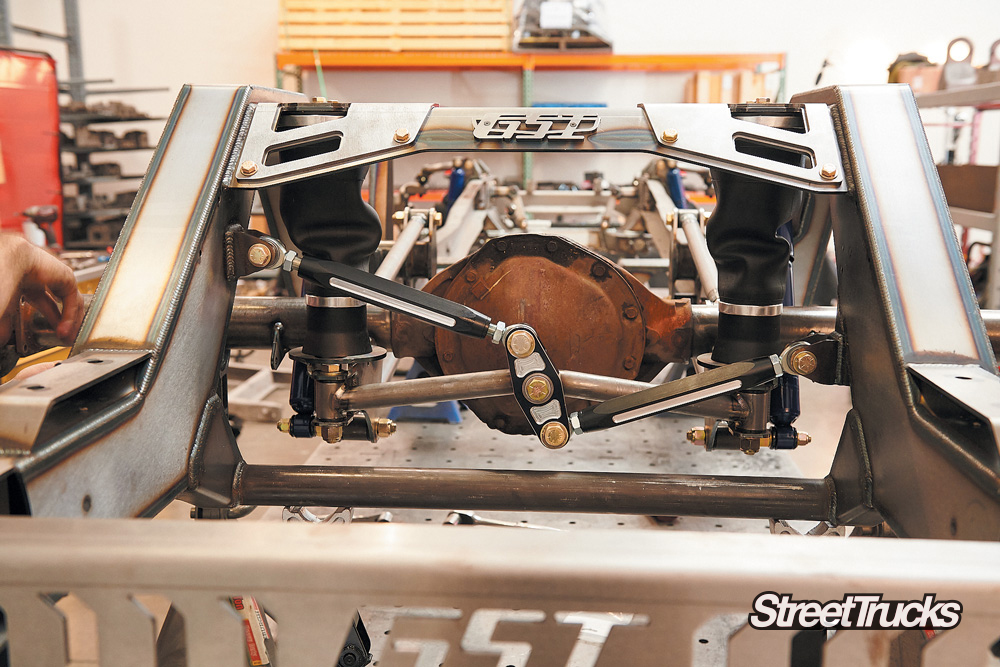

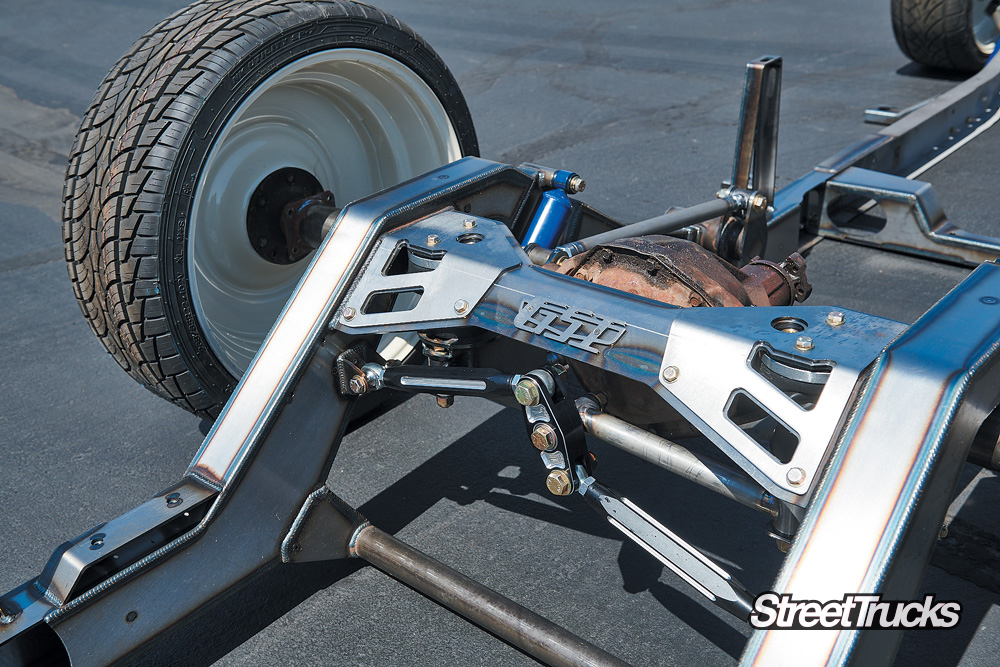

Using GSI Air-ride Machine and Fabrication’s complete back half is a no brainer when trying to accomplish one or both tasks of bagging your ’60-’87 C10 while converting it from longbed to shortbed at the same time. The GSI back half is a fully fabricated, weld-on rear clip, complete with parallel four-link and billet aluminum Watt’s link. This rear chassis section will lay the frame on a 31-inch tall tire and will fit wheels up to 15 inches wide. Follow along and watch how easy it is to take that longbed frame from tail heavy and too tall to short and slammed.

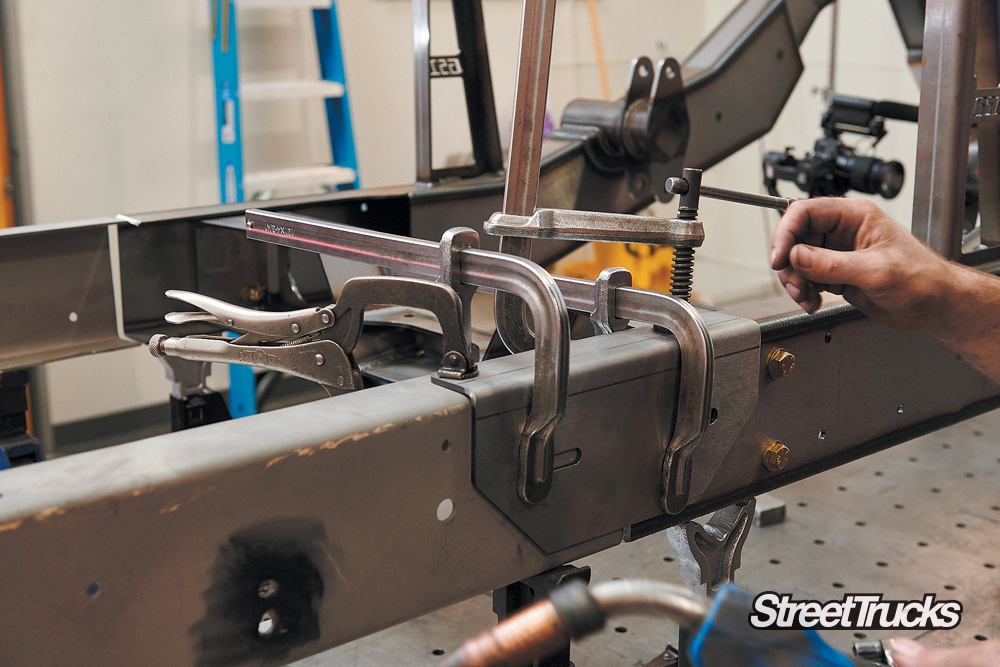

Now it’s time to match the rear. In this article we will show you how simple it is to install the GSI Air-ride back half and what the end result will look like. We have all the parts and hardware set up, so we are ready to go. We will follow the supplied instructions and take you through a step-by-step install. Let’s go!!

The GSI back half is a fully fabricated, weld-on rear clip, complete with parallel four-link and billet aluminum Watt’s link. (Part #120-5600-BH)

This system will lay the frame on a 31-inch tall tire and can accommodate up to a 15-inch wide wheel. And that’s a rolling chassis laying frame on big wheels. Next step will be to blow it apart and prep for powdercoating. We will be follow along with this build as it keeps going.

Share Link