Mike Alexander

.

June 10, 2019

.

How to

Mike Alexander

.

June 10, 2019

.

How to

From the factory, the fourth generation RAM is meant to do one thing extremely well: work. Thanks to the OEM suspension being designed to accommodate upward of 4,000 pounds in the bed or 15 tons in tow, RAM’s heavy-duty models make hard work look easy. The flipside is that these trucks don’t play nice once you venture off the beaten path. Furthermore, they aren’t all that pleasurable to pilot down the highway when empty. So, what’s an owner to do when they want their late-model RAM to ride, handle and perform well no matter the terrain or situation?

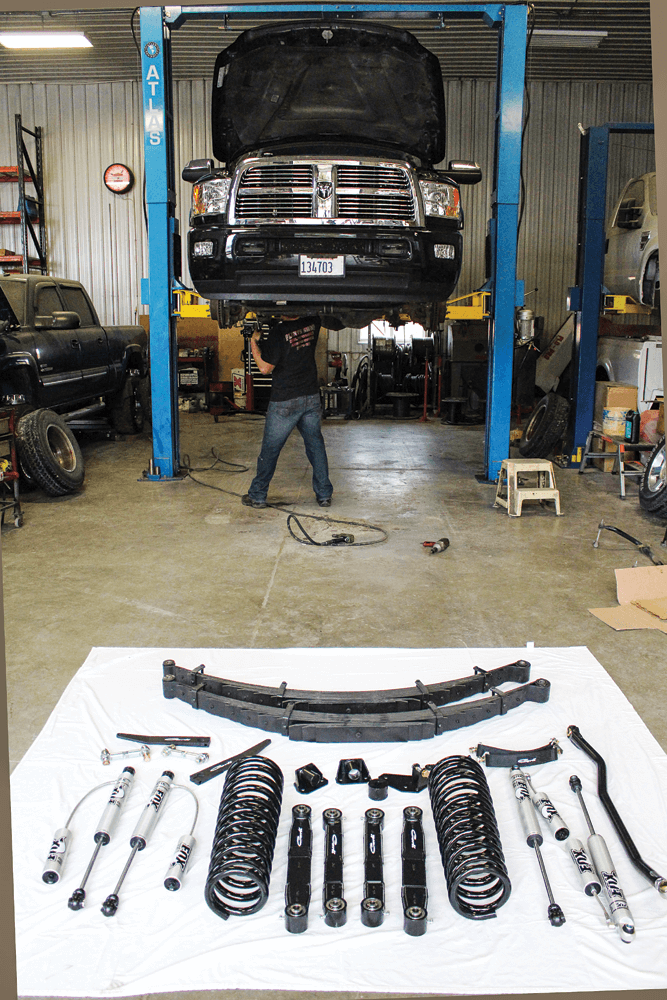

Since 2003, Carli Suspension has been offering complete bolt-on suspension systems that improve the off-road performance, on-road ride quality and overall versatility of late-model Dodge RAMs. Recently, we got our hands on one of the company’s Backcountry 2.0 kits for a ’12 RAM 2500 and set to work installing it. Spec’d with every available option, the 3-inch suspension system came with linear rate coil springs, Fox 2.0 remote reservoir shocks, high-clearance extended control arms, torsion sway bar, adjustable track bar, and progressive rate, full replacement leaf spring packs. If you want to maximize the ride comfort and off-road capability of your 2010-13 RAM, without sacrificing its intended purpose, this is the lift for you.

[divider] What We Installed: [/divider]

[dropcap size=big]01[/dropcap] Knowing that minor welding would be in store during the installation of Carli Suspension’s Backcountry 2.0 lift, the folks at Flynn’s Shop made sure to disconnect the negative battery cables before getting the truck in the air. Then the factory sway bar was loosened and removed to be replaced later with Carli’s top-of-the-line torsion sway bar.

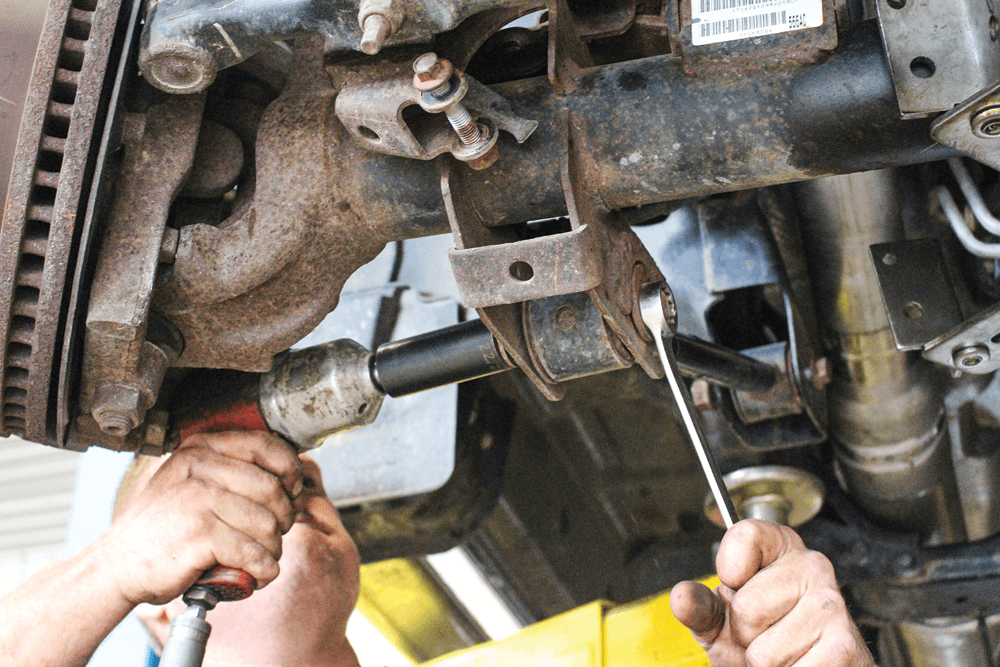

[dropcap size=big]02[/dropcap] The next item discarded was the factory steering stabilizer. It will be replaced with an upgraded Carli component, specifically Carli’s high-mount dual (opposing) steering stabilizer system. This system all but rules out the bump steer that fourth generation Rams are known for.

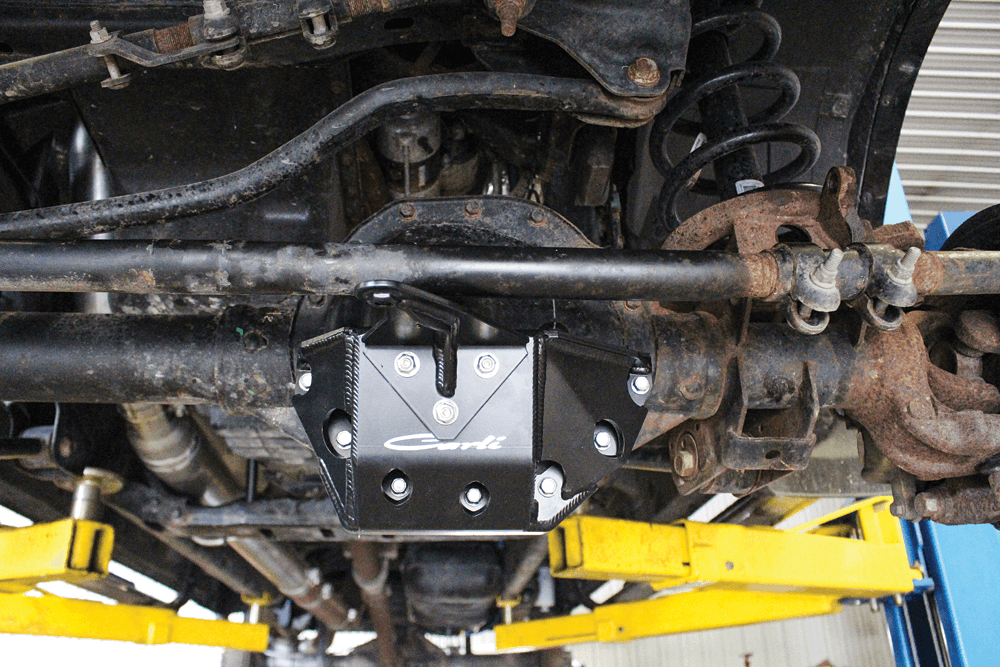

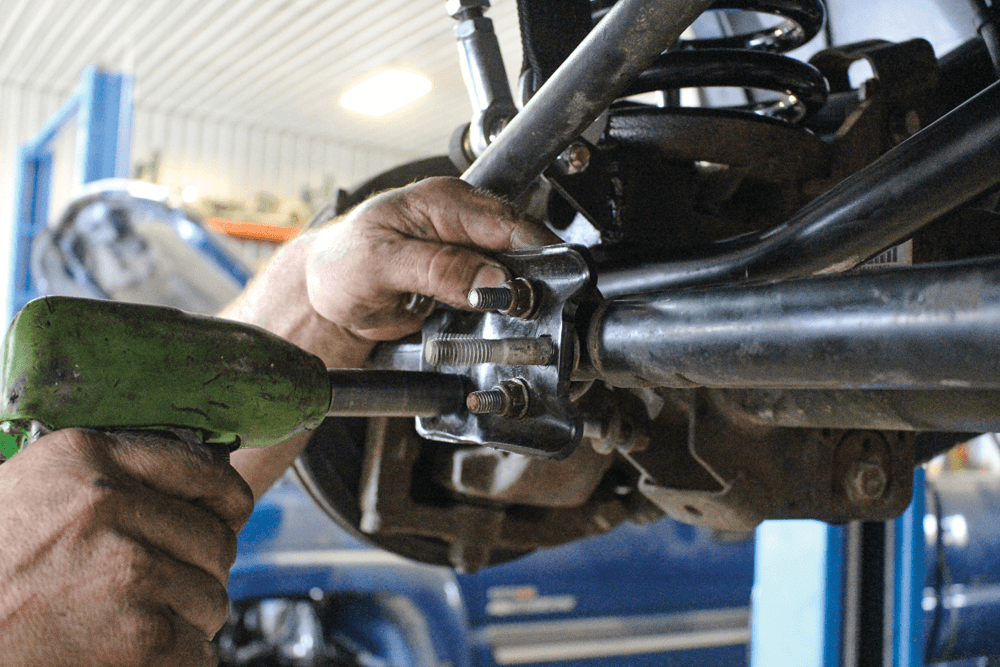

[dropcap size=big]03[/dropcap] Serving two purposes, the Carli differential guard provides added protection for the front differential and a mounting bracket for the aforementioned dual steering stabilizer setup. Installing the ¼-inch-thick differential guard requires removal of seven factory diff cover bolts, which will be replaced by brand-new M10 bolts supplied by Carli. After coating the threads of the new fasteners with Loctite, we had the differential cover bolted into place in short order.

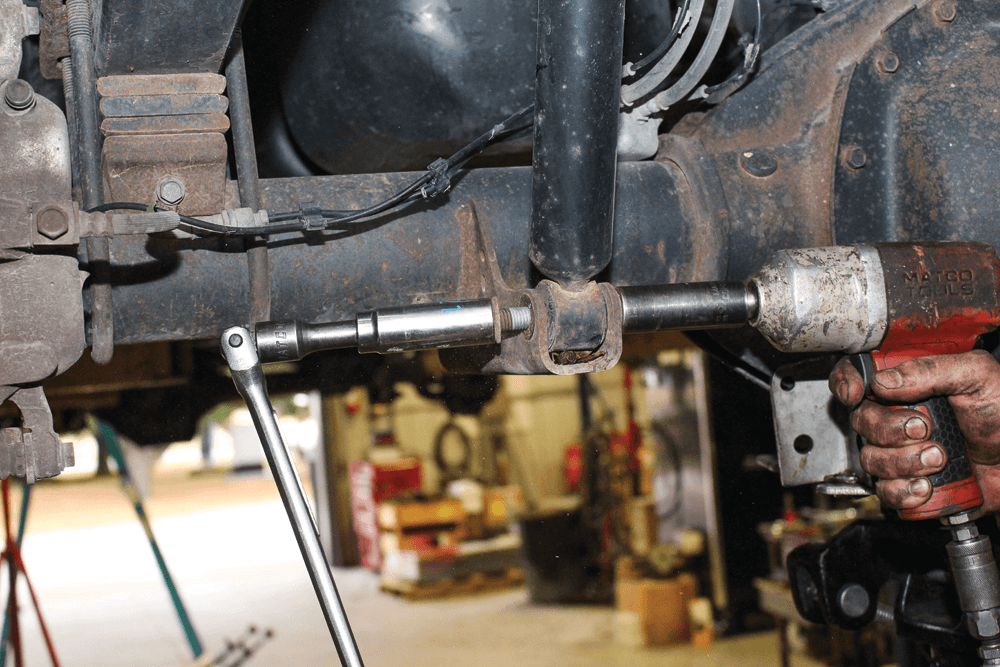

[dropcap size=big]04[/dropcap] Next, the factory track bar was broken free and removed. It would later be ditched in favor of one of Carli’s adjustable (and beefier) units, which makes use of Heim joints and uniballs to eliminate wander and improve steering response.

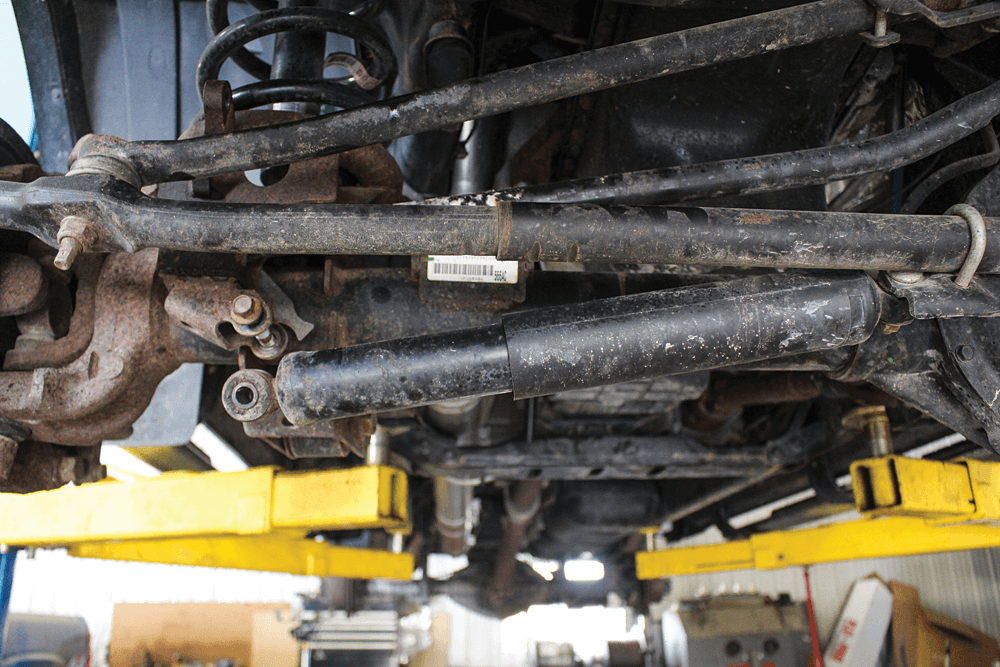

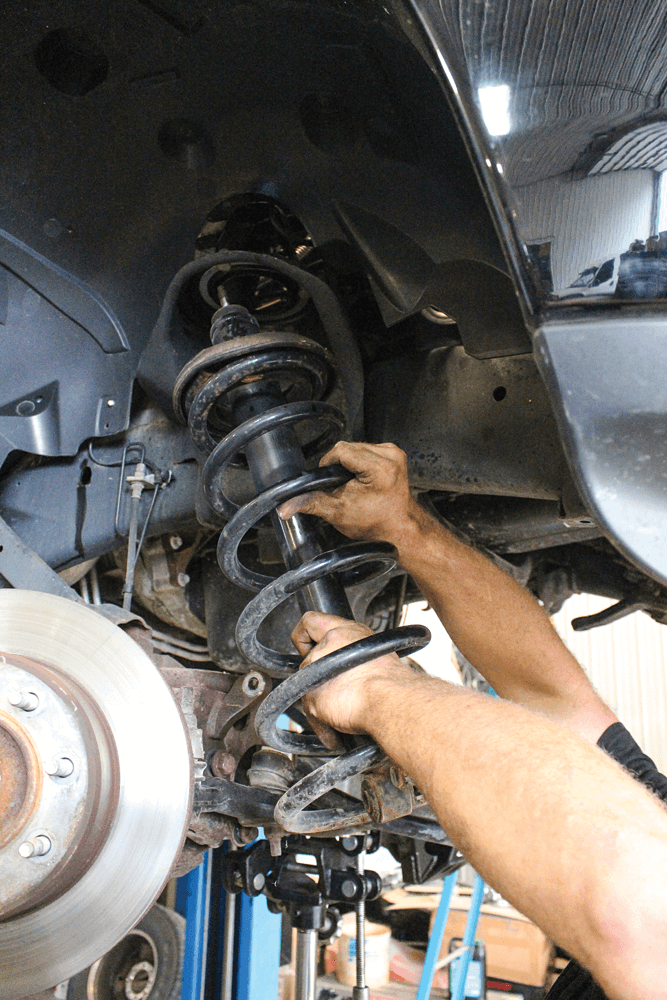

[dropcap size=big]05[/dropcap] Next, the bottom shock mounting bolts were loosened, the front axle was brought to full droop, and the factory coil springs and shock absorbers were pulled. Then, a transmission jack was employed to raise the axle back up to begin the process of removing the factory control arms.

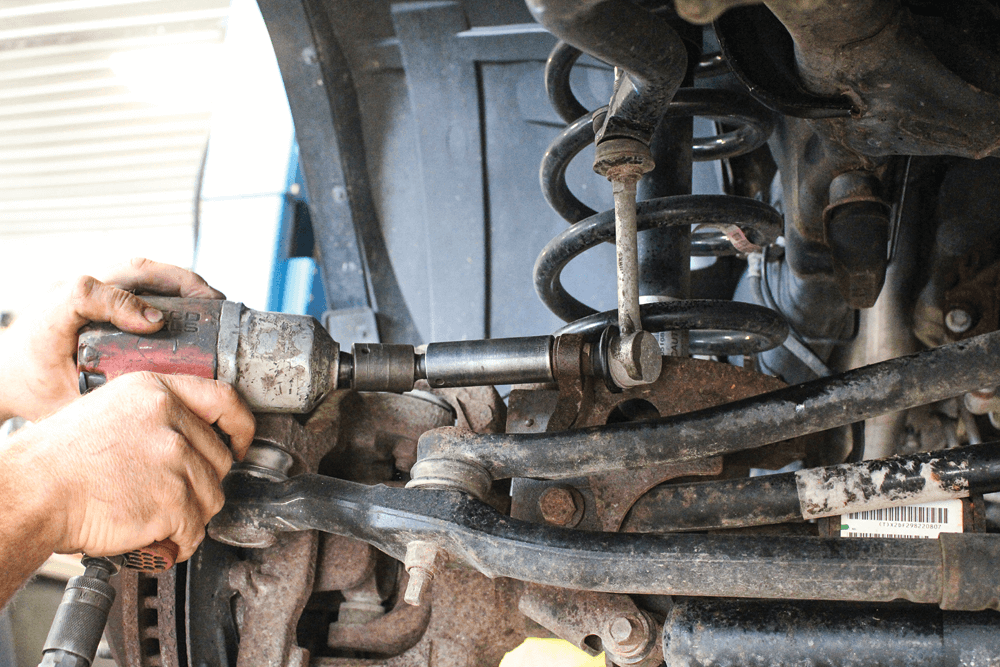

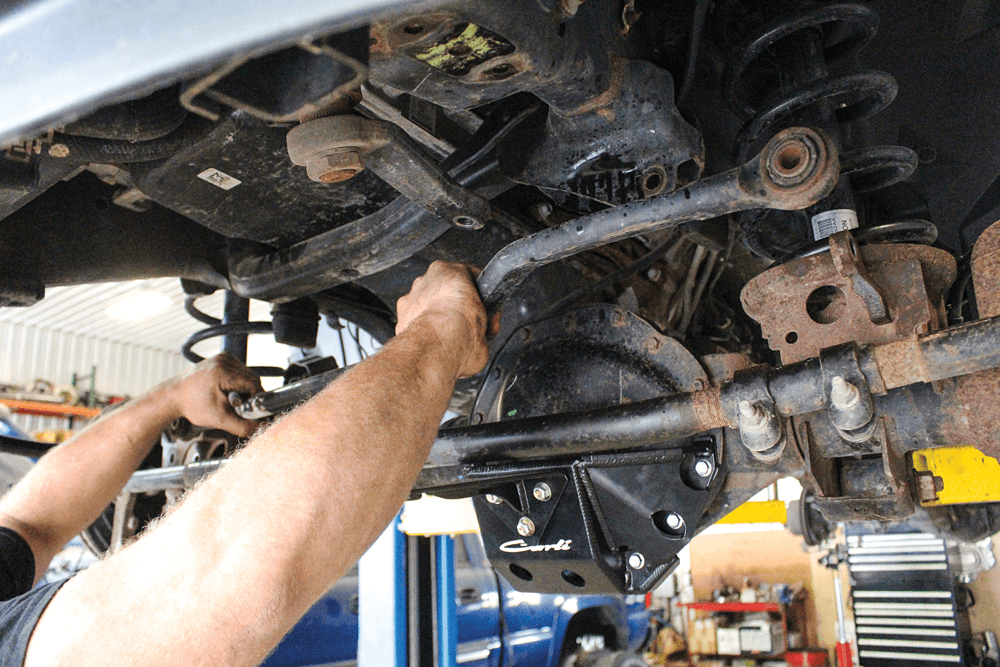

[dropcap size=big]06[/dropcap] Once they’d been hit with a liberal amount of penetrating lubricant, all factory control arm nuts were broken loose with an impact wrench. Per Carli’s recommendation, the lower control arms were removed first, and the guys at Flynn’s took note of the direction each fastener had been installed from the factory.

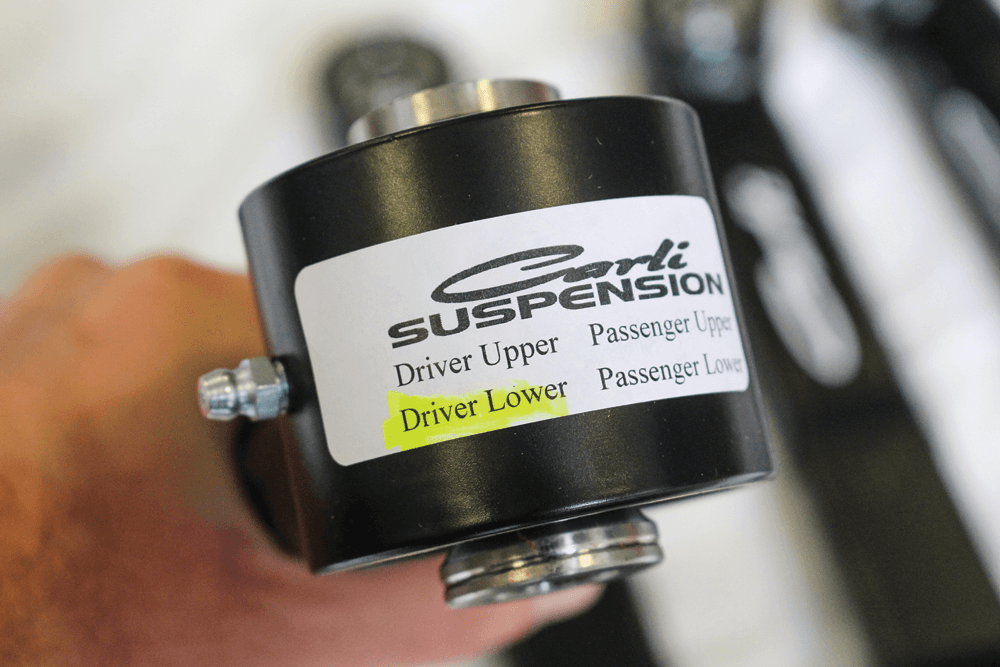

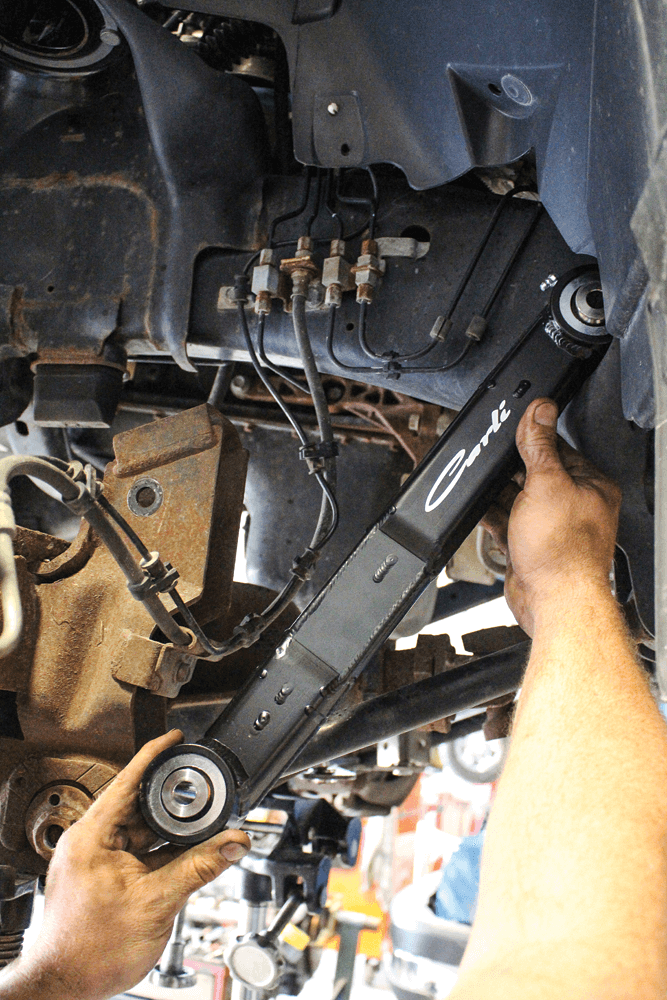

[dropcap size=big]07[/dropcap] Unlike the rubber bushings used in the factory control arms, Carli Suspension’s high-clearance extended versions accommodate fully rebuildable, sealed and greasable spherical joints. This type of bearing takes all of the play out of the front axle while eliminating the kinetic vibration that’s observed with the factory rubber bushings in place. Also notice the labeling method shown here, which makes for an idiot-proof installation.

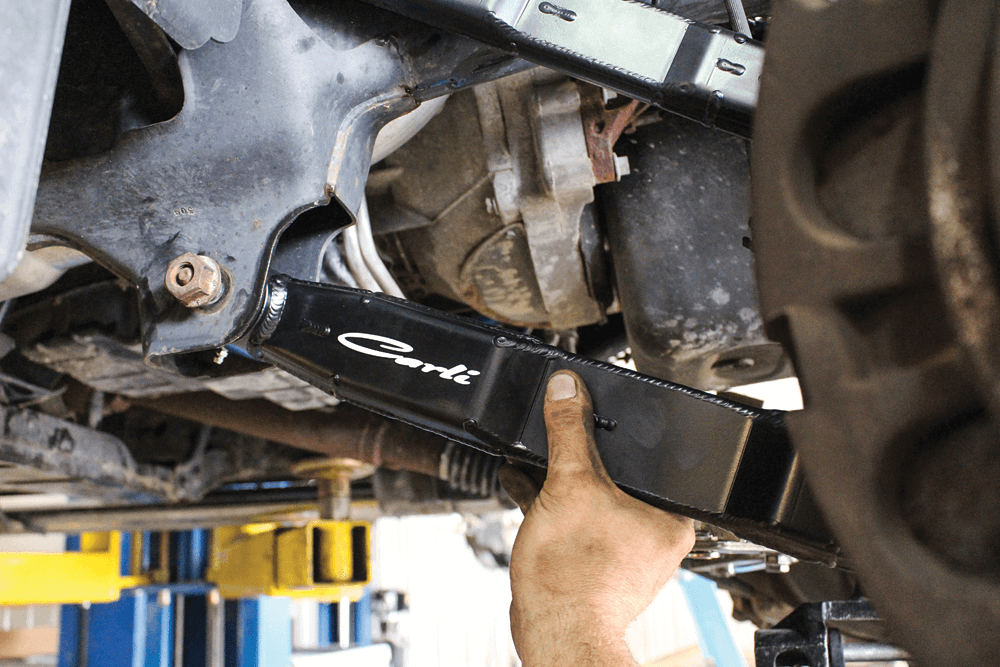

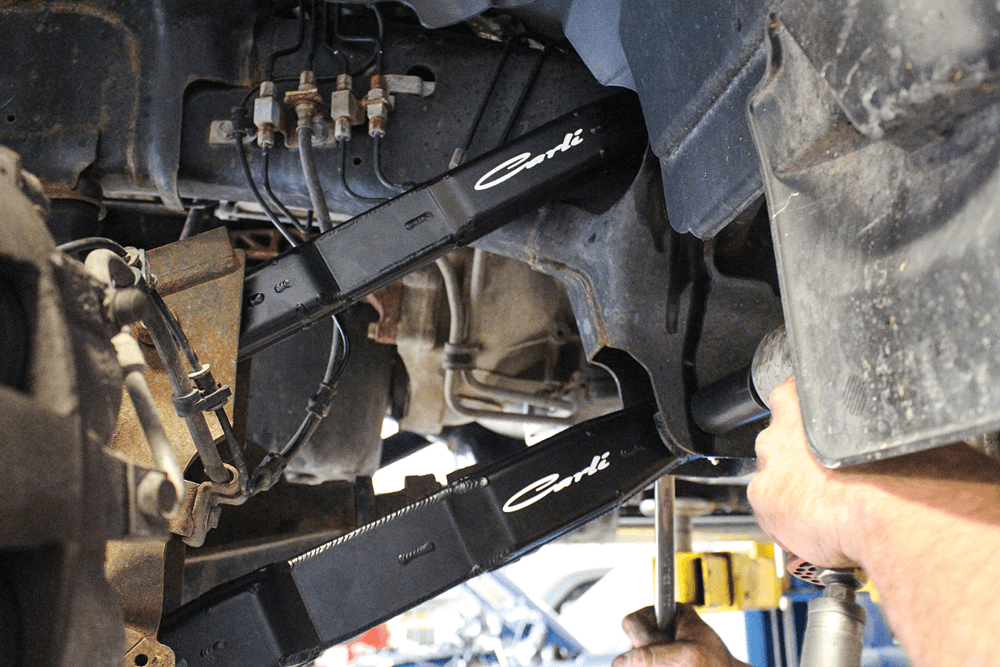

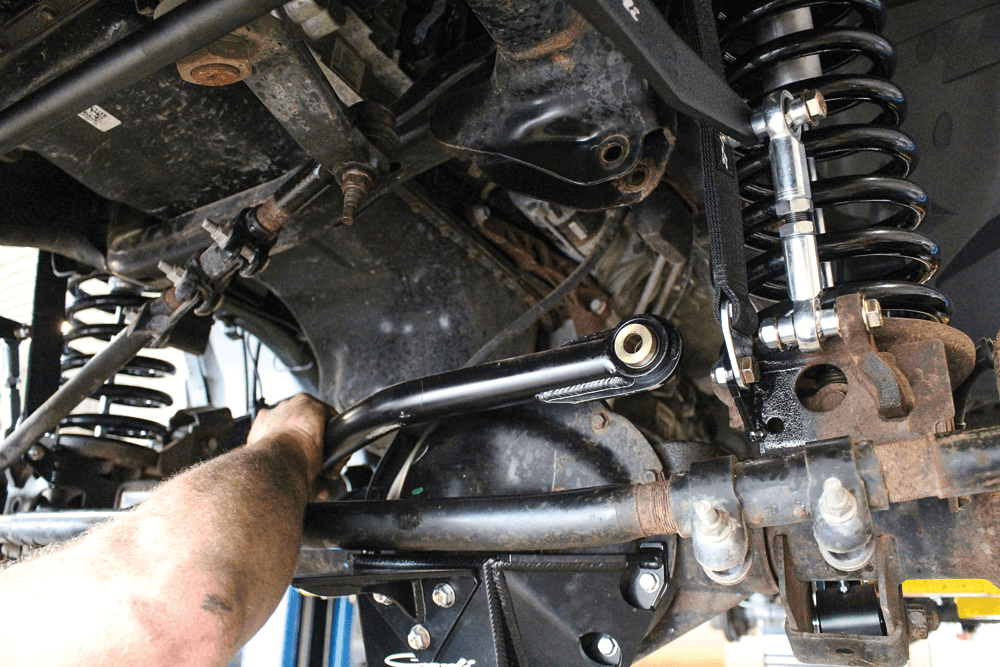

[dropcap size=big]08[/dropcap] Installing the Carli high-clearance extended control arms in the opposite manner of how the factory units were removed, the upper control arms were set in place first. Roughly an inch longer than the factory control arms, the Carli versions are designed to re-center the front axle. They’re fabricated from ¼-inch wall steel, internally gusseted for unmatched strength, and are considerably heavier than the thin-wall OEM pieces.

[dropcap size=big]09[/dropcap] With the high-clearance extended control arms in the mix, tires as large as 37 inches in diameter can be run, so long as the wheels are no wider than 9 inches with 5.75 inches of backspacing. If the aforementioned criteria are met, lock-to-lock turning won’t cause any tire rub.

[dropcap size=big]10[/dropcap] While the guys at Flynn’s were able to get the high-clearance extended control arms into place without issue, they had to hold off on tightening the top bolts (at the axle) until after the coil springs were installed. This is because the axle had to be tilted downward in order to create enough clearance for the coil springs to be finagled into their respective buckets. However, once the coil springs were in, the upper control arm bolts were torqued to 120 ft-lbs, while the lowers were snugged to a stout 175 ft-lbs.

[dropcap size=big]11[/dropcap] Shot-peened for long-term durability and pre-set for the Cummins application, the Carli coil springs add approximately 3 inches of front ride height once installed. Of a linear rate design (i.e. the spring rate increases with the compression of the spring), they offer a smooth ride on the street but provide maximum control when you’re off-road, turning or braking aggressively.

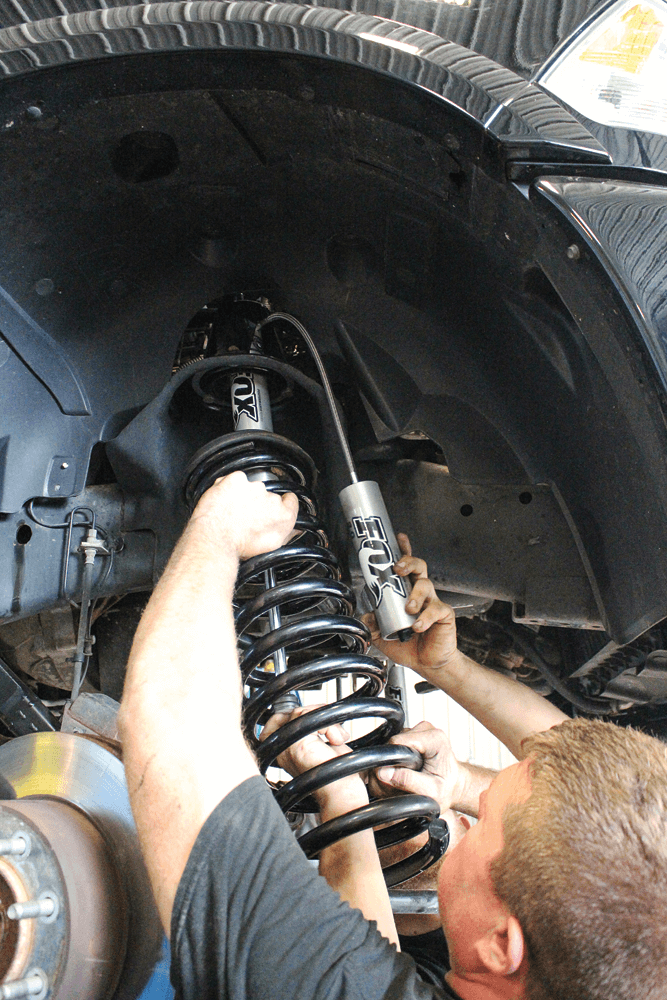

[dropcap size=big]12[/dropcap] After swapping the factory rubber coil spring isolators over to the progressive rate Carli springs, it was time to set them in place. Installing the coil springs with the supplied Fox shock absorbers contained within them (the remote reservoir having to be fed up through the shock tower) was a process that called for a second set of hands.

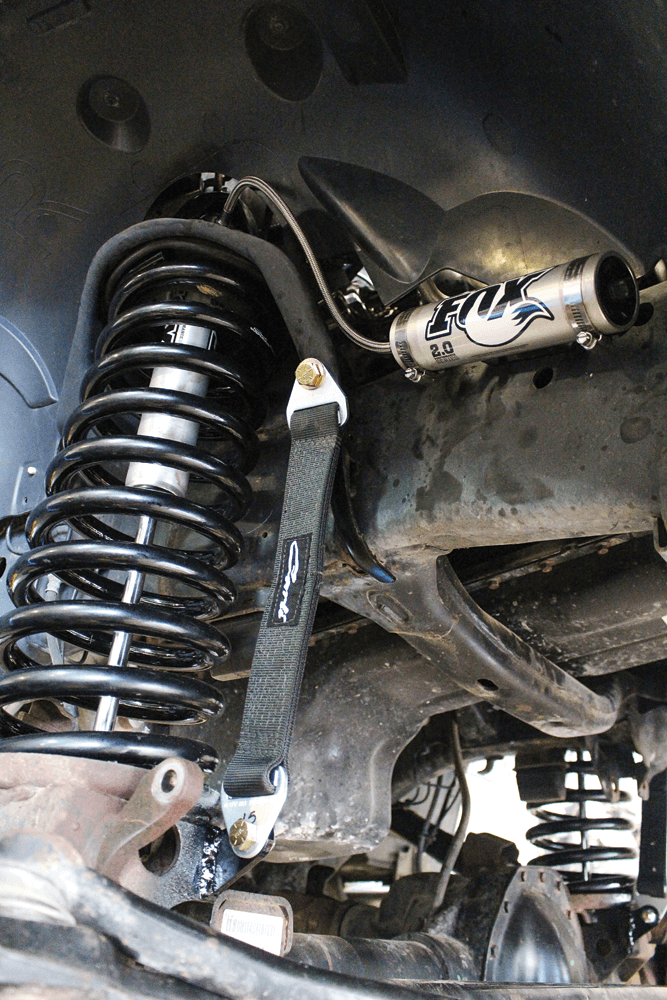

[dropcap size=big]13[/dropcap] A pair of self-tapping screws and worm gear clamps are included in the Backcountry 2.0 kit for mounting the remote reservoirs for the Fox 2.0 shocks. Flynn’s opted to mount them horizontally along the outer top portion of the frame rails.

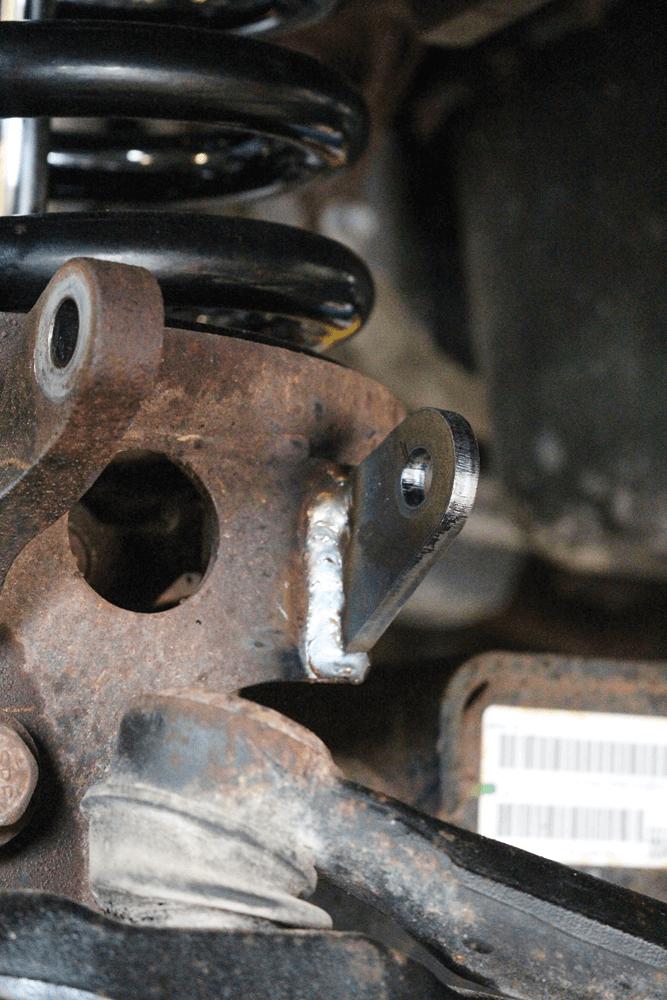

[dropcap size=big]14[/dropcap] In case the truck ever gets airborne, Carli supplies a set of limit straps to ensure the front shocks never become over-extended. Here, you can see the first piece of the puzzle: the weld-on chrome-moly tab that the bottom of the limit strap attaches to.

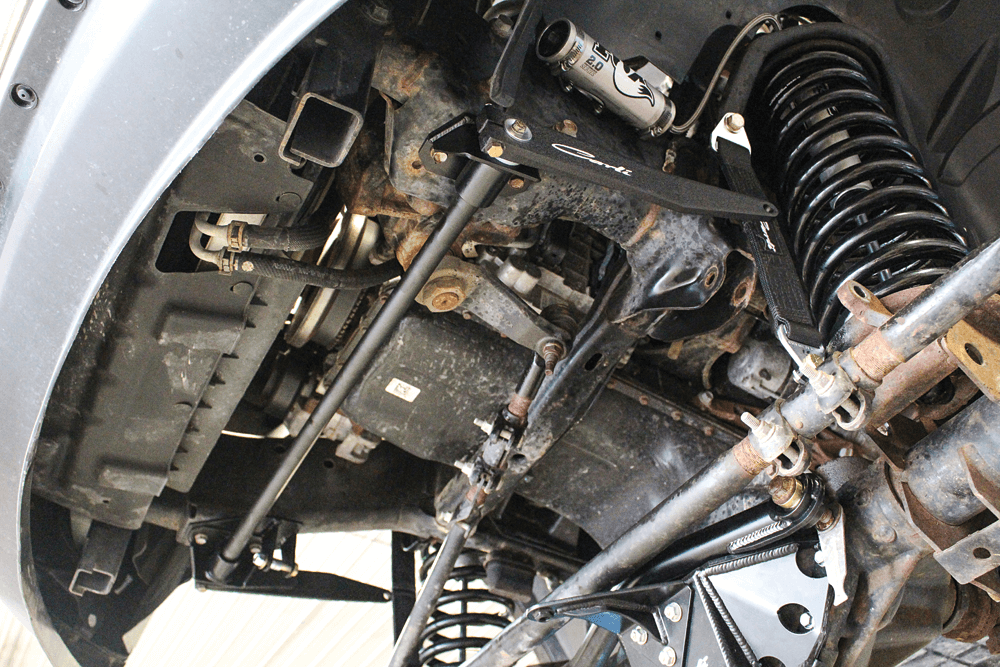

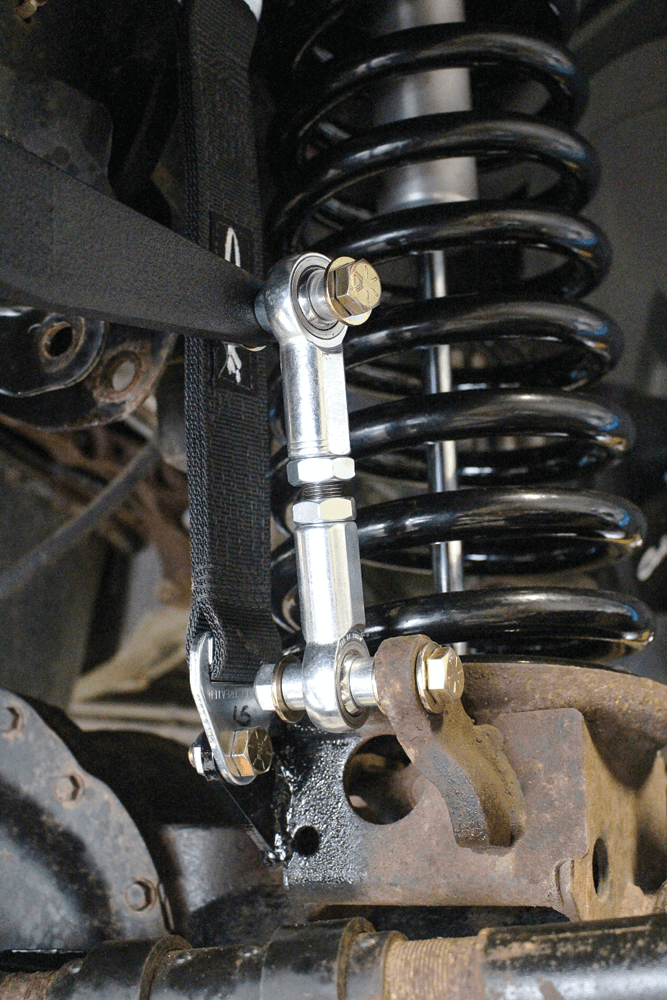

[dropcap size=big]15[/dropcap] Made from 1.75-inch nylon webbing, Carli’s limit straps feature a 4130 chrome-moly buckle at each end and a 7,000-pound rating. Notice the top mounting point, which requires installers to center punch and then drill a ½-inch hole in the top edge of each coil bucket.

[dropcap size=big]16[/dropcap] Thanks to the factory sway bar’s exceptionally high torsion rate, most fourth generation RAMs feel like the front axle is directly connected to the chassis. Carli’s torsion sway bar completely replaces the factory assembly and allows the axle and chassis to move much more independently of one another without sacrificing control. Its custom, dual purpose torsion rate makes this possible.

[dropcap size=big]17[/dropcap] Stainless steel body end links anchor the torsion sway bar’s powder-coated drop brackets to the lower coil buckets. The burly, corrosion-resistant end links are slightly longer than the factory versions in order to provide the proper engagement points for the sway bar.

[dropcap size=big]18[/dropcap] To combat the lift’s tendency to pull the axle off center (toward the driver’s side of the truck), Carli’s adjustable track bar centers the axle for proper suspension geometry. Constructed of 1.50×0.375-inch wall chrome-moly tubing, the track bar incorporates a heavy-duty F.K. uniball on the frame side and a Heim joint on the axle side for improved steering response.

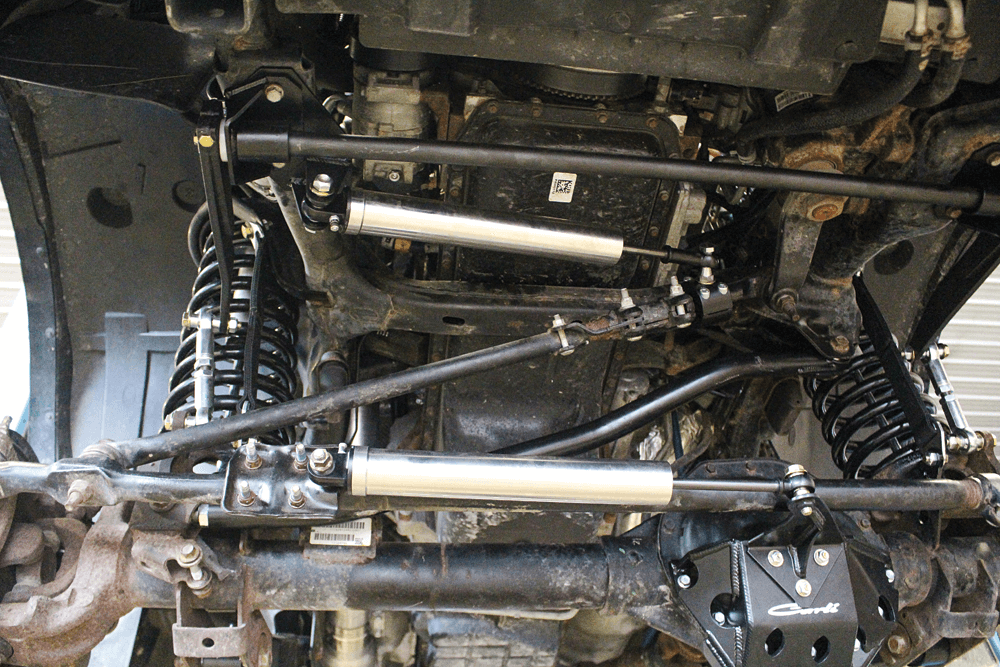

[dropcap size=big]19[/dropcap] Carli’s T-style, high-mount opposing dual steering stabilizer system rules out bump steer and can be adjusted to accommodate virtually any tire configuration. In order to accommodate the dual steering stabilizer setup, the factory (low mount) stabilizer clamp has to be relocated to the opposite end (passenger side) of the tie rod assembly, as shown.

[dropcap size=big]20[/dropcap] Both of the Carli stabilizers feature stainless steel bodies and nitride shafts for superior corrosion protection. The high-mount stabilizer is secured to the drag link via billet clamp. The driver’s side of the low-mount stabilizer effectively bolts to the differential guard via the bracket that was added earlier in this installation.

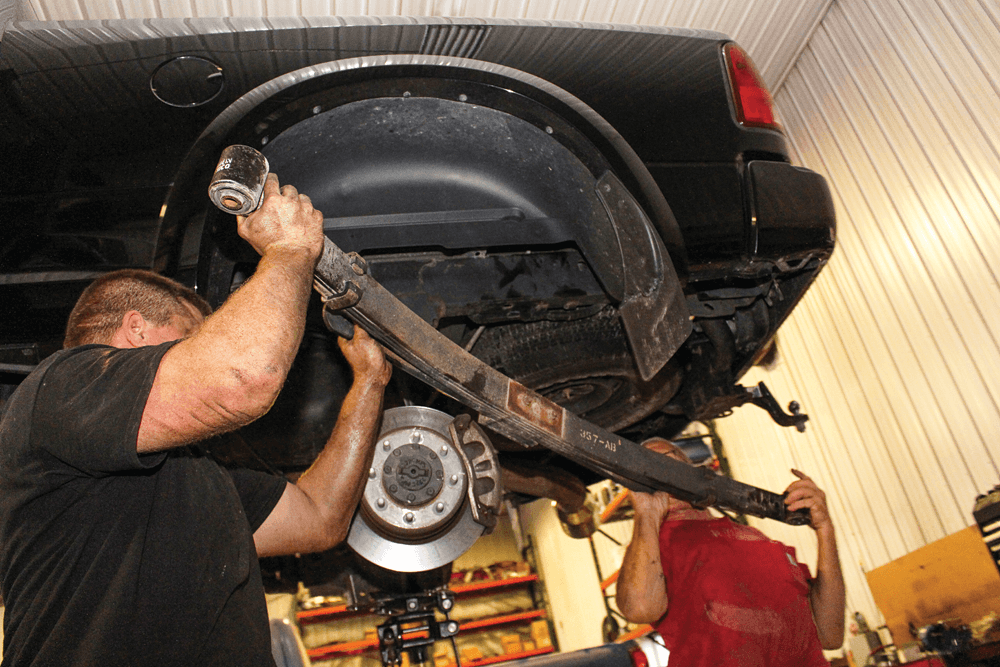

[dropcap size=big]21[/dropcap] Getting started on the rear suspension changes, Flynn’s techs removed all shock mounting bolts, followed by the factory shocks themselves. To accommodate the additional 1 inch of lift that the progressive rate leaf spring packs provide, a pair of longer Fox shocks will be used.

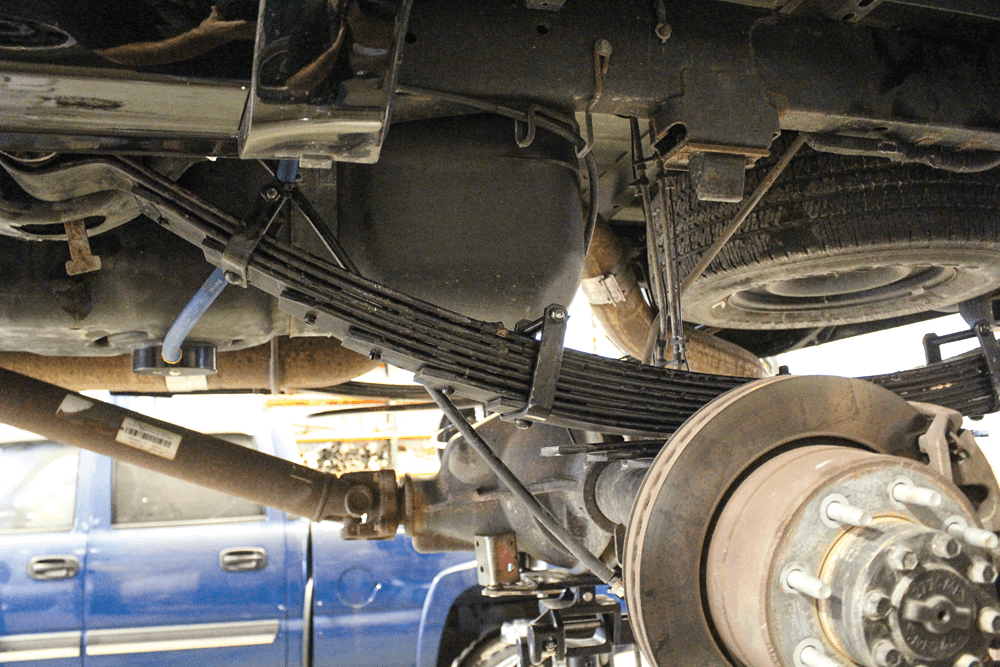

[dropcap size=big]22[/dropcap] Just like the front suspension, Fox 2.0 remote reservoir shocks are employed out back. The Carli-tuned units allow up to 12 inches of rear-wheel travel (10 inches up front), are fully rebuildable, feature an extruded aluminum construction with hard anodizing (for superior corrosion resistance), and hour-glass-style bushings in the rod ends.

[dropcap size=big]23[/dropcap] With the stock shocks removed, the factory U-bolts were scrapped (Carli sends longer, replacement units) and the rear axle was lowered. Then the leaf spring hanger bolts were removed, and the factory leaf packs were free.

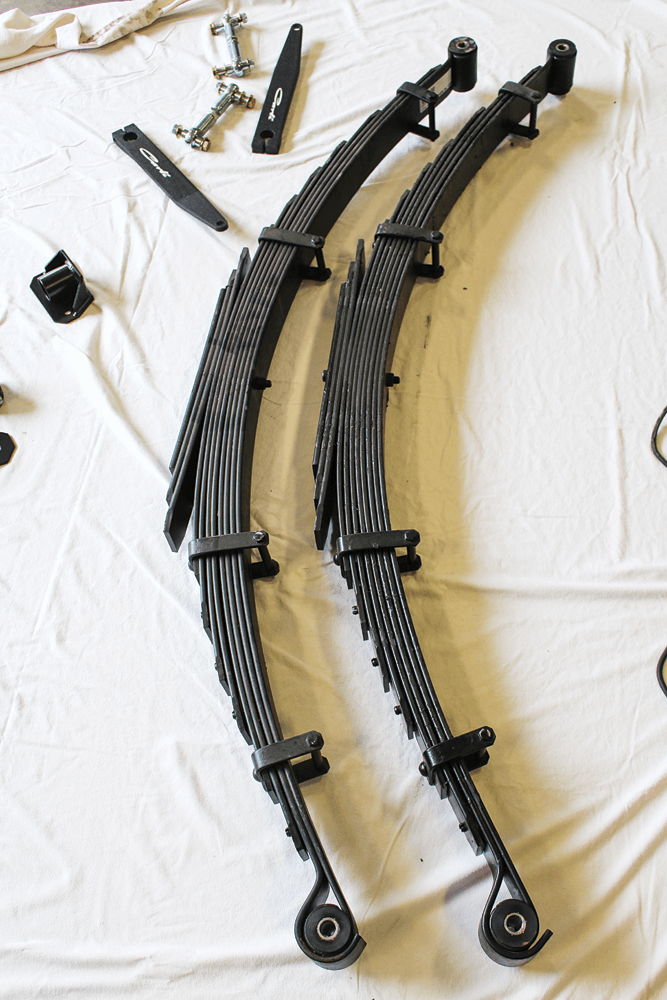

[dropcap size=big]24[/dropcap] Carli’s full progressive leaf spring packs provide the best ride quality possible by softening the initial spring rate at the truck’s ride height and also complement the custom-tuned Fox 2.0 remote reservoir shocks nicely. Built by Deaver Spring, they feature a double military wrap construction, urethane bushings, steel crush sleeves and drastically minimize axle wrap and wheel hop.

[dropcap size=big]25[/dropcap] The one trade-off of running Carli’s full progressive leaf packs is a slight decrease in payload capacity (15%). However, Carli is up front about the drop-in payload capacity and often reminds customers that the payload reduction can be supplemented by adding a set of its long-travel airbags to the equation.

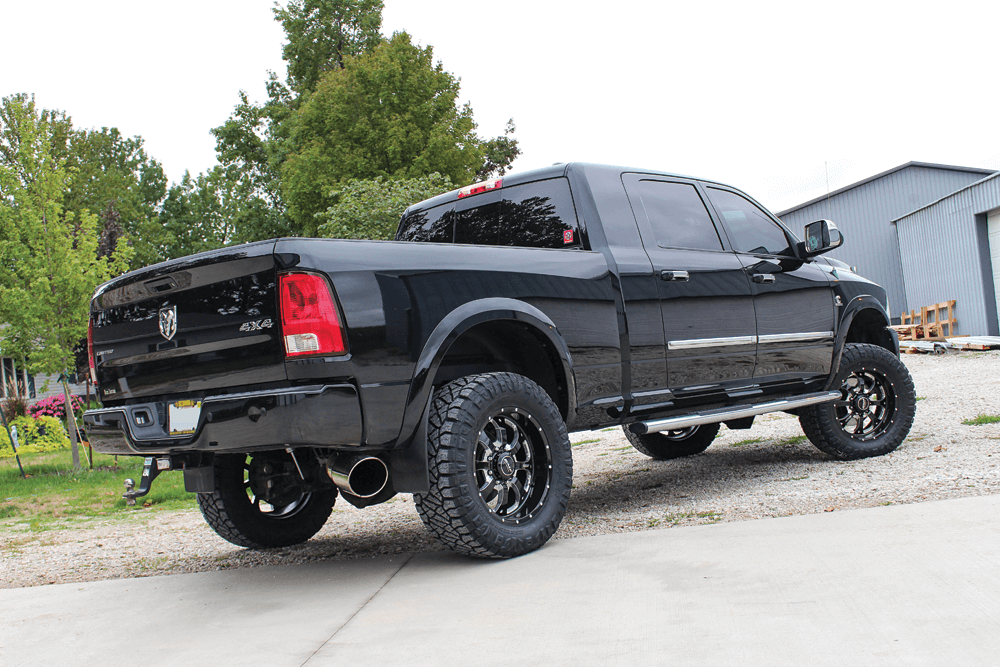

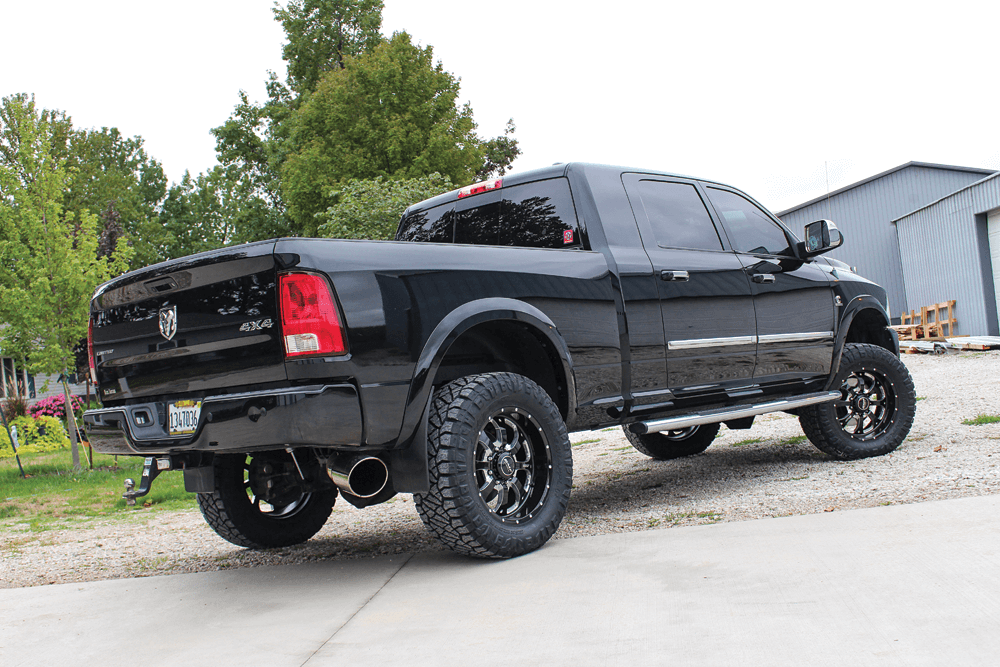

[dropcap size=big]26[/dropcap] While the finished product may look subtle (3 inches of lift, 35-inch mud terrains, 20×9-inch wheels), this is one of the most comfortable lifted trucks we’ve ever ridden in. The RAM’s ride quality—both on and off-road—has been improved tenfold, its steering is nice and tight, and the components installed are designed to last.

Carli Suspension

CarliSuspension.com

888.992.2754

Flynn’s Shop

217.478.3811

Fox Shox

RideFox.com

800.369.7469

Share Link