John Mata Jr.

.

September 14, 2020

.

Department

.

John Mata Jr.

.

September 14, 2020

.

Department

.

Street Trucks: Dave, thanks for calling back so soon. Didn’t mean to catch you right in the middle of filming. How’d it go today?

Dave Kindig: You know, I like to say that I hold the world record for the longest colonoscopy. I’ve had a camera up my ass for about 36 months now.

ST: Wow! So when you guys are in filming mode, how many days during the week are the cameras rolling?

DK: Three to five all year. P

ST: Productivity-wise, does that affect your daily routine at all, or have you already found the right balance to get work done?

DK: When we get down to the end of the seasons, there are usually easy days that we focus on continuity or to fill out stories. Today was a full day, and yesterday I had … wait, we didn’t even film at all yesterday.

ST: The days must all start to run together after a while.

DK: Yeah, it’s always nice to have some downtime away from the cameras, but it’s not a big deal; we work around it. The film crew is great. We’ve had the same guys here for the last few years so we all work well together. They understand that they are filming in a hot rod production shop.

ST: That’s cool. So how was it getting used to the cameras being shoved in your face … or other places, too, it sounds like?

DK: A lot of people might not have put it together, but I’ve been doing the filming thing for a while for other shows like “My Classic Car,” “Car Crazy TV” and SEMA coverage. I’ve been the guest on other people’s shows, but doing “Bitchin’ Rides” for the Velocity channel has been amazing.

ST: So did Velocity approach you guys about doing your own show with your crew?

DK: Yeah, they did, which was really cool. We had been putting out a big media blitz when we were working on the GM Futurliner a few years back, and they had taken notice of it. They were already familiar with my personality on TV, and I think there was a buzz going around about a rather little-known hot rod shop in Utah working on such an important piece of automotive history with the Futurliner that it just sparked some interest in how our team operates.

ST: You guys killed it with that one. Can viewers expect the same great show with season three that we’ve already grown to love?

DK: Yeah, I’d say that we have stuck with the same formula but maybe went one notch further. The first season was exciting for us because it was our own show, you know, and it was 10 episodes. At first we wanted to avoid filming too much of the projects that we were already almost done with, but we soon realized that there was still a lot of meat on the bones on a lot of those builds for stories for the first season. But by the time season two came, we had been building quite a few more cars and getting them all put together. Season three is a lot more of the same thing—there isn’t one story that hasn’t been captured from start to finish—and season four is gearing up to be even better.

ST: Since we’re all about the trucks around here, can we expect to see a fair amount of builds with beds on the show soon? Can you give us an estimated ratio of cars to trucks in season three?

DK: I don’t have my handy-dandy formula scale here in front of me, but you guys won’t be disappointed. We’ll certainly have some really cool trucks coming down the pipeline. I feel that truck guys are car guys as well in the sense that they both like things with four wheels and a steering wheel. My design cues range from all kinds of vehicles from vintage to modern, and most of our builds can range anywhere in between with any given project. I always try to incorporate the feel of high class and high quality with all projects whether they have a bed or not.

ST: Rest assured, our DVR will be set to catch each episode. Some of our readers may or may not be familiar with your background; can you paint us a picture of your early inspirations? What/who was the driving force behind your love of cars?

DK: I was into Hot Wheels and Legos when I was growing up, like I’m sure we all were. I came from the generation where “Dukes of Hazzard,” “Knight Rider,” “Starsky & Hutch” and “Hardcastle & McCormick” were on, and I was always a big fan of all those cars and got a kick out of them. My growing up was a little bit on the different side, though. I grew up with no dad around, and there was nobody building cars around me, but it was just something I always loved. I’d go to car shows with my cousin Brad. We’d get dropped off at AutoRama here in Salt Lake before it even opened, and we’d be the last ones out of the buildings. We’d also spend a lot of time watching MTV when it first came out and got a kick out of ZZ Top’s Eliminator.

ST: All those are all classic ’80s car icons right there. What kind of car was it on the cover of that ZZ Top album?

DK: A ’33 Ford coupe. Funny thing about how time flies and things change, but a while back I was in Sacramento for a show for an autograph signing, and I saw Jimmy Shine and Billy Gibbons at the airport. I saw Jimmy and I high-fived him and commented to him that they must have had us tag-teaming the signing together. Then I noticed Billy step out of the SUV next. He left his baggage sitting there, walked across the sidewalk and told me he was a big fan and asked for a picture with me. All I could think was, ‘Holy crap, yeah, of course you can.’ I remember being so nervous at that point, and then I realized later that I didn’t even pass my phone off to get a picture of us together.

ST: Wait, so if you were watching MTV when it was just coming out, you must’ve been a teenager or so in the early-’80s. What were you driving around during high school?

DK: Let’s see, I had a Toyota Celica GT coupe, and I drove that around through most of high school. I traded it to a friend for a ’59 Volkswagen Bug, and later on I got a ’60 Volkswagen that I had for the longest time back after I met my super-hot girlfriend who is now my wife of 26 years. But I was always buying Volkswagens and chopping them up back then. I got into the lowrider scene, too, but more of the sport-truck-style stuff with a ’91 Oldsmobile Custom Cruiser that was ’bagged and painted with a killer sound system.

ST: Those Olds station wagons were pretty cool back then. Where were you learning how to tear into all of these cars?

DK: You know, it just kind of snowballed. I was pretty much selftaught. I never worked at a shop or went to school for it. I always just tried to do as much of the work I could on my own, and pretty soon people were noticing that I was starting to develop my own style and wanted me to work on their cars.

ST: When was the first time you got paid to do it?

DK: I was working for Jeff Holman, president of High Performance Coatings. I had started off at the very bottom. A mechanic there had crashed his dually Suburban. It was all custompainted with a big, obnoxious wing on it. It was from Oklahoma and that was kind of the style back then. Anyway, I was commissioned to do some work on it after hours. It ended up being a six- or seven-color paint job with some fades, so that was pretty cool. Then I’d go home and paint my own cars, and then one for a friend here and there. After a while, though, I had different guys ask about having me draw renderings for them. So that’s when I first started getting paid real money for my work. It was a great feeling.

ST: How did that lead to you opening the doors to your own shop?

DK: The way I went about it may not be the exact method I’d recommend to everyone out there, but if I had to, I would do it all over again. After eight years of working at HPC, I up and quit. I cashed out on my 401K and just went for it.

ST: Whoa, did you have something planned or lined up before you left?

DK: Nope, and my wife and I just had our second kid. My son, Drew, was just two weeks old and my daughter was three when that happened. At this age now, though, I think I would be more cautious about doing something like that, but it felt right at the time, and luckily my wife had given me the thumbs-up to do it.

ST: How old were you when all this happened?

DK: Let’s see, I’m 45 now, so I was 28 at the time. It’s been 17 years since then. The first few years were very difficult, there were so many times when we almost fell on our faces. Considering the alternatives, we just kept at it because we just didn’t want to even think about losing.

ST: What was the urgency that made you make a move like that at such an unsteady time? That’s such a huge risk!

DK: I’ve always been a hard worker. I treated the company I was working for like it was my own. I put in long overtime hours and all-nighters and worked all weekend, but I was on salary back then, and I was working 60-plus hours most weeks. I respected the company and Jeff was a smart businessman. But, I just always loved drawing, and I figured that I could spend more time doing that at home as well as peddling parts I was making for friends. In renderings alone, I could finish two of them in a couple of days and make as much money as 60 hours worth of work.

ST: Yeah, if that was the case, then why not go for it?

DK: At that time I started doing stuff for Arizona Speed and Marine and worked on a couple of projects for Super Chevy and Chevy High Performance magazines. Pretty soon the word got out that I was a ‘big deal’ designer in Salt Lake, and everybody in Salt Lake thought I was a ‘big deal’ designer outside of Salt Lake. I had a list of cars to render for hundreds of dollars at a time, so it was a good time to start focusing on what could possibly become my own successful little business.

ST: After that jumping-off point, how long do you think it was before you were able to say that you’d made it and didn’t have to worry so much about going under?

DK: It took quite a few years to get there. I always imagined having a big shop with a lot of guys helping out and a lot of projects going on at the same time. So as soon as I started making some money, I’d reinvest in more equipment and more space. I outgrew my garage in two months back in June of ’99, then moved into a 4,500- square-foot building for almost three years. I kept putting more projects in front of myself and tried to do as much as I could at a time. I honestly didn’t start noticing the light at the end of the tunnel until I stopped spending so much money on growing, so about 2005/2006. But there were always growing pains and the normal rough patches along the way.

ST: It seems like the last four years or so have been great for you guys.

DK: Yeah, they really have. We’ve received some great exposure, even before the TV show. It really has been a dream come true. Our twentieth anniversary is creeping up in another three years, and I’m looking forward to seeing where we’re at when we reach that milestone.

ST: Since lots of guys out there are probably wondering, what does it take for a dude to get his car into your shop? What is the waiting list looking like these days?

DK: Before the TV stuff, we had close to a year backlog before we could bring a new project in, and we’d probably get 10 serious requests in a month. Now we get about two serious requests in an hour or so. There are about 85 cars on the list at the moment, which kind of sucks because I want to be able to please everybody, but I don’t think it’s necessarily bad to say that we may not be the shop for everyone. We have one level of quality and operate on one speed, and that’s perfection. We aim to deliver the very best to every single one of our customers. Unfortunately, some potential customers who have a huge interest and love for custom cars don’t exactly know what to expect to spend on a full custom build; so, there come those unfortunate times when I have to deliver bad news to good people.

ST: Surely most serious car enthusiasts can understand that. That whole ‘good work ain’t cheap’ line does have merit after all. On the other hand, you must run into issues with customers who have the right budget but aren’t good at the whole being patient/waiting in line thing.

DK: Yeah, sure. I’ve been around the block with this many times. I’ve found that if someone is too impatient and can’t understand that quality work can’t be rushed, I probably wouldn’t want to build a car for that kind of person in the first place. I think Troy Trepanier of Rad Rides By Troy said it best when he said that he won’t build cars for celebrities, athletes or people who haven’t had cars built before, and I know exactly what he’s talking about. Guys with $20-to-$30-million-a year contracts playing some kind of professional sport want what they want right now, and they don’t care if someone else has money, too. I think it’s safe to say that a good majority of our clients have the budgets for rather expensive cars, but they also have a good understanding of how this all works, or is supposed to work anyway.

ST: That’s a valid point, too. That kind of unnecessary pressure and headache probably isn’t even worth the hassle.

DK: It really isn’t. This life is too short to put up with any crap when it comes time to build a vehicle, and that’s on either end. This is supposed to be fun and enjoyable because it becomes a creative process for both owner and designer to enjoy together.

ST: Well, it sounds like you guys really have a good thing going and have a solid direction, obviously. You have a successful shop, you have an entertaining TV show, and you have a lot of genuine fans. What else do you have your eyes set on accomplishing in the near future?

DK: There are still lots of things I’d like to gun for. I think, as a collective unit, I’d really like to see our shop earn a Ridler award, you know? I’d really like to go after an AMBR award, too. We haven’t achieved them yet, but those are both big goals of ours.

ST: Dave, it’s been a pleasure chatting with you. We don’t want to keep you tied up too much longer, and we still have yet to talk to your right-hand man, Kevin Schiele. Are there any parting words for the fans of your work and those out there looking to follow in your footsteps in one way or another?

DK: To be honest with you, I’ve always said that any vehicle has the potential to be the coolest car you will see at the car show, it just depends what you do with it. I’ve also said that there’s an ass for every seat, so in that respect there’s nothing wrong with any type of car or truck you’re building, as long as you love it. I think the best advice I can give someone who is looking to start a shop or get into design work or other aspects of building custom vehicles is to set your goals very high and always keep an eye on those goals. Expect to take a few lumps every now and again, and don’t ever let the thought of complete failure get the better of you. Expect to take the bad with the good, and realize that the only person who can really stop you from succeeding is yourself. If you feel that you haven’t arrived yet, it just means that you haven’t arrived yet, and there’s nothing wrong with that. Hand-on experience is very important and so is documenting the steps in how you are doing things. Take lots of photos and notes along the way, and take your time, slow down a bit and aim at doing things right the first time. Also, my wife, Charity, has been my best bud over these last 26 years. I’ve always been the ‘go, go, go’ type of person, and she is very much the ‘whoa, whoa, whoa’ type in the sense that she makes sure that we have a good place to land after we jump. So get yourself a good woman, get yourself a good welder and a good set of hammers.

Street Trucks: Hey, Kevin, did you notice that Dave didn’t mention anything about the importance of having a handsome and talented shop foreman around? What’s up with that? It’s good to get some time in with you guys today. So tell us how you got mixed up with this Kindig guy anyway?

Kevin Schiele: I met Dave while going to car shows here in the Salt Lake area back in the day when I was building mini-trucks. He was big into his VWs about that time and was the western regional rep for HPC. He ended up helping me get a job there, and we just became good friends.

ST: So you guys were working there together for a while then. Were you still working there when Dave left to branch out on his own?

KS: Yeah, Dave was already doing his renderings back before he left. He’d always tell me how some of the vehicles he had designed on paper usually didn’t end up getting built the exact way he had envisioned them once SEMA time rolled around. I think that is what really made him want to build the cars he was drawing himself, and it was cool to see him go for it.

ST: Were you going out to his place often to hang out and see what he was up to?

KS: Oh for sure. I was moonlighting there in his garage early mornings before I’d go to work or in the evenings. I was driving an Isuzu Space Cab back then that was called The Bone Collector. We had been messing with the air ride system early one morning and we were rushing to get it pieced back together before I had to get to work. I ended up showing up 15 minutes late or something like that. It wasn’t even that big of a deal, but they fired me on the spot.

ST: They must’ve known that you were spending a lot of time with Dave. Did you fight to get your job back?

KS: Nope. I told Dave what had happened and all he said was, ‘Don’t worry about it, we have a ton of sht to do here, let’s get to work.’ I haven’t looked back since. Funny thing about that Space Cab, though, if you bring up the article—I think it was published in 2001 or so—check out all the bones that run up along the sides. Dave drew all of those with a pencil, and if you look at the tailgate, there’s a skeleton he drew that looks like him with a huge goatee and everything. Talk about some OG stuff right there.

ST: Wonder what that tailgate alone would bring in on eBay? So what was your take on those first few years with Dave? It must’ve been a little crazy, huh?

KS: We moved out of his garage pretty quickly and got a decent-sized shop for what we needed in the same building we’re in now. We just slowly added on, and next thing you know, we were taking up the entire 27,000-squarefoot building. When you guys were growing you obviously needed more help. Where and how did you find other skilled craftsmen to work in the shop? We were incredibly lucky in the beginning to have had the guys that we did back then; guys like Will, who is actually still with us today, and a couple of other awesome guys, who have since gone on to do other things. When we needed help, we just called the guys we knew did good work and were dependable. Today, we’ll throw a potential new guy into the mix for a week and see how he does. We just like to see if someone can walk the walk because anybody can talk.

ST: Right. So you guys must get flooded with résumés and headshots from guys looking to land a job to get on TV.

KS: Ha! Résumés, yes, but we haven’t received any headshots yet. The production crew may be holding out on us with those. But aside from having the right skills, we are looking for a guy who can get along with the rest of us and has a pretty thick skin. In the end, this is still a hot rod shop, and we all just like to have a good time and joke around to keep the day fun.

ST: You mean like running around marking people’s necks with a KevDogg stamp?

KS: Exactly, you have to be able to take a stamp.

ST: Where did you even get that thing? Was that a prop that the film crew wanted you to use in front of the cameras?

KS: My girlfriend bought me that stamp for Christmas. She’s a cosmetology teacher, and she has a stamp for the girls who pass their exams and prove they know how to give a good perm or something. She used to stamp my face with her stamp, so I guess I got that from her. Like I tell people, that kind of stuff isn’t made up for the sake of the show. It really was one of the best gifts ever.

ST: We’d be surprised if one of the guys didn’t end up grabbing that thing from you and stomping it to pieces.

KS: Nope, I still have it. But after they sprayed water on my crotch, I got the point and retired it and left the guys alone.

ST: Okay, so you do have a lady at home then. Surely that must disappoint all of the would-be stalker chicks out there.

KS: You know what, it’s the dudes who are the real creepers. I mean I work at a shop and I’m on TV and stuff, but I’m just a normal guy, so there’s no need to get all weirded out or anything. I enjoy talking to our fans and swapping ideas because we are super-appreciative of everyone who supports us. We have a crazy cool opportunity here with Kindig-It Design, and I don’t think we feel any different or that we’re better than anyone else out there who likes to work on cars.

ST: Most people get that vibe from you guys, right? You and Dave really are approachable, but you guys do operate on a pretty tight schedule, so if you say you only have a few minutes to stop and chat, chances are that really is the case.

KS: Yeah, it does get tough sometimes, but we are humble guys because we both know that there are people out there who can do things right on par or even better than us. It is a business, but this is still something that we truly enjoy doing, and we love the sht out of it. Dave and I sometimes talk about it, and we both agree that in the very best case scenario, the show might last about a decade. Who knows, it might not even make it that long. But whenever it ends, for whatever reason, you can bet that we will still be building cars and loving it because that is just what we’ve always done.

ST: Aside from the caliber of work you guys put out with every build, the approach you guys take to the business aspect of car design and building must play a huge role in why the shop has been so successful throughout the years.

KS: It is a blessing to be as consistently busy as we are and will be in the future. We have a lot of great projects lined up, and we remind ourselves everyday that we are essentially selling a product and a service that nobody actually needs, so we do our best to make sure our customers feel that they are getting their money’s worth and then some. Like Dave said, we haven’t had the chance to compete for a Ridler, but it sure is on our bucket list. It’s just something that we are not going to force or try to talk an existing client into. We will get the opportunity when the time is right, and when we get it, we will give it everything we have.

ST: Most definitely, man. So getting back to the normal routine for you, how crazy is your stress level on any given day?

KS: We have a staff of about 27, which is more than a lot of other operations, but that also actually helps me on my end a great deal. I have a lot to keep track of as far as project progress, budgeting and all that, but we have a couple of key guys that help keep everything running smoothly. We have Will who keeps tabs on the metal side, and there’s Manuel, the painter, who monitors the body department, and for the most part, I just check in with them. We all work well together, and we solve problem situations as a unit.

ST: Do the cameras get in the way at all?

KS: The camera crew understands that we are there to build cars for the customer and not for TV. They give us the room we need to operate at a productive pace. I didn’t really shy away from the camera at all because I saw it as an opportunity to see what our limits were, and to see how much of our crap they would end up editing out later. Like I said, there isn’t much on our show that is made up; we aren’t actors. They’re just capturing what we’re doing. But it was a learning curve at first, for sure. Luckily, the members of our production crew are all based about 45 minutes away in Park City, so it makes it easy to give them a call if we are reaching a point that they wanted to capture on film. Very rarely do we have to put too many things on hold for the sake of filming, which is a huge deal to us.

“WHAT I’VE ALWAYS INSTILLED IN MYSELF IS THAT THERE’S NOTHING WRONG WITH A HARD DAY’S WORK. AT THE END OF THE DAY, YOU JUST HAVE TO PUT IN THE EFFORT TO ACHIEVE YOUR DREAMS.”

ST: Do they at least bring a catering crew with them and fix you guys up some pretty good lunches?

KS: You’re thinking of something along the lines of a Discovery Channel budget, man. We don’t get lunches, we don’t have to wear makeup, and there aren’t any special lighting effects. We’re just hanging out in our shop doing our thing.

ST: At least that helps you guys stick to a diet or meal planning or whatever it’s called. So have you and Dave both grown up in the Salt Lake area?

KS: Yeah, I was born in Wyoming and moved to Salt Lake when I was six months old, so this has always been home for me. Dave was raised here, too. It’s a great place to live.

ST: Putting Utah on the map! Before we let you go, tell us what you’re building for yourself.

KS: I did sell that black Silverado that we built on the show, the one that was featured here in Street Trucks. I got my hands on an ’05 Dodge dually to haul my boat around. It’s on air and on 24s, just something clean I can drive everyday. Other than that, I’d really like to work on a 1988-98 two-door Blazer that I can roadster out, but it’s all about finding the right one. I really don’t want to pay too much for a bunch of someone else’s mods and add-ons that I don’t need.

ST: Keep us posted with what you find. That sounds like an awesome project to tear into. It’s just about that time. Got any last words that you would like to share with the fans and builders reading at home?

KS: What I’ve always instilled in myself is that there’s nothing wrong with a hard day’s work. At the end of the day, you just have to put in the effort to achieve your dreams. I mean, I’m not the college graduate guy, and I’m not the artist. I don’t feel that I have some crazy skills or anything way out there. I know how to build cars, but so do a lot of other people. The thing that can set you apart, though, is putting in the time and doing whatever it takes to get a job done the right way.

ST: That’s some solid advice right there. Thanks again for taking time out of your schedule to chat.

KS: No worries; no worries. It’s my pleasure. Next time you’re in Salt Lake stop by the shop.

ST: Thanks for the invite, is it better to call beforehand or just lurk in the shadows by your truck around closing time?

KS: Okay, creeper, I’ll be looking out for you.

What current projects are happening at Kindig-it Design?

Current Projects at Kindig-it Design

One of the most exciting projects at Kindig-it Design is an extensive widebody transformation. This unique build features a Magnusen supercharged, 1,000-horsepower Lingenfelter engine under the hood. The vehicle’s stretched F-body will also be supported by a custom independent rear suspension system, making it a standout build in the shop.

Another intriguing project involves a 1957 Oldsmobile. This isn’t your average Olds; it boasts a rare LT5 crate engine and is set on a custom Roadster Shop chassis with full IRS. This build exemplifies the shop’s love for unique and challenging projects.

Kindig-it Design’s CF1 Corvettes are also worth noting. Typically built to order in-house, these custom vehicles feature a Roadster Shop chassis, Lingenfelter engines, Wilwood brakes, and an abundance of detailed craftsmanship. The CF1 series includes both roadsters and recently-introduced convertibles, tailored for those who desire a roof and side glass on occasion.

There are rumors that due to the CF1 Corvettes’ popularity, production might move to a dedicated facility. This would enable the team to keep up with growing demand while maintaining the high quality they are known for.

In response to market trends, Kindig-it Design has also ventured into electrifying their CF1 models. Despite initial skepticism, these electric CF1s still deliver incredible performance, with instant torque delivering a thrilling driving experience. Even Dave’s own CF1, car No. 3, has been converted to an electric version, showcasing an impressive amount of torque.

Kindig-it Design continues to push the boundaries with innovative and unique car builds, blending classic craftsmanship with modern technology.

What is Kindig-it Design known for?

Kindig-it Design stands out in the custom car industry for its innovative and stylish designs. A hallmark of their craftsmanship is the exterior door handle, which has been transformed by Kindig-it into a true piece of automotive art. These handles are not just functional components; they set the vehicles apart with their sleek, sophisticated appearance.

While there’s a playful myth that these door handles can add extra horsepower to a car, their real value lies in their aesthetic appeal and unique design. Kindig-it’s custom door handles can be found on numerous bespoke cars across the country, showcasing the brand’s commitment to quality and creativity.

By focusing on these small yet significant details, Kindig-it Design has managed to carve out a niche in the competitive world of car customization.

How are CNC machines used at Kindig-it Design?

CNC (Computer Numerical Control) machines play a pivotal role at Kindig-it Design, enabling highly precise and efficient fabrication of custom car parts. These machines are essential for translating intricate design concepts into tangible, meticulously crafted components.

At Kindig-it Design, CNC machines are used to achieve unparalleled precision and customization. After designers finalize the digital blueprints, these machines take over the process of cutting, shaping, and drilling materials with extreme accuracy. This precision ensures that every part fits flawlessly into each unique car build, whether it’s a one-off custom piece or a complex, multi-part assembly.

CNC technology also boosts efficiency. Traditional methods of manufacturing custom car parts involve extensive manual labor, which can be time-consuming and prone to inconsistencies. In contrast, CNC machines can operate continuously and produce uniform parts quickly, greatly speeding up the overall production timeline without compromising on quality.

Interestingly, Kindig-it Design has utilized their CNC capabilities to maintain secrecy on high-profile projects. For instance, they discreetly used these machines in a dedicated room to build award-winning vehicles, ensuring that these special projects remained under wraps during filming for various media productions. This strategic use of CNC technology keeps groundbreaking designs confidential until their official unveiling.

Another significant advantage of CNC machines at Kindig-it Design is their versatility. Whether working with metal, plastic, or composite materials, these machines can handle a wide range of tasks. This adaptability makes them invaluable for crafting everything from bespoke engine components to intricate interior elements.

In summary, CNC machines at Kindig-it Design are vital for delivering high accuracy, efficiency, and versatility in their custom car builds, all while maintaining the confidentiality of their most innovative projects.

How does Kindig-it Design incorporate electric vehicles into their builds?

How Kindig-it Design Incorporates Electric Vehicles into Their Builds

Kindig-it Design seamlessly integrates electric vehicles (EVs) into their projects without compromising the integrity of classic cars. By converting existing models into electric-powered hot rods, they ensure that traditional aesthetics remain intact. This approach preserves the vintage appeal while offering a modern twist.

One of the fundamental principles at Kindig-it Design is preserving classic cars. They achieve this by building electric versions that do not involve dismantling or harming the original vehicles. Instead, they carefully retrofit them with electric drivetrains, thus maintaining the car’s iconic look and feel.

Electric vehicles provide an exciting enhancement to the driving experience. The instant torque offered by electric motors translates to impressive acceleration and overall performance. Kindig-it Design leverages this by incorporating electric powertrains into their builds, delivering vehicles that are not only visually stunning but also exhilarating to drive.

The team at Kindig-it Design also explores electric vehicle conversions through personal projects. Dave Kindig’s own electrified CF1 serves as a prime example. This project demonstrates their capability to blend classic design with cutting-edge electric technology, resulting in a unique and powerful ride.

Kindig-it Design acknowledges the growing niche market for electric vehicles within the car enthusiast community. By offering electric versions of classic cars, they cater to a specific segment of buyers who appreciate both nostalgia and innovation.

Through meticulous craftsmanship and a commitment to innovation, Kindig-it Design successfully incorporates electric vehicles into their builds. They offer a harmonious blend of classic design and modern technology, ensuring that both tradition and performance are celebrated in their creations.

What significant award has Kindig-it Design won?

Kindig-it Design has achieved a major milestone by winning the prestigious Ridler Award. This accolade was earned with their impressive build— an outstanding 1953 Corvette powered by a V-12 engine.

How do custom car builds at Kindig-it Design typically start?

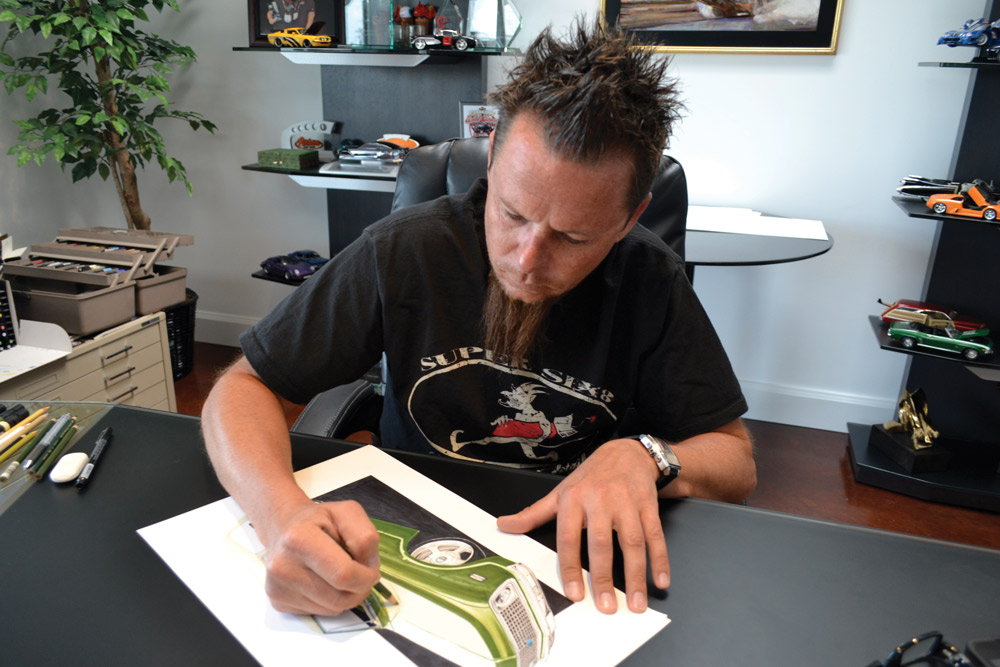

At Kindig-it Design, each custom car build kicks off with an original sketch by the talented Dave Kindig. This initial drawing serves as the blueprint, capturing the unique vision for the project. The team then brings this vision to life, translating Dave’s imaginative artwork into a tangible, one-of-a-kind automobile.

Walking into the shop, you’ll notice an impressive collection of sketches displayed on the art wall. These drawings provide a visual history of the hundreds of custom cars that have been crafted over more than two decades. Each sketch tells a story, showcasing the creativity and skill that go into every build.

How has the Kindig-it Design facility evolved over the years?

Evolution of the Kindig-It Design Facility

Over the past 25 years, Kindig-It Design has transformed from a modest garage-based operation to an extensive manufacturing hub. The company, founded by Dave Kindig and his wife Charity, began its journey in the garage of their family home.

As their reputation for custom vehicle design and fabrication grew, so did their need for space. They transitioned from their initial small-scale setup to a sprawling 27,000-square-foot building. This primary facility now houses the majority of their intricate design and fabrication work.

To accommodate the increasing number of vehicles coming in for customization, Kindig-It Design further expanded with an additional 10,000-square-foot warehouse located just a few blocks away. This warehouse serves as a holding area for vehicles awaiting their turn in the main shop, ensuring the workflow remains efficient and organized.

What was Dave Kindig’s first custom car project?

Dave Kindig’s initial foray into custom car building was a unique project that combined elements from two different years of Volkswagen Beetles. His first custom car was a 1968 Beetle, which he enhanced by adding a front end from a 1960 model. This blend of parts created a distinctive hot-rodded vehicle, showcasing his early knack for innovative design and engineering.

Who founded Kindig-it Design?

Dave Kindig and his wife, Charity, are the founders of Kindig-It Design. About 25 years ago, they started the business, which began as a small enterprise in their garage. Today, Kindig-It Design has expanded significantly, occupying a 27,000-square-foot facility.

Who handles the interior work for Kindig-it Design?

The intricate interior work for Kindig-it Design’s vehicles is expertly managed by Justin Stephens. His company, JS Custom Interiors, conveniently shares a location with Kindig-it Design. This close proximity allows for seamless collaboration and efficient project management.

By working in the same building, both teams can easily coordinate to ensure that each vehicle’s interior aligns perfectly with its custom design.

Key Points:

What role does Charity Kindig play in the company?

Charity Kindig plays a pivotal role at Kindig-It Design. As the company’s Chief Financial Officer (CFO), she manages all financial operations, ensuring the company’s growth and stability. Since the company’s inception over 25 years ago, Charity has been instrumental in transforming it from a small business in the family’s garage to a thriving enterprise now housed in a spacious 27,000-square-foot facility. Her strategic financial oversight has been crucial in scaling the business and navigating its expansion.

Who is a notable co-host on the show Bitchin’ Rides?

One of the standout co-hosts on Bitchin’ Rides is Kevin Schiele. Having joined the crew in 2004, Kevin has become an integral part of the show. His expertise in overseeing the workshop and his on-screen presence make him a fan favorite.

What family members are involved in Kindig-it Design?

At Kindig-it Design, the business is truly a family affair. The team includes both the founders and their children, Baylee and Drew. Alongside these core family members, the company also employs more than 40 dedicated staff.

How long has Kindig-it Design been in operation?

Kindig-It Design has been in business for over 25 years. From its humble beginnings in the family garage, the company has expanded into a sprawling 27,000-square-foot facility.

Can the public tour the Kindig-it Design shop?

Yes, the public can tour the Kindig-it Design shop! If you happen to be in the area, visitors are welcome to ask about tours. While they are generally accommodating, it’s best to ensure there’s not a major project, like a Ridler build, that requires confidentiality.

Here’s how to plan your visit:

By following these steps, you’re more likely to enjoy a fascinating peek behind the scenes at this renowned custom car shop.

How many employees work at Kindig-it Design?

Kindig-it Design employs over 40 individuals, including the owners’ daughter Baylee and son Drew.

What is the significance of the Ridler-winning 1953 Corvette build?

The Ridler Award, prestigious and highly sought after within the automotive community, marks a pinnacle of custom car craftsmanship and innovation. Winning this accolade with a V-12-powered 1953 Corvette is a testament to groundbreaking design and engineering excellence.

First, the Ridler Award is not just any accolade; it’s revered for its stringent judging criteria that scrutinize creativity, engineering, and attention to detail. Securing this honor places the 1953 Corvette build among the elite in the world of custom automobiles.

Moreover, the use of a V-12 engine in this Corvette signifies a daring and unconventional approach, blending classic aesthetics with modern, high-performance technology. This fusion showcases an extraordinary level of skill and forward-thinking creativity, setting new standards in custom car building.

In essence, winning the Ridler Award with this 1953 Corvette is a monumental achievement. It underscores not just the vehicle’s beauty and power but also its role as a benchmark for future custom builds.

What are CF1 Corvettes and how are they customized at Kindig-it Design?

CF1 Corvettes are high-end custom vehicles, crafted meticulously at Kindig-it Design. Each car is built to order, ensuring a unique creation for every customer. Let’s delve into the customization process that makes these Corvettes so special.

Typically, a CF1 Corvette boasts:

Every CF1 Corvette showcases an impressive level of craftsmanship. The team dedicates immense effort to make each car a masterpiece. Remarkably, they now offer both roadster and convertible versions, catering to those who prefer an occasional roof and side glass.

A popular choice among the CF1 Corvettes at Kindig-it Design features a stunning British Racing Green paint job. These vehicles exude a classic Euro sports car vibe, complete with roll bar hoops and wire-spoke-style wheels.

CF1 Corvettes come equipped with:

The customization doesn’t stop at performance. Dave Kindig himself hand-paints details like simulated burlwood dashes, adding a unique, personal touch to each vehicle.

Interestingly, Kindig-it Design also offers electric versions of the CF1. These electric models promise instant torque and high performance, showing that the fusion of classic designs and modern technology is not only possible but exhilarating.

Rumor has it that CF1 Corvettes are so popular, production might soon require a dedicated facility just for these custom marvels.

In summary, CF1 Corvettes are bespoke vehicles, personalized to the tiniest detail at Kindig-it Design, blending classic aesthetics with modern performance enhancements.

What makes the 1957 Oldsmobile build unique at Kindig-it Design?

At Kindig-it Design, the 1957 Oldsmobile build stands out as a true masterpiece in automotive customization.

In the gallery, you can find more images that capture the essence of this stunning build. Each shot highlights the unique features and dedication that went into crafting such a standout vehicle.

By breaking down the key elements, we’ve emphasized what makes the 1957 Oldsmobile build truly unique at Kindig-it Design, all while providing a structured and engaging narrative.

What is the significance of the 1969 Camaro project at Kindig-it Design?

The 1969 Camaro project at Kindig-it Design is a remarkable fusion of classic automotive aesthetics with modern engineering prowess. This project involves a comprehensive transformation of the iconic muscle car, giving it a wider body for an aggressive stance that enhances both its appearance and performance.

One of the standout features is the incorporation of a powerful Lingenfelter engine, boosted by a Magnusensupercharger. This setup delivers an astounding 1,000 horsepower, showcasing the pinnacle of engineering excellence and performance potential.

To complement the massive power upgrade, the Camaro is equipped with a custom Independent Rear Suspension (IRS) system. This modification significantly improves the vehicle’s handling and ride quality, making it not just a straight-line beast but also a machine capable of tackling corners with precision and grace.

The widebody makeover not only gives the 1969 Camaro a modern aesthetic appeal but also allows for the accommodation of wider tires. This upgrade provides better traction and stability, essential for harnessing the newly installed power. Renderings of the finished project reveal a harmonious blend of classic design and contemporary attributes, capturing the essence of both eras in one vehicle.

The project has generated significant anticipation among car enthusiasts, who eagerly await its completion. It serves as a testament to what can be achieved when cutting-edge technology meets classic automotive heritage. This restoration and modification project doesn’t merely update an old car; it redefines what a 1969 Camaro can be, blending timeless design with today’s highest standards of performance and engineering.

What is involved in the electrical systems of Kindig-it Design’s CF1s?

Attention to Detail and Precision

Creating the electrical systems for Kindig-it Design’s CF1s requires meticulous attention to detail and absolute precision. Even a small mistake can compromise the entire system, emphasizing the need for expert craftsmanship.

Every component of the electrical systems, including wiring harnesses and looms, is crafted in-house. This hands-on approach ensures consistency, quality, and that every element perfectly fits the unique specifications of each CF1.

Crafting the electrical systems demands exceptional organizational skills. Every wire must be correctly labeled and routed to avoid confusion and ensure easy maintenance. Patience is key, as rushing through even a single step can lead to errors.

Finally, the team constantly refines their processes to stay ahead of industry standards, focusing on innovation and efficiency. This dedication results in electrical systems that not only enhance the performance of the CF1s but also ensure their reliability and safety.

By handling every aspect of the electrical systems in-house and adhering to stringent quality standards, Kindig-it Design ensures that their CF1s are equipped with some of the most sophisticated and reliable electrical setups in the industry.

What is special about the British Racing Green CF1 Corvette?

The British Racing Green CF1 Corvette holds a unique charm that sets it apart from other models. This particular version, painted in a striking British Racing Green, exudes a timeless elegance reminiscent of classic European sports cars.

In essence, the British Racing Green CF1 Corvette is a harmonious blend of classic design and modern innovation, making it a standout choice for enthusiasts and collectors alike.

What are Kindig-it Design’s exterior door handles known for?

Kindig-It Design has transformed the humble exterior door handle into a signature element of custom cars. Their door handles are celebrated for their sleek and artistic designs, which can be seen embellishing vehicles nationwide.

Whether you’re restoring a classic car or customizing a new build, Kindig-It Design’s door handles offer a blend of beauty and precision engineering that stands out in the automotive world.

How does the shop culture at Kindig-it Design contribute to its success?

“The camera crew understands that we are there to build cars for the customer and not for TV. They give us the room we need to operate at a productive pace. I didn’t really shy away from the camera at all because I saw it as an opportunity to see what our limits were, and to see how much of our crap they would end up editing out later. Like I said, there isn’t much on our show that is made up; we aren’t actors. They’re just capturing what we’re doing. But it was a learning curve at first, for sure. Luckily, the members of our production crew are all based about 45 minutes away in Park City, so it makes it easy to give them a call if we are reaching a point that they wanted to capture on film. Very rarely do we have to put too many things on hold for the sake of filming, which is a huge deal to us.

At the end of the day, we had a strong impression that the shop is run by, and staffed by, gearheads and automotive craftsmen that really care about turning out super-cool, and admittedly bitchin’, rides. They all get along, and the builds speak for them without the need for over-the-top made-up TV drama. The shop isn’t there to make a good TV show; the TV show exists to showcase a first-class shop, and that’s an important distinction.

Our team is passionate about what they do, and it shows in every project we complete. The camaraderie among the staff translates into seamless teamwork, resulting in stunning builds that speak for themselves. It’s this dedication and genuine love for the craft that sets us apart and drives our success.

The production crew’s proximity is a bonus, but it’s the internal culture of the shop—marked by dedication and a focus on quality—that truly makes the difference. We aren’t just putting on a show; we are showcasing our real work, which is why the authenticity resonates with our audience and contributes to our reputation as a top-tier shop.”

How does Kindig-it Design manage the organization and cleanliness of their shop?

KS: We have a staff of about 27, which is more than a lot of other operations, but that also actually helps me on my end a great deal. I have a lot to keep track of as far as project progress, budgeting and all that, but we have a couple of key guys that help keep everything running smoothly. We have Will who keeps tabs on the metal side, and there’s Manuel, the painter, who monitors the body department, and for the most part, I just check in with them. We all work well together, and we solve problem situations as a unit.

One of the keys to our efficiency is our organization. The shop must go through crates of yellow tape! Each build is accompanied by detailed design sketches and covered in little pieces of yellow tape with important notes scribed on them. This system ensures every team member knows exactly what’s going on with each project at a glance.

Additionally, our shop’s cleanliness is something we take pride in. It’s not just about aesthetics; a clean workspace means fewer hazards and a more productive environment. Everything has its place, and our systematic labeling helps maintain this order. This meticulous attention to detail, from the design phase to the final touches, is what allows us to manage multiple custom builds simultaneously without missing a beat.

Share Link