BRANDON BURRELL

.

June 23, 2021

.

Editor

BRANDON BURRELL

.

June 23, 2021

.

Editor

Whether your truck is lifted, lowered, bagged or bodied. Making sure it has the right stance for your style and needs is important. Since you’re reading this, we’re guessing the style we left out—stock—isn’t something you’re too fond of. That’s why, when we had the chance to get our hands on this 2019 Chevy Silverado Crew Cab and upgrade the stock suspension with a 3-inch/5-inch lowering kit, we up the install and got the parts ordered.

The truck already had a set of 26-inch wheels and tires. So this mild drop would set the truck down closer to the tires and lose the massive wheel gap. To handle the install, we teamed up with the crew at Counts Kustoms in Las Vegas. If you follow through the install photos, you can see that if you have basic wrenching skills and access to a lift, or even jack stands, you can knock this install out with a couple friends.

For the parts, we reached out to IHC Suspension and got its 2019 Chevy/GMC 2WD and 4WD lowering kit with helper bags (Part # IHC-1920GMCk-35), which retails for $1,400 and comes with everything you’ll need to tackle this install.

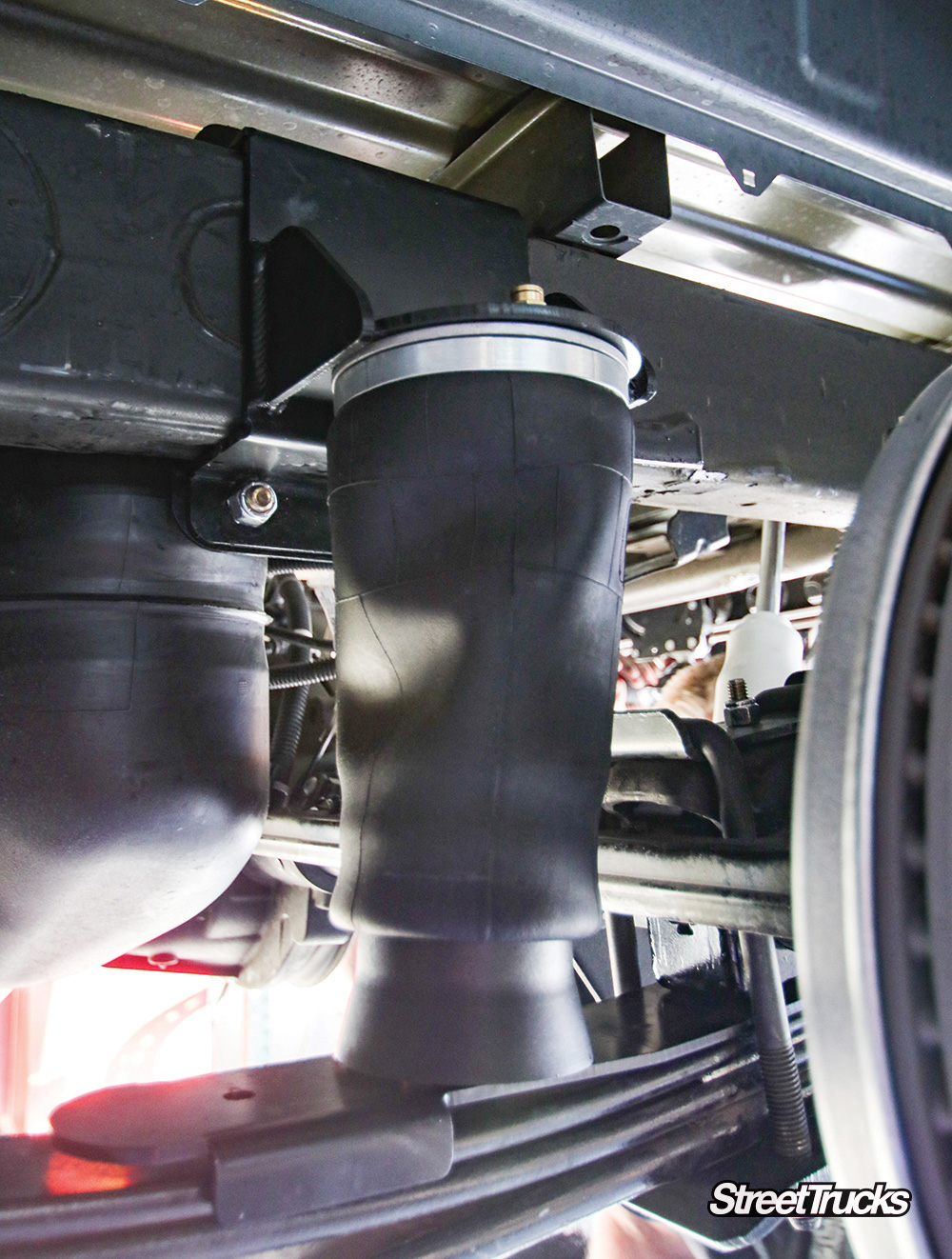

This kit will lower the front of the truck 3 inches and the rear 5 inches. This will eliminate the factory rake that all trucks come with and let the truck sit level. With it including the rear helper bags, it ensures when loading the bed or towing a trailer, the truck won’t have any sag in the rear and will still ride and handle nicely.

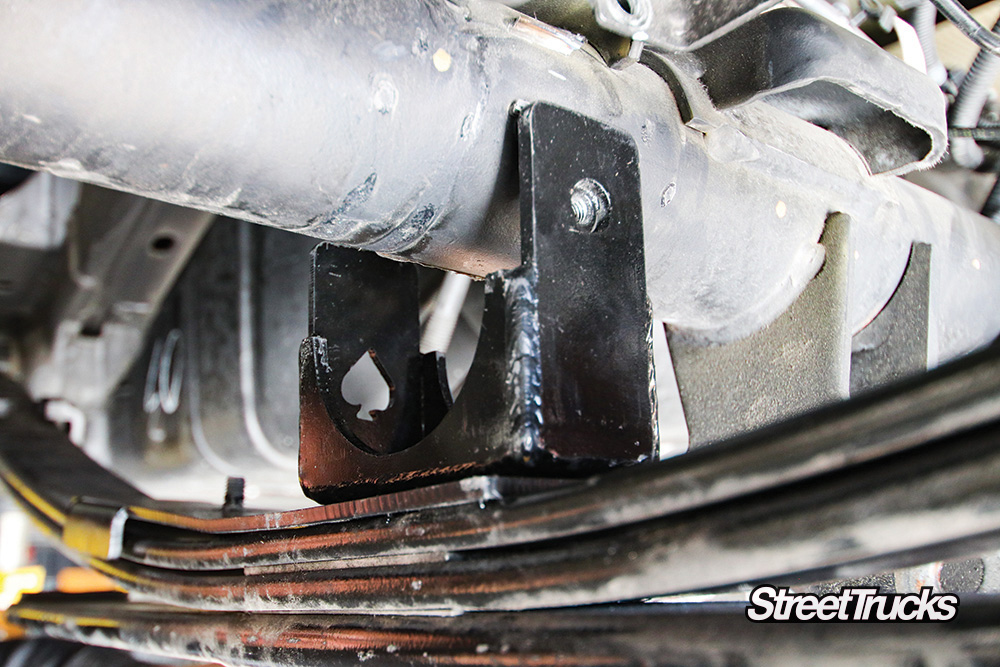

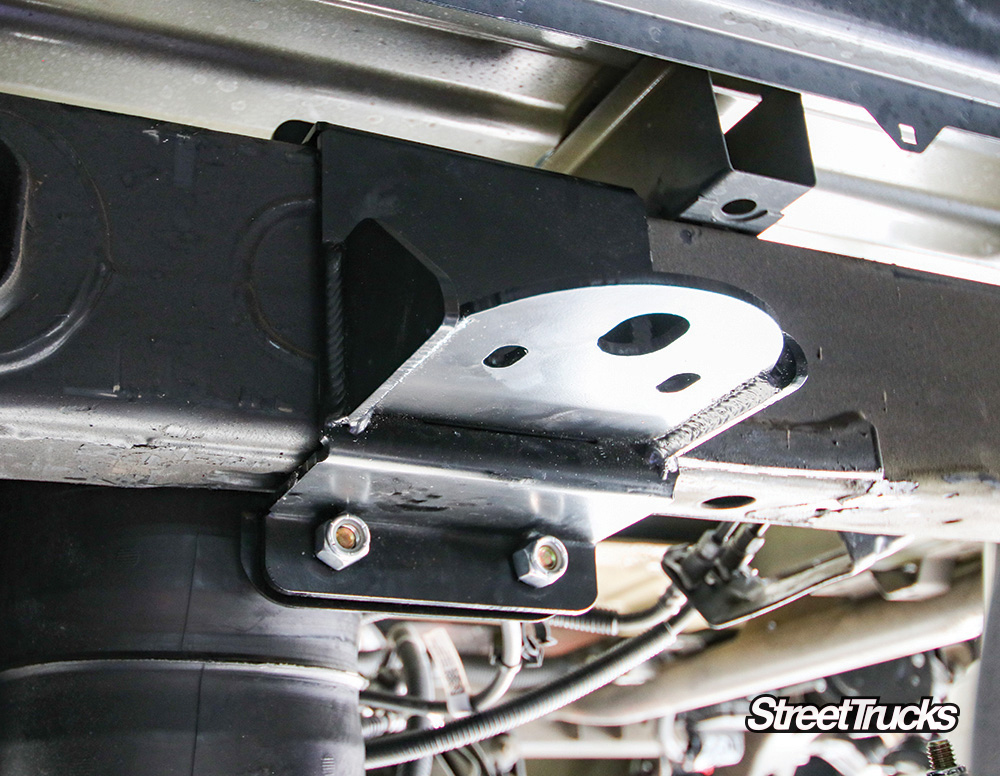

The front kit comes with new upper and lower control arms and keeps the factory spindle and strut, which keeps the truck riding the same as stock. The rear requires the leaf springs to be flipped and a new leaf spring hanger to be installed, as well as the helper bags. The install can be done in a day and gives the truck a classy look. Follow along as we show you the basic steps to install this lowering kit on this Chevy Silverado.

Front

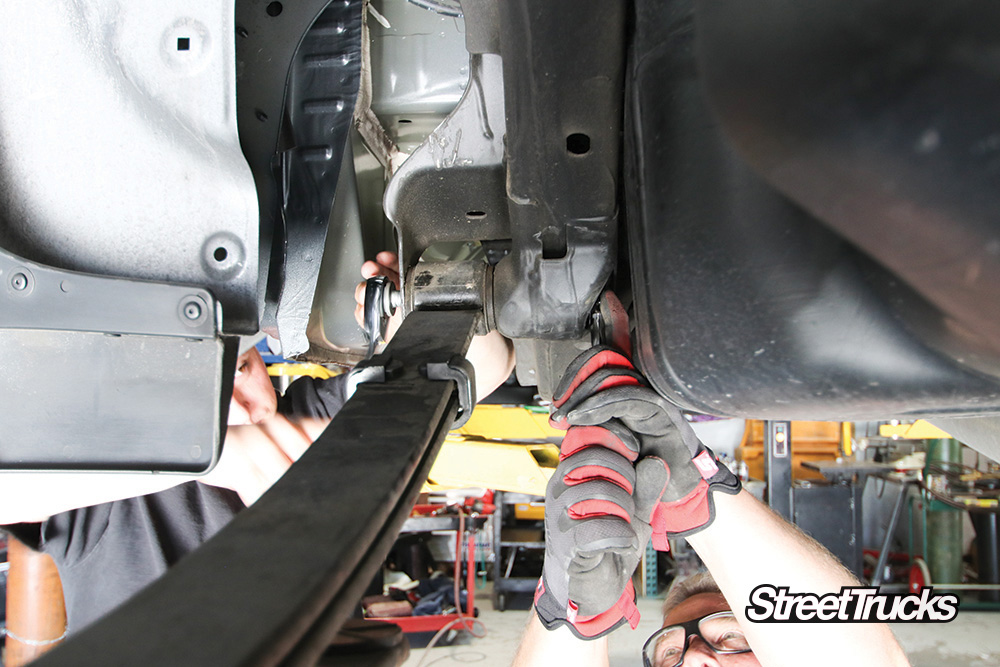

After getting the truck off the ground and the wheels off, start by removing any brackets on the front spindles and control arms to free up the brake lines and sensor wires. Also, unbolt the caliper and tie the caliper out of the way, ensuring to keep pressure off of the brake line.

REAR

Top 10 Popular Slammed Chevy and GMC Trucks

When it comes to slammed trucks, there’s no denying the allure of a perfectly lowered Chevy or GMC. In an era where lifted trucks dominate, the sight of a clean, low-to-the-ground build can be a refreshing throwback. Let’s dive into a list of the most standout slammed Chevy and GMC trucks that have captured enthusiasts’ hearts.

Keith Hathaway’s journey into truck customization began back in high school, inspired by a friend’s father who owned a Chevrolet C/K with unique features. The result? A customized 1994 Chevy C1500 that reflects years of passion and personal touch.

Chad Fincher’s 1950 Chevy 3100 isn’t just a truck; it’s a testament to the bonds formed through shared automotive interests. Over years of dedication and collaboration within the truck enthusiast community, Chad’s ride has become a true family member.

Breaking the “built not bought” stigma, the 1985 Chevy C-10 showcases what happens when you combine financial investment with expert craftsmanship. Initially purchased and modified by truck builder Tony Phillips, this ChevyC-10 strikes a perfect balance between personal touch and professional build quality.

Nick’s love for minitrucks started with his first purchase, a Chevy S-10, at the age of 16. Despite financial constraints during high school, he dreamt of future modifications, which eventually materialized in his stunning 1989 GMC Jimmy.

Ron Palmero’s story begins with the simple idea of minor adjustments. However, the more he delved into custom truck culture, the more ambitions grew, leading to significant transformations on his beautifully restored 1965 ChevyC-10. This build is a classic example of how small ideas can evolve into grand projects.

Albert’s journey with a 2010 GMC Sierra began with a solid foundation and a vision for something bigger. After acquiring the truck in Houston and collaborating with its previous owner Diego, Albert’s passion and creativity turned it into a formidable and eye-catching slammed truck.

Warren faced one of the common challenges in truck building: finding the right base vehicle. His persistence paid off with the discovery of a 1987 GMC R10. Despite initial doubts, Warren’s dedication transformed a mere engine and body into a sleek, customized masterpiece known as “The Breeze.”

Family traditions and a lifelong love for trucks culminate in Mike Snead’s 1970 Chevy Crew-Cab. Raised in a family deeply rooted in construction and craftsmanship, Mike’s build pays homage to his background while embracing the truck culture he grew to love.

Dennis Sever’s journey into the custom truck world is marked by his long-standing love for vintage trucks. His 1947 Chevy Suburban, which stood out even when custom trucks were a rarity, remains a testament to his dedication over the years and his ability to stay ahead of trends.

For Robert Sharp, a personal tragedy fueled his commitment to creating a custom truck. Alongside his brother, Robert channeled his passion into crafting a unique vehicle, making significant contributions to the custom truck scene with his 1994 GMC 1500.

Each of these trucks tells a distinct story of dedication, passion, and the unique appeal of slammed Chevy and GMC models. Whether through personal ambition, family tradition, or community bonds, these builds highlight why lowered trucks continue to captivate enthusiasts worldwide.

The durability of a lowering kit’s shock system hinges on several key features designed to withstand the rigors of daily use. Here’s a closer look:

By integrating these features, the lowering kit’s shock system is engineered for durability, effectively meeting the challenges posed by demanding environments.

Premature failure of shocks and bushings in heavy trucks is a common concern for vehicle owners. Fortunately, the heavy-duty version of the Pro Coil system is specifically engineered to tackle this challenge head-on.

Strengthened Components

These thoughtful design choices work together to increase the system’s durability while minimizing the risk of premature failure, even under the demanding conditions faced by modern trucks.

This kit will lower the front of the truck 3 inches and the rear 5 inches. This will eliminate the factory rake that all trucks come with and let the truck sit level. With it including the rear helper bags, it ensures when loading the bed or towing a trailer, the truck won’t have any sag in the rear and will still ride and handle nicely.

Experience a transformation in both style and performance with this comprehensive lowering kit. Designed specifically for Chevy Silverado and Sierra trucks, it offers maximum adjustability for achieving that perfect stance. The kit includes front coilovers with fully threaded shock bodies, allowing for precise adjustments without the hassle of shims or spacers.

The upgraded shock system, featuring polyurethane bushings and a robust chromoly T-bar, enhances durability and reduces the chance of premature failure. This means not only an improved ride quality but also a reliable performance that lasts.

With such a kit, you’re not just lowering your truck; you’re elevating its performance to a whole new level.

The kit enhances ride quality and overall performance, thanks to its design and the adjustable components that allow for a tailored truck setup.

The system includes upgraded shocks with polyurethane bushings and a 1-inch chromoly T-bar, which are selected to increase durability and reduce the risk of premature failure.

The front drop can range from 3 to 5 inches with drop spindles or 1 to 3 inches with stock spindles. The rear offers a drop range of 4 to 6 inches, giving you flexibility in customizing the stance.

The front coilover shock bodies are fully threaded, allowing adjustments without using shims or spacers, while the rear kits provide a 2-inch range to fine-tune the truck’s stance.

The kit comprises front Pro Coil Coilovers and a Rear Drop Kit, designed to provide a comprehensive lowering solution.

This kit will lower the front of the truck 3 inches and the rear 5 inches, eliminating the factory rake that all trucks come with and letting the truck sit level. With it including the rear helper bags, it ensures when loading the bed or towing a trailer, the truck won’t have any sag in the rear and will still ride and handle nicely.

For those concerned about the installation process, this kit is designed with user-friendliness in mind. It features a fully bolt-in design, which means you won’t need any special tools or complex modifications to get the job done. This approach guarantees a hassle-free installation that can be completed with basic tools, making it accessible to both seasoned mechanics and DIY enthusiasts alike.

The company prioritizes user-friendly and thoughtful product design, ensuring that each kit is practical and easy to install.

No special tools are needed, making it accessible for those without specialized equipment.

The installation is simplified by the kit’s design, which allows it to be fully bolted in without the need for complex assembly.

This kit will lower the front of the truck 3 inches and the rear 5 inches. This will eliminate the factory rake that all trucks come with and let the truck sit level.

For those looking to customize further, the front coilovers offer a versatile drop range. You can achieve a 3″-5″ drop using drop spindles or a 1″-3″ drop with stock spindles, giving you the freedom to find the perfect stance.

The rear drop kits provide an additional 2” of adjustability, allowing you to fine-tune the final rake. With a total drop range of 4-6” at the rear, you have the flexibility to match the front adjustments seamlessly.

This comprehensive adjustability ensures that whether you’re looking for a subtle change or a more dramatic stance, this lowering kit has you covered.

For the parts, we reached out to IHC Suspension and got its 2019 Chevy/GMC 2WD and 4WD lowering kit with helper bags (Part # IHC-1920GMCk-35), which retails for $1,400 and comes with everything you’ll need to tackle this install.

This comprehensive kit is designed to fit a wide range of models, making it a versatile choice for Silverado and Sierra owners. Specifically, it’s compatible with most 2007-2018 Silverado 1500 and Sierra 1500 models. However, bear in mind that it’s not suited for the 1500HD models.

Also, it’s important to note that while this kit includes almost everything necessary for installation, axle U-bolts are not part of the package. So, if you’re gearing up for an installation, make sure to source these separately.

With this kit, you can expect a seamless installation process, backed by the assurance of quality components that cater to a broad spectrum of vehicles in the Chevy/GMC lineup.

The product comes with a lifetime warranty, highlighting its durability and the manufacturer’s commitment to quality.

Axle U-bolts are not included in the kit.

The product is manufactured in Lakeville, Minnesota.

The kit is not suitable for 1500HD model trucks.

The lowering kit fits most Silverado 1500 and Sierra 1500 models from 2007 to 2018.

Share Link