John Mata Jr.

.

April 04, 2023

.

Editor

John Mata Jr.

.

April 04, 2023

.

Editor

A home shop/garage space is something most gearheads hold sacred. It’s a sanctuary, really—a place to peacefully store a completed project or a spot to rebuild an entire vehicle. For Steve Robinson of Nottingham, Pennsylvania, his garage just so happens to serve both purposes, but it wasn’t always the case. Before he purchased a home, Steve didn’t really have a legitimate workspace of his own where he could rip trucks apart and bang on metal all day long. When he finally scored a house with a proper full-size garage, you’d better believe he took full advantage of it on day one.

Aside from the physical skills I was able to grow, I have learned that through staying persistent, maybe even relentless, my final goal always seemed to remain within reach.

“I bought this ’66 F-100 the same day I bought my first house,” Steve says. “After I signed all the paperwork, I immediately drove four hours one way to go look at this thing. Now, my excitement level at this point was at an all-time high, so I did turn a blind eye to the actual condition of the truck. I didn’t really notice all the rust damage until it was sitting in the garage I was so excited to put to use.”

Everything on Steve’s F-100 seemed to be in major disrepair. From the back top to the bottom, rust and body filler greeted him everywhere he looked. The bed floor was also completely rotted away but covered with plywood and street signs to mask the true shape of the original metal. Luckily for Steve, he was in the mindset to make a lot of improvements to the truck anyway, so he definitely had his work cut out for him.

“I got pretty good at making new sheetmetal filler panels, tack welding, and general bodywork,” he says. “My skills quickly improved as the build progressed due to the amount of rust repair I had to make. It was just ridiculous to say the least. I just tackled one thing at a time and set small goals to avoid feeling overwhelmed.”

Since Steve had to do so much work to the exterior surfaces of his old Ford, he figured that he could make some extra body modifications along the way to really make the most of his time and effort.

“During the time I was working on my truck, I hadn’t seen another similar F-100 with as many shaved parts,” Steve adds.

I just tackled one thing at a time and set small goals to avoid feeling overwhelmed.

Aside from deleting every piece he could get away with, he also reworked a 1965 F-600 roll pan for the front and added a clean Grant Kustoms roll pan to the rear. A new, custom, raised bed floor was then fabricated, which included trick wheel tubs along with the smoothed back cab wall and welded-in tailgate made for a much more interesting landscape than if Steve were to have simply repaired and restored the truck’s cancerous body panels. Brent Taylor at Taylor’s Classic Auto Body soon stepped in to spray the custom-mixed BASF brown color for the exterior and set aside a champagne hue for the interior that would make for a timelessly elegant juxtaposition.

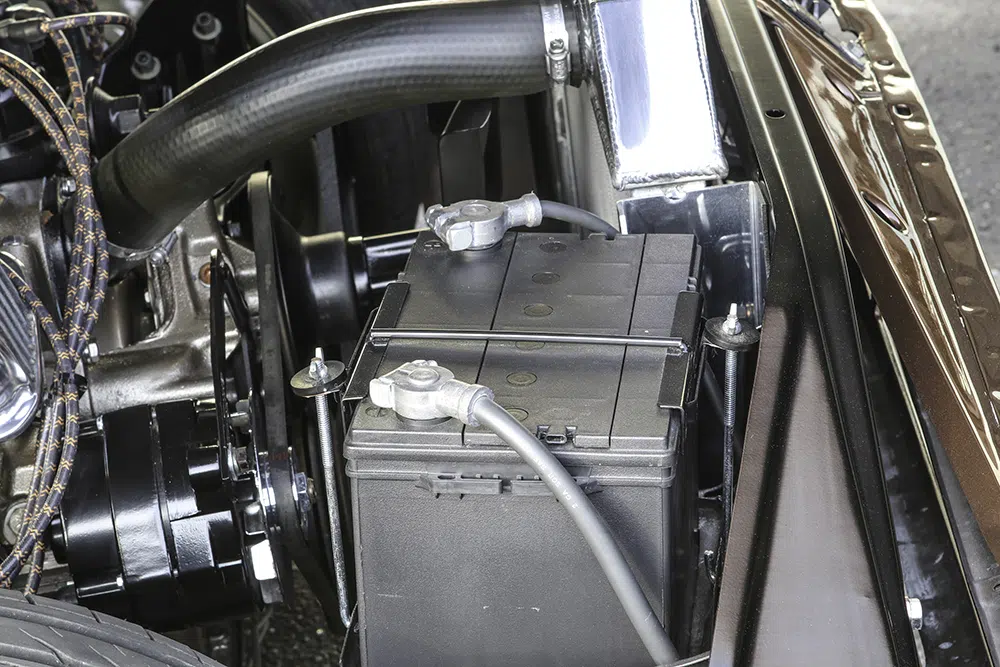

While Steve was worrying about how his F-100’s paint and bodywork were going to turn out, he was also stuck on figuring out how to slam the truck’s suspension as low as possible. To get this done, he first half boxed and reinforced the frontend of the frame and then Z’d it a total of 3 inches. Next, he opted for a Mustang II style IFS system as well as custom tubular control arms and rack-and-pinion steering for comfortable drivability as well.

At the rear, Steve grafted a Porterbuilt 4-link back half with Panhard bar to deliver the rearend drop. Of course, to deliver the ideal ride and park heights for his F-100, Steve also included a full air-ride system into the mix, as well as custom-painted 20-inch Detroit Steel smoothie wheels wrapped in custom Diamondback whitewall tires. The end result is just what he had in mind for the truck—an ultra-low stance with a highly streamlined façade.

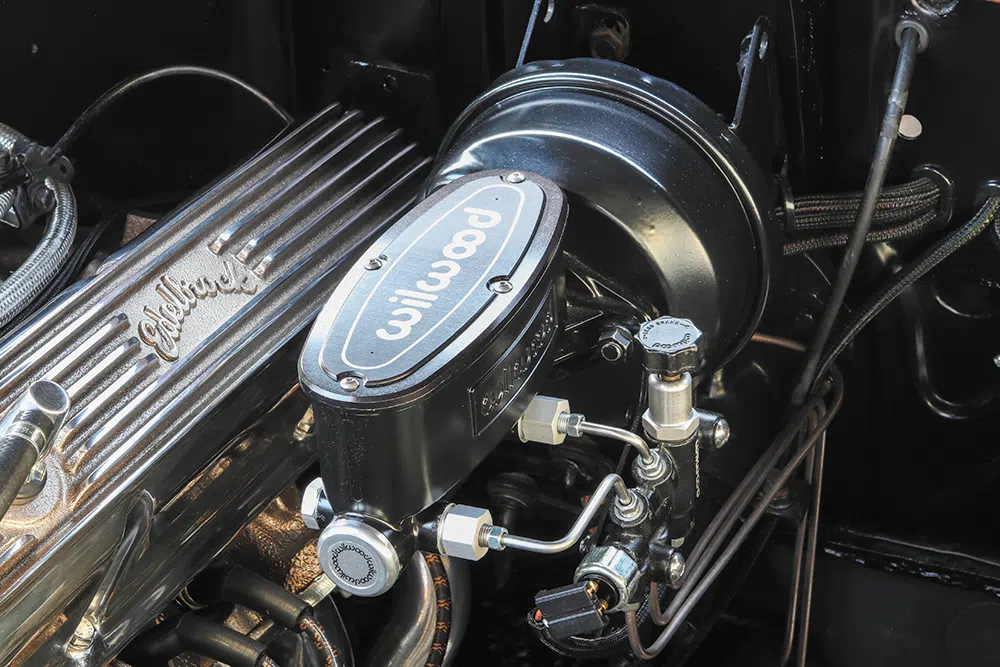

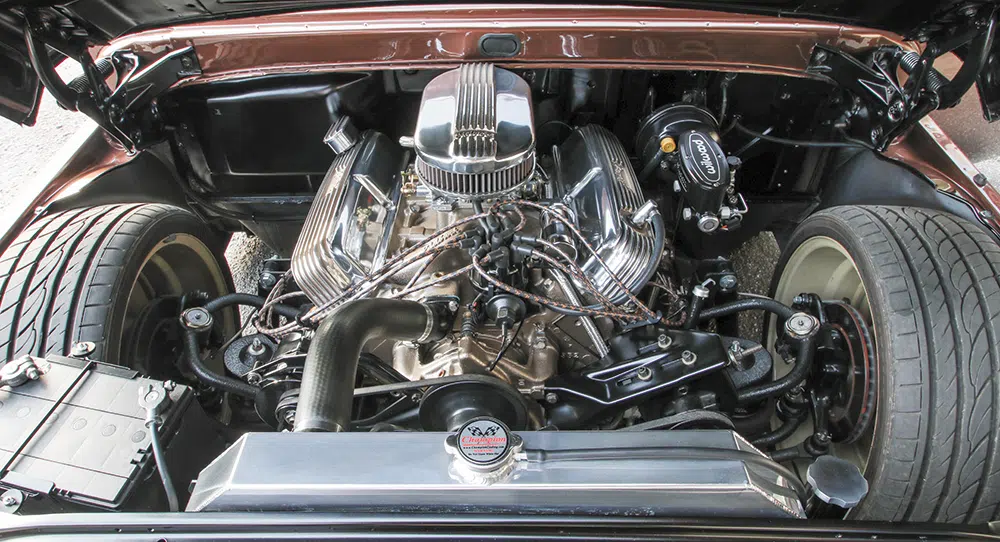

Next, Steve began work on rebuilding the original 1966 Ford big-block FE engine. With some help from Blitz Automotive Inc., which joined this phase of the project with excellent machining work, the process of disassembling and reassembling the engine with a purpose started. Steve cleaned, beefed up, and dressed the tired powerplant and transformed it into a great period-correct inclusion into the project that was quickly becoming a modernized classic pickup. The original three-on-the-tree shifter and Ford 9-inch rearend were also kept to maintain a sense of original character within the transformation.

The interior portion of the overhaul saw a very similar streamlined approach as the rest of the project. While Steve was busy shaving everything from the exterior, he also got rid of the heater vents and radio from the dash to keep things clean inside of the cab.

Following that trend, Steve enlisted the help of Bobby Moore of Evolution Creatives to recover the F-100’s bench seat in fresh vinyl upholstery as well as to whip up a fresh headliner to match. Steve then restored the factory instrument cluster and steering wheel, planted fresh carpeting, and re-chromed all the OEM parts he could. All that, along with the champagne-colored paint applied to the dash and door panels, easily created a nice contrast to the darker exterior color scheme.

In a matter of seven years, Steve’s F-100 evolved from a certified rust bucket into an absolute showstopper. The project didn’t happen overnight, and it definitely wasn’t cheap, but it was a labor of love that he will cherish for years to come.

“I didn’t take any shortcuts with this build and I learned a lot along the way,” Steve says with pride. “Aside from the physical skills I was able to grow, I have learned that through staying persistent, maybe even relentless, my final goal always seemed to remain within reach. It took a lot of hard work and dedication to save money through budgeting and being patient, but I eventually was able to complete my very own personal dream truck.”

Owner

Steve Robinson

Engine

Chassis

Wheels, Tires, & Brakes

Body & Paint

Interior

Share Link