HUMBERTO ORTIZ

.

April 28, 2020

.

c10

HUMBERTO ORTIZ

.

April 28, 2020

.

c10

ONCE UPON A time, right? That’s the way fairytales are usually told, but in the custom car world, seldom are we given the easy path to a happy ending. We have all had that idea or vision for a new project that just seems ambitious and ostentatious, but what happens when you finally start to implement those concepts? Well, for me, a multitude of roadblocks ensue, making things just a little more difficult. Sometimes, because of the big goals we set for ourselves, we find struggles. Because of those struggles, however, there is usually a great ending to a story you didn’t know you were writing.

When I first decided I needed a new project, my eyes were set on a wagon of some sort. The more I thought about it, the more I leaned toward building my own childhood family wagon, a squarebody Chevy Suburban. So, I put the word out and the search began! It didn’t take long to get DMs and text messages saying where I could find a great Suburban—but this is where my struggle began. I was looking for an untouched vehicle that I could just shine up and clean, and then spend all my efforts on the chassis and drivetrain. I wanted to build a new daily that would haul my family, haul some parts and haul ass!

I was looking for an untouched vehicle that I could just shine up and clean, and then spend all my efforts on the chassis and drivetrain. I wanted to build a new daily that would haul my family, haul some parts and haul ass!

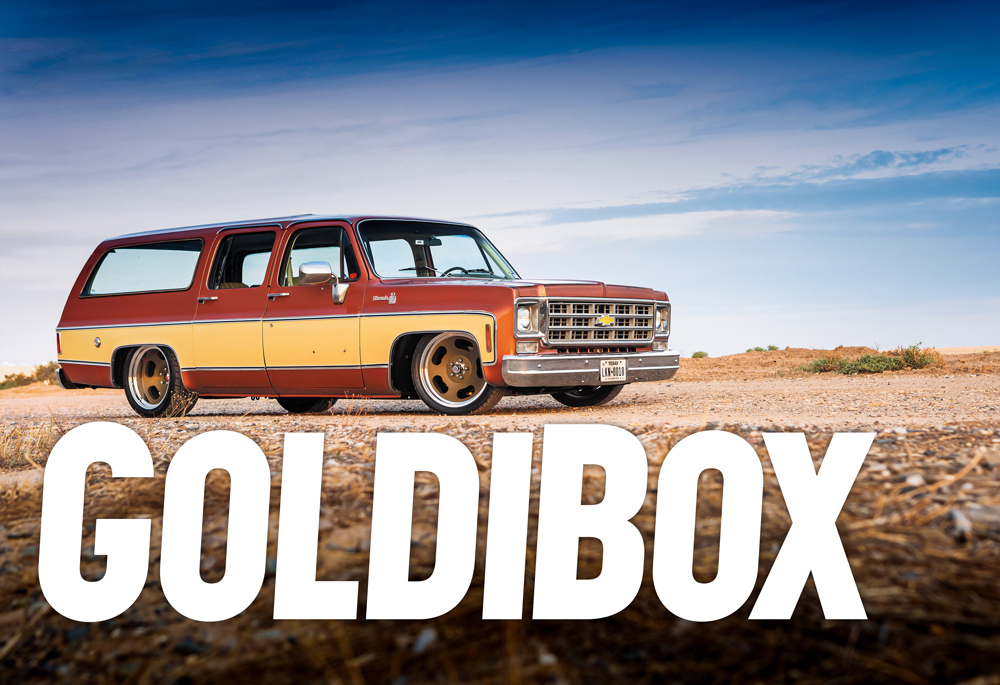

Much like the story of Goldilocks, I began to sift through all sorts of examples with none being quite the right fit, until a friend led me to a really clean Suburban in Washington state. One look at it and I thought to myself, “This is just right.” After some negotiation and lots of questions, I made a deal on the golden 1978 C10 Suburban and had it transported all the way back to Lubbock, Texas, where my shop, Vulcan Specialties, is located. This is when the ideas to build a retro styled suburban really started to flow. I’m a fanatic when it comes to nostalgic hot rods and especially drag racing. So, when I first saw the Suburban, I quickly thought I should build it into a ’70s retro-styled hot rod. Golden-copper hues with a raked stance wearing vintage slot mags and big horsepower were all I could think about.

Having spent a lot of time searching for the right “show quality patina” (as a friend of mine calls it), I assumed I would take a giant leap forward in the build process by skipping all paint and body work, along with the metal work that comes with it. Well, I was wrong. Turns out the individuals I bought the Suburban from were a little dishonest with its condition and I found that out the hard way.

So, having to take a couple steps back, I addressed the extra body damage and rust I was not told about and began to build replacement panels. The lower rear quarters were built from scratch, and then TIG welded in place and planished smooth for a clean look. I opted to keep the finished metal work bare for a couple reasons, but mostly because it gives the ’burb some character. The rest of the body is original GM paint; these particular colors are Russet Metallic over Santa Fe Tan. Then to really bring this old body to life, I enlisted the experienced hands at Distinguished Details in Lubbock, Texas. Quinn and his guys are automotive paint protection and detailing experts. They brought back a dripping wet luster with a series of wet sanding, followed by several different stages of polishing, then finally sealing in all that shine and perfect patina by ceramic coating the entire body.

After addressing the issues with the body, I eagerly moved on to the chassis where I like to spend most of my time during the build process. Having the foresight to know that I might go a little crazy with the horsepower, I thought I should go with the best of the best for the suspension components. Placing a call to GSI Machine and Fabrication out of Arizona was the first thing I did. We talked about their new coilover front crossmember kit and had one built for the project. The engineering on the GSI stuff is spot on and the welding is second to none. The biggest reason for using the GSI front crossmember is the amount of adjustment it has for dialing the ride height in relation to the spring firmness. That spring, by the way, is actually Ridetech’s HQ series coilover with dampening adjustability. Next, I sourced all the rear suspension pieces from Ridetech so that my custom automotive shop could build what I call a competition fourlink. We used Ridetech’s newly developed R-joints along with a pair of HQ coilovers attached to my own adjustable multi-hole bracketry. To compliment the handling duties offered by all these components, I added both front and rear anti-sway bars by Ridetech.

The upgraded horsepower comes by way of a local legend, Don Hardy Race Engines. Donald built a potent 5.3L LS with forged internals for the added boost. The exhaust gasses spin the Precision Turbo through the exhaust manifolds from Hooker Header, and then feed through the Vibrant intercooler and finally into the engine. To add a little style to the engine, a set of Billet Specialties valve cover adapters were added so that the classic script Chevrolet valve covers could be bolted up. All this added air is matched by the upgraded fuel system and the in tank high flow fuel pump and line kit from Tanks Inc. Once the engine starts building power, it is up to the TCI 4L60e Street Fighter Transmission to safely transfer this power to the Chevy 12-bolt rear end with 3.42 gears and Posi-Trac center section. The rear axle was cut down and custom Moser Engineering 30 spline street/strip axles were ordered. To give the Suburban a subtle sound, a Flowmaster 40-series muffler was run in line with the 3.5-inch custom bent exhaust, which exits to rear corner.

To wrap up the nostalgic drag car feel of the ’70s, a set of polished slots were in order. Not just any wheel could be bolted up, however; it needed the right offset and finish to complete the look. So, a set of Indy wheels by US Mags were ordered. A narrow 20×8-inch front wheel was built with a high offset to give the front end a real narrow track width to both lend to that drag race look but also give plenty turning radius with the lowered stance. Out back, a 20×10-inch with a deep dish offset fits just right, coupled with a concave center these slots look the part of a nostalgic drag car. But wait! There’s more! Upon delivery, I took them to my good friend Zach Pennock of BCC Coatings in Cleburne, Texas, to do his magic. Zach looked to Prismatic Powders for the right gold/bronze color to mimic the old Dow-7 coatings done to magnesium wheels in the ’70s. He masked the wheel lip and coated the remainder to give it that magnesium hue that matches the Suburban’s appearance. Once the wheels were done, I knew I had to wrap them in something aggressive, so I picked up some Nittos from my local tire shop, Kings Tire. Keeping all this rolling weight in check are the massive Wilwood Superlite six-piston calipers and 13-inch rotors. These are matched with the Wilwood compact “coffin” master cylinder with proportion valve and make easy work of controlling this family wagon.

The last bit of work was perhaps the easiest part. This is where I practiced the “less is more” theory. With the factory interior being completely original, all I had to do was clean it up a bit and fix some tears. I leaned on my local guys at Mario’s Trim Shop for the excellent work they always produce. They were able to re-dye the door panels back to their original glory while remaking the door pockets and door pulls for each door. Next, they carefully addressed the seats and recovered just the areas that needed attention and cleaned the rest so that all the buckskin material matched like factory. The only interior mod is probably the most disguised but perhaps the most important. I made a call to Dakota Digital for their latest in instrumentation, and they led me to their RTX series, which has a multitude of gauge options and settings. This factory replacement is the perfect way to keep track of all the new vitals coming from that LS powerplant.

This project may have had a few setbacks and may not quite be the fairytale ending, but ultimately it was finished correctly and is ready to log some miles with the family. I have to admit, there is nothing more fun than building a vehicle my whole family can enjoy. It’s even better when that vehicle is capable of 650 hp!

I haven’t lived the longest life just yet, but I have been slapped in the face with quite a few unexpected setbacks when it comes to building cars. We are all faced with roadblocks during a project. Sometimes these quick projects can turn into years of service, but I’ve learned it’s how we solve the problems and learn from our mistakes that makes a finished project that much more enjoyable. My dad always had that kind of influence on me and taught me lessons I didn’t even know were being taught. He showed me how to work with my hands and taught me the meaning of craftsmanship, even if the work wasn’t going to be shown. It’s important that we pass on these lessons to the next generation and share with them the car culture so that our hobby can live on for many generations to come. I just want to say thank you, dad.

[divider]BUILD SPECS[/divider]

OWNER|

HUMBERTO THE EXP ORTIZ

1978 Chevy C10 Suburban

Lubbock, Texas

CHASSIS/SUSPENSION

ENGINE/DRIVETRAIN/ PERFORMANCE

WHEELS/TIRES/BRAKES

BODY/PAINT

Share Link