John Mata Jr.

.

May 01, 2023

.

c10

John Mata Jr.

.

May 01, 2023

.

c10

There are tons of perks to owning your own fabrication shop—the long hours, unrealistic timelines, and, of course, not knowing when your clients will drop off that next check, not to mention having limited time to work on your own projects, which was probably your major motivation for opening up your shop in the first place! Yeah, there are a lot of challenges, but the rewards are usually just as great with lots of hard work and a little bit of luck.

Jason Dvorak, owner of Jay Fab Inc., definitely knows the ups and downs of owning a fab shop, but one of the big drawbacks for Jay is not being able to work on his own rides as much as he’d like to. As frustrating as it can be, though, Jay is also lucky enough to be able to rely on a network of friends and fellow shop owners to help out whenever possible. And after Jay picked up a clean ’67 C10 a couple of years ago, he eventually realized that the truck was spending a lot more time locked up in his garage than it was at the shop getting worked on. Yup, shop-owner life!

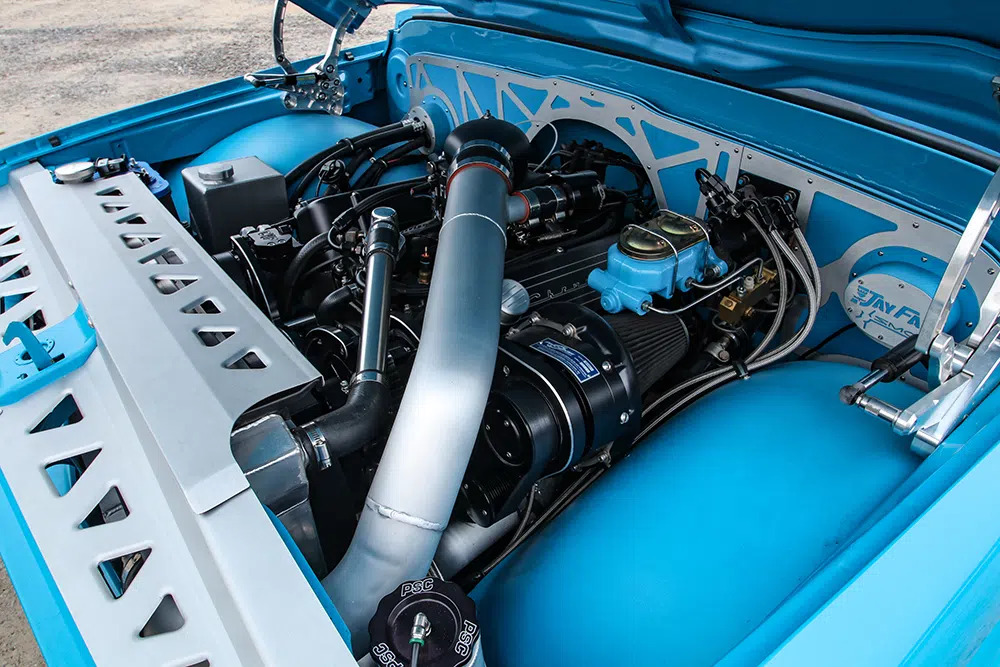

Jay builds a lot of custom parts for hot-rod and custom-truck shops, with one of those shops being Street Metal Concepts. As the shop was known for turning out insane yet classy rides, it just made sense for Jay to entrust his C10 to the SMC crew to do the heavy lifting on his project. Once his turn in the queue was up, Jay dropped off the ’67 for a full revamp, with the first item on the agenda being the suspension.

Jay certainly achieved his goal of having a C10 unlike any other, and thanks to the help from Street Metal Concepts, he didn’t have to leave the truck on the back burner (or jack stands) like so many ill-fated in-house projects are destined to be.

This is where Jay’s expertise came in handy, as he fabbed up a set of custom sheetmetal trailing arms from which to hang the narrowed Currie 9-inch axle housing, which was stuffed with an aluminum third member and limited slip bolted to the 4.11 gearing. A pair of QA1 coilovers kept the rear at just the right height, while another pair of QA1s were bolted on up front between the modified QA1 tubular control arms. Why modified? Well, for one, the arms were originally for an air-ride application, so they needed some tabs and reinforcement for coilovers. Second, when you’re stuffing 24×10-inch Ruthless Forged wheels on the front of a C10, you’re going to have to make some adjustments! The same was obviously true for the rear, since 24x14s don’t just bolt right up. Aside from the aforementioned narrowed axle, oversized rear-wheel tubs had to be fitted to the bed, allowing just enough room for the massive 405/25ZR24 Pirelli tires to roll without any issues.

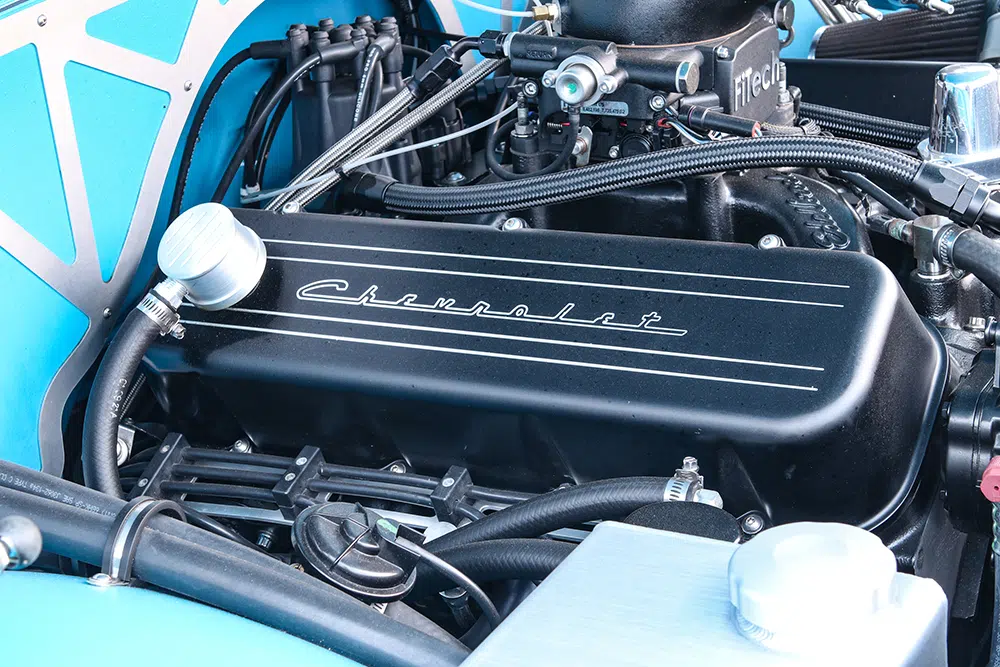

But what good is a set of 405mm-wide rear tires if you don’t have the power to melt them down to the cords? A call to Hendrix Motorsports yielded a 468-cubic-inch big-block, which is fed by a centrifugal ProCharger D-1SC blow-through supercharger setup and FiTech EFI system sitting atop the Edelbrock intake manifold. A standard 700R4 certainly wasn’t going to be able to take the abuse that the engine was ready and willing to dish out, so a built TCI 4L80E was an easy choice to spin the custom aluminum driveshaft and make sure nothing destroyed itself.

Since Jay planned on driving the truck quite a bit, he wanted the interior to not only be comfortable, but also be up to par with the rest of the truck. Again, it’s never a bad bet to go with the best, so he called up TMI Products for a complete blue plaid interior to match the Grabber Blue paint job. With everything built specifically for the truck, the interior was probably the easiest part of the build, which was the perfect way to finish things off before the crew at Street Metal Concepts handed the truck back to Jay to enjoy.

Jay certainly achieved his goal of having a C10 unlike any other, and thanks to the help from Street Metal Concepts, he didn’t have to leave the truck on the back burner (or jack stands) like so many ill-fated in-house projects are destined to be. In fact, he now spends that time taking the C10 to as many shows as possible, which is how we should all be living our lives!

Owner

Jay Dvorak

CHASSIS

DRIVETRAIN

BODY & PAINT

INTERIOR

WHEELS & TIRES

Share Link