Chris Hamilton

.

May 31, 2022

.

c10

Chris Hamilton

.

May 31, 2022

.

c10

Relating a classic truck build to an iconic movie title is a great way to get people to remember your project and point it out at the local truck shows. The concept behind project Rocky was to find an old, retired workhorse of a truck, tear it all the way down to its core, and completely rebuild it into an all new, better version of its original self.

Rocky Balboa is a well-known character in classic cinema, and his story equally relates to the tale we are telling: retired, reborn and eventually re-reigning as the king with the crown, or in this case championship belt. That’s the plan for project Rocky, although I bet we’re going in a different direction than you would expect.

This truck came from the factory in 2WD and we plan to keep it that way since it’s a street truck only. We are not towing anything, and we’re not going off road. We’re simply ripping it around the streets and enjoying a cool, fun, modernized classic truck.

To clear our 22×12 American Force wheels, we will need a bit of a lift kit installed on this truck, but not too tall. We only need to clear a 33-inch-tall Toyo tire, but the width of the wheel will require a tad more height upfront. The best way to get some extra inches out of the front of a classic 2WD truck is to simply replace the spindles. Unfortunately, no one makes lift spindles for a ’73-’87 2WD Squarebody truck. So we had to improvise and use a Rough Country 4-inch lift spindle for an ’88-’98 C1500. The upper and lower control arm ball joints will also have to be swapped to match the spindles.

This is just the beginning of what is expected to be an exciting build. Keep up to date by following us online via social media, and subscribing to both Street Trucks and C10 Builder’s Guide. This will be one of those trucks you want to ride in, and if you see us at a truck show, hop in the passenger seat and let’s go!

How do different spring and shock combinations affect the lift and ride quality?

When it comes to modifying a vehicle’s lift and ride quality, choosing the right combination of springs and shocks is crucial. Different combinations can significantly impact both the height of your lift and the overall comfort and handling of your ride.

Springs:For the front suspension, opting for a set of 4″ lift springs can elevate your vehicle’s stance. Heavy-duty (HD) springs, in particular, are engineered to support additional weight and provide a firmer ride. These springs not only contribute to a higher lift but also improve load-bearing capacity.

Shackle Hangers and Bushings:Upgrading to stronger shackle hangers and high-quality, greaseable Kevlar bushings can enhance durability and ensure smoother pivoting. These components are essential for maintaining the integrity of the lift and offering a more controlled ride.

Steering Components:A 4″ lift steering arm is necessary to correct steering geometry after a lift. Additionally, upgrading to 24″ braided brake lines helps accommodate the increased height without putting stress on the lines, ensuring reliable braking performance.

Sway Bar Disconnect Kit:Including a sway bar disconnect kit allows for better articulation on rough terrain, which improves off-road capability without sacrificing on-road stability.

Springs:For the rear, using longer springs, such as 63″ varieties from larger vehicles, can offer both lift and a softer ride. These longer springs have more flexibility, which helps in smoothing out bumps and rough patches.

Shackle Flip Kit:A 4″ shackle flip kit in the rear provides an efficient way to gain lift without compromising ride quality. This method flips the rear spring shackle, lowering its attachment point and raising the vehicle’s height.

Bushings:Just like in the front, using greaseable Kevlar bushing kits in the rear enhances durability and smoothness. These bushings make the suspension pivot more freely, which translates to a more comfortable ride.

Fuel Tanks:When lifting your vehicle, repositioning things like fuel tanks may be necessary. Installing a rear-mounted, larger capacity fuel tank not only helps with weight distribution but also allows you to move the forward rear spring mounts, fine-tuning the tension on the springs for an optimal balance of load-handling and ride softness.

In summary, combining the right springs and shocks tailored to the front and rear of your vehicle can significantly affect both the lift height and ride quality. Upgrades like greaseable bushings, shackle hangers, steering arms, and brake lines are also essential to complement these changes. The exact setup will depend on your specific needs, whether for increased cargo capacity, off-road capability, or ride comfort.

What Kind of Ride Quality Should Be Expected After Lifting a Truck?

Lifting a truck can significantly alter its ride quality, depending on the method and components you choose. Here’s a breakdown of what you can expect:

Lift blocks are an economical way to raise your truck. They are simple to install and cost-effective, making them a popular choice for many enthusiasts.However, this method may lead to an issue known as axle hop, where the rear wheels bounce excessively on rough terrain. This can impact the overall smoothness and stability of your ride.

On the other hand, a shackle flip involves reversing the orientation of the rear leaf spring shackles. This modification provides a better ride quality compared to lift blocks.Using longer shackles with greaseable bushings can improve ride comfort by allowing more movement. The increased freedom of motion helps in absorbing impacts and bumps more effectively. Unlike the stock setup with rubber bushings, greaseable bushings offer less resistance, making the ride smoother.

Another consideration is upgrading the stock rubber bushings to greaseable urethane bushings. Although a bit pricier, these bushings provide a firmer yet more responsive feel. They are less likely to deteriorate over time compared to rubber bushings and offer enhanced durability and performance.

If you opt for aftermarket rear leaf springs, be aware that you may sacrifice some load-carrying capability for a better ride quality. Aftermarket springs are typically softer, which improves comfort but reduces the weight your truck can carry. You can offset this loss by installing airbags, although this adds to the overall cost.

Lifting your truck with either lift blocks or a shackle flip leaves room for future changes. Should you decide later on to further improve your ride quality, you can still switch out the factory leaf spring pack for something softer or more advanced without much hassle.

In summary, the ride quality after lifting a truck can range from bouncy and unstable to smooth and controlled, based on your choices in components. Lift blocks may be more affordable but could lead to axle hop. Shackle flips and upgraded bushings offer better performance and smoother rides, albeit at a higher cost. Considering these factors will help you make the best decision for your specific needs and budget.

How do air-ride airbags affect the load-carrying capacity and ride quality of a lifted truck?

The provided text does not contain any entities that fall under the specified categories {“Person”, “Organization”, “Address”, “Phone”, “Email”, “Location”, “Website”}. Therefore, it remains unchanged.

Does the truck still need to maintain load-carrying capacity with a lift?

The provided text does not contain any entities that fit the specified categories.

What modifications might be necessary if lifting a truck by more than 4 inches?

Lifting a truck by more than 4 inches requires several key modifications to maintain performance, handling, and safety. Here’s a breakdown of what you’ll likely need to consider:

By addressing these areas, you can ensure your truck handles better, performs reliably, and remains safe even after a significant lift. Always consult with professionals and consider high-quality components for any modifications.

How do you ensure the lift kit components are compatible with each other and the truck?

Achieving a seamless fit between your lift kit components and your truck requires meticulous planning and understanding of various factors. Here’s a detailed guide to help you ensure everything works harmoniously:

Before purchasing any components, take note of your truck’s make, model, year, and existing modifications. This baseline understanding is crucial for selecting compatible parts.

Select a lift height that aligns with your driving needs and tire size preferences. For instance:

The interplay between springs and shocks is vital for ride quality and articulation:

With larger tires, space in the wheel well is limited. Be prepared for potential fender trimming to prevent tire rubbing, especially during articulation. This step is often necessary even with high-quality springs if you aim to maximize tire size.

Lifts alter the geometry of your steering system. Ensure compatibility by:

Beyond the core components, additional modifications might be necessary:

Allocating your budget wisely ensures better compatibility and safety:

Ensuring compatibility of lift kit components with your truck is a complex but manageable task. By carefully considering your truck’s specifications, selecting the right lift height, and choosing compatible springs and shocks, you can achieve a balanced and functional lifted setup. Remember to factor in potential fender trimming and additional modifications to truly maximize your truck’s performance and aesthetics.

What are the benefits of using all springs for a lift compared to other methods?

When considering lifting your vehicle, choosing the right method can significantly affect ride quality, handling, and overall performance. Utilizing all springs for a lift, as opposed to other methods like blocks or body lifts, offers several distinct advantages:

All spring lifts generally provide a smoother ride. Unlike stiffer lift kits, spring lifts can better absorb shocks and bumps, especially when you opt for high-quality leaf springs. This results in a ride that closely mimics the comfort offered by advanced suspension systems like link or coil setups, without the complexity of those conversions.

Springs designed for lifting allow for greater wheel articulation. This is particularly beneficial for off-roading, as your vehicle can maintain better contact with uneven terrain. Although larger tires like 35-inch models may need some adjustment to the fenders, a good spring lift can provide ample clearance while retaining excellent suspension flexibility.

Using springs for a lift distributes the vehicle’s weight more evenly across the suspension. This reduces stress on components like axles, which can be a crucial factor in vehicle longevity. Unlike block lifts that may introduce additional stress points, spring lifts engage more evenly, leading to less wear and tear.

Spring lifts are generally more straightforward to install compared to more complex systems. They often don’t require extensive modifications like cutting or welding, thereby reducing both installation time and cost. In many cases, a spring lift can be installed with just a new set of springs and appropriate shocks, which is both efficient and economical.

Spring lifts often result in better handling characteristics. Compared to body lifts, which can raise the vehicle’s center of gravity significantly, spring lifts maintain a more balanced ride height. This contributes to improved stability, both on-road and off-road, making your vehicle safer and more predictable to drive.

Spring lifts offer a range of customization options. Whether you need a mild lift for daily driving or a more aggressive setup for hardcore off-roading, you can choose from various spring rates and lengths to suit your specific needs. This versatility makes spring lifts a popular choice for many enthusiasts.

Choosing an all-spring lift for your vehicle offers numerous benefits, including superior ride quality, better articulation, reduced component stress, and improved handling. Additionally, it’s often more cost-effective and easier to install than other lifting methods, making it an attractive option for anyone looking to enhance their vehicle’s performance and aesthetics.

What are the advantages and disadvantages of different lift options, such as blocks, shackle flip, or springs?

When considering different lift options for your vehicle, it’s important to weigh the pros and cons of each method. Here’s a detailed look at the three main types: blocks, shackle flip, and springs.

Advantages:

Disadvantages:

Selecting the right lift option depends largely on your specific needs and budget. Lift blocks are ideal for those seeking a cost-effective, easy installation but come with performance trade-offs. Shackle flips offer improved ride quality and ground clearance but require a more complex installation process. Springs provide the best handling and ride comfort but come at a higher cost.

Evaluate your driving habits, vehicle use, and budget to make the best choice for your lift needs.

What are the different lift options available for my truck?

If you’re considering upgrading to 35″ or 37″ tires, it’s crucial to know the various lift options available and how they can meet your needs. Below, you’ll find a breakdown of different lift systems to help you make an informed decision.

Purpose: Leveling kits are designed to even out the front and rear suspension heights.

Benefits:

Considerations:

Purpose: Body lifts raise the truck’s body higher on its frame without altering the suspension geometry.

Benefits:

Considerations:

Purpose: Suspension lifts use modified or replaced components to elevate the entire vehicle.

Benefits:

Considerations:

Choosing the right lift depends on your needs, budget, and driving conditions. Whether you opt for a leveling kit, body lift, or suspension lift, enhancing your truck’s performance and appearance can be a rewarding experience.

What are the potential issues with frame cracking at the steering box when lifting a truck?

Lifting your truck can enhance its off-road capabilities and provide an imposing look, but it also brings potential complications. One significant issue is frame cracking at the steering box. Here’s what you need to know:

Lifting a truck can introduce stress points that may lead to frame cracking, particularly around the steering box. By adding reinforcement like a steering box brace and addressing sway bar issues, you can mitigate some of these risks and enjoy a smoother ride. Regular inspections and choosing high-quality components will go a long way in ensuring your lifted truck remains robust and reliable.

What are the potential issues with using Rough Country springs for a lift?

When considering aftermarket springs for a vehicle lift, it’s crucial to understand the potential drawbacks. Here are some issues associated with using Rough Country springs:

In summary, when opting for these springs, weigh the balance between their affordability and the potential need for further modifications to ensure a satisfactory driving experience.

What is the impact of lifting on the front sway bar and how can it be mitigated?

When you lift a vehicle, the front sway bar is directly impacted, which can lead to decreased stability and handling issues. The altered angle places additional stress on the sway bar, potentially causing poor performance during turns and uneven terrain navigation. Here’s how you can mitigate these issues:

By implementing these measures, you can effectively mitigate the impact of lifting on the front sway bar and maintain both performance and safety.

Is Crossover Steering Necessary for Highway Driving With a Lifted Truck?

For those with lifted trucks, especially when driving on highways, crossover steering can be a crucial consideration. Here’s a detailed look at why you might need this upgrade:

While not absolutely necessary, crossover steering is highly recommended for highway driving with a lifted truck. It significantly enhances control, stability, and safety, which are crucial for a smooth and predictable driving experience. If you’re planning to frequently drive on highways, upgrading to a crossover steering system can offer peace of mind and improved performance.

Do You Need to Install a Drop Steering Arm When Lifting a Truck?

When lifting a truck, the question of whether you need a drop steering arm is critical for maintaining proper handling and steering geometry. Here’s an in-depth look at why and when you might need to install one:

Lifting a truck typically raises its center of gravity, which can impact the steering linkage and alter the truck’s handling. Stock steering components are designed for the original height and suspension of the truck. When you significantly lift the vehicle, the angles of these components change.

Regardless of steering components, the type of lift springs used can affect ride quality. Some lift spring brands are known for a very stiff ride, so be sure to choose springs that provide a balance between height and comfort according to your preference.

So, do you need to install a drop steering arm when lifting a truck? The answer largely depends on how much you’re lifting the vehicle. For lifts over 4 inches, it’s highly advised to use a drop steering arm to correct the steering geometry and maintain safe handling characteristics. For moderate lifts, it might not be necessary, but it can offer added insurance against future steering issues.

What are some considerations for lifting the front versus the rear of the truck?

Lifting a truck can enhance its off-road capabilities and provide a more aggressive stance. However, different approaches are required for lifting the front and the rear. Here’s what you need to know about each:

Lifting your truck’s front and rear involves balancing cost, performance, and long-term goals. Researching and selecting the appropriate method will ensure you get the best out of your investment.

What are the benefits of crossover steering for lifts over 4″?

When it comes to lifted trucks with over 4-inch lifts, crossover steering offers several advantages that can significantly improve both your on-road and off-road experiences.

Crossover steering shines when your truck is fully articulated on challenging trails. This steering setup allows for improved control and stability, making it easier to navigate uneven and rocky terrains. The design minimizes bump steer, which happens when your wheels are forced to turn left or right as they travel over bumps, thereby offering a smoother ride.

One notable benefit is the reduction in frame flex. By triangulating the front frame and crossmember through a steering brace, you can considerably mitigate the flexing and twisting of the frame. This is particularly noticeable in trucks with larger tires, where the added stress can cause significant movement.

While some drivers might prefer traditional steering for highway driving, crossover steering can still offer a performance boost. The steering mechanisms are generally more robust, providing better alignment and responsiveness, especially useful when dealing with high-speed maneuvers or sudden lane changes.

If you’re unsure about the condition of your current steering setup, you can perform a simple test:

You’ll likely notice how much the frame flexes under stress, an issue that crossover steering can significantly reduce.

Crossover steering is a valuable upgrade for trucks with lifts over 4 inches, offering improved handling on rugged trails, reducing frame flex, and potentially enhancing highway driving stability. If you frequently venture off-road, this steering system can make your driving experience safer and more enjoyable.

What is a Steering Box Brace and When Might You Need One?

When lifting a truck, several modifications become necessary to ensure both safety and performance. One significant component to consider is a steering box brace.

A steering box brace is a device designed to strengthen and support the steering box section of the vehicle’s frame. It’s particularly important for vehicles that experience a lot of stress in this area, such as trucks with oversized tires or those used for off-roading.

A steering box brace is an invaluable addition to any truck, particularly those that have been lifted or outfitted with larger tires. It provides crucial reinforcement to the vehicle’s frame, ensuring longevity and reliability under demanding conditions. Understanding when to install one can save you from costly repairs and enhance your driving experience.

What are the differences between remanufactured and brand new steering boxes?

Choosing between a remanufactured and a brand new steering box can be crucial for your vehicle’s performance and longevity. Here’s a breakdown to help you make an informed decision:

Pros:

Cons:

Pros:

Cons:

Here are some factors to consider when deciding which type of steering box to purchase:

Making an informed decision about steering boxes can greatly impact your vehicle’s performance and safety. Always weigh the pros and cons before you invest.

What are some recommended brands for lift springs and kits?

When considering lift springs and kits, several reputable brands stand out for their quality and reliability:

By opting for brands such as Tuff Country, Old Man Emu, Bilstein, Rancho Suspension, or Skyjacker, you can enhance your vehicle’s performance and handling tailored to your specific needs.

Do You Need to Lengthen the Rear Drive Shaft When Lifting a Truck?

When lifting a truck, one common question that arises is whether the rear drive shaft needs to be lengthened. The answer isn’t always straightforward and largely depends on the extent of the lift and the specific vehicle model.

In summary, whether you need to lengthen the rear drive shaft when lifting a truck hinges on multiple factors such as the height of the lift, specific vehicle model, and the intended use of the truck. Taking these into account will help ensure your truck remains safe, reliable, and performs flawlessly.

How does a drop Pitman arm compare to a drop drag link for the front lift?

When it comes to lifting your vehicle’s front end, the choice between a drop Pitman arm and a drop drag link is crucial for both performance and safety. Let’s dive into the differences and see which option might be best for your needs.

A drop Pitman arm is specifically designed to correct the steering geometry after lifting the front end of your vehicle. Here are some of its advantages:

However, it does have some limitations:

Drop Drag Link: The Alternative

A drop drag link, on the other hand, connects directly to the steering knuckle, offering a different approach to managing lifted steering geometry. Here’s why you might consider it:

However, there are a few considerations to keep in mind:

If your lift is modest—up to 4 inches—a drop Pitman arm should suffice, offering a blend of affordability and ease of installation. For higher lifts, especially over 4 inches, a drop drag link, or even a crossover steering system, becomes a better option, providing superior performance and stability.

Choosing between the two depends largely on the lift height and your specific driving needs. Always consider getting professional advice tailored to your vehicle’s specifications for optimal results.

What are some recommended lift kits for a truck?

If you’re considering larger tires, like 35″ or 37″ AT tires, you’ll need a lift kit. With a range of options available, here’s a breakdown to help you choose the best lift system for your truck.

Suspension lift kits are a comprehensive solution, offering benefits beyond mere tire clearance. They typically include new shocks, springs, and other components designed to enhance your vehicle’s off-road capabilities.

Body lift kits raise the body off the frame, giving you additional tire clearance without altering the suspension.

Leveling kits focus on correcting the factory rake, where the front of the truck sits lower than the rear. These kits are perfect if you want a slight lift to accommodate larger tires without a full suspension overhaul.

Selecting the right lift kit can transform your truck’s appearance and performance. With the aforementioned options, you can make an informed decision that suits your requirements.

What is the minimum lift required to fit 35″ tires on my truck?

When fitting 35″ tires on your truck, ensuring the proper lift is crucial for adequate clearance and performance. The minimum lift you’ll need depends on the specific model and weight class of your vehicle.

By adhering to these recommendations, you can confidently fit 35″ tires on your truck without compromising safety or performance.

Do you need to replace the front brake hoses when lifting a truck?

When lifting a truck, you do need to consider replacing the front brake hoses. Lifting your truck alters the geometry of your suspension and steering components, which can impact the length and tension of your brake hoses.

In summary, replacing the front brake hoses is a crucial step when lifting your truck to ensure safety and maintain proper brake functionality. Always select quality parts and follow correct installation procedures to get the best results.

How Does the Budget Affect the Choice of Lift Kit?

When planning to upgrade your vehicle with a lift kit, the budget plays a crucial role in determining your options. Here’s how:

Practical Example:If your current budget doesn’t allow for a complete high-end lift kit build, you might start with a basic suspension lift and add premium shocks or leaf springs as your budget permits. Over time, your vehicle will gradually transform, spreading out the financial impact.

Conclusion:Ultimately, your budget will dictate the lift kit choices and the customization pace. Carefully research and plan your purchases to balance quality, performance, and cost effectively.

How Does the Cost of a Lift Kit Affect Its Quality?

When evaluating the cost and quality of a lift kit, it’s essential to understand how investment correlates with overall performance and durability.

In many cases, the adage “you get what you pay for” holds true. More expensive lift kits usually incorporate higher-quality materials and more advanced engineering, offering superior performance and longevity. When you invest in a premium lift kit, you’re often paying for:

However, this doesn’t mean that more affordable kits are outright inferior. They can still provide excellent performance, especially for moderate off-road use or drivers who don’t demand the utmost from their vehicles.

Rear Lift Options

The rear lift options—blocks, shackle flips, or new springs—all come with their pros and cons:

Front Lift Options

For the front, the selection of components becomes critical, particularly beyond a 4-inch lift:

In summary, the cost of a lift kit is generally a good indicator of its quality and suitability for heavy-duty usage. Whether you’re lifting the rear with blocks or new springs, or adjusting the front with a drop Pitman arm or crossover steering, investing in a more expensive kit can lead to better performance, durability, and overall satisfaction. However, always consider your specific needs and usage to make the best choice for your vehicle.

How Does Off-Roading Use Affect the Choice of Lift Kit?

Choosing the right lift kit for your off-roading needs can significantly impact your vehicle’s performance and durability. Here’s a detailed guide to help you make an informed decision.

1. Cost vs. Quality

Generally, the more expensive the lift kit, the better the quality. Investing in a high-quality kit can save you money in the long run by reducing wear and tear on your vehicle.

2. Type of Lift: Rear vs. Front

3. Lift Height and Tire Size

For those planning to use 35-inch tires, a minimum of 4 inches of lift is recommended for most vehicles. In some cases, heavier-duty vehicles may require only a 3-inch lift due to their higher starting stance.

4. Ride Quality

Specific spring types can dramatically affect your ride:

5. Expert Advice

Experience varies, so consulting someone with extensive off-roading experience can provide invaluable insights tailored to your specific needs.

By evaluating these factors, you can select a lift kit that enhances your vehicle’s performance, ensuring a safer and more enjoyable off-roading experience.

Are there any good YouTube tutorials on installing a lift kit?

If you’re considering installing a lift kit to accommodate 35″ or 37″ all-terrain tires, you’ll find numerous YouTube tutorials to help guide you through the process. Here are some tips on finding the best ones:

Remember, installing a lift kit can be complex and might also tie into other jobs, like replacing your steering gearbox. Make sure the tutorial addresses any interconnected tasks to ensure a smooth installation process.

What Size Tires Can I Fit on My Truck Without a Lift?

When considering what size tires you can fit on your truck without a lift, it’s essential to understand the limitations and potential modifications needed for different scenarios.

If you’re willing to do some minor modifications, such as fender trimming, you might squeeze in slightly larger tires without a lift:

The type of tire and the condition of your suspension will also impact fitment:

The wheel well size is a crucial factor irrespective of other modifications. Larger, more capable springs that articulate well could cause rubbing with 35-inch tires, necessitating either a lift or trimming.

Understanding the interplay of tire size, suspension type, and potential modifications will help you make an informed decision about what fits best for your truck without lifting it.

What additional parts and modifications might be necessary when installing a lift kit?

To clear our 22×12 American Force wheels, we will need a bit of a lift kit installed on this truck, but not too tall. We only need to clear a 33-inch-tall Toyo tire, but the width of the wheel will require a tad more height upfront. The best way to get some extra inches out of the front of a classic 2WD truck is to simply replace the spindles. Unfortunately, no one makes lift spindles for a ’73-’87 2WD Squarebody truck. So we had to improvise and use a Rough Country 4-inch lift spindle for an ’88-’98 C1500. The upper and lower control arm ball joints will also have to be swapped to match the spindles.

When installing a lift kit, several additional parts and modifications might be necessary to ensure the job is done right and the truck performs optimally:

Both options allow you to maintain flexibility. If you change your mind later, you can still swap out the factory pack for something softer.

The parts for these upgrades can add up to $400-$500 if you go for quality components. This includes:

These modifications, while adding to the initial cost, will ensure a smoother ride and better handling. They also provide the flexibility to make future adjustments as your needs evolve.

What are the steps involved in installing a lift kit on a truck?

To clear our 22×12 American Force wheels, we will need a bit of a lift kit installed on this truck, but not too tall. We only need to clear a 33-inch-tall Toyo tire, but the width of the wheel will require a tad more height upfront. The best way to get some extra inches out of the front of a classic 2WD truck is to simply replace the spindles. Unfortunately, no one makes lift spindles for a ’73-’87 2WD Squarebody truck. So we had to improvise and use a Rough Country 4-inch lift spindle for an ’88-’98 C1500. The upper and lower control arm ball joints will also have to be swapped to match the spindles.

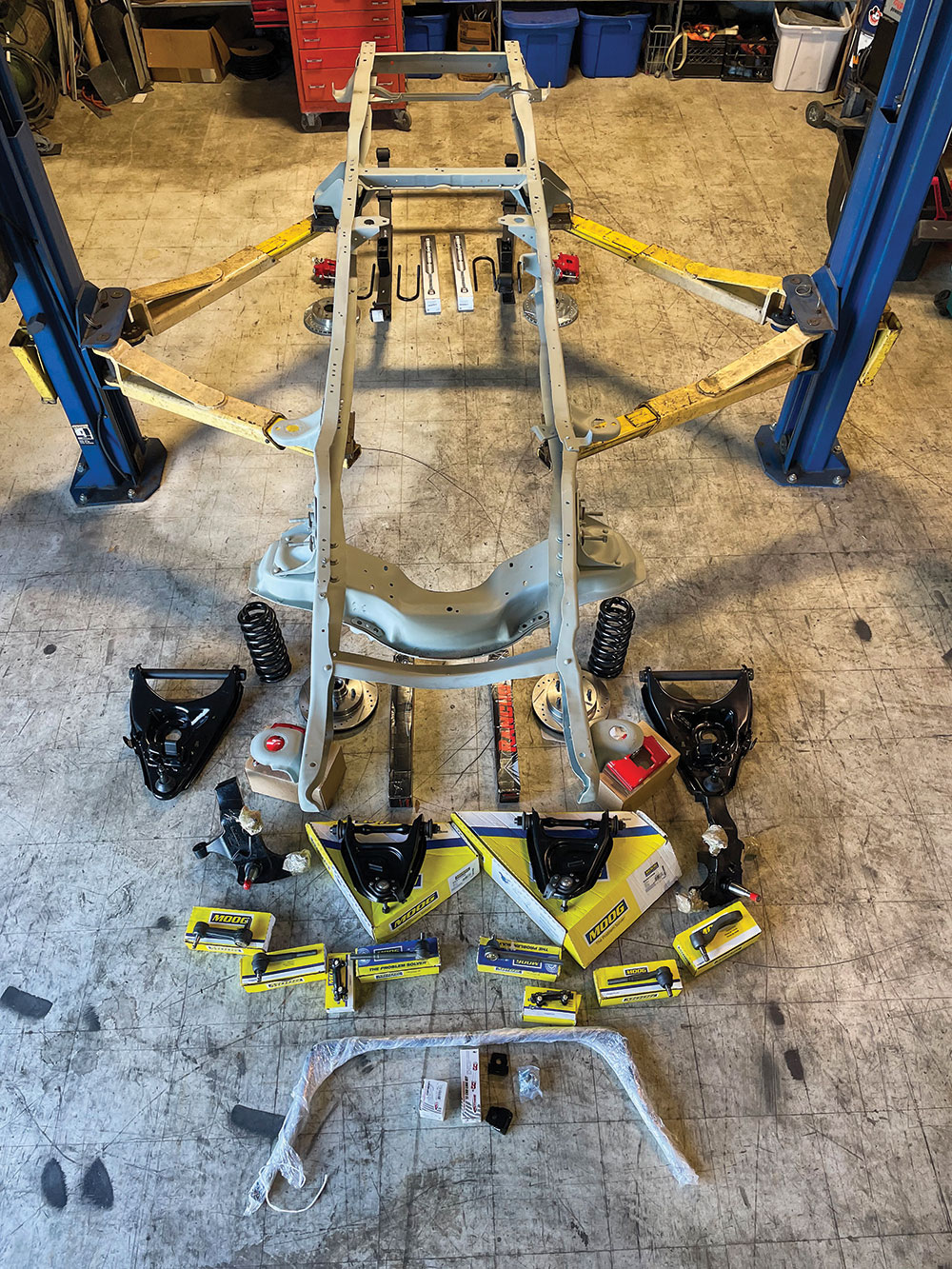

Now that the body is removed, we can start on the frame rails. With the factory suspension removed, we brought it over to the sandblaster to clean all the metal.

The first new part from Rock Auto are the upper control arms. These are factory original for ’79 Chevy C10 HD trucks with ’88-’98 TTX ball joints from Mevotech. The lower control arms are also from a ’79 ChevyC10 HD truck with ’88-’98 ball joints. The trick to the lift is this 4-inch lift spindle for ’88-’98 Chevy trucks. With the swapped out ball joints, everything matches up correctly.

What size tires can I fit on my truck with a lift?

“To clear our 22×12 American Force wheels, we will need a bit of a lift kit installed on this truck, but not too tall. We only need to clear a 33-inch-tall Toyo tire, but the width of the wheel will require a tad more height upfront.

When considering larger tires like 35″ or even 37″, different lift heights are necessary. Generally, a 4-inch lift is the minimum required for 35″ tires, especially on a 3/4 ton truck. However, if you’re driving a 1-ton truck, you might get away with a 2-3 inch lift due to the higher default clearance.

When installing a lift kit, you might need to:

If you go beyond a 4-inch lift, all these modifications become necessary.

In summary, while a moderate lift can accommodate larger tires, always consider the additional modifications and costs involved to ensure a smooth and safe ride.”

Can the coilover conversion be done only in the front suspension?

Absolutely, you can choose to perform the coilover conversion on just the front suspension. This option provides a significant upgrade in ride quality and performance while remaining budget-friendly. By retaining the leaf springs in the rear, you achieve a blend of improved handling and cost-effectiveness.

Many off-road enthusiasts and restoration projects opt for this partial conversion to enhance the front end and enjoy much of the coilover benefits without committing to a full swap. Whether aiming for a smoother ride, better suspension articulation, or improved shock absorption, focusing the conversion on the front suspension is a viable and efficient choice.

For those looking to maximize performance, a 4-link setup with coilovers on both the front and back is available. However, starting with just the front suspension allows for customization and gradual upgrades based on your needs and budget.

What are the benefits of the custom spring lift kit for these trucks?

If you’re considering a custom spring lift kit for your truck, particularly models from 1973 to 1991, you’re probably curious about the advantages it offers. Here’s why this upgrade might be exactly what you need:

By investing in a custom spring lift kit, you’re not just lifting your vehicle; you’re enhancing its overall functionality and performance, making it a smart choice for passionate truck enthusiasts.

What are the options for rear coilover conversion kits, and how much do they cost?

Looking to upgrade your vehicle’s suspension? Rear coilover conversion kits can enhance your ride’s performance, offering a smoother and more controlled driving experience. Here’s a breakdown of the available options and their respective price ranges:

Each option caters to different needs and budgets, ensuring you can find the perfect rear coilover conversion kit for your vehicle.

What are the options for front coilover conversion kits, and how much do they cost?

When it comes to upgrading your vehicle’s suspension, front coilover conversion kits offer a significant enhancement. These kits come with various options to suit different needs and budgets. Here’s a breakdown of what’s available:

Consider your driving needs, whether it’s daily commuting or rugged off-road adventures, to select the appropriate kit. Both Fox and King options cater to distinct preferences and performance demands.

What is the price range for the custom spring lift kit?

The custom spring lift kit, specifically made for 1973-1991 GM/Chevy trucks, ranges from $33.00 to $4,454.80. This pricing reflects variations in the lift height, which can be tailored from 2 to 7 inches, and the customization level to enhance ride quality and wheel travel.

What options are available for the standard spring lift kit?

When considering a standard spring lift kit, there are numerous options to suit your needs. This customizable kit offers lift choices ranging from 2 to 12 inches. Here’s what you can expect:

When you’re ready to enhance your vehicle’s capabilities, simply add your selected configuration to a wish list or directly to your cart. You can also compare different configurations to ensure you’re making the best choice for your needs.

What are the features of the budget spring lift kits for these trucks?

Looking to elevate your truck without breaking the bank? Our budget spring lift kits are designed to offer just that. Here’s what they bring to the table:

So, whether you’re looking for a temporary boost or a stepping stone to more extensive modifications, our budget spring lift kits have you covered.

What are the features of the 4-link coilover conversion kits?

Experience unparalleled ride quality and performance with our versatile 4-link coilover conversion kits. Designed for both restoration projects and rock crawlers, these kits offer customizable options to suit your specific needs.

This level of flexibility and performance can significantly elevate your vehicle’s capabilities, providing seamless control and a smooth, enjoyable ride.

What is the price range for the standard spring lift kit?

The standard spring lift kit, designed for 1973-1991 GM/Chevy trucks, offers a customizable lift ranging from 2 to 12 inches. The price for this kit can vary significantly, starting at an affordable $33.00 and extending up to $3,094.18, depending on the specific components and spring brands selected.

How much does a 6″ budget spring lift kit cost for 1973-1991 GM/Chevy trucks?

If you’re looking to elevate the height of your 1973-1991 GM or Chevy truck with a 6-inch budget spring lift kit, you’ll find that prices generally start around $1,037.50. This cost can vary depending on the specific features and components included with the lift kit. It’s essential to compare different kits from various third-party brands to find the one that best suits your needs and budget.

How much does a 4″ budget spring lift kit cost for 1973-1991 GM/Chevy trucks?

If you’re looking to elevate your 1973-1991 GM or Chevy truck, a 4-inch budget spring lift kit will set you back starting around $789.10. This price can vary depending on additional features or components, but it’s a solid starting point for those exploring offroad enhancements. Be sure to compare third-party brands to ensure you’re getting the best value and quality for your truck upgrade needs.

What are some of the featured products related to lift kits for 1973-1991 GM/Chevy trucks?

The first new part from Rock Auto are the upper control arms. These are factory original for ’79 Chevy C10 HD trucks with ’88-’98 TTX ball joints from Mevotech. The lower control arms are also from a ’79 ChevyC10 HD truck with ’88-’98 ball joints. The trick to the lift is this 4-inch lift spindle for ’88-’98 Chevy trucks. With the swapped out ball joints, everything matches up correctly. Cotter pins complete the front and now we can focus on the steering.

To enhance the ride height and performance of your 1973-1991 GM/Chevy trucks, consider these featured lift kit products:

These options are designed to give your truck a personalized touch, ensuring that every component functions seamlessly with existing parts. Whether you’re looking to upgrade for off-road adventures or simply enhance the truck’s stance, these kits offer reliable choices tailored to the classic GM/Chevy lineup.

What are the options for spring lengths in these lift kits?

Spring lengths for the front include options like 52 inches, while the rear springs are available in lengths such as 60 and 64 inches, allowing for precise customization.

Are there any additional drivetrain components available?

Yes, the Magnum Underdrive is offered, providing an option for those looking to enhance their drivetrain performance.

What are the specific components available for customizing suspension in these trucks?

Custom front and rear springs are available, with various length options to tailor the suspension setup, enhancing performance and ride quality.

What are the prices for these lift kits and related components?

The 6″ lift kit starts at approximately $1,037.50, while the 4″ lift kit is priced from around $789.10. Prices for other components vary, such as custom front springs starting at $980.00.

What are the available lift kits for 1973-1991 GM/Chevy trucks?

There are 6″ and 4″ lift kits available specifically designed for these trucks, offering a choice depending on the desired lift height.

What types of lift kits are available for 1973-1991 GM/Chevy trucks?

If you’re considering upgrading to 35″ or 37″ tires, it’s crucial to know the various lift options available and how they can meet your needs. Below, you’ll find a breakdown of different lift systems to help you make an informed decision.

Purpose: Leveling kits are designed to even out the front and rear suspension heights.

Benefits:

Considerations:

Purpose: Body lifts raise the truck’s body higher on its frame without altering the suspension geometry.

Benefits:

Considerations:

Purpose: Suspension lifts use modified or replaced components to elevate the entire vehicle.

Benefits:

Considerations:

When it comes to 1973-1991 GM/Chevy trucks, there are several specific lift kit options to consider that can transform your vehicle’s performance and aesthetic.

For those seeking affordability without sacrificing quality, budget spring lift kits are available in both 4″ and 6″ versions. These kits offer a practical solution for moderate lifting needs.

Standard spring lift kits provide a range of lift from 2 to 12 inches, allowing for flexibility based on your desired height. For a more personalized setup, custom spring lift kits deliver enhanced ride quality and increased wheel travel, specifically designed for your truck. These can be tailored for 2 to 7 inches of lift.

For a more advanced upgrade, consider front and rear coilover conversion kits featuring renowned options like Fox and King shocks. These kits offer extensive customization and superior suspension performance, with price ranges accommodating various budgets.

Choosing the right lift depends on your needs, budget, and driving conditions. Whether you opt for a leveling kit, body lift, or suspension lift, enhancing your truck’s performance and appearance can be a rewarding experience. By understanding the specific options available for your 1973-1991 GM/Chevy truck, you can ensure a choice that aligns perfectly with your automotive aspirations.

What are the differences between front and rear coilover conversion kits?

The front and rear coilover conversion kits differ mainly in their application locations (front vs. Rear) and offer options in shock brands, with the price for each varying based on whether Fox or King shocks are selected. The rear kits have slightly lower pricing compared to the front kits.

What are the specific features and specifications of each lift kit type?

Budget spring lift kits offer a cost-effective lift solution, while standard spring lift kits provide a range of lift heights with off-the-shelf spring brands. Custom spring lift kits are designed for improved ride quality and increased wheel travel. Coilover conversion kits allow for high-performance shock upgrades and are available for both front and rear applications.

What customization options are available for these lift kits?

Customization options include choosing the lift height for standard spring kits (2″ to 12″) and custom spring kits (2″ to 7″), as well as selecting between different brands of shocks (Fox or King) for the coilover conversion kits.

What are the price ranges for these lift kits?

Pricing for the lift kits varies: budget spring lift kits start at approximately $789.10, standard spring lift kits range from $33.00 to $3,094.18, custom spring lift kits range from $33.00 to $4,454.80, and coilover conversion kits are priced from $60.00 to $7,414.50, depending on the configuration and brand of shocks chosen.

What are the specific lift kit options available for 1973-1991 GM/Chevy trucks?

The available lift kit options include budget spring lift kits in 4″ and 6″ configurations, standard spring lift kits with customizable lift heights from 2″ to 12″, custom spring lift kits specifically crafted for lift heights between 2″ and 7″, and both front and rear coilover conversion kits with choices of Fox or King shocks.

How do body lift kits and coil spring spacers compare in terms of safety and effectiveness?

When considering ways to lift a 2WD vehicle, body lift kits and coil spring spacers both present viable options. However, they differ in terms of safety and effectiveness, making it crucial to understand their pros and cons before proceeding.

Effectiveness:

Safety Considerations:

Effectiveness:

Safety Considerations:

Both body lift kits and coil spring spacers can be effective ways to elevate a vehicle, enhancing aesthetics and function. However, they each come with specific safety considerations that must be acknowledged. Always prioritize quality components and professional installation to ensure safety and optimal performance.

Are there any successful case studies of lifted 2wd trucks that could provide guidance?

For truck enthusiasts considering lifting a 2WD vehicle, it’s crucial to balance excitement with safety and performance. While the process is more commonly associated with 4WD trucks, there are successful cases and methods that can guide you through a 2WD lift.

Lifting a 2WD truck can be both successful and rewarding, offering enhanced ground clearance and a more aggressive look. By learning from proven strategies and case studies, you can approach your project with confidence and clarity.

What tire options can contribute to a lifted appearance without modifying suspension?

If you’re looking to elevate your vehicle’s appearance without diving into suspension modifications, the right tires can make a significant difference. Here’s how you can achieve that desired look:

While these options provide a more elevated look to your vehicle, ensure that any changes align with manufacturer guidelines to maintain safety and performance standards.

Is it safe to use coil spring clamps for lifting a truck?

When considering lifting your truck, safety should be the top priority. Coil spring clamps might seem like a quick and cost-effective solution, but they come with significant risks. Here’s why they might not be the best choice:

Instead of using coil spring clamps, explore these safer options:

In conclusion, it is recommended to avoid using coil spring clamps due to their risks. Instead, invest in a solution designed specifically for vehicle lifting, ensuring both safety and performance.

Is it possible to swap a 4wd chassis under a 2wd truck?

Swapping a 4WD chassis under a 2WD truck is certainly possible, but it requires careful planning and execution. Here’s what you need to know:

While feasible, swapping a 4WD chassis under a 2WD truck is a complex project that requires a lot of resources and skills. Carefully assess whether you’re prepared for the time and cost involved.

Are there any community opinions on lifting versus lowering trucks?

When it comes to the debate of lifting versus lowering trucks, enthusiasts in the truck community have a plethora of opinions, each backed by experiences and personal preferences.

Pros:

Cons:

Pros:

Cons:

Opinions differ greatly, with some enthusiasts advocating for keeping trucks at stock height and simply modifying tire sizes for a moderate lift effect. This approach maintains a balance between aesthetics and functionality without compromising safety.

For those contemplating a lift, alternatives like purchasing a 4WD model are suggested, particularly if off-roading is a goal. This step avoids the complex modifications that can lead to safety issues.

Ultimately, the decision to lift or lower a truck depends heavily on intended use and personal preference. Enthusiasts stress the importance of safety and practicality, advising thorough research and consultation with professionals before making significant modifications.

What are the benefits of switching to a 4×4 truck instead of lifting a 2wd?

When considering the leap from a two-wheel drive (2WD) to a four-wheel drive (4×4) truck, it’s important to weigh the benefits that come with this transformation. Here’s why opting for a 4×4 might be your best choice:

In conclusion, making the switch to a 4×4 truck doesn’t just offer practical benefits; it lends an appeal and level of performance that elevates your driving experience. Whether for adventure or utility, a 4×4 option can deliver where modified 2WD trucks may fall short.

What are some considerations when planning to lift a truck with children passengers?

When planning to lift a truck with children passengers, safety must be your top priority. Here are some key considerations to keep in mind:

By thoroughly considering these factors, you’ll ensure that your truck remains a safe and reliable mode of transportation for you and your children.

How can I lift a 1968 2wd Chevrolet C10 truck?

Lifting a 2WD 1968 Chevrolet C10 truck can enhance its appearance and potentially improve its functionality. However, it’s essential to approach this modification with caution as it can alter the vehicle’s steering angles, impacting ride quality and safety. Here are some ways to achieve a lifted look:

By carefully choosing the right lift method and prioritizing safety, you can successfully elevate your C10 truck while maintaining its reliability and roadworthiness.

Are there any aftermarket solutions for lifting a 1968 2wd C10 safely?

Lifting a 1968 2WD C10 truck can enhance its aesthetic appeal and off-road capabilities. However, safety is a primary concern due to the changes in steering and ride dynamics. Here’s what you need to know:

For a comprehensive lift, swapping out the existing 2WD chassis for a 4WD version might be necessary. This option allows for better compatibility with coil setups, but it is a significant undertaking that requires expertise.

While lifting a 1968 2WD C10 is achievable, selecting the correct aftermarket solutions is essential for safety. Consult with professionals or experienced enthusiasts to ensure that any modifications make your truck both stylish and safe on the road.

Are there lift kits available for a 1968 2wd C10 with coil springs?

Looking to lift a 1968 2WD C10 with coil springs? Here’s what you need to know:

The 1968 2WD C10 uses coil springs, which makes finding lift kits a bit tricky. This suspension setup means that aftermarket support for a straightforward lift kit isn’t as robust as with some other models.

While traditional lift kits might not be readily available, there are still options to achieve that lifted look:

While dedicated kits are scarce, some enthusiasts have had success by piecing together kits using available parts from third-party brands. Investigate various suspension components that might be adaptable for your model.

Always prioritize safety. Altering suspension systems requires careful planning and execution to maintain vehicle stability and performance. Consulting with a suspension specialist or automotive engineer can ensure modifications are safe and effective.

By exploring these avenues, you can effectively lift your 1968 2WD C10, enhancing its style and performance to meet your needs.

Could lifting a 2wd truck affect its driving experience or ride quality?

Lifting a 2WD truck can certainly alter its driving dynamics. When you lift a 2WD, you’re changing steering angles, which can impact both ride quality and safety. As a result, your driving experience might shift away from the ‘normal’ feel you’re accustomed to when cruising down the road. It’s important to weigh these potential changes against your desires for a lifted look or improved off-road capability.

When considering a lift, the choice of springs plays a crucial role in determining how your truck handles post-modification:

While these kits provide options suited to different driving needs, remember that a lifted 4×4 doesn’t drive like a stock 2x. Expect your 2WD, once lifted, to feel even further from the standard experience. Balancing aesthetics with functionality ensures you achieve the ride quality you desire without compromising on safety.

Is lifting a 2wd truck safe or advisable?

Lifting a 2wd truck may not be the safest option, as it can lead to changes that negatively impact driving experience and safety. It is important to weigh these potential drawbacks before proceeding with such modifications.

How will the driving experience of a lifted 2wd truck compare to a stock 2wd or a lifted 4×4?

A lifted 2wd truck will likely drive significantly differently than a stock 2wd, with a departure from the normal feel on the road. It also won’t match the driving dynamics of a properly lifted 4×4, which is designed to handle such modifications more effectively.

How does lifting a 2wd truck affect steering angles and safety?

Lifting a 2wd truck alters the steering angles, which can compromise ride quality and safety. This change can lead to handling issues and potentially affect the overall stability of the vehicle.

What are the potential issues or risks with lifting a 2wd truck?

To clear our 22×12 American Force wheels, we will need a bit of a lift kit installed on this truck, but not too tall. We only need to clear a 33-inch-tall Toyo tire, but the width of the wheel will require a tad more height upfront. The best way to get some extra inches out of the front of a classic 2WD truck is to simply replace the spindles. Unfortunately, no one makes lift spindles for a ’73-’87 2WD Squarebody truck. So we had to improvise and use a Rough Country 4-inch lift spindle for an ’88-’98 C1500. The upper and lower control arm ball joints will also have to be swapped to match the spindles.

However, it’s crucial to understand the potential implications of lifting a 2WD truck.

Lifting a 2WD can alter steering angles, which might affect both ride quality and safety. These modifications can lead to major steering issues, making the handling unpredictable. This is not unlike what some Jeep owners experience when they lift their vehicles, potentially resulting in dangerous driving conditions and even accidents.

It’s important to note that a lifted 2WD truck won’t drive the same as a stock model. The handling and feel of the vehicle will change significantly. If you’re used to a conventional, smooth ride, expect the driving experience to shift to something less predictable and quite different from a properly lifted 4WD.

If the truck is a family vehicle, consider the safety of your passengers. If lifting cannot be done safely, it might be worth reconsidering the modification or even switching to a vehicle that better meets your needs, especially if children frequently ride with you.

In summary, while the technical aspects of lifting your truck can be managed with the right components, it’s essential to weigh these against the potential risks to safety and driving comfort.

If safety cannot be ensured in lifting a 2WD truck, what alternative options are there?

If lifting the truck safely is not feasible, selling it and purchasing a 4×4 that can accommodate the desired modifications might be a safer and more practical solution.

How does the driving experience of a lifted 2WD truck compare to that of a stock or properly lifted 4WD truck?

A lifted 2WD truck will likely drive differently from both a stock 2WD and a properly lifted 4WD truck. The experience may be less stable and further from the “normal” driving feel, potentially reducing driving satisfaction.

What personal considerations should be taken into account when deciding to lift a 2WD truck?

Personal safety, especially when transporting passengers like children, should be a priority. If lifting compromises safety, it might be wiser to consider alternatives, such as opting for a vehicle better suited for modifications.

How does lifting a 2WD truck affect ride quality and handling?

Changing the steering angles by lifting a 2WD truck can degrade ride quality and handling. The truck may not respond predictably, leading to a less comfortable and potentially unsafe driving experience.

What are the safety risks associated with lifting a 2WD truck?

Lifting a 2WD truck can lead to significant steering issues, making the vehicle potentially dangerous to drive. Altered steering angles can result in unpredictable handling, increasing the risk of accidents.

Can steering issues arise from lifting a truck, and how can they be addressed?

To clear our 22×12 American Force wheels, we will need a bit of a lift kit installed on this truck, but not too tall. We only need to clear a 33-inch-tall Toyo tire, but the width of the wheel will require a tad more height upfront. The best way to get some extra inches out of the front of a classic 2WD truck is to simply replace the spindles. Unfortunately, no one makes lift spindles for a ’73-’87 2WD Squarebody truck. So we had to improvise and use a Rough Country 4-inch lift spindle for an ’88-’98 C1500. The upper and lower control arm ball joints will also have to be swapped to match the spindles.

However, it’s crucial to consider the potential steering issues that may arise from this modification. Lifting a truck can alter the steering angles significantly, leading to unpredictable handling and compromising ride quality and safety.

By keeping these considerations in mind, you can enjoy the aesthetic and functional benefits of a lift while ensuring your truck remains safe to drive.

What alternatives are available if lifting a truck safely is not possible?

If lifting the truck cannot be done safely, one alternative is to consider selling the vehicle and opting for a 4×4 model, especially if safety for passengers, like children, is a priority.

Is lifting a 2WD truck advisable from a safety perspective?

While it is technically feasible to lift a 2WD truck, it might not be the safest choice. Altering the steering angles can negatively impact both ride quality and safety.

Are there safety concerns associated with lifting a truck?

Yes, lifting a truck can lead to significant steering issues that may pose a danger. These modifications can make the steering unpredictable, increasing the risk of accidents.

What are some alternative methods to lift a 2wd C10?

To clear our 22×12 American Force wheels, we will need a bit of a lift kit installed on this truck, but not too tall. We only need to clear a 33-inch-tall Toyo tire, but the width of the wheel will require a tad more height upfront. The best way to get some extra inches out of the front of a classic 2WD truck is to simply replace the spindles. Unfortunately, no one makes lift spindles for a ’73-’87 2WD Squarebody truck. So we had to improvise and use a Rough Country 4-inch lift spindle for an ’88-’98 C1500. The upper and lower control arm ball joints will also have to be swapped to match the spindles.

When it comes to lifting a 2WD C10, there are several alternative methods you can consider to achieve the desired height. Here’s a closer look at some options:

Each method comes with its own set of considerations, from cost to safety implications. Whether you’re modifying your truck for larger wheels or simply seeking a more aggressive stance, weighing these options is key to making an informed decision.

What are the cost considerations for lifting a 2WD vehicle?

Body lift kits for 2WD vehicles are generally inexpensive, making them a budget-friendly option for vehicle lifts.

Are there any safety concerns associated with lifting a 2WD vehicle?

Yes, altering steering angles can impact both ride quality and safety. Additionally, using coil spring clamps is considered very unsafe.

What are some common methods to lift a 2WD vehicle?

You can lift a 2WD vehicle using body lift kits or coil spring spacers, typically available in 2-3 inch sizes.

How do airbags complement or complicate the lifting of a truck’s suspension system?

When lifting a truck’s suspension system, one of the key considerations is maintaining optimal load-carrying capacity. This is where airbags can play a significant role, but they come with their own set of complexities.

Considering airbags in your suspension setup can significantly boost your truck’s performance when carrying heavy loads. However, it’s crucial to weigh the benefits against the potential complexities, such as installation challenges and ongoing maintenance, to make an informed decision.

What are the potential benefits and drawbacks of switching to a four-speed transmission in a lifted truck?

Switching to a four-speed transmission in a lifted truck can seem appealing, but it’s essential to weigh the potential benefits and drawbacks.

Ultimately, whether switching to a four-speed transmission is the right move depends largely on your driving habits and how you envision using your lifted truck. Balancing these potential benefits and challenges will help you make a decision that fits your needs.

What factors should be considered when choosing a lift kit for an older truck model?

Factors to Consider

Generally, the more expensive the lift kit, the better the quality. Investing in a high-quality kit can save you money in the long run by reducing wear and tear on your vehicle. However, consider your budget constraints. Are you looking for the cheapest option, or is quality your top priority?

Older truck models, like certain Chevy 1/2 tons and 3/4 tons, may have unique issues, such as frames cracking at the steering box, especially with larger tires. It’s essential to examine whether a steering box brace—either bolt-in or weld-in—might be necessary for your model to maintain structural integrity.

For those planning to use 35-inch tires, a minimum of 4 inches of lift is recommended for most vehicles. In some cases, heavier-duty vehicles may require only a 3-inch lift due to their higher starting stance. Consider whether your truck still needs load carrying capacity and how that might affect your lift height decision.

Specific spring types can dramatically affect your ride:

After lifting, the front sway bar might get tilted, often making the ride harsh. You might want to remove the sway bar completely as a trial, or consider a quick disconnect kit for more flexibility.

Define the type of off-roading you plan to do. Is it just gravel roads and washboard, or are you tackling more challenging off-road trails? Your off-roading style will significantly influence the type of lift kit you choose.

Experience varies, so consulting someone with extensive off-roading experience can provide invaluable insights tailored to your specific needs. Seeking advice from knowledgeable sources can help you understand the nuances of each lift option and make an informed decision.

By evaluating these factors, you can select a lift kit that enhances your vehicle’s performance, ensuring a safer and more enjoyable off-roading experience.

How does lifting a truck affect its ride quality, especially on highways?

When considering how lifting a truck affects its ride quality, especially on highways, several factors come into play. Lifting a truck can significantly alter its handling dynamics and ride comfort. Here’s what you need to know:

Specific spring types can dramatically affect your ride:

A lifted truck can ride harder on highways, making long-distance driving less comfortable. This is particularly true if you opt for a lift that doesn’t prioritize highway stability. Adding a significant lift, such as a 4″, might make your truck feel more rigid and less forgiving on uneven pavement.

However, there’s more to consider. If you’re worried about highway performance, you might think about enhancing the transmission. Upgrading from a three-speed to a four-speed transmission can introduce an overdrive gear, potentially increasing gas mileage and making highway cruising more efficient. This tweak can make a lifted truck more viable for longer journeys.

Ultimately, the key is balancing your off-road aspirations with on-road comfort. By carefully selecting the right components and considering additional modifications like transmission upgrades, you can enjoy both rugged adventures and smooth highway rides.

How might modifications align with or change the driver’s habits?

By improving fuel efficiency and ride quality with modifications, the driver might be more inclined to take the truck on longer journeys beyond the usual local trips.

What are the current driving habits and intended use of the truck?

The truck is typically driven within a limited range, not often venturing beyond nearby areas like Bozeman or Idaho Falls.

What are the considerations for upgrading the transmission?

Upgrading from a three-speed to a four-speed transmission could enhance fuel efficiency, as the additional gear would function like an overdrive, making longer trips more appealing.

How might a 4″ lift affect highway driving?

A 4″ lift could potentially make highway driving less enjoyable due to changes in ride dynamics, but this depends on the specifics of the lift and personal preferences.

What is the current ride quality of the truck?

The truck currently provides a rough ride, though it improves when carrying a heavy load like a yard of sand.

What additional components might need to be upgraded when installing a lift kit, such as brake lines or shocks?

When installing a lift kit, several additional parts and modifications might be necessary to ensure the job is done right and the truck performs optimally. Beyond the basic components, there are several considerations to keep in mind:

Both options allow you to maintain flexibility. If you change your mind later, you can still swap out the factory pack for something softer.

The parts for these upgrades can add up to $400-$500 if you go for quality components. This includes:

These modifications, while adding to the initial cost, will ensure a smoother ride and better handling. They also provide the flexibility to make future adjustments as your needs evolve. It’s important to assess your specific requirements, such as the truck’s load capacity and off-roading needs, to choose the best components and solutions.

Are there any known issues with the truck’s frame or steering box?

Larger tires can lead to frame cracking at the steering box, an issue that can affect even heavier-duty models. Installing a steering box brace can help prevent these problems, providing additional support and stability.

What type of off-roading will the truck be used for?

The choice of modifications should be influenced by the type of off-roading planned. Whether you’re sticking to gravel roads or tackling challenging trails, different setups will be required to handle varying terrains effectively.

Are you looking for the softest ride possible?

If a softer ride is a priority, consider suspension options that enhance comfort. This might include selecting specific shocks or springs designed for a smoother driving experience.

Does the truck need to maintain its load carrying capacity?

If maintaining load carrying capacity is important, this will influence the choice of suspension components. Selecting parts that support the vehicle’s original load capacity is crucial for performance and safety.

What is the budget for the project?

The budget can vary significantly based on the selection of parts and modifications. Options range from economical solutions to more premium offerings, so it’s important to decide how much you’re willing to invest in the truck’s upgrades.

How do different lift kit options compare in terms of performance and cost?

Factors to Consider

Generally, the more expensive the lift kit, the better the quality. Investing in a high-quality kit can save you money in the long run by reducing wear and tear on your vehicle. However, it’s essential to keep a firm grip on your credit card, as some premium options can quickly escalate in price.

For those considering 35-inch tires, a minimum lift of 4 inches is recommended in the front. Vehicles like the 3500, which sit slightly higher than others, might manage with a 3-inch lift. If you’re aiming for a significant lift, crossover steering becomes crucial to ensure stability and handling remain intact.

By combining cost considerations with detailed performance insights, you can make an informed decision that balances your budget with your off-roading needs.

What steering modifications are necessary for certain lift heights?

For lifts exceeding 4 inches, crossover steering is advised for improved handling and stability. A drop Pitman arm is preferred over a drop drag link for more precise steering control.

Are some lift components better suited for high-power applications?

If you’re planning to put significant power through your vehicle, options like new springs or shackle flips are preferable over blocks, as they provide better stability and handling under stress.

How do different vehicle models affect lift requirements?

Vehicle models such as the 3500 may only need a 3-inch lift due to their inherently higher stance compared to models like the K20, which might require a minimum of a 4-inch lift for similar tire clearance.

What are user experiences with specific lift kit brands?

Some users report that Rough Country springs offer a very stiff ride, which might not be comfortable for everyone. It’s essential to consider personal preferences and ride quality expectations.

Where should I consider purchasing a lift kit for quality assurance?

Buying from reputable companies like ORD is recommended for quality assurance, but be mindful of the cost as high-quality kits can be expensive.

How do modifications like crossover steering or steering braces impact a lifted truck’s performance?

Crossover Steering: Essential for lifts over 4 inches, providing better handling and stability. While crossover steering can significantly enhance off-road performance by improving maneuverability on rugged trails, it’s important to consider its impact on everyday driving. Some drivers find that traditional steering offers a more comfortable experience on highways.

For those looking to maximize their truck’s performance, a steering brace can be a valuable addition. By triangulating the front frame and crossmember, a brace helps reduce flex and twist in the frame—an issue that becomes more pronounced with larger tires.

Pro Tip: To see the effect of frame stress, conduct a simple test. Park your truck on a flat surface and have someone turn the steering wheel from lock to lock. Observe the power steering box and frame area to witness how much the frame flexes under pressure, especially in 1/2-ton models. This insight underscores the need for modifications like a steering brace to maintain structural integrity and improve overall handling.

What are the potential challenges of installing a lift kit on a truck with an existing steering gearbox issue?

When installing a lift kit on a truck, addressing potential steering issues is essential. One consistent challenge that arises is the tendency for bolts in the steering box to loosen over time. This problem can escalate with the additional stress a lift kit places on the vehicle.

Before proceeding with a lift kit, consider reinforcing the steering box. While there are bolt-in and weld-in options for steering box braces, choosing one that suits your specific needs can be cost-effective. It bolsters your vehicle’s frame without necessitating a complete overhaul.

For those already experiencing loose bolts in the steering box, a practical fix involves using over-long #8 bolts and lock nuts. By securing these through the frame with lock nuts on the opposite side, you can significantly enhance stability.

However, if your steering box is worn out and leads to a “loose-goosey” feel, it’s crucial to replace it before any major modifications. A new steering box will not only improve handling but also ensure that your lift kit installation proceeds smoothly without compromising safety.

Ensuring the integrity of your steering components is key to a successful lift kit installation, providing both safety and performance benefits.

Would a crossover steering system help with the identified problem?

A crossover steering system might help address the issue by providing a more robust steering setup, potentially reducing the likelihood of bolt loosening.

Does the existing steering issue necessitate replacement, regardless of modifications?

Yes, if the steering box is worn out and affecting steering performance, it requires replacement, regardless of any other modifications made to the vehicle.

What are the symptoms of a worn-out steering box?

Symptoms include very loose steering, often described as “loose-goosey,” which can affect the vehicle’s handling and control.

How can existing steering gearbox issues be temporarily fixed?

One temporary fix involves using longer bolts and lock nuts to secure the steering box by fastening them through the vehicle’s frame, providing a more stable attachment.

What specific issues can occur with the steering gearbox?

A common issue is the loosening of bolts in the steering box, which can lead to instability and compromised steering performance.

What are the general recommendations for installing larger tires on a truck?

“When considering larger tires like 35″ or even 37″, different lift heights are necessary. Generally, a 4-inch lift is the minimum required for 35″ tires, especially on a 3/4 ton truck. However, if you’re driving a 1-ton truck, you might get away with a 2-3 inch lift due to the higher default clearance.”

To achieve the desired lift, you’ll need to look into the various lift options available. Here are some key considerations:

These adjustments are often necessary when exceeding a 4-inch lift.

By addressing these factors, you’ll be better equipped to install larger tires, enhancing both the look and functionality of your truck.

What are common issues with steering boxes in lifted trucks, and how can they be addressed?

When lifting a truck, several modifications become necessary to ensure both safety and performance. One significant component to consider is a steering box brace.

A steering box brace is a device designed to strengthen and support the steering box section of the vehicle’s frame. It’s particularly important for vehicles that experience a lot of stress in this area, such as trucks with oversized tires or those used for off-roading.

One consistent problem with lifted trucks is the loosening of bolts in the steering box. This can lead to a “loose-goosey” steering experience, which compromises safety and handling. A practical solution involves using new over-long #8 bolts and lock nuts, securing them through the frame to ensure they remain tight. However, if the steering box itself becomes worn out, as is often the case, replacing it becomes essential regardless of other modifications.

In some cases, exploring options like crossover steering systems can provide additional stability and help prevent similar issues in the future. This consideration becomes crucial when dealing with persistent steering problems that a simple brace might not fully resolve.

A steering box brace is an invaluable addition to any truck, particularly those that have been lifted or outfitted with larger tires. It provides crucial reinforcement to the vehicle’s frame, ensuring longevity and reliability under demanding conditions. Understanding when to install one, along with addressing common issues like bolt loosening, can save you from costly repairs and enhance your driving experience.

What approach can be taken if the steering box needs replacement?

If the steering box is severely worn, it will ultimately need to be replaced to restore proper steering functionality, regardless of temporary fixes.

What additional modifications might be considered to address steering issues?

Considering a “crossover” steering modification could potentially help in addressing steering issues by providing more robust steering control.

What are the effects of a worn-out steering box?

A worn-out steering box can result in loose and unresponsive steering, making vehicle control more challenging.

What practical solution can be applied to fix a loosening steering box?

One effective solution is to replace the original bolts with longer ones and secure them with lock nuts, extending through the frame for added stability.

What specific problem can occur with the steering box components?

A common issue is the loosening of bolts within the steering box, which can lead to instability in steering.

What steps are involved in installing a leaf spring lift kit on a truck?