JEREMY BUMPUS

.

March 09, 2023

.

Cover

JEREMY BUMPUS

.

March 09, 2023

.

Cover

The news that Ford was releasing a new mini-truck called the Maverick immediately piqued our interest. But when we heard that one was being built with a full ’90s throwback theme, we knew we had to bring it to our readers. We did some digging and found out that Jeremy Bumpus from Corinth, Mississippi, was the one building it. Jeremy owns and runs The Hot Rod Shop in his hometown, where they build a ton of high-end vehicles and do every aspect of the build in-house–from suspension and metalwork to paint and interior. If the shop name sounds familiar, it’s probably because you’ve seen Jeremy as the host of Motortrend TV’s show “Carfix.” Before that, he was on “Truck Tech” on PowerNation TV.

I felt like I didn’t leave the booth for the next two weeks; I just sat and airbrushed.”

We sat down with Jeremy to hear all about the background of this build. Here’s what he had to say about this old-school-meets-new-school build:

In March of 2021, when a “spy” over at Ford told me the Maverick was coming out and it was going to be a mini-truck, that was all it took for me. I always wanted to take a brand-new truck and build a custom, and this was the perfect time. By April, we had a line drawing to start the rendering process. The idea: an old school ’90s-themed mini. I pitched it to my guys at the shop and everyone was immediately on board. We knew right away we needed ’90s-style paint; that we wanted it not only to lay, but to hop; one crazy-stupid sound system; and of course, old-school wheels. We had everything drawn out exactly the way we wanted it and a plan in place. All we needed was the truck. Ford and our local dealership helped us place the order: a base-model Ecoboost Ford Maverick in Velocity Blue. We opted not to go with the hybrid or AWD for the ease of being able to lay it out with less to deal with.

We freehanded everything–from one side to the other, with each BASF color custom-mixed.”

Although we had the truck in our hands a few months later, we didn’t get started right away. With many other big-customer projects going, we chose to wait until after SEMA 21. In the meantime, we reached out to some of our friends in the industry, and I was blown away by the support we received for this project. I’d already known that building the Maverick would be cool, but I didn’t know how well our ’90s theme would be received. We knew we weren’t going to try and tuck the biggest wheels; we do that every day on our other builds. We really wanted to stay true to the theme–love it or hate it.

I wanted a wheel from back in the day, so some of the first things I got were the 18s and 20-inch GS69s from Billet Specialties. I went with these wheels because I had a set that I never ended up running on anything, and I always said I’d get another set. Something that has become a trend of ours is staggering wheels. We did this, then wrapped them in Continental ExtremeContact tires. With the wheels ordered, we were ready to start on suspension.

I wanted the truck to hop a few inches and I wanted that fast ’bag setup from back in the day. I was close to going with hydraulics like I’d used on my first couple of minis, but I talked myself out of it. I gave Bryan at Cool Cars Engineering a call and we got the air management on the way. I did 8 ½-inch valves, ½-inch line, 16 gallons of air, and four Viair 480 compressors. We got everything mounted and hid under the bed and it was tight! Since the Maverick was front-wheel drive, the rear was pretty simple. We removed the coils and built a couple of cups in their place, then mounted Slam Specialties SS6 airbags.

Up front, things got interesting. I hadn’t messed with much front-wheel-drive stuff. Initially, we didn’t want to run a strut because it wouldn’t move as fast as we wanted. Since we build a lot of chassis and suspensions, we ended up building an upper A-arms, and a ’bag setup that would ride above that. This setup is really no different than a first-generation Mustang-style front setup. It ended up working really well, rode great, and would hop like we wanted. The only downside to running such a short upper arm is that you get a lot of camber change. I had been chatting with Universal Air while configuring this and learned the company was interested in making a strut for the Maverick. After a little back-and-forth, our crew worked with the guys at Universal Air to design a strut.

When the first set arrived, we put it on and I was really pleased with how well it worked out. We were able to lay and not have to raise our strut tower, with the only downside being that it’s not super quick, but certainly quick enough. The back, though? FAST!

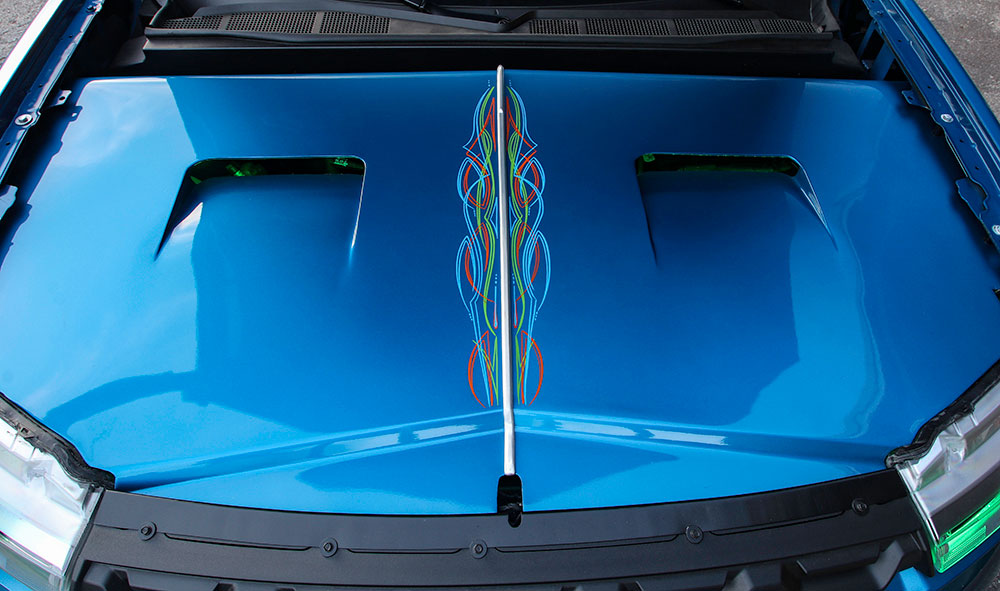

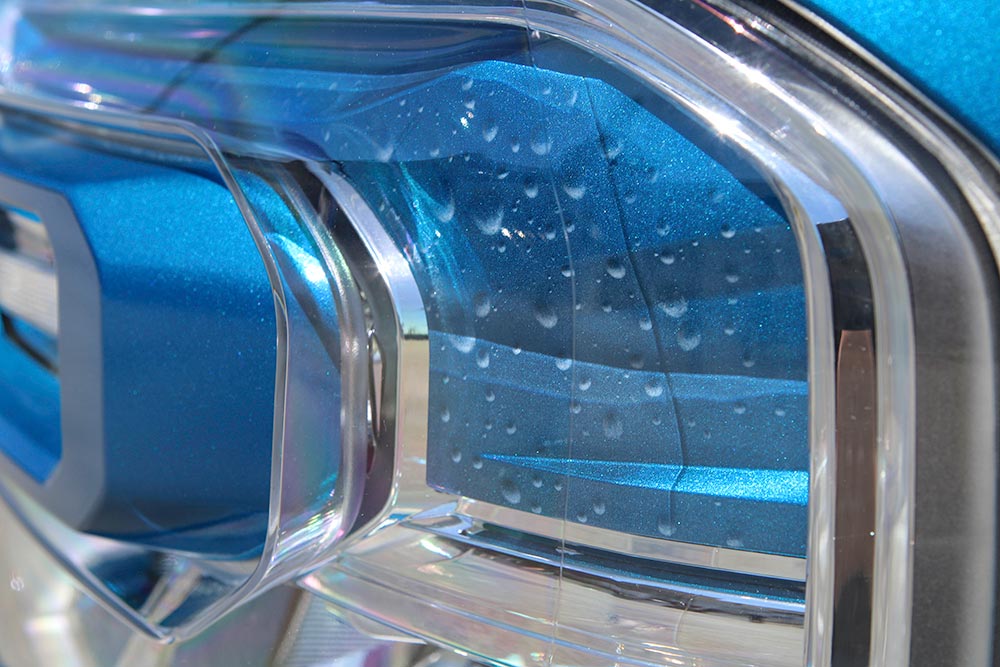

Next came paint, which is what I was most excited about and enjoy doing the most. During the rough-rendering stage months earlier, I had worked with Bob, one of my good friends and employees, to lay down what we were thinking for the graphics. Both Bob and I had painted a lot of minis from the ’90s era, so we knew exactly where we were headed. We got the Maverick sanded down, then started the purple fade from the bottom, adding in a few different shades of blue. After that, we started pulling tape and laying down graphics and shadowing. I felt like I didn’t leave the booth for the next two weeks; I just sat and airbrushed. We freehanded everything–from one side to the other, with each BASF color custom-mixed. We pulled it out of the booth, got it color-sanded and buffed with our Indasa products, and the ’90s were in full effect … almost. It was then that I realized: We need some neons. I talked with Oracle Lighting. While we blew the headlights apart and did some custom painting on those, the Oracle Lighting guys added some LEDs. They also sent us some strips and we lined the bottom to give it even more color.

I wanted to go with tweed for the interior, but knowing how much use the truck would get, I knew it wouldn’t last. I decided to call my friends at Apex Leather and got some material on the way. I pulled the seats, did away with the headrest, and kept the design simple and clean. I chose blue and white to match the Maverick’s interior and sewed pleats in the inserts with an orange stitching.

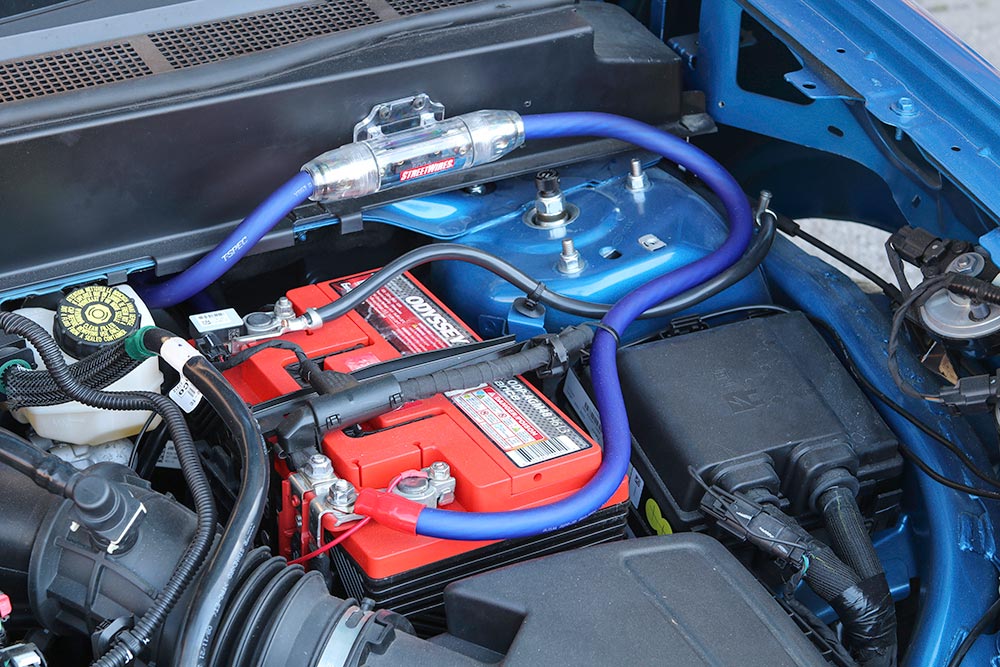

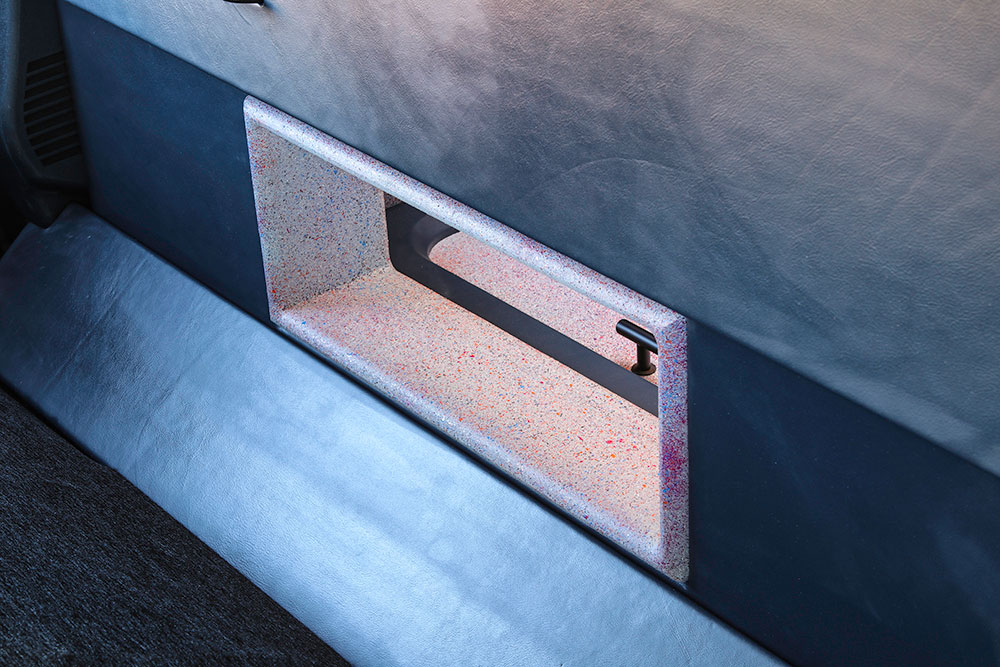

Every vehicle we build at the shop (including my own) has a sound system. Back in the ’90s, it was all about who could be the loudest, so I wanted to make sure this mini’s sound system was insane. I decided on MTX for a couple of reasons. One, they are bulletproof and I’ve hit some really high-decibel numbers with those guys, and two, they were my go-to back then when I started building minis. Even though we do everything in-house, I hadn’t done a crazy system like this in a long time. I called my good friend Joey Williams, who owns The Outlaw Garage in Columbia, Tennessee, a couple of hours down the road. Joey, Jason from MTX, and I came up with an awesome system: six MTX S65 series 12s and three Jackhammer 1500w amps to run the subs. Joey got to work on the box and built a blow-through enclosure tuned to 36 hertz. We ended up running eight MTX coaxials in the doors with two more amps to power those. We did the full install on “Carfix” where my co-host, Bryan Fuller, Joey, and I got the blow-through cut and everything installed and wired to run off of the Ford head unit. We installed four Odyssey batteries to power the 5000-watt system, and when we fired it off, it was all the roof and windshield flex you could hope for.

We upped the performance a bit with a Magnaflow exhaust and a tune, so she’s got a bit more pep. It’s super fun to drive and definitely a neck breaker when we cruise through town. Now we get to enjoy it for a bit, hit a few shows, and I think we are going to do the unthinkable before SEMA 2022 … but we’ve got to keep that hush-hush!

Owner

Jeremy Bumpus

2022 Ford Maverick XL

Corinth, MS

SUSPENSION

ENGINE

BODY & PAINT

INTERIOR

WHEELS & TIRES

RENDERING

SPECIAL THANKS FROM OWNER

“Thanks to all of our sponsors that we work with daily. It’s great to have so many awesome companies in this industry always willing to help. To the guys at the shop for always killing it, and to my wife, Kim (the boss), for keeping her foot shoved so far up our ass to get it done. We could not do what we do without her doing all of the real work running the shop.”

Share Link