Chris Hamilton

.

January 06, 2023

.

America

Chris Hamilton

.

January 06, 2023

.

America

One of our most respected editorial series is back, and we kick it off with one of our favorite parts manufacturers in the U.S.—QA1. The company also happens to be our 2019 Street Trucks Manufacturer of the Year. After a few emails and schedule checks, we booked our flights to Minnesota and packed our camera gear anticipating an eye-opening experience into one of the industry’s highest-quality component makers.

Whether your goal is a Saturday night sprint across the checkered flag or a slow, easy cruise down main street in your classic Chevy C10, QA1 is one of the industry leaders you should consider when ordering a complete suspension package for your pickup. Quality and affordability are top priorities at QA1, and the company achieves this by having a robust quality-management system and a culture of continuous improvement.

Quality and affordability are top priorities at QA1, and the company achieves this by having a robust quality-management system and a culture of continuous improvement.

The crew at QA1 believes vehicles were meant to be driven, and we couldn’t agree more. They’re engineering products that are designed to be bolted on by anyone with basic mechanical skills to get you behind the wheel faster. Increase your 60-foot times, handle curves with confidence, and increase the pride in your pickup. Everything QA1 does is designed to get you out on the road. No matter what you drive, QA1 just wants you to #goDRIVEit!

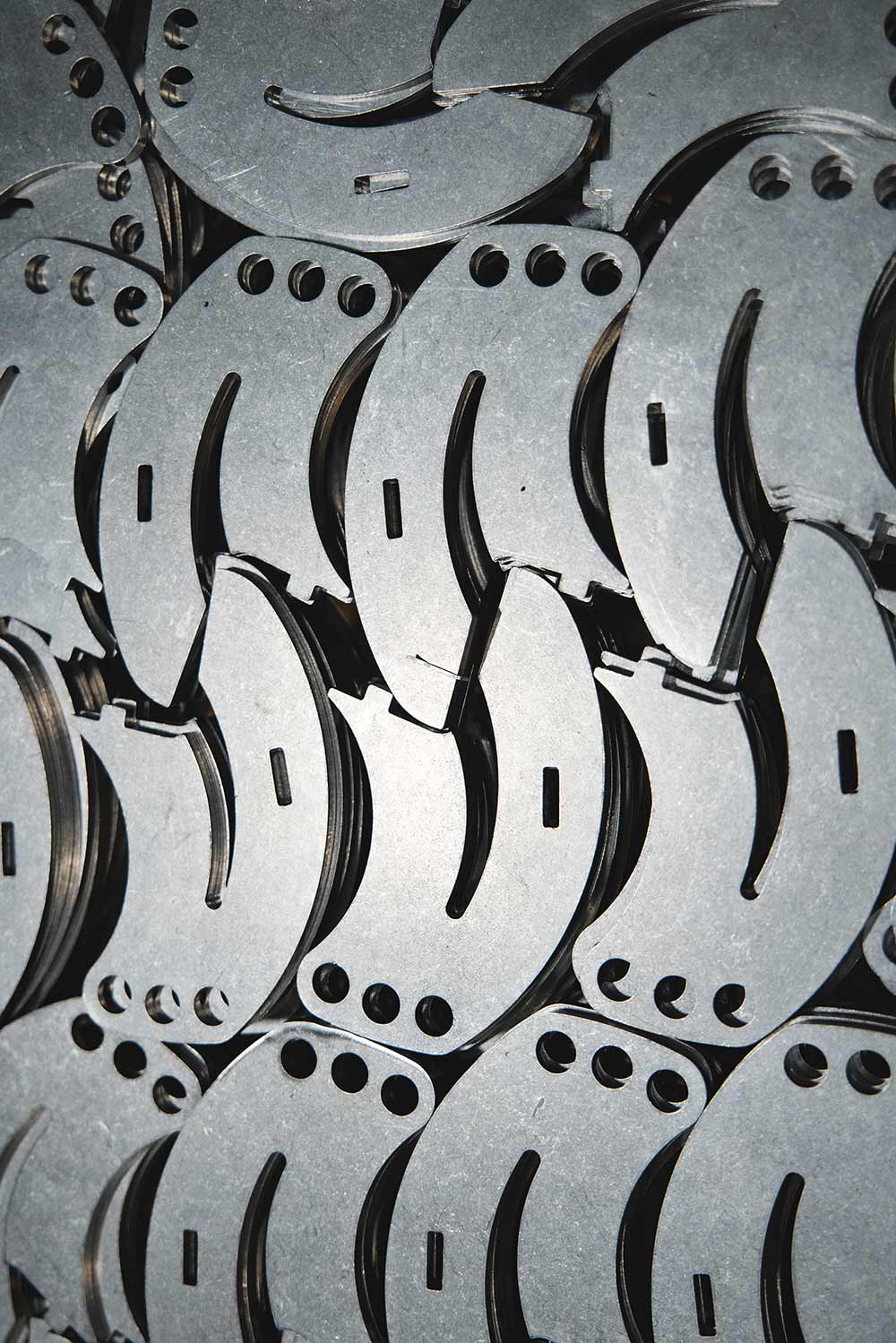

The priority at QA1 is quality above all, which is why the company’s system is certified to the ISO 9001 standard. What’s the you ask? ISO 9001 sets out the criteria for a quality management system and is the only quality standard that you can receive certification for. It’s based on a number of principles, including a strong customer focus, the motivation of top management, the process approach, and continual improvement. The QA1 crew follows a strict process, uses precision machinery, and inspects all of their products to ensure the quality meets the high standards. QA1 products are designed, built, and tested to ensure consistent quality, ultimate reliability, and unbeatable performance.

ISO 9001 sets out the criteria for a quality management system and is the only quality standard that you can receive certification for.

QA1 products are designed, built, and tested to ensure consistent quality, ultimate reliability, and unbeatable performance.

Share Link