Chris Hamilton

.

April 06, 2020

.

HEADLINE

Chris Hamilton

.

April 06, 2020

.

HEADLINE

THE RAVEN” FROM Edgar Allan Poe was his most popular literary creation, although it did not bring him much financial success.

Over the years, this poem has been reprinted, parodied and illustrated countless times, making it a cultural icon. Critical opinion has always been divided, but it nevertheless remains one of the most famous poems ever written. Reading a statement like that is motivating in ways most people can’t comprehend. But if you’re a truck guy like I am, I bet you can instantly relate.

Over the years, this poem has been reprinted, parodied and illustrated countless times, making it a cultural icon. Critical opinion has always been divided, but it nevertheless remains one of the most famous poems ever written. Reading a statement like that is motivating in ways most people can’t comprehend. But if you’re a truck guy like I am, I bet you can instantly relate.

Do we build these trucks to make big profits and retirement funds? Certainly not. But I bet you would get excited to build a truck that impacted an audience and was the topic of conversation throughout the entire industry. The pride you get from appreciation and admiration can easily outweigh the feeling of seeing big digits in your bank account, but we can’t lose money either, right? Sometimes, to the criticism of others, you sacrifice hidden details to save on labor costs, but when you have a budget in mind you stick to it. These details can always be revisited when we’re ready.

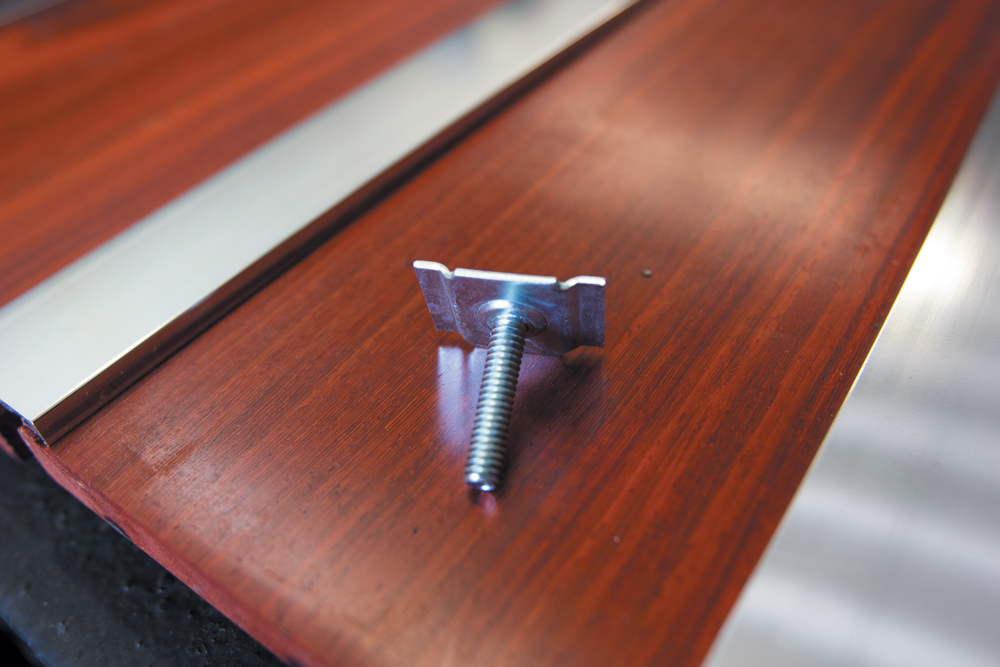

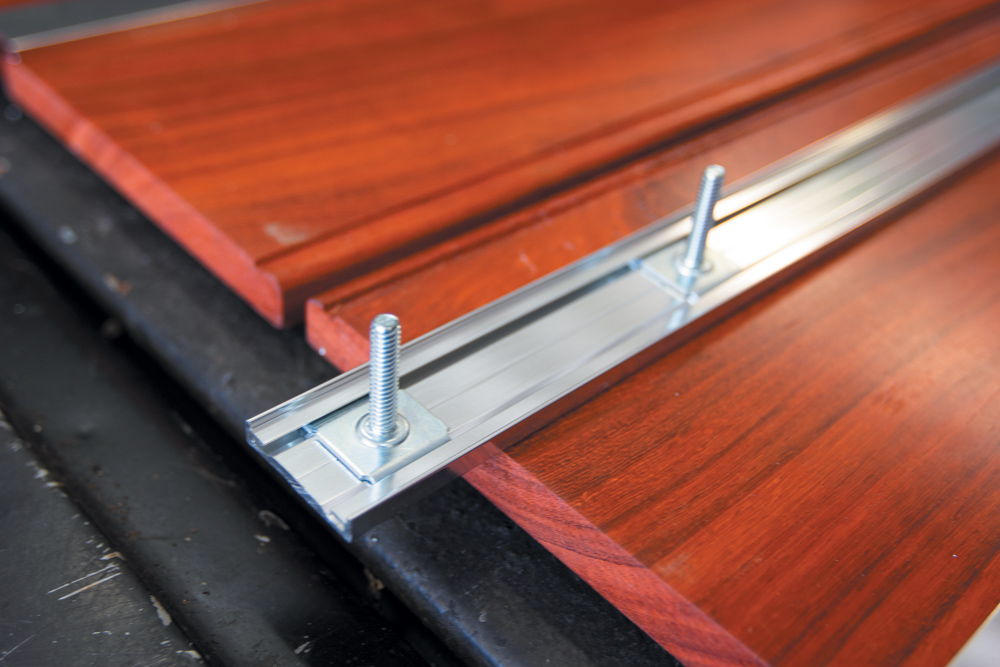

In this case, should we rebuild the bed floor on project Raven or cover it up with a wood bed? We plan to rock the patina for a while and paint it later on, so mounting the wood on top may actually look pretty cool anyway. This decision would hurt us financially if we planned to sell it for as much profit as possible, but we’re building a reliable driver on a budget. This is the right choice for us and gives us something to address when were ready for paint. So, let’s get to it!

[divider]SOURCES[/divider]

Bedwood and Parts

877-206-9663

bedwoodandparts.com

Overpower Customs

561-844-3777

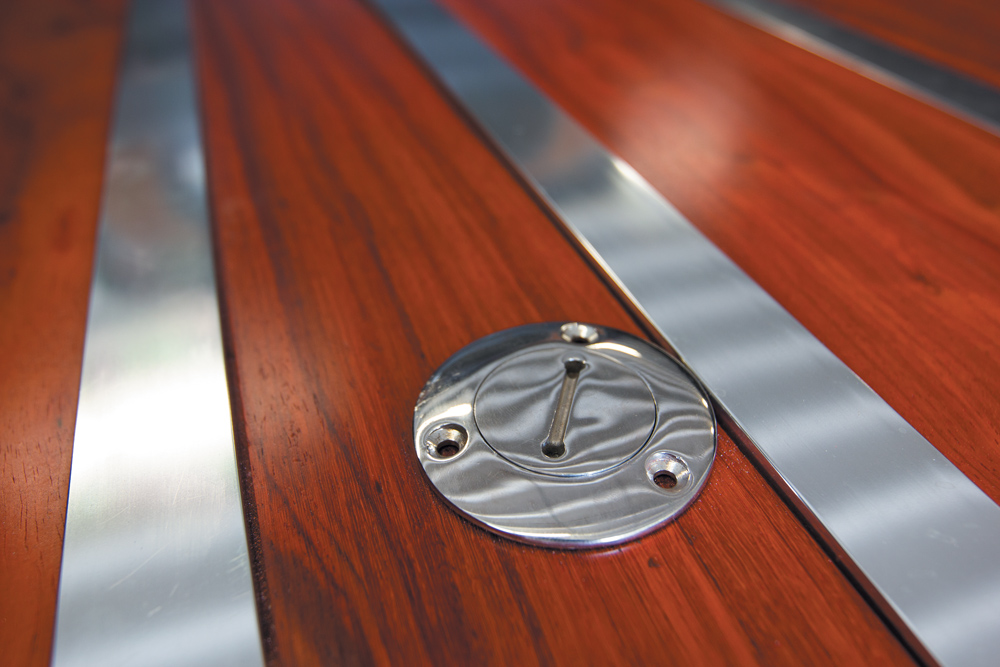

The fuel cell filler hose is routed through the bed floor as well.

Share Link