MICHAEL J. PHILLIPS

.

April 28, 2022

.

F100 Builders

MICHAEL J. PHILLIPS

.

April 28, 2022

.

F100 Builders

There are quite a few factors that set apart F-100 builds in general. The model is finally gaining mainstream traction in the classic and custom communities but has for years been the unsung hero of the truck class.

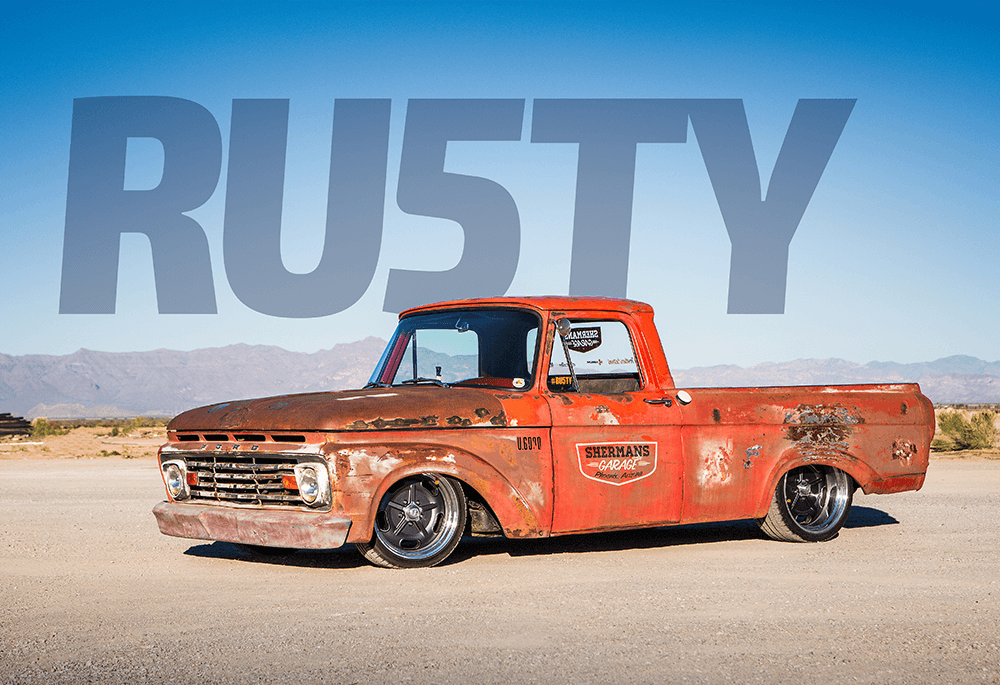

Uniqueness is a hard thing to come by, especially in this day and age. Traditionally the word was used to describe a true one of a kind. It’s often now used as an alternative for “different” or “special.” But when something is genuinely unique, it deserves a second look. There are quite a few factors that set apart F-100 builds in general. The model is finally gaining mainstream traction in the classic and custom communities but has for years been the unsung hero of the truck class. The fourth-generation, in particular, has really spiked in popularity as a customs platform. The unibody version of 1961-62 is of course even more rare. But in a sea of similar styles, uniqueness requires some out-of-the-box approaches. Thinking outside the box is exactly how Brian Sherman approached his 1961 F-100 Unibody build. He decided to team up with Drew Brothers Customs of Chandler, Arizona, to make it happen.

Underneath the unique Uni is an uncommon chassis swap. Most people would not associate the Buick Roadmaster of the 1990s with Ford hot rodding. But when you weigh the pros and cons, it quickly becomes a slam dunk. The Roadmaster reached its final form in 1991 after a 30-plus year layoff. The final body style was built upon General Motor’s B-body. The B-body chassis supplied the bones to dozens of models across the GM lineup for decades. A few notable standouts are the 1966-96 Caprice Police Interceptor and the 1994-96 Impala SS. The Roadmaster underpinning RU5TY is its very last iteration of ’96.

The ’96 Roadmaster brought a huge increase in factory performance. The B-body garners a ton of aftermarket support and OEM reliability, all of which are plus factors to the RU5TY equation. The original F-100 Unibodies utilized a 115-inch wheelbase in their short-bed form. The late-generation B-bodies measured just 0.9 inch longer in the wheelbase. This minimal discrepancy allowed for fine tuning the frame fit. The team fabricated custom body mounts to complete the swap and the suspension has been refreshed with a set of KYB shocks in the front and rear and Eibach lowering springs at each corner. The lower height of the sedan, combined with the high-performance springs, make for a far more aggressive stance beneath this F-100. The modification is striking and truly makes for a unique hot-rod inspired look.

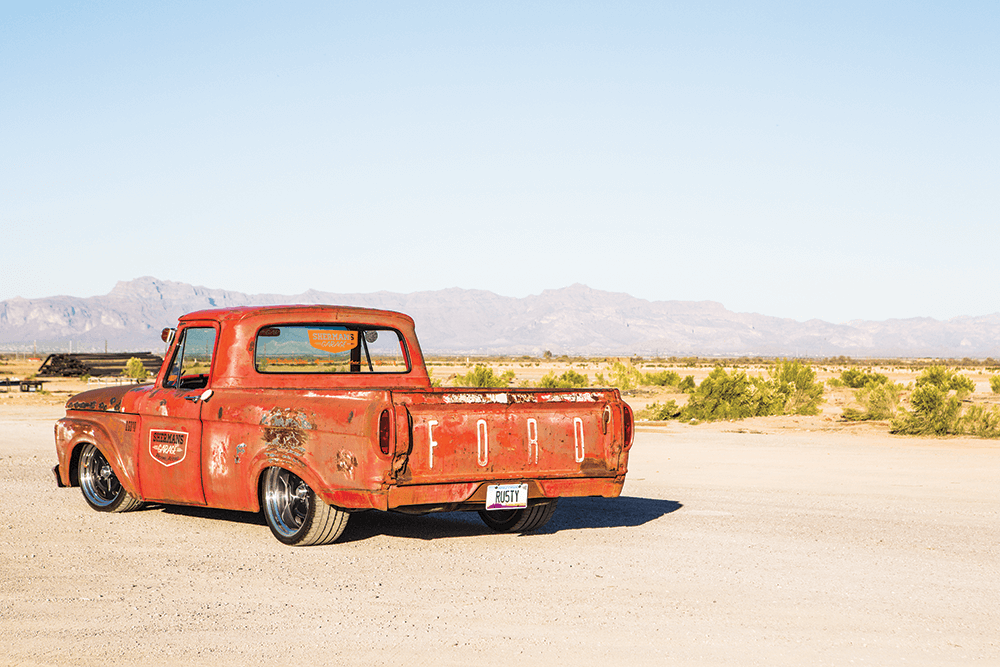

Further pushing the new bad-ass visual, RU5TY is sitting on a set of American Racing Salt Flat Specials. The vintage-style features a perimeter bellowing, ovate and rounded-over cutouts, and star-pattern fluting. The faces are finished in metallic satin gray. The two-piece construction used a J-style polished lip. Brian opted for a bit of hot-rod rake and stagger using 18-inch wheels in the front and 20s out back. The wheels are matched with Goodyear Eagle F1 tires measuring 235/40/18 and 285/35/20. The wheel design is an obvious throwback that boasts multiple modern cues. The contrast fits this mashup build perfectly.

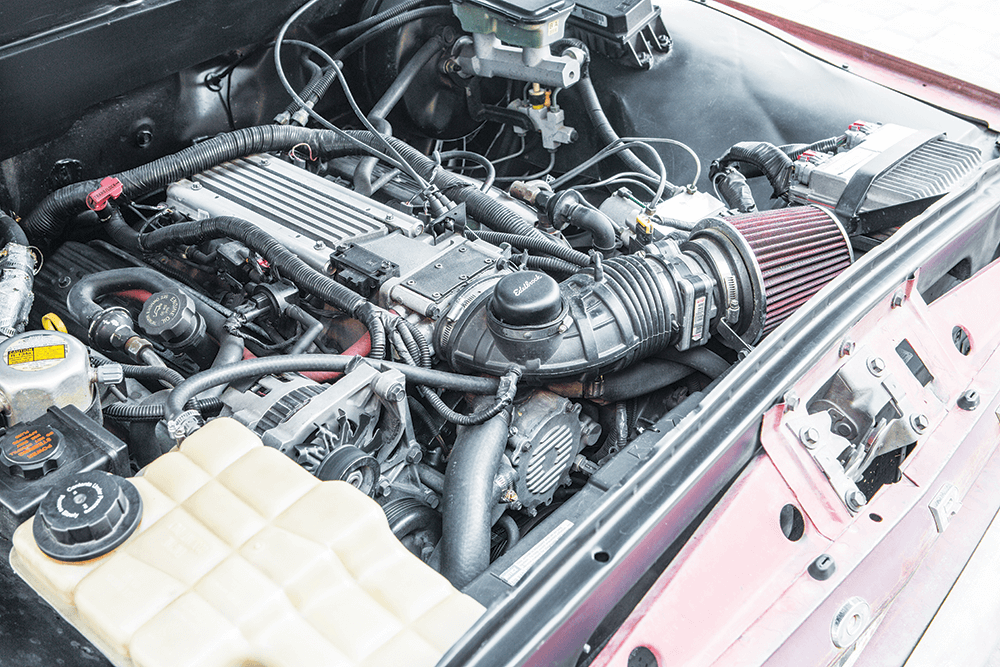

The ’96 is equipped with Chevy’s LT1 350 small-block V-8. The 5.7L engine is the direct predecessor to the LS series. It offers fuel-efficiency, reliability, and a treasure-trove of torque potential. When first introduced to the Roadmaster, the Corvette-derived V-8 brought an 80hp increase. It’s paired up with the 4L60E automatic transmission for smooth cruising. For the time being, Brian’s truck retains is stock motor and supporting components. For a few extra horses and driver enjoyments, Drew Brothers fabricated a custom 3-inch stainless exhaust. The system ends in twin Flowmaster mufflers, turned down in front of the axle.

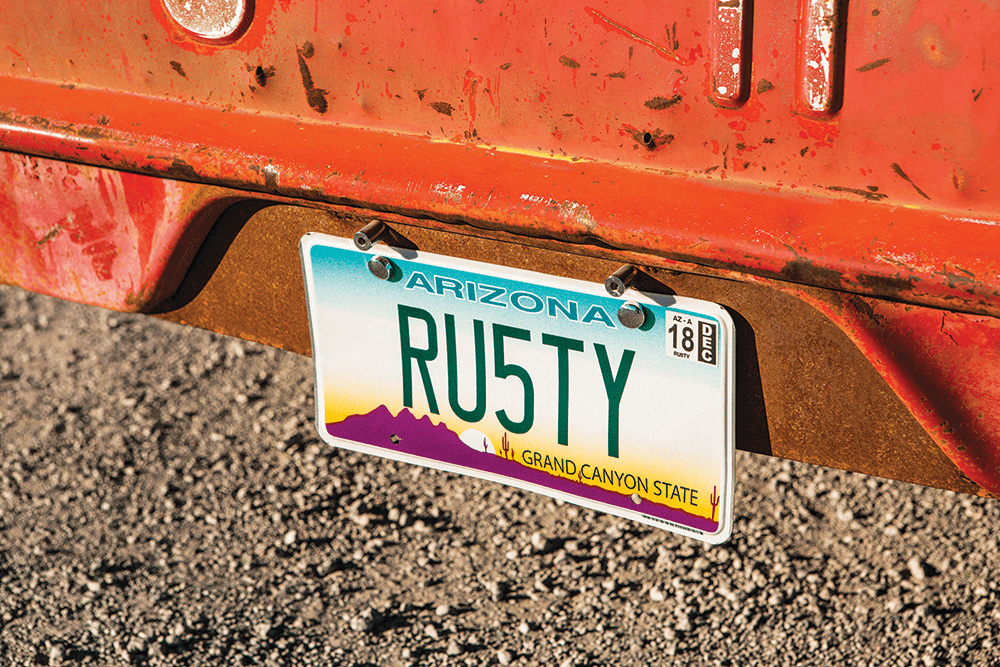

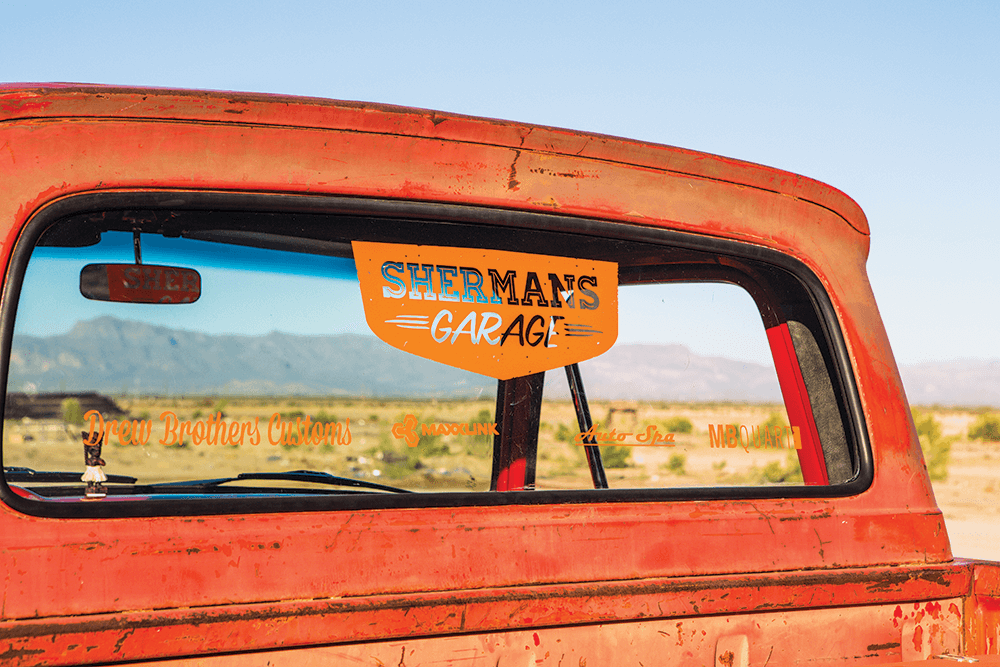

The exterior of RU5TY is its obvious namesake. As Brian perfectly puts it, his build is sponsored by “Mother Nature.” The super rad patina was originally “Torch Red,” or R70540 according to the Ford Factory. The natural weathering has left plenty of primer in plain sight. The painted bumper aged to a different shade entirely bringing a special point of visual interest. But as the title suggests, the surface rust and peeking bare metal seams stands out. The brown lowlights adorn the rear fenders and several seams along the unibody. The driver’s side of the hood sports several rust patterns that look suspiciously like bullet wounds. Brian and the Drew Brothers decided to enhance the all-natural paint job with some period correct door graphics. Rob Drew hand painted the “Sherman’s Garage” logo for Brian Sherman, including his home town of Phoenix.

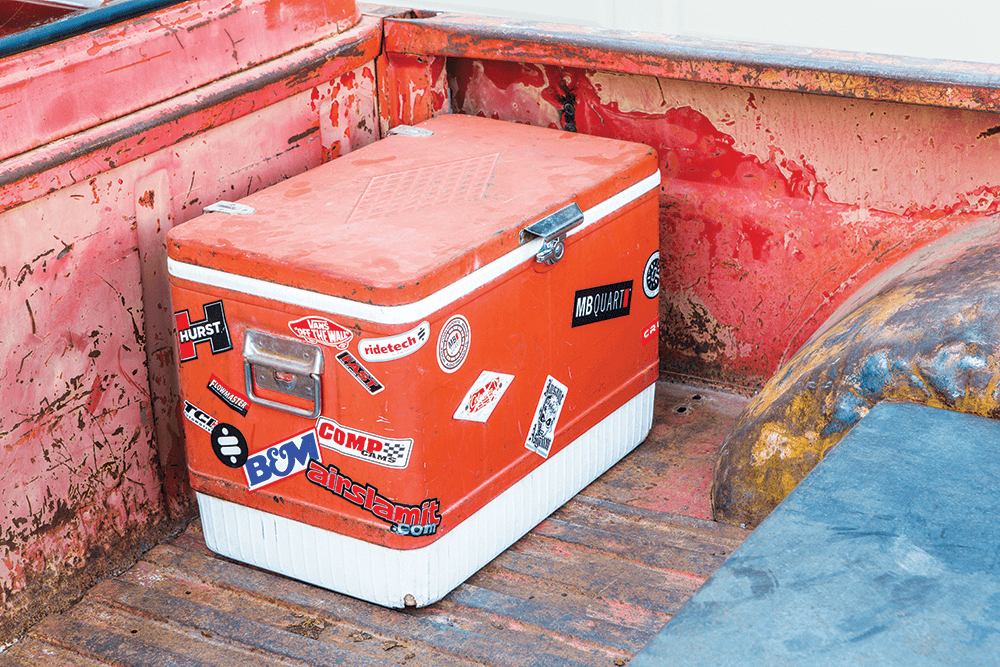

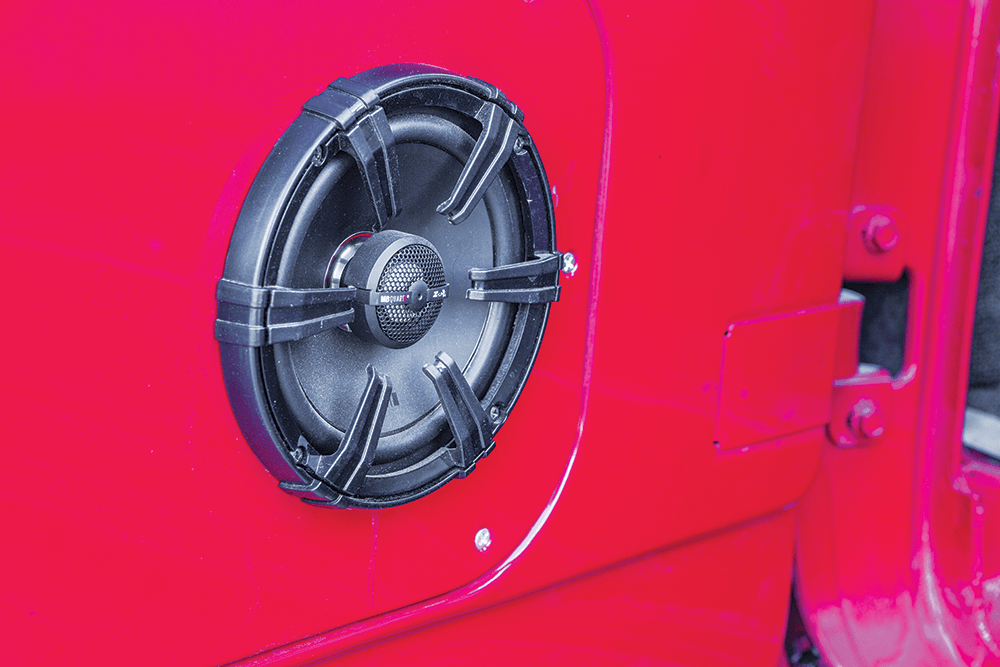

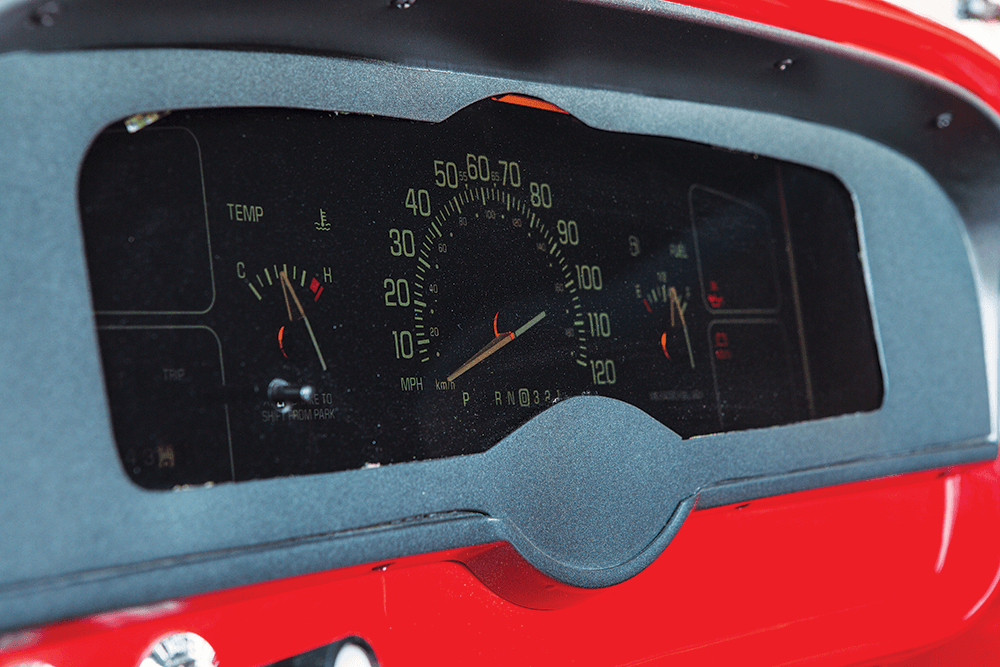

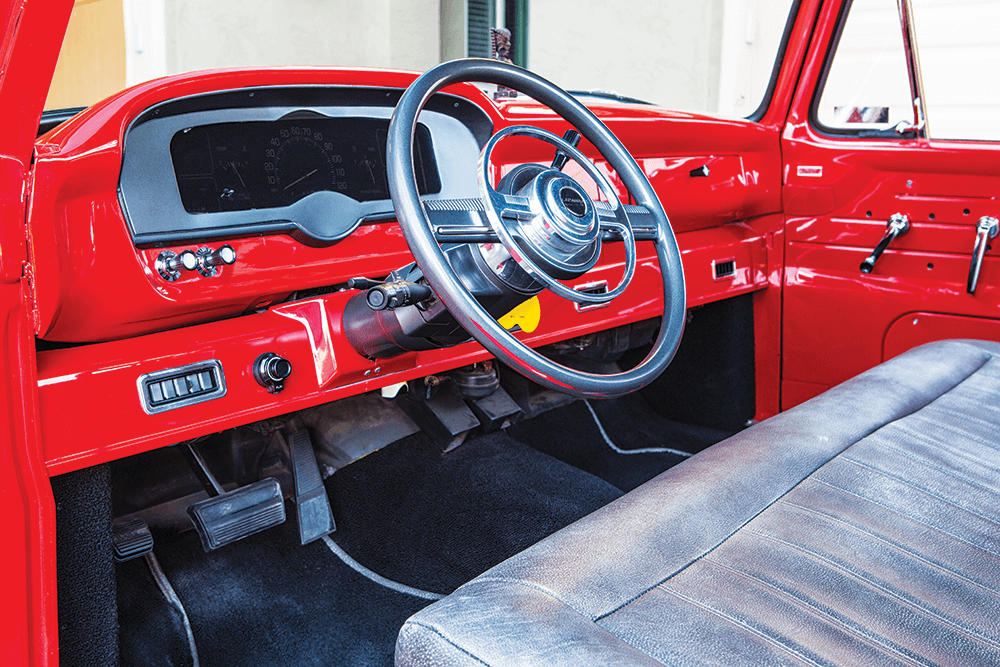

While the exterior is almost completely preserved, the interior has been comfortably updated. The Roadmaster frame swap included the use of the sedan’s firewall and all the attached components. Not only did this come with ice-cold A/C and cruise control, but this meant a fair bit of additional leg room and driver comfort. The Drew Brothers discarded the tired Roadmaster seats. In their place is a third-row bench from a second-generation Chevy suburban. The new-old seat now sports fresh upholstery in aged saddle leather thanks to Steve Nappi of Mesa, Arizona. The aged leather is perfectly at home with RU5TY’s signature style. The original F-100 dash remains in place, refurbished with a Lecarra Mark-10 steering wheel. The two-spoke style is a hot rod classic. Finally, the cabin now features a Hifonics TPS-BT1 stereo system. The whole of the cabin interior is sprayed in a custom red mix to highlight the Torch Red patina.

Brian Sherman and the Drew Brothers took this patina project head on. They struck true uniqueness by building the truck with an out-of-the-box approach. The Roadmaster chassis swap presented a challenge and a risk. But if it paid off, it would mean power potential, comfort, styling, and a truly unique Unibody. Needless to say, it did pay off in dividends and RU5TY is a truly one-of-a-kind ’61.

[divider] TECH SPECS[/divider]

Brian Sherman

1961 Ford F100 Unibody

Phoenix, Arizona

Chassis/Suspension

Engine/Performance

Wheels/Brakes

Body/Paint

Accessories/Interior

How did the simple shop truck idea evolve into a full custom build?

When initially conceived, the shop truck was meant to be a straightforward, functional vehicle for daily tasks. However, as Ryno began working on it, the vision expanded beyond its utilitarian purpose.

Ryno explains that the transformation was a natural progression:

“It evolved.”

Indeed, it did. This truck didn’t just undergo minor tweaks; it became a centerpiece for both work and leisure. Here’s how functionality met style in an extraordinary evolution:

Ryno’s philosophy encapsulates the entire journey:

“If I’m going to have a shop truck, it’s going to look cool.”

And in that regard, the project is a soaring success. The truck seamlessly blends the practical aspects of a work vehicle with the appeal of a custom-built ride, ultimately achieving a perfect duality.

How did the truck perform during its initial shakedown drive?

The initial shakedown drive for the truck was quite the adventure, offering valuable insights into its performance. After three weeks of intense building, the truck, lacking some of the finishing touches like the hood and side glass, embarked on a 1,000-mile round trip.

Surprisingly, the journey was largely trouble-free. The only notable issue was a center cap falling off one of the wheels during the trip. Otherwise, the truck demonstrated impressive reliability. Despite its unfinished state, it averaged a solid 12 miles per gallon at highway speeds, thanks to its 3.25:1 rear gear ratio, which undoubtedly contributed to its smooth operation on the open road.

How was the truck’s stopping power improved?

The truck’s stopping power was significantly enhanced by upgrading its braking system. Here’s a breakdown of the improvements:

These modifications collectively contribute to more reliable and effective braking performance, ensuring greater control and safety for the truck.

What was the original plan for the 1961 Ford F-100 Unibody truck?

The initial vision for the 1961 Ford F-100 Unibody truck was straightforward. Ryan Lieberman, also known as Ryno, aimed to create a practical, no-frills shop truck. His goal was to build a reliable vehicle for quick runs to the parts store or grabbing lunch, even if it meant still being covered in grease and grime from working on more intricate custom cars and hot rods in his garage. Essentially, Ryno wanted a simple, functional truck that could handle daily errands without the need for meticulous upkeep or concern for minor wear and tear.

What electrical upgrades were made to the truck?

The truck underwent a significant electrical overhaul to bring it up to modern standards. The original, outdated wiring was completely replaced with a new, reliable harness system. This meticulous upgrade involved installing a sophisticated 9+3 panel, ensuring that the truck’s electrical framework is now robust and efficient.

In addition to the new panel, a set of fresh harnesses was integrated to ensure seamless connectivity and optimal performance of all electrical components. These upgrades not only enhance the truck’s safety but also ensure consistent and reliable operation of all its systems, from headlights to engine management.

By modernizing the truck’s electrical system, these improvements provide a dependable and secure driving experience, ready to handle any demands placed upon it.

What challenges did Ryno face with rust during the build?

Ryno encountered numerous rust-related issues that significantly complicated the truck restoration project. After thoroughly pressure-washing both the interior and underside of the vehicle, it became evident that rust was a pervasive problem.

Each of these challenges demanded specialized treatment and posed unique obstacles, making the task far more arduous than initially anticipated. The pervasive rust required not just surface cleaning but detailed restorative efforts to ensure structural integrity and longevity.

Who is Ryno (Ryan Lieberman) and what role did he play in the build?

Ryan “Ryno” Lieberman is a seasoned car enthusiast known for his hands-on approach to custom automotive projects. Despite initially having reservations, Ryno found himself deeply involved in another build he hadn’t planned on. His vision was straightforward: he wanted a practical shop truck. This vehicle would be perfect for quick trips to the parts store or grabbing lunch, even when he was still covered in grease from working on custom cars or hot rods.

Ryno’s expertise and commitment to the craft were instrumental in the project’s success. His experience shaped every decision, ensuring the truck would meet the demands of a busy shop environment while offering a touch of personalized flair.

How did Ryno find the 1961 Ford F-100 Unibody for the project?

Ryno’s discovery of the 1961 Ford F-100 Unibody for his project began while he was browsing various online forums. He stumbled upon a listing by a fellow enthusiast, known by the username “Chadillac,” who had rescued the truck from being scrapped. It was through this serendipitous online encounter that Ryno found the perfect vehicle for his restoration ambitions.

How was the truck’s bed floor modified, and why?

The truck’s bed floor was elevated to create space for the notch. This adjustment ensures the bed remains flat, which is essential for its function as a shop truck designed for hauling items.

What are the specifications of the Hi-Po 289 engine used in the truck?

The Hi-Po 289 engine in the truck has been upgraded and fine-tuned for optimal performance. Here are the detailed specifications:

These specifications highlight the truck’s powerful and performance-oriented Hi-Po 289 engine, designed for both reliability and excitement on the road.

What drivetrain components were sourced from a 1965 Mustang Shelby GT350?

The project build sourced several critical drivetrain components from a 1965 Mustang Shelby GT350. The components included the 289 cubic inch V8 engine and its matching transmission. This powerful engine, known for its robust performance, brought a significant upgrade to the truck.

Additionally, the seats from the Shelby GT350 were incorporated into the build, enhancing both the comfort and aesthetic of the interior. The gas tank was also repurposed, ensuring efficient fuel delivery to the upgraded drivetrain.

In summary, the key drivetrain components sourced from the 1965 Mustang Shelby GT350 were:

These elements collectively transformed the build, infusing it with the performance prowess of a classic road-racing machine.

What body modifications were made to the truck?

Underneath the unique Uni is an uncommon chassis swap. Most people would not associate the Buick Roadmaster of the 1990s with Ford hot rodding. But when you weigh the pros and cons, it quickly becomes a slam dunk. The Roadmaster reached its final form in 1991 after a 30-plus year layoff. The final body style was built upon General Motor’s B-body. The B-body chassis supplied the bones to dozens of models across the GM lineup for decades. A few notable standouts are the 1966-96 Caprice Police Interceptor and the 1994-96 Impala SS. The Roadmaster underpinning RU5TY is its very last iteration of ’96.

The ’96 Roadmaster brought a huge increase in factory performance. The B-body garners a ton of aftermarket support and OEM reliability, all of which are plus factors to the RU5TY equation. The original F-100 Unibodies utilized a 115-inch wheelbase in their short-bed form. The late-generation B-bodies measured just 0.9 inch longer in the wheelbase. This minimal discrepancy allowed for fine tuning the frame fit. The team fabricated custom body mounts to complete the swap and the suspension has been refreshed with a set of KYB shocks in the front and rear and Eibach lowering springs at each corner. The lower height of the sedan, combined with the high-performance springs, make for a far more aggressive stance beneath this F-100. The modification is striking and truly makes for a unique hot-rod inspired look.

In terms of body modifications, the RU5TY boasts a raised bed floor and a shaved fuel filler. These changes not only enhance the truck’s aesthetic appeal but also contribute to its unique character.

While the exterior is almost completely preserved, the interior has been comfortably updated. The Roadmaster frame swap included the use of the sedan’s firewall and all the attached components. Not only did this come with ice-cold A/C and cruise control, but this meant a fair bit of additional leg room and driver comfort. The Drew Brothers discarded the tired Roadmaster seats. In their place is a third-row bench from a second-generation Chevysuburban. The new-old seat now sports fresh upholstery in aged saddle leather thanks to Steve Nappi of Mesa, Arizona. The aged leather is perfectly at home with RU5TY’s signature style. The original F-100 dash remains in place, refurbished with a Lecarra Mark-10 steering wheel. The two-spoke style is a hot rod classic. Finally, the cabin now features a Hifonics TPS-BT1 stereo system. The whole of the cabin interior is sprayed in a custom red mix to highlight the Torch Red patina.

What are the detailed specifications of the truck’s drivetrain?

Heads: Factory LT1 aluminum

Valve covers: Polished aluminum

Manifold / Induction: Factory LT1 intake / Sequential fuel injection

Ignition: MSD electronic ignition system

Headers: Custom stainless steel

Exhaust / Mufflers: Custom 3” stainless exhaust / Twin Flowmaster mufflers

Transmission: 4L60E 4-speed automatic

Shifter: Stock console-mounted

The drivetrain setup features a robust Chevy LT1 5.7L V-8 engine paired with a reliable 4L60E 4-speed automatic transmission, ensuring both power and smooth shifting. The factory LT1 aluminum heads and polished aluminum valve covers add to the engine’s durability and aesthetic appeal. A factory LT1 intake manifold combined with sequential fuel injection optimizes performance and efficiency.

For ignition, an MSD electronic ignition system ensures reliable starts and efficient combustion. The custom stainless steel headers and the custom 3” stainless exhaust system, complemented by twin Flowmaster mufflers, provide a deep, aggressive exhaust note and enhanced performance.

The 4L60E 4-speed automatic transmission offers smooth gear changes, while the stock console-mounted shifter maintains a classic feel within the cabin. This comprehensive setup ensures a perfect blend of power, reliability, and modern performance enhancements.

What modifications were made to the truck’s suspension?

Underneath the unique Uni is an uncommon chassis swap. Most people would not associate the Buick Roadmaster of the 1990s with Ford hot rodding. But when you weigh the pros and cons, it quickly becomes a slam dunk. The Roadmaster reached its final form in 1991 after a 30-plus year layoff. The final body style was built upon General Motor’s B-body. The B-body chassis supplied the bones to dozens of models across the GM lineup for decades. A few notable standouts are the 1966-96 Caprice Police Interceptor and the 1994-96 Impala SS. The Roadmaster underpinning RU5TY is its very last iteration of ’96.

The original F-100 Unibodies utilized a 115-inch wheelbase in their short-bed form. The late-generation B-bodies measured just 0.9 inch longer in the wheelbase. This minimal discrepancy allowed for fine tuning the frame fit. The team fabricated custom body mounts to complete the swap and the suspension has been refreshed with a set of KYBshocks in the front and rear and Eibach lowering springs at each corner. The lower height of the sedan, combined with the high-performance springs, make for a far more aggressive stance beneath this F-100. The modification is striking and truly makes for a unique hot-rod inspired look.

To get the suspension down to a reasonable height and improve handling and drivability, several specific modifications were made:

These precise adjustments ensure the F-100 not only sits lower but also handles remarkably well, combining the aesthetic appeal of a modern hot rod with the time-tested reliability of classic components.

What unique paint techniques were used on the truck?

The exterior of RU5TY is its obvious namesake. As Brian perfectly puts it, his build is sponsored by “Mother Nature.” The super rad patina was originally “Torch Red,” or R70540 according to the Ford Factory. The natural weathering has left plenty of primer in plain sight. The painted bumper aged to a different shade entirely bringing a special point of visual interest. But as the title suggests, the surface rust and peeking bare metal seams stand out. The brown lowlights adorn the rear fenders and several seams along the unibody. The driver’s side of the hood sports several rust patterns that look suspiciously like bullet wounds. Brian and the Drew Brothers decided to enhance the all-natural paint job with some period correct door graphics. Rob Drew hand painted the “Sherman’s Garage” logo for Brian Sherman, including his home town of Phoenix.

To elevate the visual impact, several unique paint techniques were employed. Panel paint was meticulously applied over three different sizes of flake, reminiscent of the wild lowrider paintjobs of the 1970s. This intricate work includes endless lines and a ribbon that runs from the front of the hood over the dash and roof. Lace work, scales, shells, and fades were also incorporated, creating a symphony of textures. Bandana styles add a final touch, making the truck explode in color and old-school cool.

For the base color, a Silver Sheen was chosen, while a variety of Pearls and Candies were used to bring the panels to life. The combination of these elements results in a paint job that is both complex and visually stunning, embodying a perfect blend of vintage and custom aesthetics.

Brian and his team would like to extend their gratitude to the skilled artists who contributed to laying out this intense paint job. Their expertise and creativity have undoubtedly taken RU5TY to the next level, making it a true masterpiece on wheels.

This detailed blend of natural and artistic elements ensures that RU5TY is not just a truck, but a rolling canvas that tells a story of time, craftsmanship, and innovation.

Share Link