Chris Hamilton

.

August 27, 2024

.

Department

Chris Hamilton

.

August 27, 2024

.

Department

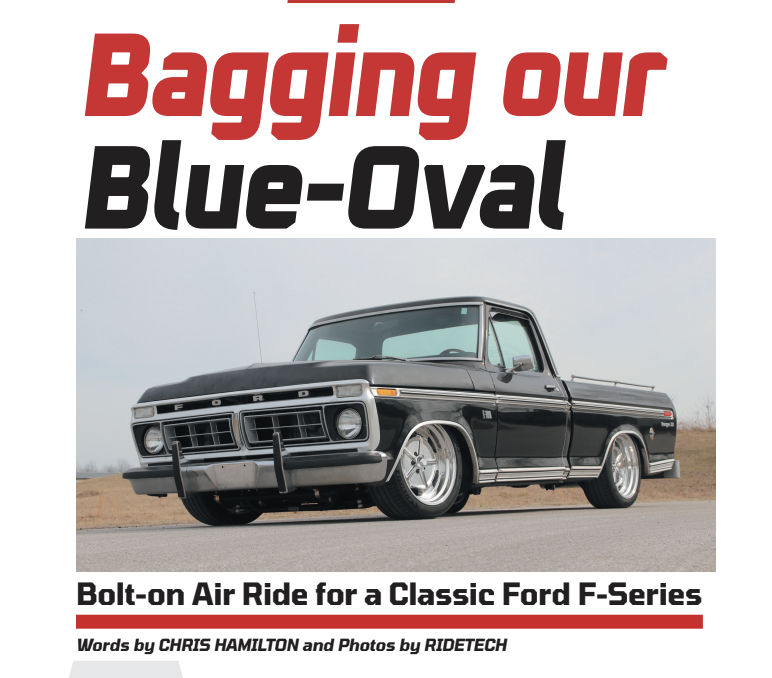

As editors of F-Series Builders Guide, we’re always on the lookout for innovations that blend the classic charm of Ford trucks with modern performance and ease of installation. Ridetech recently installed a full air-ride suspension system on a 1976 Ford F-100, and we are extremely impressed with the results.

The challenge with classic Ford F-100 and F-150 trucks lies in upgrading their suspension while preserving their original character. These trucks were built tough for a different era, prioritizing reliability over corner-carving agility. However, with the Ridetech suspension system, we found a solution that perfectly balances heritage with handling.

One of the standout features of Ridetech’s system is its ease of installation. The complete bolt-in suspension system replaces the factory front crossmember with a stout, bolt-on alternative. Designed to align seamlessly with the original rivet holes in the frame, installation is straightforward with basic hand tools and a bit of elbow grease. The result? A front suspension that’s not only stronger and more rigid than the original, but also significantly improves ride quality and handling.

At the heart of the system is the “Fox Mustang” style steering rack, a popular and easily accessible component. Combined with control arms featuring pre-installed ball joints and Delrin bushings, Ridetech ensures smooth, squeak-free performance with options for customizable caster settings. Compared to other aftermarket options, Ridetech’s system stands out for its structural integrity and uncompromised suspension geometry, making it a superior choice for enthusiasts seeking both performance and simplicity.

At the heart of the system is the “Fox Mustang” style steering rack, a popular and easily accessible component. Combined with control arms featuring pre-installed ball joints and Delrin bushings, Ridetech ensures smooth, squeak-free performance with options for customizable caster settings. Compared to other aftermarket options, Ridetech’s system stands out for its structural integrity and uncompromised suspension geometry, making it a superior choice for enthusiasts seeking both performance and simplicity.

Moving to the rear of the truck, Ridetech employs a proven 4-link design to achieve a low stance while retaining full bed floor utility and load capacity. The bolt-in C-notch further enhances the frame’s strength, providing all necessary mounts for control arms and Panhard bar. Whether opting for Shockwaves or coilovers, both options elevate the truck’s ride and handling to new heights.

Ridetech’s suspension system offers a transformative experience for classic Ford truck enthusiasts. With its easy installation, robust construction, and exceptional ride quality, it’s a must-have upgrade for anyone looking to take their F-Series to the next level.

Sources

Ridetech

www.ridetech.com

Ridetech used a super clean 1976 Ford F-100 for this install. This made it easier to take off the factory installed parts!

The front suspension was removed first after spraying a generous amount of WD40 to loosen the threads.

Next to come off was the sway bar and steering link. This freed up the frontend so we could get it all out in one shot.

Now the truck could be easily lifted off the front crossmember and moved out of the way all in one piece.

Some simple cuts to make extra room for the new parts were made before we cleaned and painted the front frame rails.

Now the new upper shock mounts could be bolted onto the frame.

Next up was the new front crossmember. A few holes needed to be drilled in the frame and the included hardware bolted it all in place.

The new upper control arms include Delrin bushings for a smooth, squeak-free long life, and the cross shaft allows for easy alignment and use of caster slugs. These also have adjustable steering stops.

The upper control arms bolted to the new brackets with the supplied hardware.

The lower control arms went on next, again using the supplied hardware.

We chose to install airbags on this truck, but you can pick coilovers as well. The process is the same; we just bolted in the option we chose.

This kit utilizes Ridetech’s tall “pin” spindle, which uses “AFX brake kits.” Many brake kits (including Wilwood) are dual-drilled for a 5×4.5- or 5×4.75-inch lug pattern.

Now the spindle could be bolted on along with the brake caliper bracket.

Optional “hub” spindles offer the same geometry improvements as the pin spindle but add the performance and simplicity of late model Mustang hubs and brakes.

The last step on the spindle install was inserting the cotter pins—don’t skip this step!

The sway bar holes were marked and drilled next. Ridetech is well known for its beefy front and rear sway bars.

With the holes drilled, we could install the new muscle bar using the provided hardware.

We followed that up by attaching the sway bar end links.

The front brake calipers could be installed, and we could now move to the rear of the truck.

Taking off the bed was the first step, and we hope you have a few friends to help because these classic Ford truck beds are heavy!!

The leaf springs were the first part of the rear suspension we needed to remove.

Followed by the leaf spring shackles and hangers.

The rear 4-link suspension kit from Ridetech includes a parallel 4-link with Panhard and C-notch. It works with coilover or Shockwave airbags.

The rear C-notch is not a fun job, but it’s not a tough job either. We simply used the provided paper template to mark and notch the rear frame with a cutoff wheel.

With the frame notched, cleaned, and puff-can painted, we placed the new bracket in the frame and drilled out the mounting holes.

The rear link bars include R-joints on all links for smooth, bind-free, quiet operation and long life. This setup is engineered for an optimized roll center and anti-squat (60% anti-dive) for amazing traction and elimination of wheel hop. It also reduces rear weight by 50 pounds!

Next up were the axle brackets that bolted to the new C-notch bracket.

The lower Shockwave mounts bolted directly to the brackets we just installed.

Now we could add the new link bars which are thick and solid—perfect for a high performance classic truck.

The last suspension piece to install was the new Shockwave air bag. Again, you can choose coilovers also if you would rather go that route.

It was then time to put the bed back on. Remember to lift with your legs, not your back!

Here is what our truck looked like with the factory wheels installed. It’s hammered but those wheels need to go.

Voilâ! The difference a set of wheels makes on a classic truck is immeasurable. Easy install, dramatic upgrades to performance and looks—we can’t recommend this kit enough!

Share Link