DEVAN ENCE

.

December 14, 2023

.

c10

DEVAN ENCE

.

December 14, 2023

.

c10

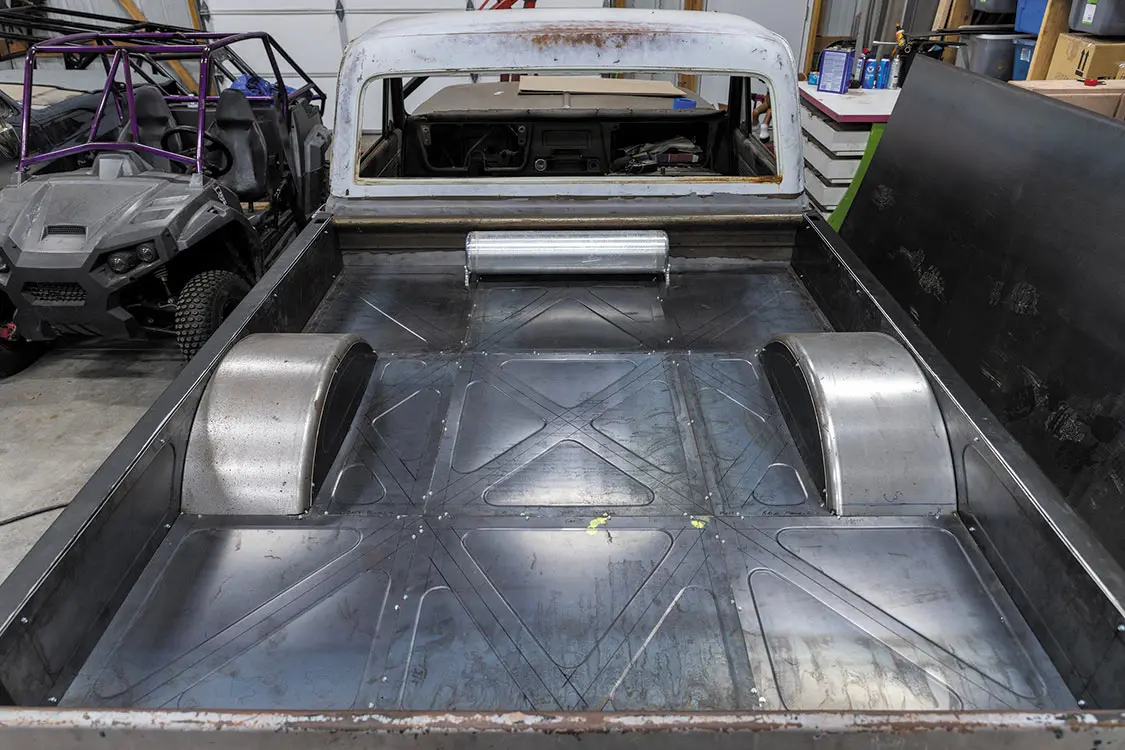

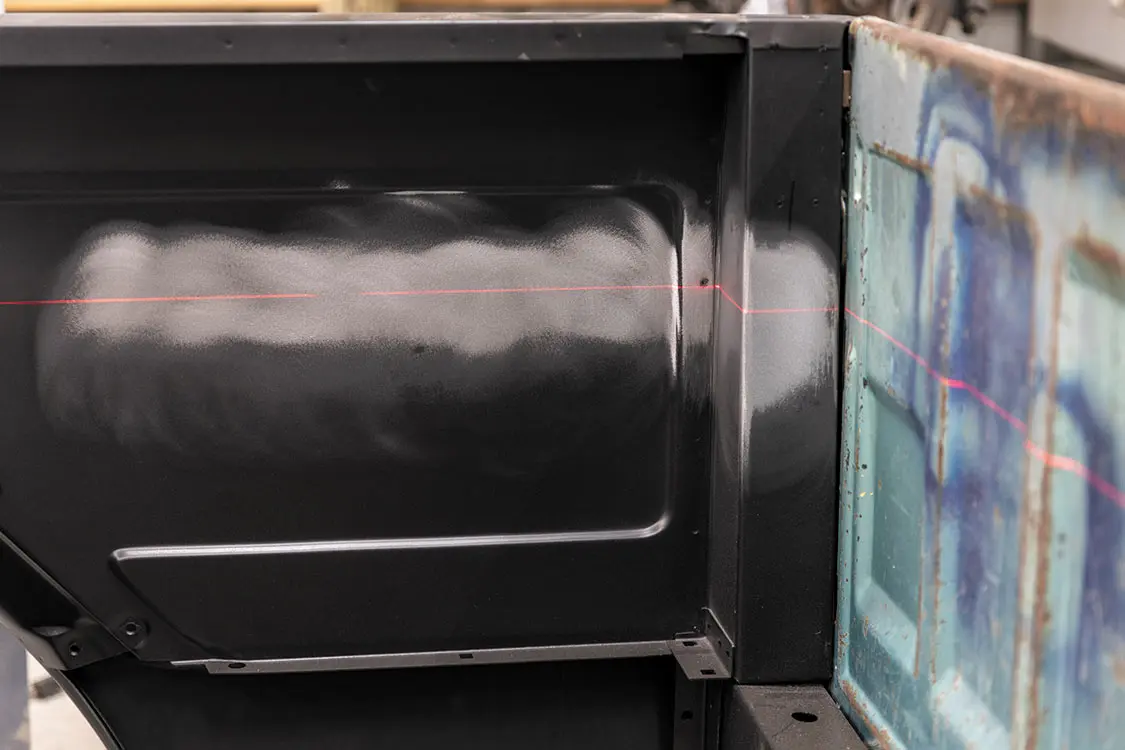

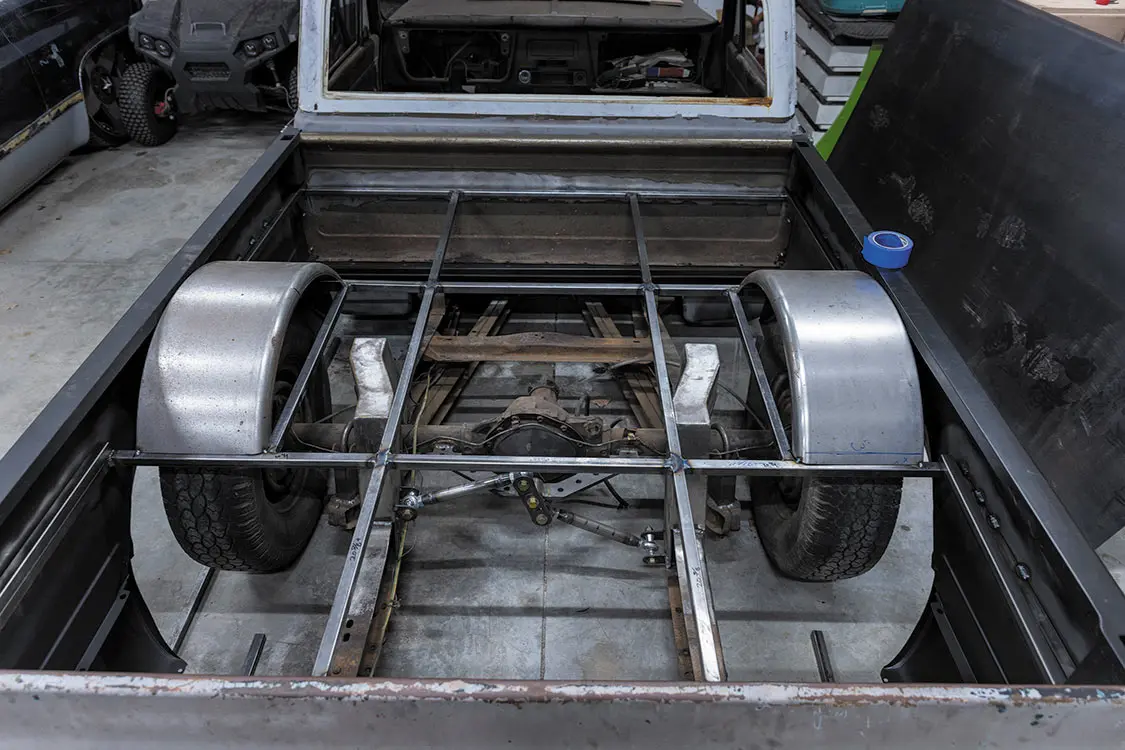

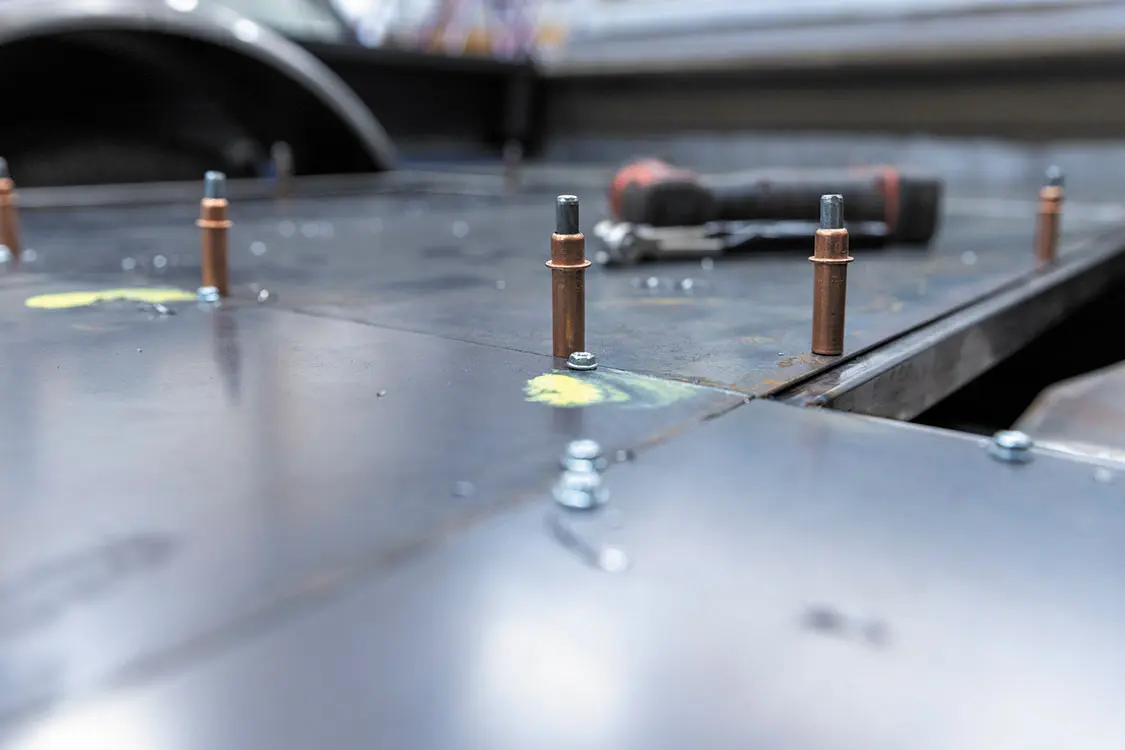

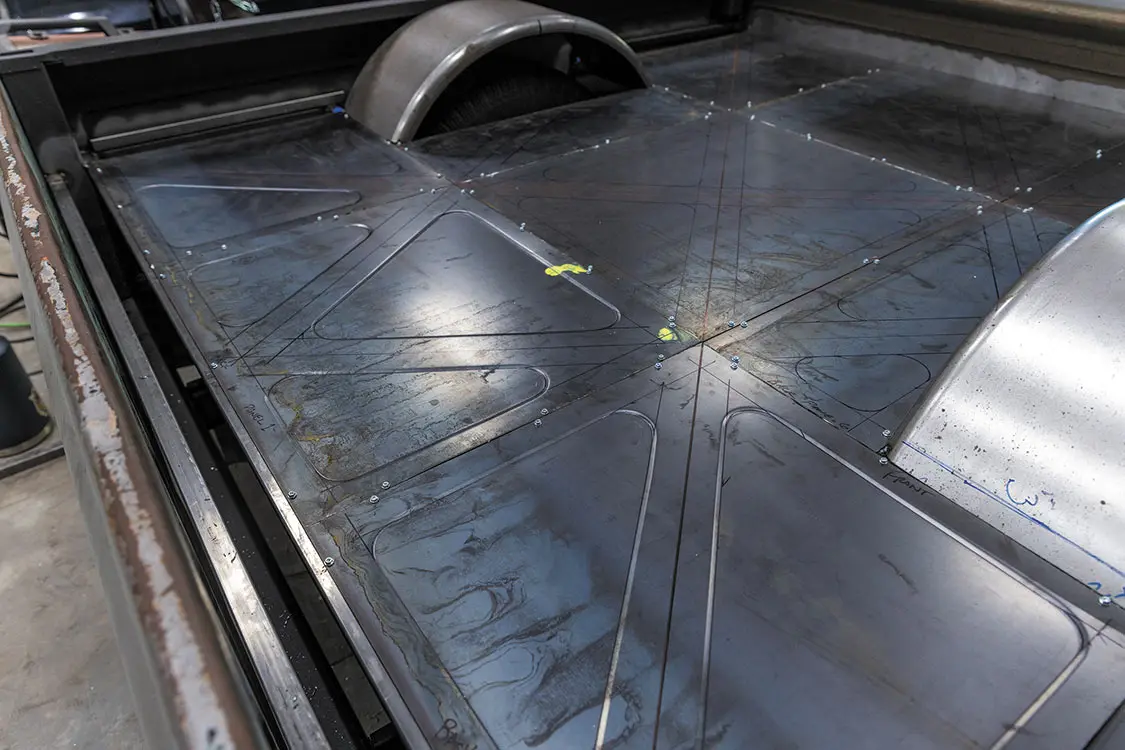

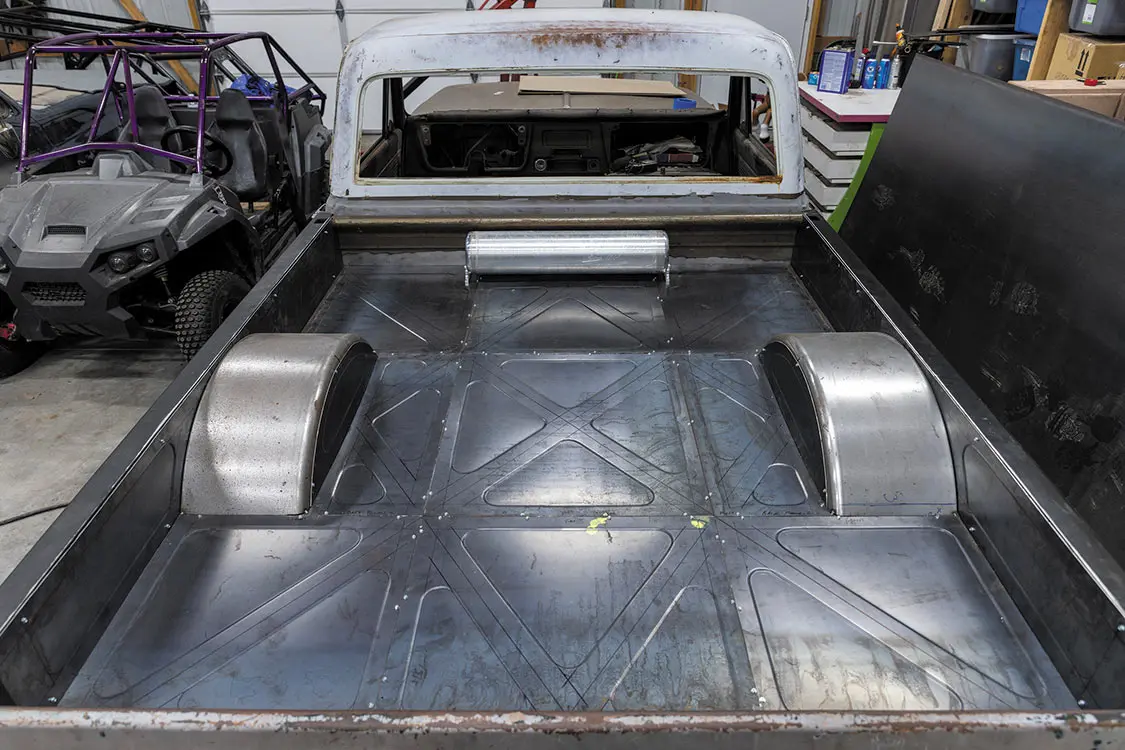

ARE YOU LOOKING to make your C10 stand out from the crowd? A way you can truly make your build one of a kind is with a custom bed floor that fits your project and your own unique style. With such a large canvas, you can really let your artistic side come out on full display.

The steps below are just one of the many ways to get started and your creativity flowing! For custom sheetmetal work like we’ve shown here, you have quite a few ways to go about it. Most are just personal preference, meaning that beyond the basics, there’s no real “right” or “wrong” way to some of what’s shown. There are a ton of amazing fabricators out there who use many different techniques, so don’t be afraid to experiment with what works best for you and your build!

Share Link