Phil Gordon

.

February 09, 2023

.

c10

Phil Gordon

.

February 09, 2023

.

c10

Nothing soothes more than a good dose of nostalgia. For Derrick Ramsey of Heber Springs, Arkansas, nostalgia came from his childhood of riding with his grandfather in a Chevy Squarebody.

My youngest memories were standing on a bench seat of an old farm truck. My grandfather and I went everywhere together. It was a huge part of my childhood.

“My youngest memories were standing on a bench seat of an old farm truck,” Derrick says. “My grandfather and I went everywhere together. It was a huge part of my childhood.”

Decades later, Derrick was conversing with a friend and shared his farm-truck memories. His friend told him that he knew of an ’84 Chevy C10 for sale for only $1,500. At that price, it was a no-brainer to scoop up the truck. Luckily, it was only one town over.

When Derrick arrived, he was shocked at how clean it was.

“It was mint, not a single speck of rust anywhere,” Derrick says.

The tail shaft was broken so it wouldn’t drive, but that didn’t stop Derrick at all. He winched the Chevy onto a trailer and took it home. The same day he unloaded it into his garage he began the stripping-down process. Without a clear path towards the level of customization Derrick was going to achieve, he laid out two different paths: It was either a clean, static drop with minor additions; or it was to blow it completely apart and learn as he went.

The decision came down to the flip of a coin, and I think you know which side it landed on.

With only minor experience in truck building, Derrick had quite the mission ahead of him. The first step was removing the front clip and yanking out the 305 from under the hood.

“I ended up taking that 305 to the scrapyard because that’s where 305s belong,” Derrick says with a laugh.

Derrick went online to several C10 forums and started researching and asking questions. After some in-depth research, Derrick realized that a huge problem with these trucks is that they don’t lay out in the front unless you raise the crossmember in one of three ways. He started looking into options, and people were talking about these new drop members that fixed every issue and would convert the truck to rack-and-pinion. At the time of the build process, only Thorbeck and Porterbuilt were making this drop member. While flipping through an issue of Street Trucks, Derrick saw a picture of Jason Thorbeck’s crossmember in one of the advertisements, and right then he decided that’s what he wanted for his C10. He ordered it along with a new back half and waited like a child on Christmas for it to arrive.

While waiting, Derrick took the frame to Rock Hard Powder Coating in Oil Trough, Arkansas. He found a Stroker 388 locally and a 700r4, which he added to the empty engine compartment. The rolling chassis was assembled, but the problem was that he hadn’t decided on what wheels to add yet.

“I know I’m not alone in this thinking,” Derrick says. “But wheels are the single most influential piece on any build.”

He spent hours looking through different wheels and, once again, turned to Street Trucks where he saw a set of Static 5s on a truck called Family Ties. Once he logged onto the Raceline website, the Jaded 5 popped up and he immediately made the call to order them.

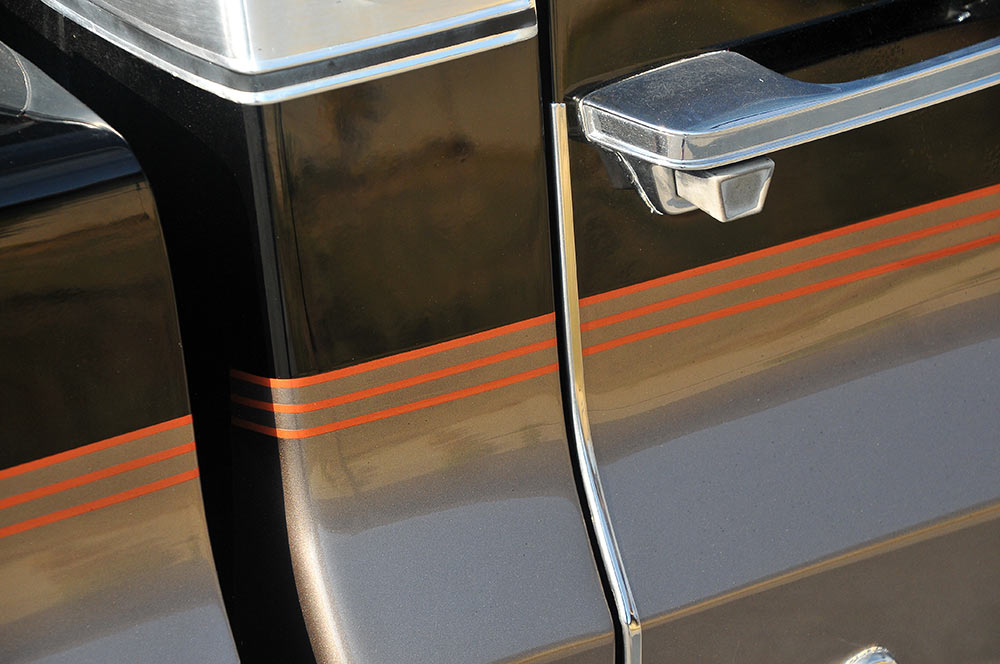

With all the components arriving around the same time, Derrick began the long process. He installed the full air-ride suspension system, bringing the C10 to the ground. For the bodywork, Derrick’s good friend Shawn Stone at Heber Springs Collision allowed him to borrow the tools and materials to complete all the work. The next step was adding paint to the blank canvas by bringing the Chevy to Scott Churchwell for a complete paint job. At this point, Derrick thought he was finished with the build, but he was wrong.

While trailering his C10 to a local show in Fort Smith, Arkansas, he laid it out on the wood platform and gave the appearance of a body-drop. After seeing this, Derrick had a whole new mission.

He ordered larger wheels of the same brand and model and 2×4 tubing for the frame. The truck was torn down once again. The rolling chassis was brought to a friend’s shop, and a 3/4-inch frame was built for the 2.5-inch stock floor body-drop. Three days later the truck was once again on the road but now able to be dropped on the frame. To finish the body-drop process, Derrick built the bed floor and upgraded the air-management system.

When he needed extra parts for the C10, he found a donor truck. When he arrived to buy it, the owner told him he had named this truck Becky but thought the name was stupid for a truck.

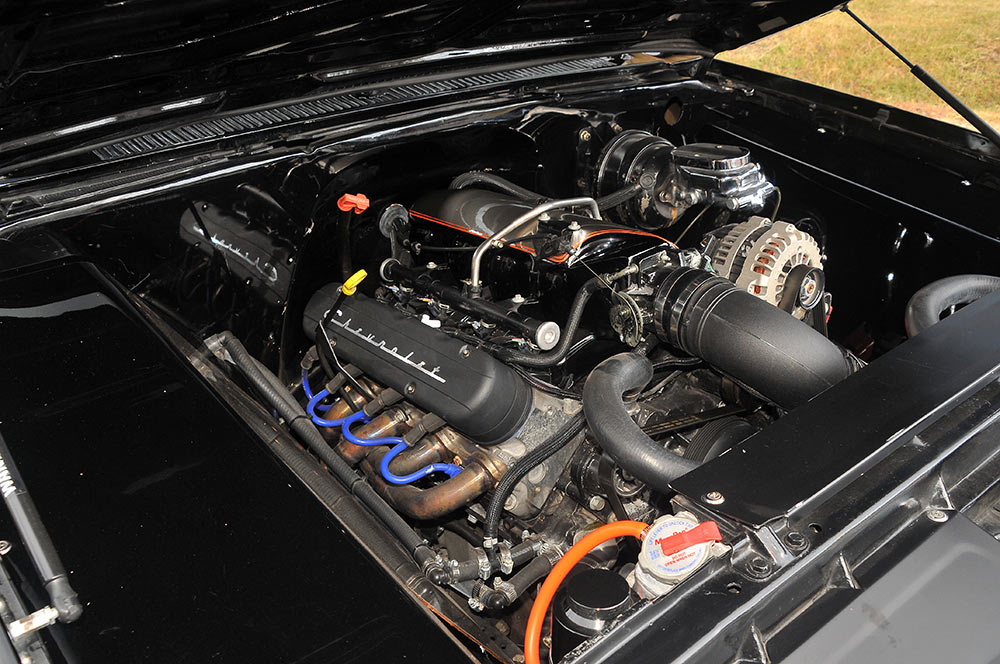

On the way to dinner with his wife, Derrick’s transmission went out, so to get the biggest bang for his buck, he pulled the whole motor, added an LS motor, and had it tuned and dialed in.

As a habit, Derrick names most of the things he owns, from cars to lawnmowers. The names, for some reason, always start with the letter B. His last truck was Betsy, his lawnmower is Beowolf, and he has a street bike named Beatrice. When he needed extra parts for the C10, he found a donor truck. When he arrived to buy it, the owner told him he had named this truck Becky but thought the name was stupid for a truck. Derrick disagreed and said, “That’s the name of this truck, I can’t change it.”

That’s her identity now. When anyone meets her at a show, they always address her as “Becky.”

OWNER

Derrick Ramsey

1984 Chevy C10

Heber Springs, Arkansas

Club Affiliation: Acrophobia

Chassis

Drivetrain

Body/Paint

Interior

Wheels & Tires

Special Thanks

First and foremost, thanks to my wife, Chelsea. She has put up with a lot and supported everything. Thanks to my mom and dad. My mom would stop by the house every afternoon to watch our son so I could get into the garage and work on the truck. My dad would drop what he was doing and come help every time I was ready to give up. If it weren’t for those people, it would have never gotten finished. Mike McElroy and Jody Brooks always came to my aid with electrical issues. Thanks to Shawn Stone for letting me take up space in his place of business to do my bodywork and Scott Churchwell for the paintwork.

What is the history and significance of the Chevrolet C/K series, particularly the C10?

In 1960, the Chevrolet C/K series marked a pivotal shift in the landscape of American trucks, setting a new standard for performance and design. Renowned for their robust build and versatility, the C/K series trucks were manufactured in the United States until 1998.

Among these, the C10 emerged as the most prevalent model. It was a half-ton truck available with either a 6.5-foot or 8-foot bed, making it a popular choice for both personal and commercial use.

From its inception, the styling of the C/K series trucks remained largely consistent. Minor updates and refinements were introduced over the years, but the fundamental design saw a significant overhaul only in 1997. These trucks were not only utilitarian but also exuded a timeless style that appealed to a broad audience.

The Chevrolet C/K series, especially the C10, remains an icon in the automotive world, celebrated for its significant contribution to the development of modern pickups.

What types of classic Chevrolet C10 trucks are available for sale?

Looking for a classic Chevrolet C10 truck? The market is bustling with diverse options that cater to different tastes and budgets. Here’s a snapshot of what you can find:

These classic trucks range from beautifully restored models to unique custom builds, ensuring there’s something for every enthusiast.

What are the price ranges for the Chevrolet C10 trucks listed?

If you’re interested in the diverse lineup of Chevrolet C10 trucks, the listed prices reveal a broad range based on year, condition, and customizations. Here’s a quick rundown to give you an idea of what to expect:

Whether you’re looking for an affordable project truck or a fully restored showpiece, the prices for Chevrolet C10 models span from about $5,000 to $80,000. This range includes everything from original classics to highly customized restomods, offering options to fit various budgets and preferences.

What are some examples of dealership listings for Chevrolet C10 trucks?

1979 Chevrolet C10 Scottsdale

A dealership in Kansas City presents this well-maintained 1979 Chevrolet C10 Scottsdale, available for $36,000. This classic model is sure to turn heads with its sleek lines and timeless appeal.

1968 Chevrolet C10

This 1968 Chevrolet C10 comes with a factory short bed and is listed at $20,995. Featuring a clean title, it boasts 2-inch drop spindles and new tires and wheels, along with disc brakes for enhanced performance.

1964 Chevrolet C10 Fleetside Longbed

Offered at $35,495, this 1964 Chevrolet C10 Fleetside Longbed Pick-up is a solid choice for collectors. It includes a Custom Cab, chrome bumpers, and grille, accentuating its classic design.

1971 Chevrolet C10

A worldwide vintage auto dealership has this 1971 Chevrolet C10 listed at $22,900. Known for being one of the largest classic automobile consignment venues, they guarantee quality and authenticity.

These listings showcase a variety of Chevrolet C10 trucks from different model years, offering options for every classic truck enthusiast.

What are some examples of featured private seller listings for Chevrolet C10 trucks?

Here are some examples of private seller listings for Chevrolet C10 trucks:

These listings represent a variety of Chevrolet C10 models, each with unique features and pricing to suit different preferences and budgets.

What are some popular searches related to classic cars?

If you’re diving into the world of classic cars, you’ll find some models that enthusiasts can’t stop talking about. Here’s a list of some hot searches:

Classic cars capture the imagination with their unique designs and storied pasts, making them perpetual favorites in search trends.

What types of customizations and conditions are noted in the Chevrolet C10 listings?

This Brian Tooley-built ’01 5.3L LS engine has a few upgrades including a truck cam, Holley Script coil pack covers, a shaved stock intake that is painted to match, and Taylor spark plug wires.

The tail shaft was broken so it wouldn’t drive, but that didn’t stop Derrick at all. He winched the Chevy onto a trailer and took it home. The same day he unloaded it into his garage he began the stripping-down process. Without a clear path towards the level of customization Derrick was going to achieve, he laid out two different paths: It was either a clean, static drop with minor additions; or it was to blow it completely apart and learn as he went.

Derrick went online to several C10 forums and started researching and asking questions. After some in-depth research, Derrick realized that a huge problem with these trucks is that they don’t lay out in the front unless you raise the crossmember in one of three ways. He started looking into options, and people were talking about these new drop members that fixed every issue and would convert the truck to rack-and-pinion. At the time of the build process, only Thorbeck and Porterbuilt were making this drop member.

While waiting, Derrick took the frame to Rock Hard Powder Coating in Oil Trough, Arkansas. He found a Stroker 388 locally and a 700r4, which he added to the empty engine compartment. The rolling chassis was assembled, but the problem was that he hadn’t decided on what wheels to add yet.

He spent hours looking through different wheels and, once again, turned to Street Trucks where he saw a set of Static 5s on a truck called Family Ties. Once he logged onto the Raceline website, the Jaded 5 popped up and he immediately made the call to order them.

With all the components arriving around the same time, Derrick began the long process. He installed the full air-ride suspension system, bringing the C10 to the ground. For the bodywork, Derrick’s good friend Shawn Stone at Heber Springs Collision allowed him to borrow the tools and materials to complete all the work. The next step was adding paint to the blank canvas by bringing the Chevy to Scott Churchwell for a complete paint job. At this point, Derrick thought he was finished with the build, but he was wrong.

While trailering his C10 to a local show in Fort Smith, Arkansas, he laid it out on the wood platform and gave the appearance of a body-drop. After seeing this, Derrick had a whole new mission.

He ordered larger wheels of the same brand and model and 2×4 tubing for the frame. The truck was torn down once again. The rolling chassis was brought to a friend’s shop, and a 3/4-inch frame was built for the 2.5-inch stock floor body-drop. Three days later the truck was once again on the road but now able to be dropped on the frame. To finish the body-drop process, Derrick built the bed floor and upgraded the air-management system.

On the way to dinner with his wife, Derrick’s transmission went out, so to get the biggest bang for his buck, he pulled the whole motor, added an LS motor, and had it tuned and dialed in.

As a habit, Derrick names most of the things he owns, from cars to lawnmowers. The names, for some reason, always start with the letter B.

When he needed extra parts for the C10, he found a donor truck. When he arrived to buy it, the owner told him he had named this truck Becky but thought the name was stupid for a truck. Derrick disagreed and said, “That’s the name of this truck, I can’t change it.”

That’s her identity now. When anyone meets her at a show, they always address her as “Becky.”

Derrick’s journey is just one of many unique stories in the world of Chevrolet C10 customizations. The variety of builds out there is truly staggering:

These builds underscore the endless possibilities for customizing a C10, whether it’s keeping it original, adding modern powertrains, or creating a show-stopping custom. Just like Derrick’s “Becky,” each truck tells its own story and reflects the unique vision of its owner.

How does the chassis system accommodate larger tires when modifications like mini-tubbing are performed?

When you’re looking to fit larger tires on your vehicle, particularly those up to 12 inches in width, certain modifications are necessary to ensure a seamless integration. One of the common techniques used is mini-tubbing, which involves altering the frame rail designs.

The chassis system in question has been engineered with flexible frame rail designs. These innovations are specifically intended to support modifications like mini-tubbing. This approach not only enlarges the wheel well area but also ensures that the vehicle can accommodate substantially wider tires.

To manage the increased tire width, the rear frame rails are especially noteworthy. Once mini-tubbing is performed, these rails can support tires up to a size of 345 millimeters. This enhanced capacity is crucial for enthusiasts looking to achieve both aesthetic and performance upgrades with their vehicle’s larger tires.

In summary, the frame rail and rear rail modifications, including mini-tubbing, play a pivotal role in accommodating larger tires. This adaptability is particularly beneficial for automotive enthusiasts keen on enhancing both the look and performance of their vehicles.

What are the benefits of the new suspension geometry in the chassis system?

Incorporating these benefits, the new suspension geometry not only revolutionizes the aesthetic and structural aspects of vehicles but also simplifies the upgrade process for enthusiasts looking for both performance and style.

What features contribute to the strength and precision of the chassis system?

When evaluating a top-tier chassis system, it’s crucial to consider the features that enhance its strength and precision. Here are some key elements that set a superior chassis apart from the rest:

In summary, the strength and precision of this chassis system are primarily derived from its modern materials, advanced engineering techniques, and compatibility with current automotive innovations. These features work together to provide a robust and reliable foundation for any vehicle.

What types of engine mounts are available with this chassis system?

When selecting the right engine mounts for your vehicle, you have a range of options designed to accommodate various engine types. Here’s a quick overview of what’s available:

This chassis system is versatile, providing a perfect fit for a wide selection of engine configurations, whether you’re restoring a classic or building a custom project.

Is it necessary to modify the vehicle’s floor for the installation of the chassis system?

When installing a new chassis system, one common concern is whether altering the vehicle’s floor is necessary. Fortunately, for many modern chassis systems, floor modifications are not required. This is great news for vehicle owners looking to maintain the original integrity and design of their car.

For those concerned about extensive vehicle alterations, rest assured that many chassis systems are designed to fit seamlessly without the need for floor modifications. Always ensure you check the specifications of the third-party brand you are considering to confirm compatibility.

What type of rear suspension is included in the chassis system for the 1967-72 C10 Slammed?

The chassis system for the 1967-72 C10 Slammed includes an advanced rear suspension design known as the parallel four-link suspension. This setup specifically aids in maintaining stability and comfort, even at lower ride heights, essential for achieving that sleek, slammed appearance.

Overall, the parallel four-link suspension is pivotal in transforming the riding experience of the C10, making it not only aesthetically pleasing but also performance-oriented.

What is the engineering approach used in the chassis system for the 1967-72 C10 Slammed?

The engineering approach for the 1967-72 C10 Slammed chassis system is at the forefront of innovation, utilizing cutting-edge manufacturing techniques. This approach focuses on creating a chassis that is exceptionally lightweight and durable. By incorporating advanced manufacturing technologies, the system ensures ease of installation, making it accessible for users of varying skill levels.

Engineers have meticulously devised a proprietary suspension geometry tailored specifically for this chassis. The result is a seamless blend of ride quality and high-performance capabilities, positioning it as a leader within its category. The design emphasizes streamlining processes to achieve cost efficiency and reduced lead times without compromising performance.

This meticulous attention to detail results in a chassis system that meets high standards of efficiency and performance while providing unparalleled ride and handling quality. Whether for casual enthusiasts or seasoned builders, this system offers a user-friendly and dependable solution.

What are the standard features included in the chassis installation for the 1967-72 C10 Slammed?

Enhance your 1967-72 C10 with this comprehensive chassis installation that promises precision and performance. Here’s a detailed look at what comes standard:

This expertly designed chassis ensures not just performance but also reliability, making your C10 Slammed an epitome of engineering excellence.

What steering and suspension components are used in the chassis system?

Derrick Ramsey

1984 Chevy C10

Heber Springs, Arkansas

Club Affiliation: Acrophobia

Chassis

This comprehensive setup not only elevates the truck’s performance but also ensures a balanced and responsive driving experience, making Derrick’s Chevy C10 a standout in the Acrophobia club lineup.

What specific coilovers are used?

It features RS SV coilovers by Fox, which have a fixed valve design.

What kind of rear suspension setup is used?

The vehicle utilizes a parallel 4-bar rear suspension system.

What specific brand and model are used for the spindles?

The spindles are from the Wilwood brand, specifically their Pro Spindle model.

What specific components are used to facilitate alignment?

The setup includes adjustable upper a-arm mounts with eccentric features for quick and precise alignment adjustments.

What type of steering system is used?

The vehicle is equipped with a power-assisted rack and pinion steering system.

How does the chassis system accommodate stock floors and minimize modifications?

The truck was torn down once again. The rolling chassis was brought to a friend’s shop, and a 3/4-inch frame was built for the 2.5-inch stock floor body-drop. Three days later the truck was once again on the road but now able to be dropped on the frame. To finish the body-drop process, Derrick built the bed floor and upgraded the air-management system.

The beauty of this setup lies in its ability to contour to stock floors, allowing for most applications to require no floor modifications. This means you can enjoy a sleek, low-profile look without the hassle of extensive alterations. The engineering behind this design ensures that the chassis system aligns perfectly with the stock floor, maintaining the structural integrity of your vehicle while giving it a standout appearance.

Incorporating these features, Derrick not only achieved the desired body-drop but also ensured that the truck retained its original floor structure, minimizing the time and effort typically associated with such modifications.

Is the system suitable for a wide range of applications?

Yes, the system is versatile and intended to be compatible with a variety of applications, reducing the need for alterations.

Does the chassis system require floor modifications?

Generally, the system is installed without the need for floor modifications in most cases, ensuring a straightforward integration.

How does the chassis system interact with stock floors?

The chassis system is designed to adapt to the contours of stock floors, allowing it to fit smoothly with the existing floor structure.

Share Link