Mike Self

.

June 23, 2022

.

Department

Mike Self

.

June 23, 2022

.

Department

When thinking about lowering your truck, it’s understandable that you’d have some questions about what’s involved, as well as how to handle any problems that may present themselves after the fact. If it’s your first foray into the world of slammed trucks, you might be anxious making such a huge change to your ride, but lucky for you we’re here to help!

We’ve compiled 10 of the most common questions we get about lowered trucks, along with our thoughts on each. Hopefully they’ll help put your mind at ease when it’s time to drop your own truck and will get you hyped up about living the low life!

Of course! But, like any truck, it has to be set up correctly! Don’t expect to tow much of anything if you cut your front springs and pulled a bunch of leafs out of your rear spring packs. However, if you have a quality lowering kit (with helper bags depending on the truck) or a full-on air-ride setup with properly rated airbags, you’ll be golden.

Well, we say you should have a lifted truck and a lowered truck, but if you insist on lifting your lowered truck, it can definitely be done. If you’re running drop spindles, you’ll have to swap them out for stock or lifted spindles. Same with your front coil springs. If you’ve got a rear axle flip kit installed, you’ll be removing that in order to put your axle back under your leaf springs. And, if you have drop hangers and/or drop shackles, you’ll be swapping those out as well.

In some cases, you might have to buy stock replacement parts if you don’t have the originals. For instance, most people toss their stock leaf hangers when installing drop hangers, so stock ones will have to be purchased before lifting your truck. If you’re wanting to lift a bagged truck, things are a bit more complicated, but it’s totally doable. In reality, though, it’d be much easier to sell the truck and start over with a stock or already lifted truck.

In some cases, you might have to buy stock replacement parts if you don’t have the originals. For instance, most people toss their stock leaf hangers when installing drop hangers, so stock ones will have to be purchased before lifting your truck. If you’re wanting to lift a bagged truck, things are a bit more complicated, but it’s totally doable. In reality, though, it’d be much easier to sell the truck and start over with a stock or already lifted truck.

This one is a lot like the previous question. Basically, you’ll need to replace any lowering parts with stock or factory replacement parts. Drop spindles and coils? Replace them with stock parts. Lowered struts? Swap them out with stock replacements. Same with the rest—drop shackles, drop hangers, and lowered leaf springs all get pulled and replaced with the stock stuff. If your axle is flipped, unflip it with new replacement U-bolts. That frame notch? Well, you’re kind of stuck there unless you want to go through the trouble of replacing that section of frame.

In most cases, a lowered truck that rides poorly is due to the owner skimping on something somewhere along the line. Cut (or even worse—heated) springs, improperly valved shocks (or using the factory shocks), and not maintaining enough suspension travel are the usual culprits. You wouldn’t believe how often I’ve seen someone complain about their rough-riding truck, only to crawl underneath and see the front and rear sitting on the bumpstops.

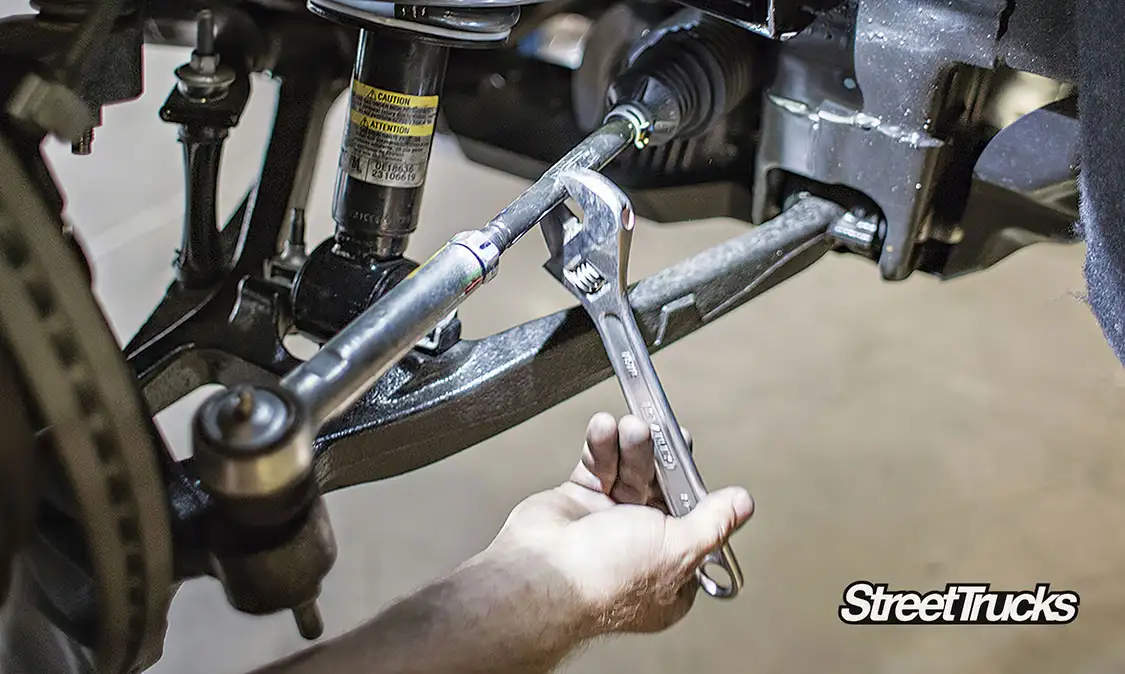

A common misconception about lowered trucks is that they can’t be properly aligned. The truth is, it all comes down to how comfortable your local alignment shop is with lowered vehicles. They may not be able to properly align your truck, but a shop that’s well-versed in the ways of lowered suspensions certainly can. Technically, the goal is the same as for a stock truck—get the camber, caster, and toe as close to factory specs as possible to minimize tire wear and maintain optimum performance. To do this, your local shop may need to install a camber kit, which allows for more adjustment than the factory alignment parts.

Yes, you can certainly do an “eyeball” alignment yourself, but that’s usually limited to toe in/toe out since caster is a bit trickier to figure out, and camber adjustment often requires shims/spacers that most people don’t just have sitting around. If you’re really determined to do it yourself, there are plenty of DIY alignment tools on the market, but they can be spendy. We’d only suggest going that route if you plan to change your suspension settings often, such as with an autocross truck.

Yes, you can certainly do an “eyeball” alignment yourself, but that’s usually limited to toe in/toe out since caster is a bit trickier to figure out, and camber adjustment often requires shims/spacers that most people don’t just have sitting around. If you’re really determined to do it yourself, there are plenty of DIY alignment tools on the market, but they can be spendy. We’d only suggest going that route if you plan to change your suspension settings often, such as with an autocross truck.

Our suggestion is to talk to folks at your local cruise spot and ask around about shops that can handle your alignment. And for those of you with bagged trucks, remember to set your truck to your preferred ride height before handing the keys over to the shop!

Our suggestion is to talk to folks at your local cruise spot and ask around about shops that can handle your alignment. And for those of you with bagged trucks, remember to set your truck to your preferred ride height before handing the keys over to the shop!

Yeah…. yeah, you can, but we’re not fans of doing things twice, and you’ll likely eventually get tired of the harsh ride that comes with taking the cheap way out. You’re probably fine if you only plan to go down 1 or 2 inches, but springs that are made for lowered trucks tend to perform better, with stiffer spring rates that help take advantage of your truck’s lower center of gravity. This is one of those things that people kind of need to experience for themselves, so if you’re really dead set on lowering your truck the cheapest way possible, give it a shot. Just don’t ever, ever, heat your springs to lower your truck!

We’re actually big fans of running drop springs and spindles together to slam trucks, but if you’re only going down a couple of inches, either is great. Drop spindles have the advantage of maintaining your original suspension travel (assuming you’re not also installing drop springs), while lowering springs tend to cost quite a bit less than drop spindles. The only cons to drop spindles are that, depending on the truck, you sometimes can’t run your factory wheels, and in some cases your turning radius can be slightly reduced. When deciding which spindles to buy, visit each manufacturer’s website to find out if this applies to your application.

Again, this is one of those situations where we recommend using both together to slam the crud out of your truck, but if a major lowering job isn’t your style, either one achieves the same effect if you’re just going down a couple of inches. Drop shackles are definitely easier to install, as well as cheaper, so they’re the most popular choice by far. Drop hangers require you to remove the large factory rivets on your stock hangers, then bolt on the new hangers. Not a terribly complicated job, but definitely more time consuming than shackles.

This question kind of hurts our feelings. Have you not thumbed through these pages before?! OK, OK, give us a sec to calm down a bit… Let’s start with the look. Lowering a truck always makes it look better. Always. And then there are the added benefits that come with a lower center of gravity and a performance-minded suspension. Also, it’s easier to find your truck in a parking lot when it doesn’t look like every other Chevy/Ford/Ram out there, not to mention how much easier it is to get into your truck! Why should’t you lower your truck? Did you ever think about that?

Whether you’ll need to notch your frame will depend on how low your truck is going to be. Generally speaking, if you’re going to be installing an axle flip kit, you’re going to want to install a C-notch or step notch since your frame to axle clearance will be minimal at best. Notching your frame will give you back the suspension travel you need, which is especially important if you ever plan on hauling anything. If your axle isn’t flipped, you will probably still have enough clearance to be fine in most cases. All of this is assuming, of course, that your axle came installed underneath your leaf springs from the factory. Most 2WD mini-trucks come with the axle installed over the springs, so the above info mostly applies to full-size trucks. If you have a mini, we generally start thinking about a notch with anything more than a 3-inch drop.

What are the recommendations for lowering a truck that is regularly driven on streets and highways?

When it comes to lowering a truck that sees regular street and highway use, there are some guidelines you should follow to ensure a safe and comfortable ride.

For stock-height pickups, a common recommendation is to lower the front by up to 2 inches and the rear by up to 4 inches. This range typically provides a good balance between aesthetics and functionality without severely impacting ride quality or handling.

If you’re considering a more dramatic drop, keep in mind that significant frame modifications might be required. Full-on slam setups can be achieved, but these often involve extensive adjustments to the truck’s frame, which can be complex and costly.

By following these recommendations, you can achieve a lowered stance that not only looks great but also performs reliably on both streets and highways.

Why is choosing the right shock absorbers critical for a lowered truck?

The provided text does not contain any entities that fall under the categories: {“Person”, “Organization”, “Address”, “Phone”, “Email”, “Location”, “Website”}. Therefore, no tags are necessary.

How does extreme lowering impact the suspension and driveline of a truck?

Lowering a truck to extreme levels, especially by cutting stock springs and retaining the original shocks, can have significant negative effects on its suspension and driveline components.

When a truck is drastically lowered, its undercarriage is much more likely to make contact with the ground. This can happen frequently when driving over bumps, potholes, and uneven road surfaces:

The most vulnerable components during these impacts are positioned low to the ground, such as:

Overall, extreme lowering of a truck compromises the longevity and functionality of its suspension and driveline, making it crucial for owners to consider these risks carefully before modifying their vehicle.

By understanding the potential hazards, drivers can make informed decisions about adjusting their vehicles and possibly opt for adjustable air or hydraulic suspensions to mitigate these issues.

Why are airbags and hydraulic suspension systems considered the best options for lowering a truck?

When it comes to lowering a truck, airbags and hydraulic suspension systems stand out for several compelling reasons:

While airbags and hydraulic suspension systems are more expensive than conventional options, their benefits often justify the higher price point:

By investing in airbags or hydraulic suspension systems, you not only enhance your truck’s functionality but also elevate its look and feel, making these setups the top choice for serious truck enthusiasts.

What towing challenges might one face with a lowered truck?

Of course! But, like any truck, it has to be set up correctly! Don’t expect to tow much of anything if you cut your front springs and pulled a bunch of leafs out of your rear spring packs. However, if you have a quality lowering kit (with helper bags depending on the truck) or a full-on air-ride setup with properly rated airbags, you’ll be golden.

Yet, even with a proper setup, there are some practical challenges you should be aware of:

So, while a top-notch lowering kit and air-ride system can make towing feasible, always be prepared for the occasional hiccup that comes with a lowered truck.

How can poorly executed lowering affect a truck’s tires?

In most cases, a lowered truck that rides poorly is due to the owner skimping on something somewhere along the line. Cut (or even worse—heated) springs, improperly valved shocks (or using the factory shocks), and not maintaining enough suspension travel are the usual culprits. You wouldn’t believe how often I’ve seen someone complain about their rough-riding truck, only to crawl underneath and see the front and rear sitting on the bump stops.

But there’s more at stake than just the ride quality. Lowering a truck can also bring on issues when new or replacement parts for lowering come into contact with other pieces like anti-roll bars, wheels, and/or tires. Specifically, suspension binding brought on by poorly executed lowering can promote aggressive tire attrition. This means that your tires can wear out much faster than expected, leading to increased costs and potential safety hazards.

The key takeaway? Properly executed lowering is not just about aesthetics or even ride comfort—it’s crucial for the overall health and longevity of your truck’s components, including the tires.

What are the suspension-related issues that can arise from lowering a truck?

In most cases, a lowered truck that rides poorly is due to the owner skimping on something somewhere along the line. Cut (or even worse—heated) springs, improperly valved shocks (or using the factory shocks), and not maintaining enough suspension travel are the usual culprits. You wouldn’t believe how often I’ve seen someone complain about their rough-riding truck, only to crawl underneath and see the front and rear sitting on the bumpstops.

Lowering a truck can also bring on issues when new or replacement parts for lowering come into contact with other pieces like anti-roll bars, wheels, and/or tires. With regard to tires, suspension binding brought on by poorly executed lowering can promote aggressive tire attrition. This means your tires wear out much faster than they should, costing you more in the long run.

To avoid these issues, it’s crucial to invest in quality components and ensure proper installation. Opt for lowering kits from reputable brands that are designed to work harmoniously with the rest of your vehicle’s suspension system. This not only improves ride quality but also extends the lifespan of your truck’s components.

By addressing both the common mistakes and the specific mechanical issues, you can enjoy the aesthetic and performance benefits of a lowered truck without compromising on safety or comfort.

How can lowering a truck affect its handling and ride quality?

Lowering a truck can yield performance improvements in several areas. Better aerodynamics and enhanced traction are often cited benefits, along with gains in handling and overall ride quality. However, the latter two criteria are highly subjective. One driver may feel the truck handles and rides better than ever, while another could view the change—which typically results in a harder or stiffer ride—as the worst thing that ever happened to their pickup.

In most cases, a lowered truck that rides poorly is due to the owner skimping on something somewhere along the line. Cut (or even worse—heated) springs, improperly valved shocks (or using the factory shocks), and not maintaining enough suspension travel are the usual culprits. You wouldn’t believe how often I’ve seen someone complain about their rough-riding truck, only to crawl underneath and see the front and rear sitting on the bumpstops.

When done correctly, lowering a truck can offer significant performance and aesthetic benefits. However, careful consideration and quality components are essential to avoid compromising ride quality. Always ensure that modifications are done with precision and attention to detail to enjoy the full benefits without the pitfalls.

What are the potential benefits of lowering a truck’s suspension?

This question kind of hurts our feelings. Have you not thumbed through these pages before?! OK, OK, give us a sec to calm down a bit… Let’s start with the look. Lowering a truck always makes it look better. Always. And then there are the added benefits that come with a lower center of gravity and a performance-minded suspension. Also, it’s easier to find your truck in a parking lot when it doesn’t look like every other Chevy/Ford/Ram out there, not to mention how much easier it is to get into your truck! Why shouldn’t you lower your truck? Did you ever think about that?

But wait, there’s more! Contrary to popular belief, dropping a rig down low isn’t always done for show. Performance improvements such as better aerodynamics and traction can come with lowering a suspension, along with gains in handling and overall ride quality.

So, whether you’re in it for the looks or the performance upgrades, lowering your truck offers a multitude of benefits that go beyond just turning heads.

What are the chassis-related problems associated with lowering a truck by cutting stock springs and retaining original shocks?

Yeah…. Yeah, you can, but we’re not fans of doing things twice, and you’ll likely eventually get tired of the harsh ride that comes with taking the cheap way out. You’re probably fine if you only plan to go down 1 or 2 inches, but springs that are made for lowered trucks tend to perform better, with stiffer spring rates that help take advantage of your truck’s lower center of gravity. This is one of those things that people kind of need to experience for themselves, so if you’re really dead set on lowering your truck the cheapest way possible, give it a shot. Just don’t ever, ever, heat your springs to lower your truck!

Let’s dive into why cutting your stock springs can be a bad idea. When you lower a truck to extreme levels using cut springs and original shocks, you risk the belly of your truck bottoming out. This means the undercarriage can literally hit the pavement hard as you drive over bumps and uneven roads. Ouch, right?

This constant contact with the road isn’t just uncomfortable; it’s hazardous. Critical components like the suspension (think control arms, ball joints, tie rods), the chassis (frame), and the driveline (driveshaft, differential, transmission, oil pan) are put in jeopardy. They’re in the direct line of fire when you encounter speed bumps, manhole covers, and those sneaky potholes.

So, while cutting springs might seem like an easy fix, it can lead to frequent and costly repairs. Opting for springs designed for lowered trucks is a smarter move—they’re specifically engineered to handle the lower stance without compromising your ride quality or endangering your truck’s vital parts.

What are the common drawbacks of lowering a truck without using an application-specific system?

Yeah…. Yeah, you can, but we’re not fans of doing things twice, and you’ll likely eventually get tired of the harsh ride that comes with taking the cheap way out. You’re probably fine if you only plan to go down 1 or 2 inches, but springs that are made for lowered trucks tend to perform better, with stiffer spring rates that help take advantage of your truck’s lower center of gravity.

This is one of those things that people kind of need to experience for themselves, so if you’re really dead set on lowering your truck the cheapest way possible, give it a shot. Just don’t ever, ever, heat your springs to lower your truck!

Despite the fact that pickups with chassis-scraping, low-and-mean postures (especially crew-cab longbeds) often look amazing, drawbacks to lowering are a lot more common than any favorable results of the profile change. Here are some of the issues you might encounter:

To avoid these problems, it’s crucial to use an all-encompassing, application-specific system. These systems are designed to address the unique needs of your truck’s make and model, ensuring not just a better look, but also a safer and more comfortable ride.

So, if you’re really committed to lowering your truck, invest in the right components from the start. Trust us, your back and your truck will thank you.

What potential damage can occur to a truck’s tires and parts when lowered?

Lowering a truck can lead to various types of damage if not done correctly. Here’s a detailed look at the potential issues:

When a truck is lowered excessively, the suspension and steering components may touch or interfere with each other. This can lead to premature wear and tear, resulting in costly repairs or replacements. Ensuring adequate clearance between these parts is crucial to maintaining overall vehicle health.

Lowering a truck often alters its alignment, leading to uneven tire wear. The tires might also rub against the wheel wells if there’s not enough clearance, causing them to wear out faster or even blow out unexpectedly. Regular checks and adjustments can help prevent this kind of damage.

A lowered truck is closer to the ground, which increases the risk of scraping its undercarriage on speed bumps, curbs, or uneven roads. Frequent contact with such obstacles can lead to damage to the exhaust system, oil pan, and other vital components under the vehicle.

Lowering can alter the truck’s center of gravity, potentially affecting its handling and stability. This might lead to difficulties in controlling the vehicle, especially during sharp turns or sudden maneuvers.

To minimize these risks, ensure the lowering process is done professionally and that all parts are carefully adjusted. Regular maintenance checks can help identify and address any alignment or clearance issues before they escalate into more severe problems.

What role do torsion bars play in lowering a truck?

Torsion bars are integral to the suspension system of many heavy trucks, especially those requiring support for substantial weight. While they aren’t designed to allow drastic drops, they offer a straightforward method for minor height adjustments.

By altering the tension on the torsion bars, you can subtly adjust the truck’s stance without major modifications, making it a popular choice for those looking to tweak their vehicle’s height on a moderate scale.

What are the possible warranty issues associated with lowering a truck?

Lowering a truck is a popular modification among enthusiasts. However, it’s important to be aware of potential warranty complications that may arise:

By thoroughly understanding these aspects, you can make an informed decision and avoid unexpected expenses.

How does lowering a truck affect its handling and performance?

Lowering a truck can yield performance improvements in several areas. Better aerodynamics and enhanced traction are often cited benefits, along with gains in handling and overall ride quality. However, the latter two criteria are highly subjective. One driver may feel the truck handles and rides better than ever, while another could view the change—which typically results in a harder or stiffer ride—as the worst thing that ever happened to their pickup.

In most cases, a lowered truck that rides poorly is due to the owner skimping on something somewhere along the line. Cut (or even worse—heated) springs, improperly valved shocks (or using the factory shocks), and not maintaining enough suspension travel are the usual culprits. You wouldn’t believe how often I’ve seen someone complain about their rough-riding truck, only to crawl underneath and see the front and rear sitting on the bumpstops.

Always ensure that modifications are done with precision and attention to detail to enjoy the full benefits without the pitfalls. Lowering a truck, when executed thoughtfully, can transform the driving experience, offering a blend of performance enhancements and visual appeal.

What are the pros and cons of lowering your truck?

This question kind of hurts our feelings. Have you not thumbed through these pages before?! OK, OK, give us a sec to calm down a bit… Let’s start with the look. Lowering a truck always makes it look better. Always. And then there are the added benefits that come with a lower center of gravity and a performance-minded suspension. Also, it’s easier to find your truck in a parking lot when it doesn’t look like every other Chevy/Ford/Ram out there, not to mention how much easier it is to get into your truck! Why shouldn’t you lower your truck? Did you ever think about that?

But wait, there’s more! Contrary to popular belief, dropping a rig down low isn’t always done for show. Performance improvements such as better aerodynamics and traction can come with lowering a suspension, along with gains in handling and overall ride quality.

However, let’s not overlook the potential downsides.

So, whether you’re in it for the looks or the performance upgrades, lowering your truck offers a multitude of benefits that go beyond just turning heads. Just be sure to weigh these advantages against the potential drawbacks to make the choice that’s right for you.

What potential damage could occur from lowering a truck too much?

If a truck is lowered excessively, there’s a risk of damage to the tires and other components. The suspension and steering parts might come into contact with the ground, especially on uneven surfaces, leading to costly repairs.

How might lowering a truck affect the vehicle’s warranty?

Some manufacturers may void the warranty if you lower your truck without their approval. It’s crucial to consult your user manual or speak with the manufacturer to avoid any warranty issues.

What are the financial implications of lowering a truck?

Lowering a truck can be costly as it involves purchasing additional parts and components. Moreover, maintaining the vehicle’s alignment can become more expensive, adding to the overall cost.

What practical challenges might I face when maintaining a lowered truck?

One of the main challenges is using a standard jack, which often won’t fit under a lowered truck. You’ll need a specialized jack to perform simple tasks like changing a flat tire.

How do drop spindles affect a truck’s suspension and ride quality?

We’re actually big fans of running drop springs and spindles together to slam trucks, but if you’re only going down a couple of inches, either is great. Drop spindles have the advantage of maintaining your original suspension travel (assuming you’re not also installing drop springs), while lowering springs tend to cost quite a bit less than drop spindles.

Maintaining Factory Geometry: One of the standout benefits of drop spindles is that they maintain the factory suspension geometry. This means your truck retains its original handling characteristics while the spindles raise the front wheel mounting position. The result? A smooth, stable ride without compromising on suspension travel.

Average Drop and Installation: Typically, drop spindles offer an average drop of around 2 inches. Installation is often more straightforward than switching springs, which can save time and reduce the risk of installation errors.

However, it’s important to consider a couple of potential cons. Depending on the truck, you sometimes can’t run your factory wheels, and in some cases, your turning radius can be slightly reduced.

When deciding which spindles to buy, visit each manufacturer’s website to find out if this applies to your application. Balancing cost, compatibility, and your desired drop will ensure you make the best choice for your truck.

How do spindles affect the front wheel mounting position?

Drop spindles alter the front wheel mounting position by raising it, which contributes to the overall lowered stance of the vehicle.

How does the installation complexity of spindles compare to other lowering methods like springs?

Installing drop spindles is generally simpler than replacing springs, making them a convenient option for those who prefer a less complicated installation process.

What is the typical amount of drop achieved with spindles?

Typically, drop spindles provide a height reduction of about 2 inches, which is a common target for those looking to lower their vehicle moderately.

How do drop spindles affect suspension geometry?

Drop spindles maintain the original suspension geometry, ensuring that the vehicle’s handling characteristics remain consistent while lowering the ride height.

What is spring lowering in the context of truck suspension?

Yeah…. Yeah, you can, but we’re not fans of doing things twice, and you’ll likely eventually get tired of the harsh ride that comes with taking the cheap way out. You’re probably fine if you only plan to go down 1 or 2 inches, but springs that are made for lowered trucks tend to perform better, with stiffer spring rates that help take advantage of your truck’s lower center of gravity. This is one of those things that people kind of need to experience for themselves, so if you’re really dead set on lowering your truck the cheapest way possible, give it a shot. Just don’t ever, ever, heat your springs to lower your truck!

In the past, spring lowering often involved chopping or heating the springs to achieve a lower ride height. While these methods got the job done, they came with significant downsides, like compromising performance and ride quality. Fast forward to today, and the game has changed.

A multitude of aftermarket manufacturers now offer shorter springs specifically designed to work correctly with your vehicle’s suspension system. These springs are crafted to maintain performance while achieving that sleek, lowered look. But keep in mind, even with these modern solutions, there are trade-offs.

Ultimately, it’s about finding what works for you. If budget constraints lead you down the cheaper path, just be prepared for a potentially harsher ride. And remember, heating springs is a big no-no—trust us on this one!

What are the trade-offs of using shorter springs?

While shorter springs are a cost-effective way to lower a vehicle, they can negatively impact ride comfort and limit the suspension’s travel range.

What modern solutions are available for spring lowering?

Today, many aftermarket companies offer specially designed shorter springs that effectively lower the vehicle while maintaining performance standards.

What are the drawbacks of traditional methods?

Using these older techniques often led to a decline in performance and a rougher ride, as the structural integrity and function of the springs were compromised.

What were traditional methods of spring lowering?

In the past, vehicle enthusiasts would either chop or apply heat to springs to reduce the vehicle’s height. These were common methods before more advanced solutions became available.

How are trucks lowered?

This one is a lot like the previous question. Basically, you’ll need to replace any lowering parts with stock or factory replacement parts. Drop spindles and coils? Replace them with stock parts. Lowered struts? Swap them out with stock replacements. Same with the rest—drop shackles, drop hangers, and lowered leaf springs all get pulled and replaced with the stock stuff. If your axle is flipped, unflip it with new replacement U-bolts. That frame notch? Well, you’re kind of stuck there unless you want to go through the trouble of replacing that section of frame.

Lowering a truck is a popular modification for achieving a sporty appearance or crafting a custom show car. The process involves several methods, each with its own impact on performance and ride quality.

Understanding these lowering techniques is essential not only for modifying your truck but also for restoring it to stock. Knowing what components have been altered will help you effectively replace them with their original counterparts.

What are the historical techniques used for lowering trucks, and how have they evolved?

Historically, customizers chopped or heated springs to lower trucks, which negatively affected performance. Modern advancements have led to the development of aftermarket parts, like shorter springs and drop spindles, that offer improved performance while achieving the desired lowered look.

How does each method affect the truck’s performance and ride quality?

Shorter springs can compromise ride smoothness and suspension travel. Drop spindles ensure a smoother ride by preserving the original suspension setup. Adjusting torsion bars is simple but may not significantly impact performance.

What are the advantages and disadvantages of each method?

Shorter springs are cost-effective but may reduce ride quality and suspension travel. Drop spindles provide a smoother ride and maintain factory suspension geometry, though they are more expensive. Torsion bars offer easy adjustments but provide limited lowering potential.

How do each of these methods work?

Shorter springs replace the original ones to lower the truck, while drop spindles alter the wheel mounting position without changing suspension geometry. Torsion bars can be adjusted by loosening the torsion keys, making it a straightforward method for heavier trucks.

What are the different methods to lower a truck?

Truck owners can choose from several methods to lower their vehicles, including using shorter springs, installing drop spindles, and adjusting torsion bars. Each method offers a distinct approach to achieving a lowered stance.

Share Link