Chris Stafford @CK Syndicate

.

September 28, 2022

.

Department

Chris Stafford @CK Syndicate

.

September 28, 2022

.

Department

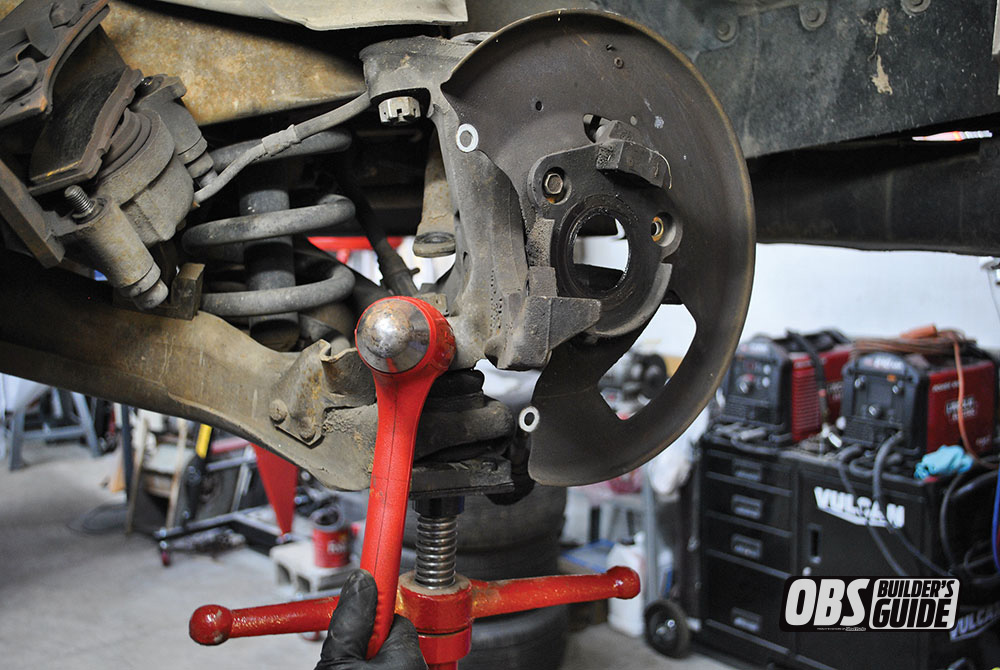

When considering a lowering kit for your 1988-1998 C1500 or (OBS GM Truck), you’ll find there are quite a few options out there. Most companies offer parts individually, so you can get creative with parts combinations in order to get your desired results. In our case, we wanted to try and get this job done with performance and ultimate ride quality in mind. Being that Belltech Suspension was a huge part of the sport truck movement back in the ’90s, the company knows a thing or two about OBS GM trucks. With that said, naturally they were our first call when we decided to tackle the suspension on our 1990 C1500.

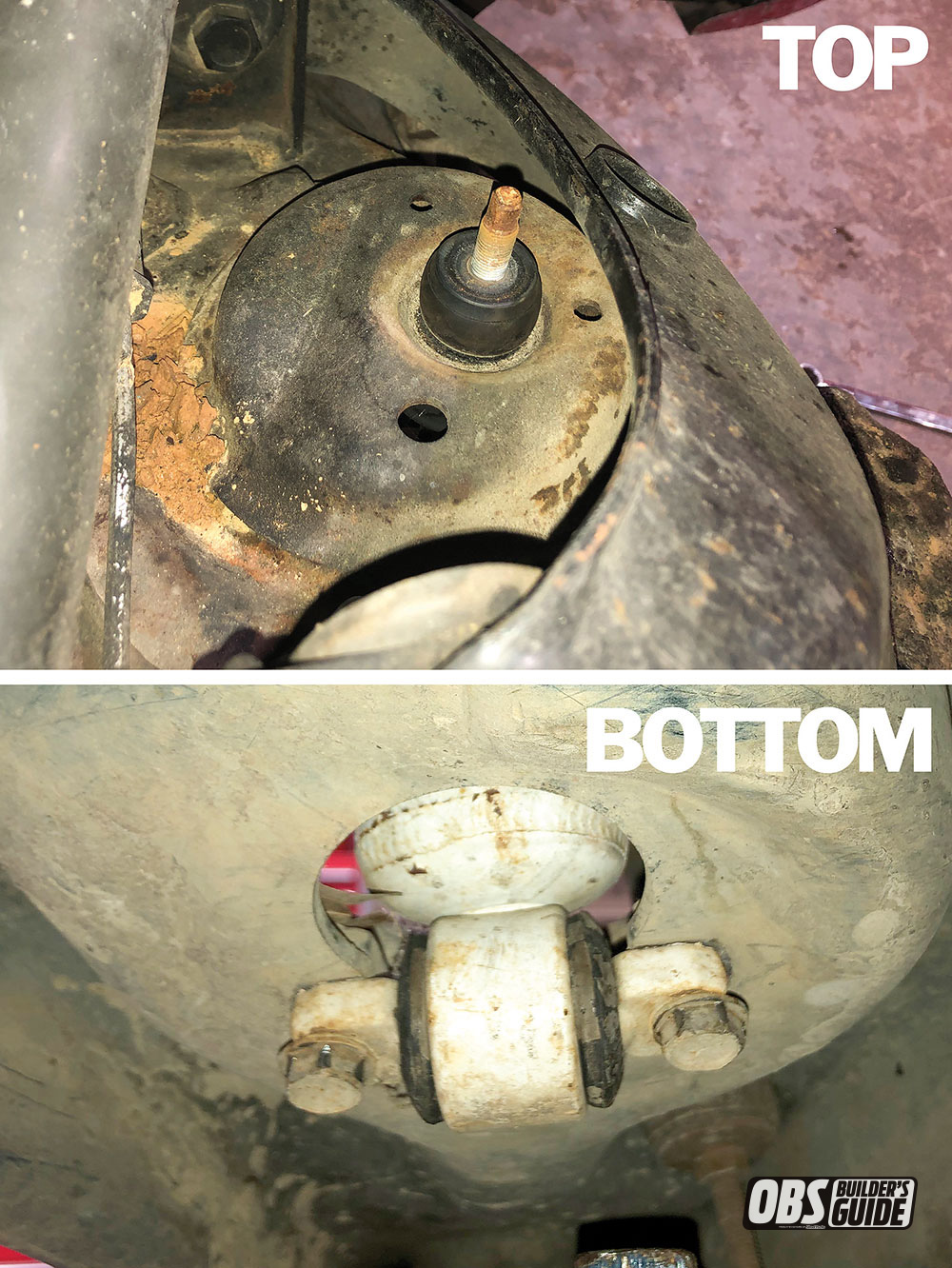

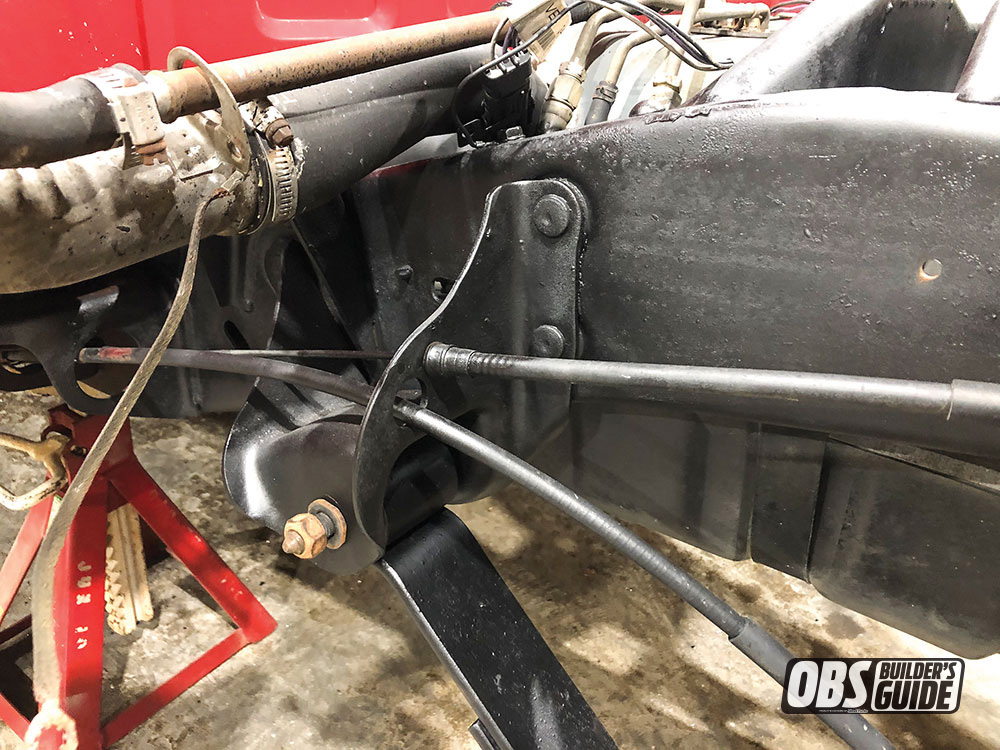

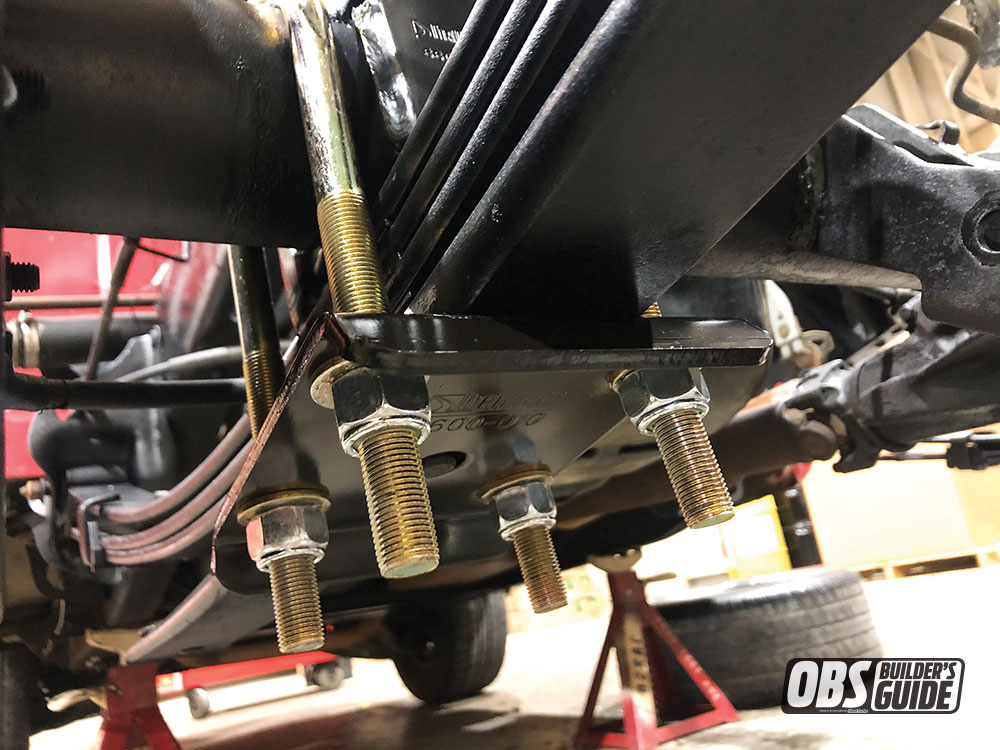

We decided to utilize the 3-inch drop spring and paired those with the 2-inch drop spindle up front. To achieve our desired drop out back, we went with a flip kit. The flip kit is also adjustable drop because it comes with new rear shackle mounts that when paired with the flip kit will yield either a 7 inch or 8 inch. We topped everything off with Street Performance Shocks/Shock extenders and front and rear sway bar kit.

Belltech lowering kits include all the parts and pieces you need to achieve not only the look you want, but the alignment, and performance and safety you need. These complete lowering kits are your all-in-one-box solution, providing you with all the necessary parts to lower your truck. Made up of a variety of combinations as well as all the installation and alignment pieces necessary to achieve the listed lowering, choosing your kit has never been simpler. And the install is even easier! Let’s get started.

Share Link