Chris Hamilton

.

September 14, 2021

.

c10

Chris Hamilton

.

September 14, 2021

.

c10

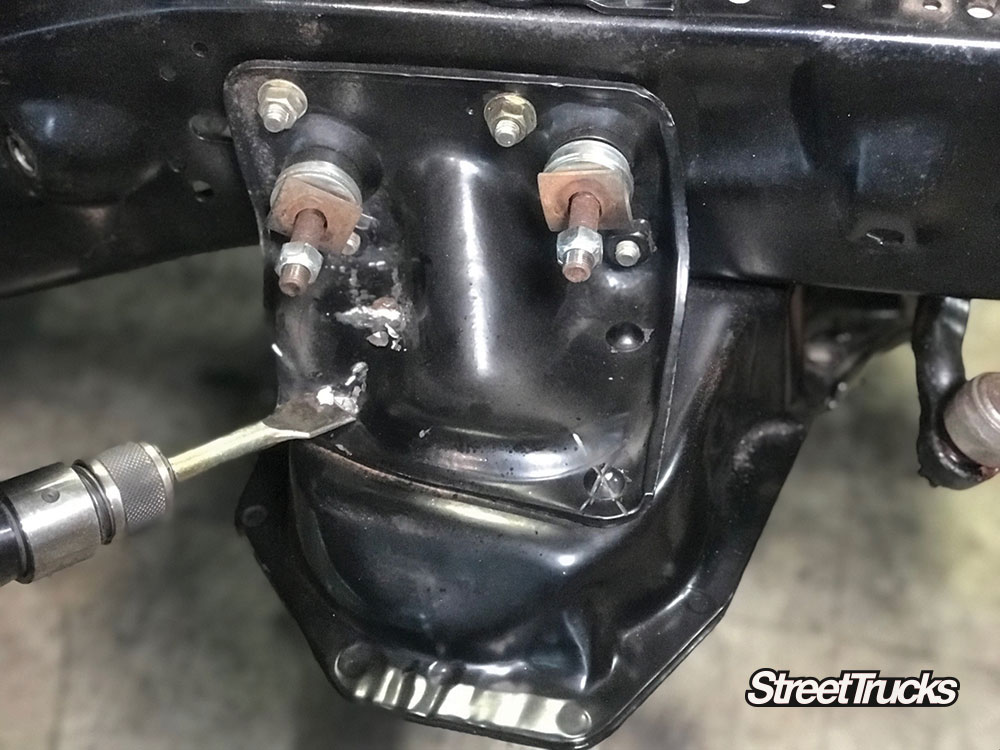

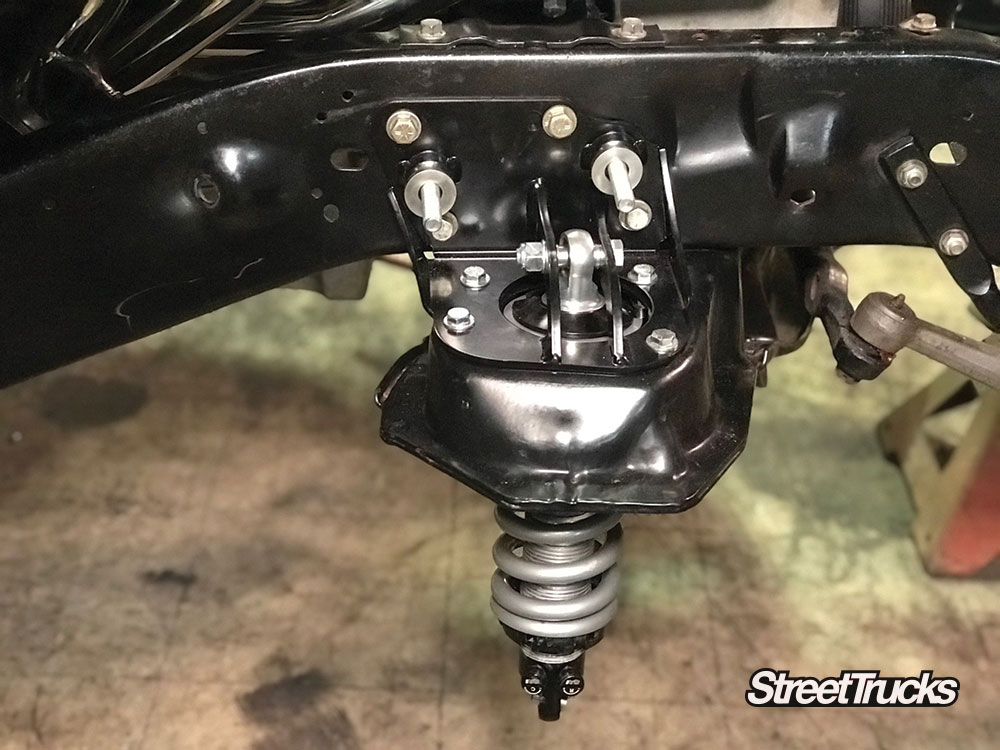

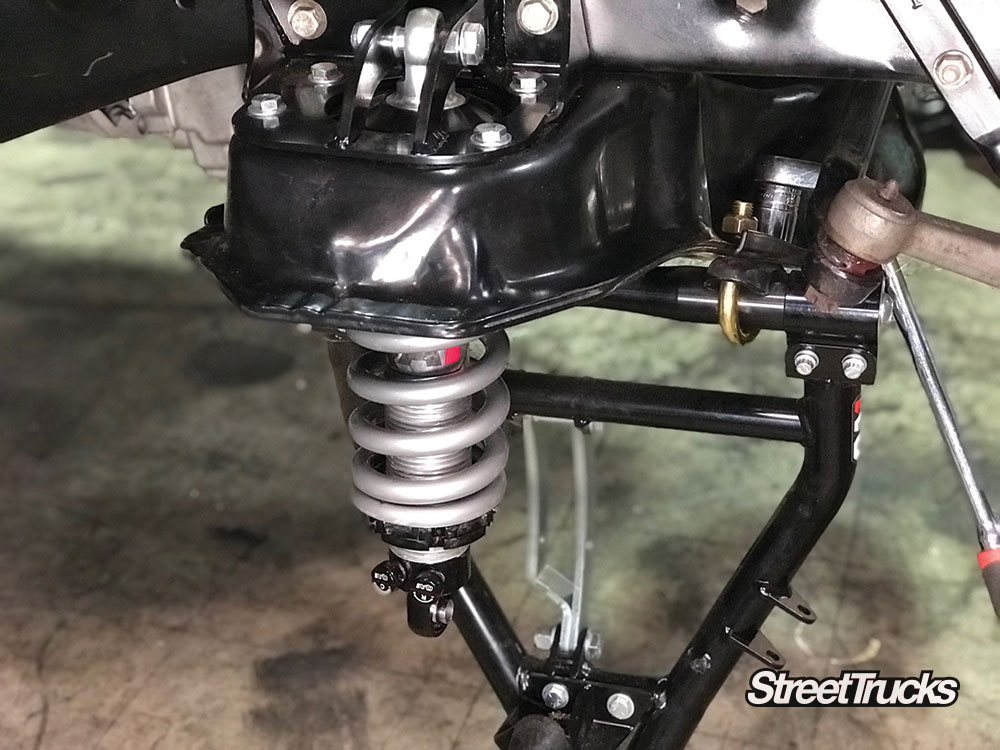

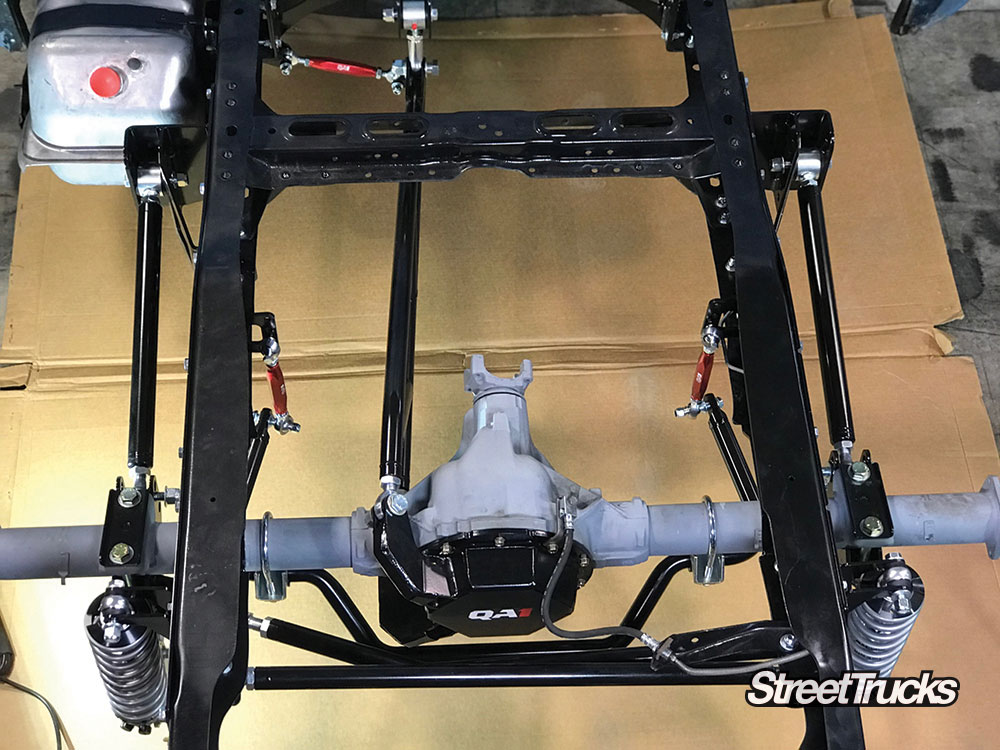

This old ’77 square body Chevy is being converted from farm truck to corner carving, coilover carrying street truck. In the last issue we installed the rear of this impressively engineered squarebody coilover conversion kit. We chose QA1 for our squarebody build for the simple reason that we wanted a painless, DIY installation with no wiring, running air hoses or dealing with leaky systems. Just a solid stance, a smooth ride and some really nice new parts for our truck!

Dialing in the stance will be easy with the adjustable coilover system—4 to 7 inches of adjustment below stock can easily be achieved. The major benefit of the torque arm design is that each component is designed to perform one function. This provides superior control over suspension movement, resulting in a smooth ride and great handling characteristics. QA1 engineered this unique bolt-in torque arm design, which maximizes performance without the inherent binding issues of other four-link systems.

We will also be installing a 6L LS engine using new engine mounts and a new wiring harness. The real question is whether to keep the topper on it while we rip up the corners! The paint is not that bad for a 40+ year old truck, so we will simply buff it and let it ride. There is no reason we shouldn’t be ripping it around the track later this year!

Share Link