MARCEL VENABLE

.

July 08, 2021

.

Department

MARCEL VENABLE

.

July 08, 2021

.

Department

There’s just something cool about a lifted truck. Ample ground clearance to mob over speed bumps and a line of sight over every other vehicle on the road are just a few of the many benefits to taking your truck up instead of down. Cruising down the highway hearing the hum of the tires as small passenger cars trail way below and behind is just cool.

The other benefit to a lifted truck is excess ground clearance for trail, desert and lake activities. If you have an off-road machine and you need a truck to haul it out to go riding, a lifted truck will do the job much more effectively than a lowered one. Same goes for you boaters out there. Dropping a boat in the water with a lifted truck is much more practical on boat ramps when the trailer has to go a bit deeper. Plus, if you loan your truck to a buddy for his yearly move, you won’t have to worry about bent and scratched rims from hitting curbs.

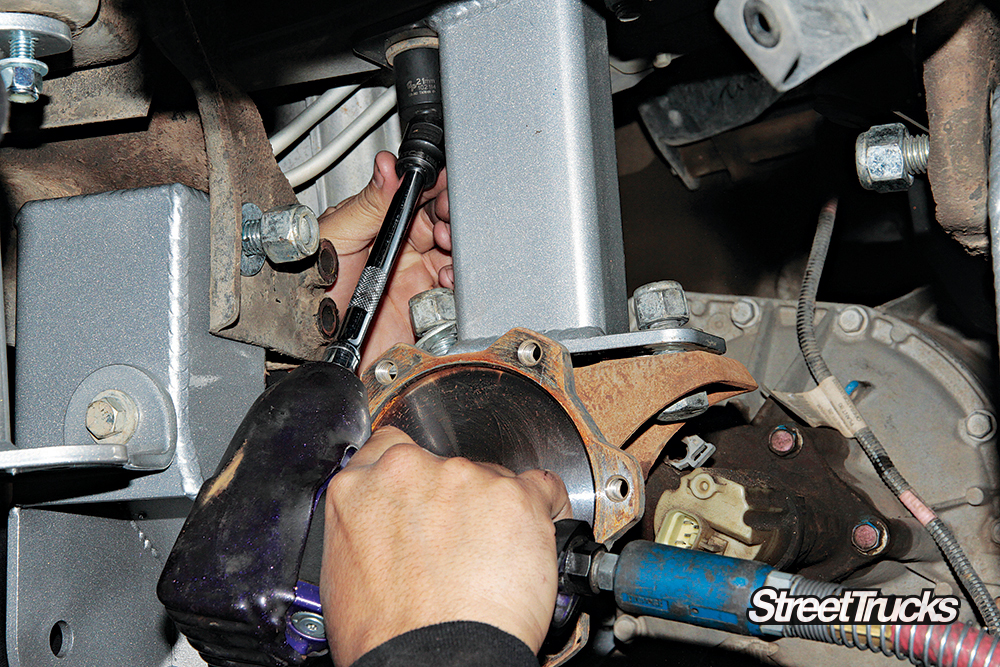

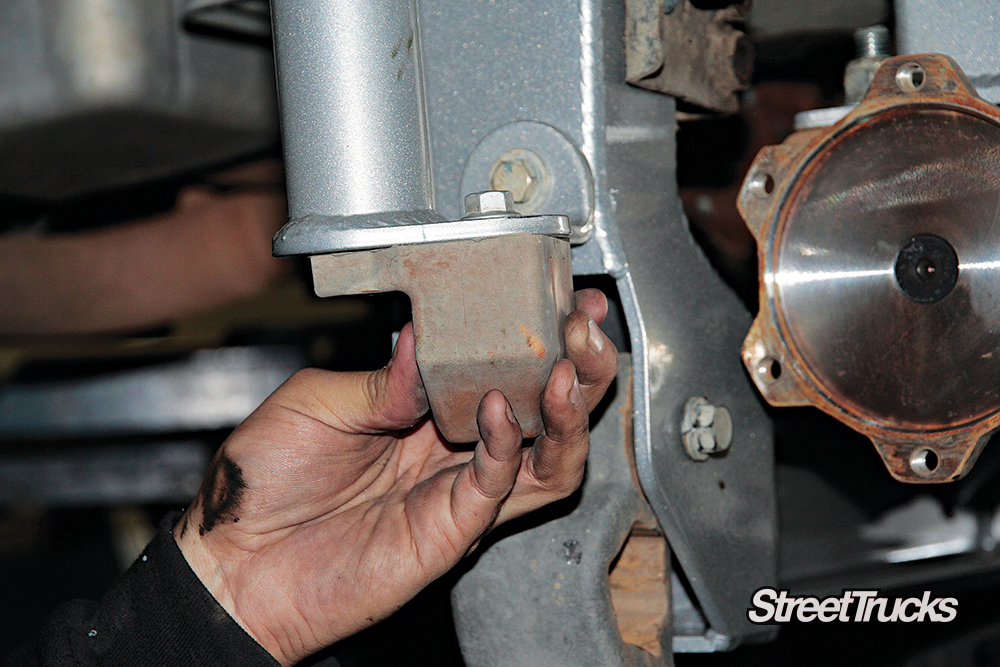

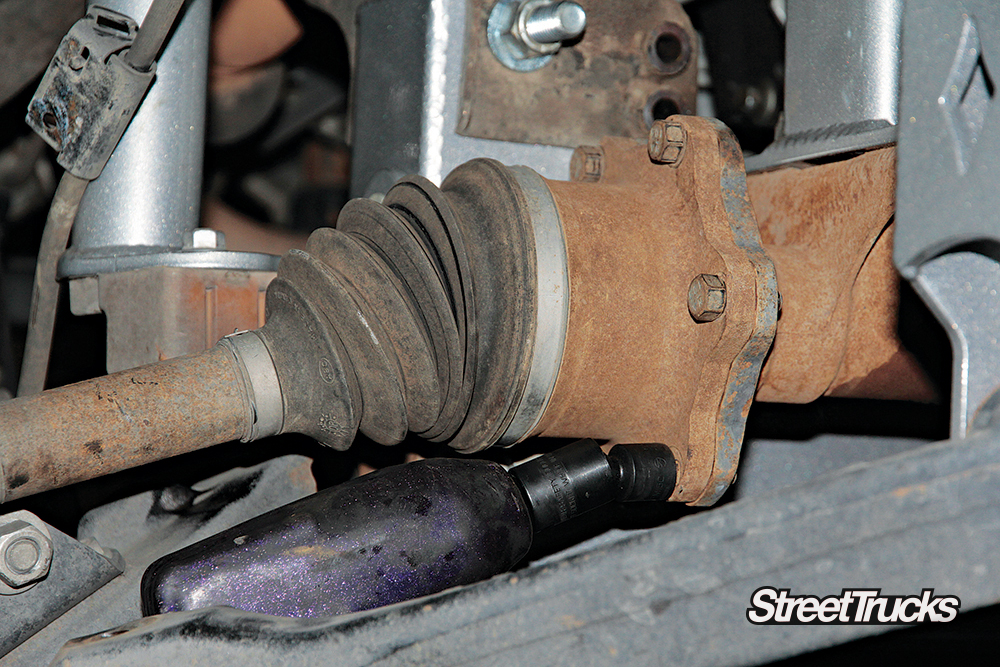

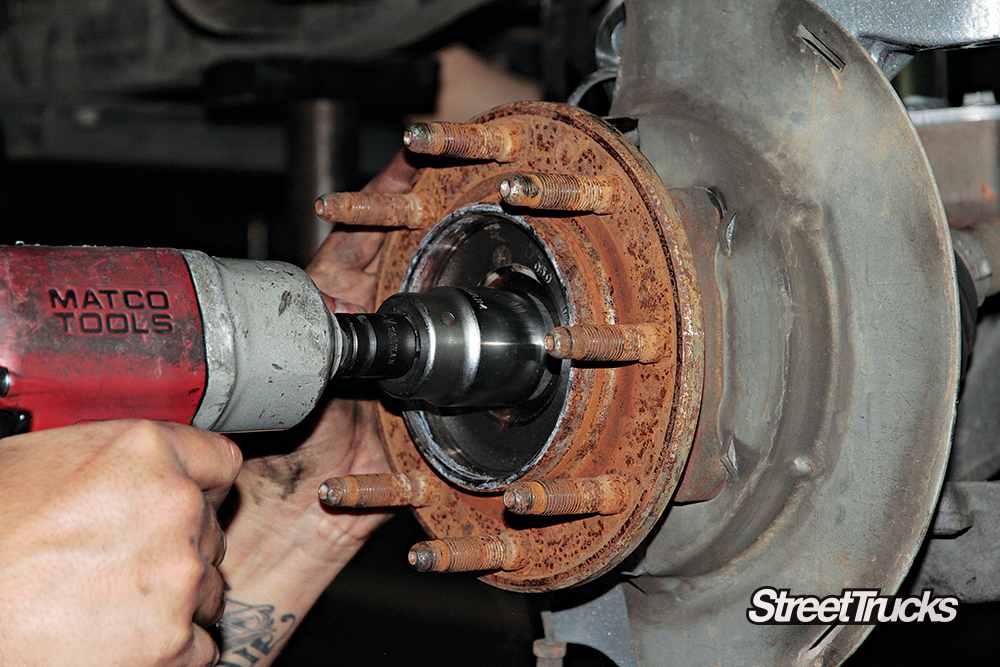

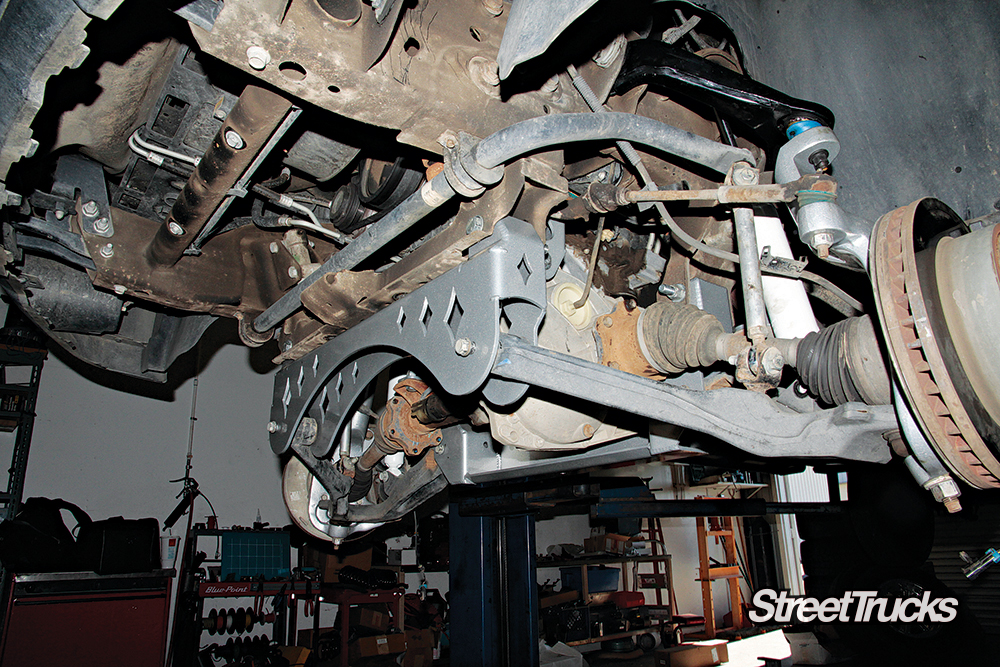

Full Throttle Suspension out of Fresno, California, has been a driving force in lifted truck suspension kits for many years and offers a wide array of lift kits to get your ½-ton, ¾-ton or 1-ton out of the stock zone and into the head-turning lifted zone. We got word that PPC Customs was putting an ’07 GMC 2500 HD 4 x 4 in the air with a Full Throttle Suspension 7-inch lift and we couldn’t draw our cameras from their holsters fast enough. Check out what it takes to put a late-model HD in the sky with help from Full Throttle Suspension and PPC Customs.

Share Link