Adam Blattenberg

.

October 24, 2016

.

Tech

Adam Blattenberg

.

October 24, 2016

.

Tech

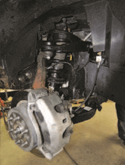

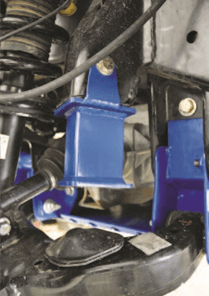

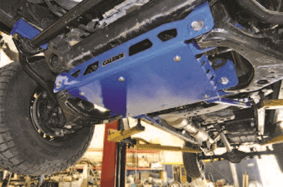

The Titan XD is here and the aftermarket has gone full steam ahead creating products to make these smaller diesels our own. When Nissan announced it’d be releasing this new truck with the Cummins engine, the Nissan suspension experts at CalMini grabbed one of the first XDs made and immediately tore it apart. Their goal? A 6-inch lift kit for the new pickup. After a few weeks of R&D, the dust settled and CalMini had created the first ever 6-inch lift for the new Titan XD. The kit consists of multiple drop-down brackets used to drop the lower control arm mounting points, new upper control arms, new steering knuckles and a whole slew of other parts to get the truck sitting at a trail-ready stance.

CalMini owner, Steve Kraemer, called us and asked if we’d like to see the first production kit being installed. Of course we were in, but there was a catch. Because it’s such a new truck (with an even newer suspension system) no one had designed a wheel specifically for the XD. So we gave Ultra Wheel Co. a call. Ultra Wheel was great and worked with us to find the perfect wheel to fit the truck and to match the Titan’s style. As it turned out, some of the same wheels that fit on a full-size Chevy 1500 fit the Titan XD. So designing a wheel specific to the Titan XD wasn’t necessary at all.

SOURCES CalMini (800.345.3305) Worx Alloy (800.321.4456) Falken Tire Corporation (800.723.2553)

Editor’s Note: A version of this article first appeared in the July 2016 print issue of Street Trucks Magazine.

Share Link