Chris Hamilton

.

August 19, 2020

.

Editor

Chris Hamilton

.

August 19, 2020

.

Editor

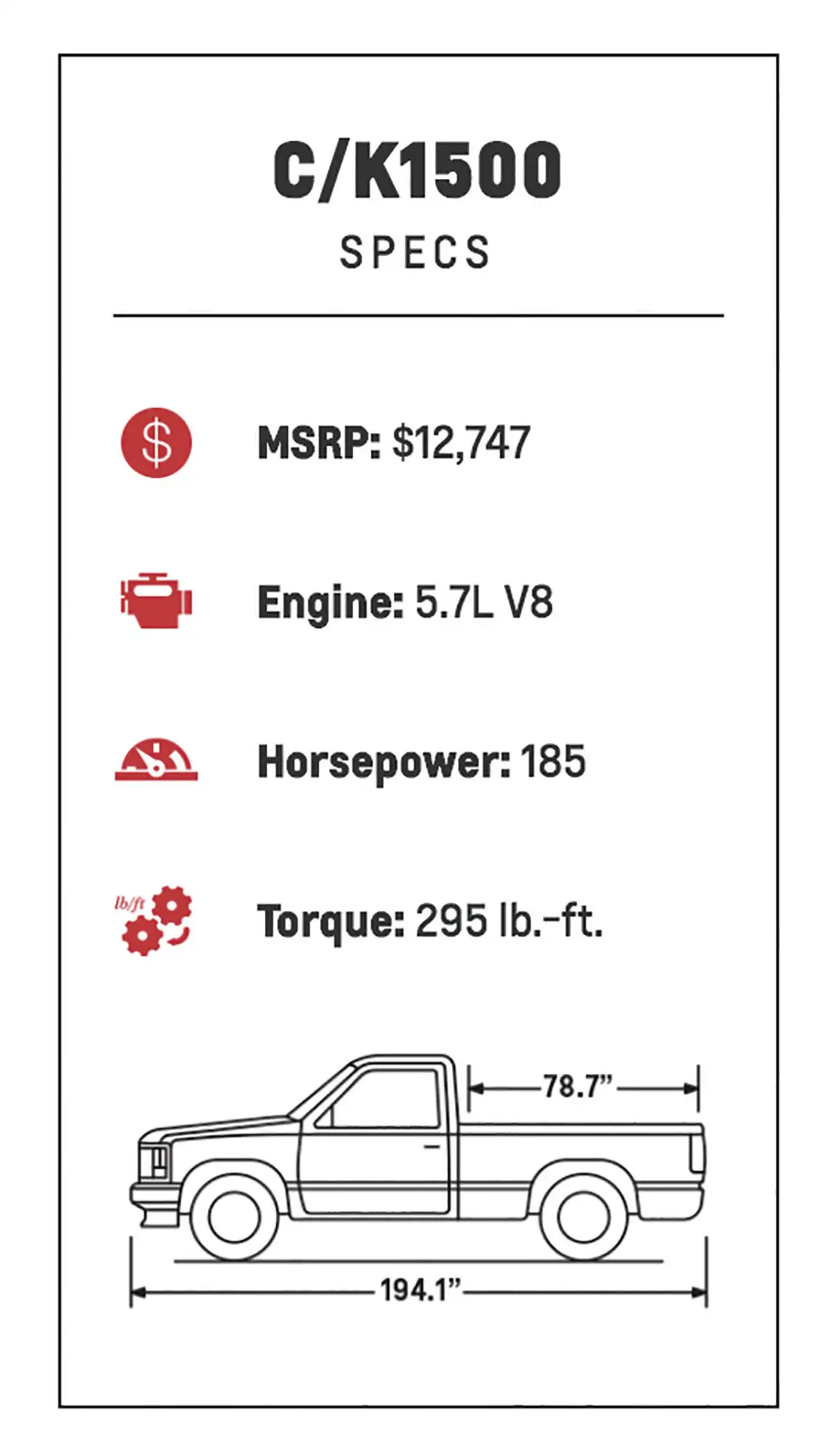

OBS refers to Chevy C/K trucks that were manufactured by General Motors between the years 1988 and 1998. Marketed under the Chevrolet and GMC brands, the C/K series included a wide range of vehicles including a truck and two SUV models. While most commonly associated with pickup trucks, the model line also included medium-duty and heavy-duty trucks. The “C” denoted a two-wheel drive; “K” denoted four-wheel drive.

General Motors released eight different versions of the C/K line for 1988: Fleetside Single Cab, Fleetside Extended Cab, Fleetside Crew Cab and Stepside Single Cab models, each in either 2WD or 4WD drivelines. Three trim levels were available for these trucks, including Cheyenne, Scottsdale and Silverado.

GMT400/480 ’88–’00 Chevrolet C/K – GMC Sierra

GMT410 ’92–’99 Chevrolet Suburban

GMT415 ’92–’94 Chevrolet Full-Size Blazer

GMT420 ’95–’00 Chevrolet Tahoe

GMT425 ’92–’99 GMC Suburban

GMT430 ’92–’00 GMC Yukon

In 1989, a Sport Equipment Package was available on either C/K 1500 Fleetside shortbed single cab model. The package featured a black grille with red outlined bow-tie emblem, black moldings outlined in red, body color front and rear bumpers, black mirrors and “SPORT” identification decals on the box and on the tailgate. There were no suspension or engine upgrades provided with any of the sport packages as this was an appearance only option.

Throttle body (TBI) fuel injection was used on ’88-’95 gas engines.

Central point injection (CPI) was used on the ’96-’00 4.3L V-6, 5.0L V-8 and 5.7L V-8.

The Work Truck (W/T) was introduced in 1988, which featured a single cab longbed with Cheyenne trim and a new grille with black bumpers.

In 1990, Chevrolet introduced a high-performance variant of the GMT400 under the Super Sport emblem called the 454 SS. It was available only as a 2WD half-ton regular cab short box in Onyx Black with a garnet red interior. Unique exterior features included a front air dam with fog lights, special rims, decals displaying “454 SS” on the bed sides, red trim emblems, and black painted grille, bumpers and mirrors.

The MSRP of the 1990 model was $18,295. A total of 16,953 units were sold over the four years the 454 SS was in production; 13,748 units were sold in 1990 alone.

The 454 SS was powered by a 454ci (7.4L) V-8 producing 230hp. A Turbo Hydra-Matic 400, 3-speed automatic transmission and 3.73 rear axle ratio added to the truck’s performance. The axle itself is unique, being a 14-bolt semi-floating unit that uses standard Chevrolet 5 on 5-inch wheels—the only factory-produced 14-bolt axle with such a wheel bolt pattern.

In 1991, the 4L80-E automatic transmission was added for three-quarter and one-ton trucks.

In 1991, California introduced a standard called OBD-I in order to curb vehicle emissions. All cars had to be equipped with a system that could detect engine issues and report trouble codes. Unlike the later OBD-II standard, however, OBD-I wasn’t standardized across manufacturers.

This means that an OBD-I scan tool will often work for only one make of car. In addition, the codes themselves aren’t standardized, so a Ford with the same engine issue as a Toyota might give a totally different trouble code.

In 1993 General Motors re-introduced the Sport branded trucks along with the 454 SS. The 454 SS was discontinued after the 1994 model year.

In 1993, the 700-R4/4L60 transmission was revised with electronic controls, becoming the 4L60-E.

The 1994 models received a new front fascia, federally mandated center high-mount stop lamp, many new exterior colors including a new two-tone option on the rocker panels, and new tire and wheel combinations.

All 1995 models received a new interior that included a new steering wheel with the 1500s containing a driver’s-side airbag, a new dashboard containing a more centrally mounted radio, dial-operated HVAC system, and an improved gauge cluster. New front door panels and new seats were also included.

In 1996, OBD-II became a nationwide standard and it has been used ever since. Unlike OBD-I, OBD-II equipped cars all support the same type of scanner. The trouble codes themselves have also been standardized across all manufacturers.

For 1996, a passenger-side-mounted third door became optional on extended cab models.

C/K 1500 models received a passenger-side airbag for 1997 to comply with new federal regulations for light trucks.

1997 was to be the last year the C/K Silverado would display “CHEVROLET” on the tailgate.

In 1999, the Chevrolet Silverado became the divisional replacement for the C/K.

The Chevrolet Tahoe is a full-size SUV from General Motors. Chevrolet and GMC sold two different-sized SUVs under their Blazer/Jimmy model names through the early 1990s. This situation changed when GMC rebadged the full-size Jimmy as the Yukon in 1991. All were two-door models through 1994.

The Chevrolet K5 Blazer name was discontinued after the 1994 model year, and the Chevrolet Tahoe was introduced in 1995 with the addition of an all-new four-door version.

The Tahoe has regularly been the bestselling full-size SUV in the United States, frequently outselling its competition by 2 to 1.

Both two-door and four-door models were produced in rear- and four-wheel drive. The two-door weighs roughly 4,500 pounds while the four-door weighs approximately 5,500 pounds. The two-door has a 6-inch shorter wheelbase than the four-door.

The standard engine was Chevrolet’s 5.7L (350ci) small-block V-8, while a turbocharged 6.5L (395ci) Detroit Diesel V-8 was available beginning in 1994.

The GMT400-based Suburbans were introduced in December 1991 for the 1992 model year even though the similar pickup truck models had switched to the newer platforms in the 1988. Both 2WD and 4WD models, designated “C” and “K”, were offered, as well as half ton and three-quarter ton versions.

The GMT400 series introduced independent front suspension. The 2WD models used coil springs and 4WD models used torsion bars in the front suspension. All models used a live axle and leaf springs in the rear.

For a 1995 Suburban, 0–60 mph times were around 9.3 seconds at best. The top speed of a 1995 Suburban was governed on the engine for economy and a maximum of 98 mph could be obtained with a fuel economy of 13 mpg.

What are some of the sources for aftermarket and performance parts for GMT400 trucks?

If you’re looking to upgrade your GMT400 truck, there are several reputable sources that offer a wide range of aftermarket and performance parts. Here’s a breakdown of some of the best:

For those interested in upgrading their transmission systems, American Powertrain provides a variety of high-performance transmission solutions.

Looking for custom and performance enhancements? Elevated Concepts, Inc. specializes in aftermarket solutions that can take your truck to the next level.

Renowned for their expertly crafted transmissions, Gearstar serves the needs of performance enthusiasts who demand reliability and superior engineering.

From body parts to complete restoration kits, LMC Truck offers a comprehensive selection of components tailored specifically to GMT400 trucks.

For those who want to boost their truck’s performance, Pro Performance provides a variety of parts, from suspensions to brakes, that meet the highest standards of quality.

If performance tuning and specialized suspension components are what you’re after, QA1 offers a range of products to enhance your truck’s handling and comfort.

To completely transform your truck’s ride quality, check out Ridetech for advanced suspension systems and air ride solutions.

A one-stop-shop for virtually any aftermarket or replacement part you might need, Rock Auto offers a vast inventory from multiple brands, ensuring you find the right fit for your GMT400.

By exploring these trusted sources, you’ll secure top-tier aftermarket and performance parts to elevate your GMT400 truck’s capabilities.

How has the popularity of the GMT400 platform evolved over time?

From its launch, the GMT400 platform has captivated enthusiasts, gaining immediate traction in the customization scene. Early modifiers, including renowned builders, quickly saw its potential and began to innovate.

This platform didn’t just flash and fade; its appeal has remained constant over the years. What’s particularly fascinating, however, is the surge in recent attention. Over the past two years, there’s been an impressive uptick in both the volume and quality of aftermarket performance parts available.

With the expanding array of aftermarket options, the possibilities for the GMT400 seem limitless, promising exciting developments in the near future.

What are the future plans for Project Jake?

Looking ahead, Project Jake has a number of exciting upgrades on the horizon.

First, a brake upgrade is high on the priority list to enhance safety and performance. This update will ensure better stopping power and overall handling. Additionally, there’s a plan to swap out the current transmission for a manual one. This change will give a more engaging driving experience, adding that extra thrill of control on the road.

Suspension improvements are also in the works. Plans include possibly upgrading to coilovers for a smoother, more responsive ride. This modification will improve both comfort and handling, allowing Project Jake to tackle any terrain confidently.

Under the hood, a significant performance boost is planned. The goal is to build a clean, efficient small-block engine that delivers around 350 horsepower. Future modifications may include incorporating a tuneable port fuel injection system like Holley EFI or Edelbrock ProFlo 4, provided it complies with local regulations.

These upgrades aim to keep Project Jake not only a reliable daily driver but also a high-performance machine ready for any adventure. The vision is to blend practicality with power, ensuring this beloved pickup remains a standout on the road for years to come.

What maintenance and modifications have been done to Project Jake?

Since acquiring in July 2017, a myriad of maintenance and modifications have been undertaken to keep it in top shape and enhance its performance. Here’s a detailed breakdown of the work done:

has been a reliable daily driver since its purchase, thanks to these meticulous maintenance efforts and thoughtful upgrades.

What is the history and significance of Project Jake?

In 2004, Jeff Smith came across a 1993 GMC Sierra C1500 single cab short bed pickup at a government auction, a former workhorse for Caltrans—a reminder of its utilitarian past. This wasn’t just any Sierra; Jeff’s fascination with pickups led him to purchase this specific truck, which bore the nickname “Jake.”

Alongside his friend Tim Moore, who also nabbed a similar truck, they began a dual project journey. They humorously named their trucks Jake and Elwood, drawing inspiration from a famous duo. Both vehicles were destined for a transformation, each to be featured in different automotive enthusiast magazines.

Jeff’s Sierra had already seen over 200,000 miles of duty. However, it had a relatively new engine, marking its second life under the hood. This starting point was more than enough for Jeff, who set out to revamp Jake both cosmetically and mechanically. The makeover included:

The modifications were aimed not just at aesthetics but at redefining the truck’s performance within a budget. Jeff dubbed these revamped vehicles “Blue collar bruisers,” highlighting their robust nature coupled with enhanced capabilities.

With its formidable new look and improved performance, Jake made several magazine appearances, offering readers step-by-step insights into practical, yet impressive transformations. This project underscored the accomplishment of turning a government surplus vehicle into a showpiece brimming with renewed life and charisma.

Project Jake stands as a testament to the potential within even the most well-worn vehicles. By focusing on strategic enhancements, Jeff Smith transformed an everyday work truck into a head-turning, high-performance machine, illustrating the power of vision, dedication, and a bit of elbow grease.

What manual transmission options are available for performance applications in GMT400 trucks?

If you’re considering switching to a manual transmission for performance purposes in your GMT400 truck, opting for a specialized car transmission can be a more effective choice over the standard New Venture units.

When upgrading, you typically need more than just the transmission itself. Comprehensive kits are available that include:

These kits often provide all the necessary parts to ensure a smooth and hassle-free installation. Additionally, sourcing a clutch pedal can be challenging but is essential for the proper functionality of your manual setup.

Switching to one of these high-performance car transmissions will significantly enhance your GMT400 truck’s driving experience. Whether you go with the TKO five-speed for balanced performance or the T56 Magnum six-speed for ultimate power handling, these options will undoubtedly elevate your vehicle’s capabilities.

What are the complications of engine performance upgrades in states with strict emissions laws?

Upgrading engine performance in states with stringent emissions laws like California can be quite challenging. Here’s why:

Engines from the throttle body injected (TBI) era and the 1996-and-later Vortec 350 face particularly tough restrictions. The market offers fewer compliant parts for these older systems, making performance upgrades more complicated and often more expensive.

States with strict emissions regulations enforce rigorous visual and rolling tailpipe tests. This means that any modifications must meet specific standards. While parts like CARB-compliant cylinder heads, camshafts, and headers are available, they must be correctly installed and tuned to pass these tests.

Tuning engines with OBD-1 and early OBD-II systems is especially tricky. These older models often require new PROM chips to be burned and installed into the engine control unit (ECU) or powertrain control module (PCM). This adds an extra layer of complexity and cost.

Despite the challenges, there are solutions available. Flash-programmable EEPROM conversions and tuning software for OBD-1 computers can simplify the process, but they require specialized knowledge and tools. Websites like Moates.net and GearheadEFI offer valuable resources for those navigating these upgrades.

Upgrading your engine in a state with tough emissions laws isn’t impossible, but it demands careful planning, specialized components, and sometimes, expert assistance.

What suspension upgrades are available for GMT400 trucks?

If you’re looking to enhance the suspension of your GMT400 truck, there are several options available that go beyond the standard drop spindle and axle flip lowering kits.

Front and rear coilover conversion kits offer an advanced alternative. These kits not only lower your truck but also significantly improve handling and ride quality. For instance, some companies utilize unique rear upper A-arms to position the axle housing, while others prefer a torque arm and Panhard bar setup for the rear suspension.

Upgrading to tubular front A-arms can make a noticeable difference. These components are often paired with larger sway bars to provide a more stable and controlled ride. Additionally, adjustable shocks allow for fine-tuning the suspension to suit different driving conditions and preferences.

For those looking for a more customized approach, there are specialized companies that focus solely on suspension and frame stiffening systems. These niche solutions often include enhancements like rack and pinion steering systems, specifically designed for the GMT400 platform, delivering a unique driving experience.

No matter which suspension upgrade you choose, a combination of lowering, quality shocks, and high-performance tires will dramatically improve both the look and handling of your GMT400 truck.

What performance upgrades are available for GMT400 trucks?

The GMT400 platform has become increasingly popular for enthusiasts looking to enhance their truck’s performance. In recent years, we’ve seen a surge in the variety and quality of aftermarket parts designed for these trucks. Here’s a detailed look at some of the top performance upgrades you can consider for your GMT400:

The evolution of aftermarket performance parts for GMT400 trucks is fascinating. From improving overall power to fine-tuning handling and braking, the options are vast and continually expanding.

With the right upgrades, your GMT400 can achieve remarkable gains in performance, making it a beast both on-road and off-road.

What aftermarket options are available for addressing rust issues on GMT400 trucks?

Dealing with rust issues on GMT400 trucks? There’s an array of aftermarket solutions available to restore these classic vehicles to their former glory.

For starters, you can replace rusted components with brand-new sheet metal sourced from various restoration companies and truck specialists. Options include:

What’s great is that these components are often surprisingly affordable, making it feasible to maintain your truck’s condition without breaking the bank.

Using aftermarket parts allows for high customization and ensures compatibility with your specific truck model. These parts can often be more accessible and cost-effective than original manufacturer parts.

By investing in quality aftermarket parts, you’ll not only address rust issues but also enhance the overall aesthetic and functionality of your GMT400 truck.

Why are the brakes on the GMT400 trucks considered insufficient?

The brakes on GMT400 trucks have garnered criticism for several reasons, particularly from those who require reliable stopping power for towing, hauling, or spirited driving.

The front brakes come with relatively small 11-inch or 11.25-inch rotors paired with single-piston calipers. The rear brakes aren’t much better, offering 10-inch or 11-inch drums. This size limitation means they quickly become inadequate under heavy load or intense driving conditions.

For tasks like towing or hauling, the standard braking system simply can’t keep up. Drivers often find themselves wishing for larger, more capable brakes, especially in situations where quick and reliable stopping is crucial.

Adding to the frustration, the Quick Take Up brake master cylinder combined with low-drag brake calipers results in a brake pedal feel that many describe as “mushy.” The long pedal travel distance can be disconcerting, giving drivers less confidence in the vehicle’s braking capabilities.

Given these points, it’s clear why the stock braking system on GMT400 trucks leaves much to be desired. For those requiring more robust performance, upgrading to larger, more efficient brakes is often considered a necessary improvement.

What issues are associated with the clear coat on GMT400 trucks?

The GMT400 series of trucks, produced during the late ’80s and ’90s, often face challenges related to their clear coat. These vehicles are particularly prone to oxidation, a process where the clear coat deteriorates due to prolonged exposure to the sun. Over time, this exposure can lead to visible wear and damage.

Here are key issues you might encounter:

To mitigate these problems, regular maintenance and specific treatments can help:

Keeping these points in mind will help maintain the appearance and longevity of your GMT400 truck’s clear coat.

What are some common problems associated with the GMT400 series trucks?

When it comes to the GMT400 series trucks, owners often encounter a few recurring issues. Here’s a rundown of the most common problems:

Rust is a notorious issue for these trucks. Even though they were touted as having good corrosion protection, this claim was only valid when comparing them to their predecessors. Key areas prone to rust include:

This is especially true for trucks in wet and snowy climates, where moisture accelerates the rusting process.

The dashboard design saw a significant overhaul in 1995, which improved its durability. However, earlier models suffer from:

While the later dashboards offer better resistance, it’s a common point of concern for those with older models.

Interior materials vary in longevity. Generally:

This difference is important to consider if you value your truck’s interior condition.

Like many American vehicles from the ’80s and ’90s, the GMT400 series struggles with clear coat problems. Sun exposure tends to:

This typically results from manufacturers adapting to new paint emission regulations, which affected the durability of the paint.

The brake system is another common complaint. GMT400 trucks come with:

These brakes often prove insufficient for towing, hauling, or spirited driving. Issues include:

The system’s Quick Take-Up master cylinder and low-drag calipers sound good on paper but don’t always deliver the best performance.

While the GMT400 series trucks are celebrated for their reliability, these common issues warrant attention from any prospective or current owner. Addressing rust, interior wear, paint degradation, and brake performance can help maintain the truck’s value and functionality.

How Did the GMT400 Series Trucks Differ From Their Predecessors?

The GMT400 series introduced several groundbreaking changes that set it apart from earlier models.

First and foremost, the GMT400 series was the debut lineup to feature independent front suspension on its 4×4 models. This advanced design replaced the older solid front axle and leaf springs with torsion bars and CV joints.

These modifications not only improved the driving experience but also significantly boosted the safety and convenience of the GMT400 series, marking a notable evolution from its predecessors.

What are some transmission upgrade options for GMT400 trucks?

In 1991, the 4L80-E automatic transmission was added for three-quarter and one-ton trucks.

In 1993, the 700-R4/4L60 transmission was revised with electronic controls, becoming the 4L60-E.

For those considering manual transmission upgrades, several options were available during the production of GMT400 trucks. The half-ton pickups typically came with HM290/5LM60 or NV3550 five-speed transmissions, generally rated to handle around 300 lb-ft of torque. Meanwhile, the more robust NV4500 was an option for the 2500 and 3500 series trucks. These transmissions were designed specifically for these trucks, featuring a steeper first gear and larger RPM drops between shifts.

If you’re looking to enhance performance by switching from an automatic to a manual transmission, opting for a “car” transmission might be more beneficial. Kits are available that offer TKO five-speed or T56 Magnum six-speed options, depending on your power requirements. These kits often include the necessary flywheel, clutch assembly, and hydraulic components, and can assist in sourcing a clutch pedal, which can be hard to find.

These smoother-shifting transmissions can significantly transform your truck’s driving experience, providing a more engaging and responsive feel behind the wheel.

How did the redesign of the dashboard in 1995 improve the GMT400 trucks?

All 1995 models received a new interior that included a new steering wheel with the 1500s containing a driver’s-side airbag, a new dashboard containing a more centrally mounted radio, dial-operated HVAC system, and an improved gauge cluster. New front door panels and new seats were also included.

The redesign of the dashboard in 1995 marked a significant improvement over the earlier models. The earlier versions used hard plastics that were prone to cracking or disintegrating completely due to sun damage. The new design utilized materials that were much more resistant to these issues, ensuring greater durability and longevity.

Additionally, the cloth upholstery in the updated models fared better over time compared to the leather seats, adding another layer of quality to the interior.

The combination of these upgrades made the 1995 interior not just more functional but also more durable, addressing common issues faced by owners of earlier models.

What innovations were introduced with the GMT400 series?

“The GMT400 series introduced independent front suspension. The 2WD models used coil springs and 4WD models used torsion bars in the front suspension. All models used a live axle and leaf springs in the rear.”

Notably, the GMT400 was more than just a visual update from its predecessors. This series marked the first use of independent front suspension on 4×4 models, with torsion bars and CV joints replacing the solid front axle and leaf springs of the older trucks.

Another significant innovation was the introduction of shift on the fly four-wheel drive, eliminating the need for manually locking hubs. This new feature made transitioning between two-wheel and four-wheel drive seamless and more convenient.

In addition to these mechanical upgrades, the GMT400 addressed safety concerns by widening the frame to move the fuel tank inboard. This change mitigated risks associated with the previous generation’s side-saddle gas tanks, enhancing overall safety for drivers and passengers.

What are the OBS Chevys, and why are they gaining popularity?

What is an OBS? (Old Body Style or Original Body Style)

OBS refers to Chevy C/K trucks that were manufactured by General Motors between the years 1988 and 1998. Marketed under the Chevrolet and GMC brands, the C/K series included a wide range of vehicles, including a truck and two SUV models. While most commonly associated with pickup trucks, the model line also included medium-duty and heavy-duty trucks. The “C” denoted a two-wheel drive; “K” denoted four-wheel drive.

The OBS label was assigned to the GMT400 once the GMT800 (model years 1999-2006) were introduced, and that generation is known as NBS, or ‘new body style.’ In SUV form (Tahoe, Yukon, and Suburban), the GMT400 continued through the 2000 model year and even into 2002 for the one-ton C3500 pickups.

Outwardly, the GMT400 represented a significant visual departure from the square body trucks it replaced, featuring a sleek, aerodynamic body. More noteworthy changes, however, could be found underneath. This was the first GM pickup to feature an independent front suspension on their 4×4 models, utilizing torsion bars and CV joints to replace the solid front axle and leaf springs of the previous generation.

These trucks are not just cherished for their nostalgic value but also for the practical and innovative improvements they introduced. The combination of visual appeal and mechanical advancements makes them highly sought after by both collectors and enthusiasts. Whether for restoration projects or daily use, the OBS Chevys offer a blend of classic design and forward-thinking engineering.

What modifications does “Burntoutaccountant” plan to make to the 1989 4×4 Stepside truck?

Planned Modifications for the 1989 4×4 Stepside Truck by “Burntoutaccountant”

The immediate plan is to replace the existing 10-bolt rear axle with a sturdier 14-bolt 8-lug axle. The current axle has failed, likely due to an attempted repair on the axle tube that led to cracks and fluid leaks. This upgrade will enhance the truck’s durability and performance, especially for daily driving needs.

The front differential in the 1500 model is notoriously weak. To address this, “Burntoutaccountant” is considering swapping it out for a 9.25-inch differential. The challenge lies in configuring the control arm, knuckle, and axle setup to accommodate this upgrade. Input and advice from experienced truck enthusiasts could play a crucial role in finalizing this modification.

An eventual engine swap is planned, replacing the stock 350 with a more powerful L92 engine. For the transmission, the preference is an NV4500, though finding one has been difficult. This setup aims to improve both power and reliability, turning the truck into a more robust daily driver.

The truck’s exterior will undergo a full repaint to address its rough condition. While the body has no rust and only minor dings, a fresh coat of paint will rejuvenate its appearance and protect it from future deterioration.

By focusing on these key areas, “Burntoutaccountant” aims to transform the 1989 4×4 Stepside into a reliable, powerful daily driver while maintaining a balance between form and function.

What engine swap is “Burntoutaccountant” planning for the truck?

“Burntoutaccountant” is planning to upgrade the truck’s engine by swapping in an L92. However, they haven’t yet decided which transmission to pair with the new engine.

What advice does “JOHNGAAA1” give to “Burntoutaccountant” regarding the rear axle swap?

Welcome to the forum!

For your rear axle swap, consider opting for a 14-bolt, 6-lug axle. This particular axle can be directly installed without needing to modify the front end of your vehicle—an essential aspect for maintaining balance and performance.

Although this type of axle is somewhat rare, it does exist and can be found with some diligent searching. I have successfully installed one of these axles in my own 1998 Z71, so I can vouch for its compatibility and ease of installation.

Good luck with your project!

Why does “Burntoutaccountant” need to replace the rear axle of the truck?

“Burntoutaccountant” needs to replace the rear axle of their truck due to a series of mechanical failures that have compromised the vehicle’s safety and functionality.

Shortly after purchasing the truck, the 10-bolt rear axle failed. This critical component is essential for distributing power from the engine to the wheels. A failure here can render the truck immobile or, worse, unsafe to drive.

Upon inspecting the damage, it became evident that the previous owner had attempted an improper repair on the axle tube. They attempted to weld the axle tube, which ultimately led to it cracking.

The cracked axle tube resulted in a fluid leak, which is especially concerning. Axle fluid is crucial for lubricating the gears and preventing overheating. A lack of fluid could lead to further mechanical breakdowns and even more costly repairs.

“Burntoutaccountant” initially missed this issue when inspecting the truck for rust, indicating the crack might have been subtle or obscured by other factors.

Given these issues, swapping out the damaged 10-bolt rear axle for a more robust 14-bolt 8-lug axle is a necessary upgrade. This replacement not only addresses the immediate mechanical failures but also promises improved durability and performance for the future.

What are the potential options for improving the front differential of the truck?

Upgrading the front differential of your truck can significantly enhance its performance and durability. Here are some viable options you might consider:

Consider replacing the current differential with a more robust one. For instance:

There are various aftermarket kits designed to fortify the front differential. These can include:

If you’re looking for a tailor-made solution, working with a restomod shop could be beneficial. They can:

Sometimes, reinforcing the existing differential can also yield benefits:

Before committing to any upgrade, it’s advisable to:

By exploring these options, you can significantly improve the durability and performance of your truck’s front differential, tailored to meet your specific needs and driving conditions.

What alternative axle options are mentioned in the forum discussion?

Welcome to the forum! If you’re searching for alternative axle options, here’s a viable solution discussed among members.

One member even mentioned successfully using this axle in their own vehicle, specifically a 1998 model, showcasing its practicality and ease of installation.

Feel free to explore this option or share your experiences for more insights!

What transmission is “Burntoutaccountant” considering to pair with the new engine?

Burntoutaccountant is contemplating different transmission options for pairing with a new L92 engine. While they have not made a definitive decision, one transmission under consideration is the NV4500. However, they have faced challenges in locating this specific model during their initial search. Currently, the plan is to continue using the existing 350 until it eventually needs replacement.

What challenges is “Burntoutaccountant” facing with the front end of the truck?

“Burntoutaccountant” is encountering several hurdles with the front end of the truck.

These elements collectively contribute to the difficulties “Burntoutaccountant” is grappling with as they seek to enhance their truck’s front end.

What is the current condition of the 1989 4×4 Stepside truck acquired by “Burntoutaccountant”?

The “Burntoutaccountant” recently picked up a 1989 4×4 Stepside truck. The exterior is in pretty rough shape, needing a complete repaint to bring it back to life. However, the good news is there’s no rust on the body. You’ll find a few minor dents, but nothing that can’t be repaired.

What kind of vehicles has the user “Burntoutaccountant” previously owned and modified?

Burntoutaccountant has a history of owning and modifying various high-performance vehicles, particularly trucks. Initially, they focused on LS-powered cars before shifting their attention to trucks in recent years.

Burntoutaccountant’s passion is evident in the extensive customizations and performance upgrades made to each vehicle, showcasing a deep commitment to truck and car modification.

What personal experiences do other forum members share regarding similar vehicle modifications?

Forum members have shared a variety of insights and personal experiences related to vehicle modifications, particularly focusing on axle swaps and project builds.

One member highlighted the feasibility of a 14-bolt 6-lug axle swap, noting that it’s a straightforward process that allows you to retain your existing front setup. Although these axles are rare, they can be found, as evidenced by a participant who successfully installed one in their own truck.

Another user expressed enthusiasm for vehicle projects, emphasizing the excitement of embarking on a new modification journey. They mentioned the importance of documenting the process with plenty of pictures, implying that visual updates are highly appreciated within the community.

A different forum member shared a specific case related to a 1993 model with a 6.5 engine, 5-speed manual transmission, and 4.10 gears. They offered to facilitate connections with another forum member looking to part out a similar vehicle, suggesting a sense of camaraderie and resource sharing within the group.

Lastly, an off-topic comment alluded to the financial considerations that can come into play during extensive vehicle projects. One person mentioned the burden of paying off loans while working in accounting, hinting at the financial planning required for significant vehicle modifications or restorations.

These anecdotes collectively paint a picture of a supportive community willing to offer advice, share resources, and provide encouragement for those tackling similar vehicle modifications.

What kind of support and feedback do other forum members provide to “Burntoutaccountant”?

Forum members offer solid guidance and encouragement to Burntoutaccountant, ensuring a supportive community experience. Here’s a breakdown of their responses:

Overall, the forum provides a nurturing environment with valuable advice, heartfelt welcomes, and consistent encouragement for new members taking on ambitious projects.

What are the community’s general sentiments and support towards new members and their projects?

Community Sentiments and Support Towards New Members and Their Projects

The community has a decidedly welcoming atmosphere. When new members introduce themselves, established members often respond with greetings and words of encouragement. For instance, one might find responses like, “Welcome to the forum! Excited to see what you have in store.”

Members are enthusiastic about new projects. They often express genuine interest in seeing progress updates and photos. Comments such as “Sounds like a wicked project! Keep us posted with lots of pics!” are common, showing that the community is eager to follow along and offer support.

There is a strong sense of shared expertise within the community. Experienced members often provide practical advice to newcomers. A typical response might include, “A 14 bolt 6 lug axle should fit perfectly. They are rare but worth the search if you find one.”

The community doesn’t shy away from making personal connections. Members often share a bit about their own backgrounds and even inject humor into their interactions. One might read, “Hilarious username! As someone also in auditing, I can relate to the busy season.”

Beyond the primary focus on projects, there’s also a willingness to discuss career paths and major life changes. Members might share, “I left public accounting for a repair shop advisory role and couldn’t be happier,” followed by supportive replies like, “Heard that. Planning to switch careers once my loans are paid off too.”

In summary, the community is not only welcoming and enthusiastic about new members and their projects but also offers constructive advice, shares personal experiences, and fosters a supportive, friendly environment.

What are the advantages of using a 14 bolt 6 lug axle as suggested by “JOHNGAAA1”?

By considering these advantages, you can see why many enthusiasts and professionals prefer the 14 bolt 6 lug axlefor their vehicles.

What is Open Broadcaster Software (OBS) and what platforms is it compatible with?

Open Broadcaster Software, commonly known as OBS, is a powerful and versatile tool designed for both video recording and live streaming. As a free and open-source platform, it provides users with a plethora of features to produce professional-quality content without the need for expensive software.

OBS is compatible with multiple operating systems, ensuring a wide range of users can take advantage of its capabilities:

In summary, OBS is a comprehensive tool for anyone looking to engage in video recording and live streaming across Windows, macOS, or Linux platforms. With its array of features and widespread compatibility, OBS stands out as a top choice for content creators around the world.

How Does OBS Facilitate Video Recording and Live Streaming?

OBS Studio is a powerful tool that simplifies both video recording and live streaming, catering to both Mac and Windows users. It’s an open-source platform, meaning it’s completely free and highly customizable to suit different needs.

OBS allows you to record videos directly to your computer’s hard drive. You can enter a dedicated recording mode that focuses solely on capturing high-quality footage. This ensures you can create content effortlessly without live streaming, making it suitable for pre-recorded videos like tutorials or presentations. The ease of use is due to its ability to mix various audio and video inputs seamlessly.

When it comes to live streaming, OBS provides a robust solution that connects to multiple popular streaming platforms. Whether you’re broadcasting to YouTube, Facebook Live, Twitch, or Twitter, OBS handles the streaming process smoothly. It also supports streaming to custom RTMP servers, allowing for greater flexibility in how you reach your audience.

The open canvas approach of OBS means you can creatively manage multiple audio and video sources. You can overlay videos, integrate different media types, and apply transitions live. This enables content creators to produce professional-grade broadcasts without the need for expensive equipment or software.

In summary, OBS facilitates video recording and live streaming through its user-friendly interface, versatile platform support, and creative capabilities, all at no cost. Whether you’re a novice or a seasoned professional, OBS caters to all your multimedia needs.

What Are Some Use Cases for OBS?

OBS Studio is a versatile tool that offers a wide range of applications for various needs and industries. Here are some key use cases where OBS can make a significant impact:

Incorporating OBS into your workflow can enhance how you create and share content across different platforms, making it a valuable tool for both personal and professional use.

How can one learn more about using OBS?

Are you eager to enhance your OBS skills? Here’s how you can dive deeper:

By leveraging these resources, you can become proficient in OBS and maximize its potential for your streaming or recording needs.

What Are the Potential Benefits of Using OBS for Instructors?

What Are the Potential Benefits of Using OBS for Students?

Open Broadcaster Software (OBS) offers a range of advantages for students, particularly those interested in media, technology, and creative fields. Here’s a closer look at what students can gain:

What are the live streaming platforms that OBS supports?

OBS Studio provides robust support for live streaming across a wide array of popular platforms. Users can effortlessly broadcast their content to major services such as YouTube, Facebook Live, Twitch, Twitter, and what was formerly known as Mixer. Additionally, OBS offers the flexibility to connect to custom RTMP servers, allowing streamers to reach virtually any platform that supports this protocol. This versatility makes OBS a favored choice for content creators seeking to reach diverse audiences.

What customizations are popular in the interior of OBS trucks?

When it comes to customizing the interior of OBS (Old Body Style) trucks, enthusiasts have a variety of options to express their personal style and preferences. Here are some popular interior modifications:

While these customizations are common across the enthusiast community, a significant number of OBS truck owners prefer to keep their vehicles in original or refurbished condition. This approach respects the truck’s classic appeal while ensuring it maintains its authenticity and potential value.

In summary, whether you’re seeking a modern edge or preserving a vintage look, there’s an array of interior customization possibilities for OBS trucks.

How did the design and manufacturing focus of trucks change in the late ’90s and early 2000s?

In the late ’90s and early 2000s, the design and manufacturing focus of trucks underwent a significant transformation. During this period, there was a notable shift towards cost-efficient production methods. Manufacturers began prioritizing affordability and mass appeal over the rugged, long-lasting construction that had previously defined trucks.

This change led to more generic truck designs as companies aimed to attract a broader customer base. The innovative and distinctive styling that had once set trucks apart started to fade, reflecting a more mainstream aesthetic. This transition coincided with many of the once-reliable models reaching the end of their standard production cycle, marking the end of an era for traditionally durable trucks.

How do oversized all-terrain tires contribute to the look of a lifted OBS truck?

When you’re looking to enhance the visual appeal of a lifted OBS (Old Body Style) truck, adding oversized all-terrain tires is a game-changer. These robust tires do more than just fill out the wheel wells; they transform the entire presence of your vehicle.

Installing oversized all-terrain tires is a strategic way to boost both the performance and appearance of a lifted OBS truck, instantly elevating its presence from ordinary to extraordinary.

What modifications are typically made to the headlights and taillights of OBS trucks?

When it comes to modifying the headlights and taillights of older body style (OBS) trucks, enthusiasts often opt for enhancements that blend style with functionality. Here are some popular modifications:

Pair these lighting enhancements with additions like a custom chrome grille to accentuate your truck’s revamped style and make it truly stand out on the road.

How can a custom paint job enhance the appearance of an OBS truck?

A custom paint job can breathe new life into an OBS truck, elevating its aesthetic appeal far beyond its aging, original coat. Here’s how a fresh paint job can make a difference:

With these modifications, your OBS truck can become a head-turner, showcasing both traditional roots and modern style.

Why are chrome-plated exhaust tips considered a necessity for OBS trucks?

Chrome-plated exhaust tips have become nearly synonymous with OBS (Old Body Style) trucks, particularly those customized beyond their original stock builds. But why do these shiny accessories seem like an essential touch for truck enthusiasts?

The primary reason is aesthetics. Chrome tips offer a polished, high-end look that significantly enhances the visual appeal of any vehicle. They give an impression of both power and prestige, making these trucks stand out on the road.

Though often primarily cosmetic, chrome exhaust tips are frequently part of broader exhaust system upgrades. Enthusiasts often replace entire exhaust systems to boost performance metrics such as horsepower and torque. With such enhancements, the sound emitted from the vehicle becomes deeper and more resonant, aptly complemented by the striking appearance of chrome-plated tips.

Chrome-plating also provides a layer of protection against rust and corrosion. This durability ensures that the exhaust tips maintain their brilliance over time, even under harsh weather conditions. Easy to clean and maintain, they remain a favorite for those who want their trucks to look pristine with minimal effort.

Lastly, upgrading to chrome exhaust tips allows owners to express individuality. It’s a canvas for customization, whether sticking with classic designs or opting for more unique, personalized shapes.

In summary, chrome-plated exhaust tips are considered essential for OBS trucks because they enhance appearance, improve performance aspects, offer resilience, and allow for personal expression. These benefits make them a staple choice for truck enthusiasts aiming to combine style with substance.

What is the purpose of window tinting in OBS truck modifications?

Window tinting serves multiple purposes when modifying OBS (Old Body Style) trucks, beyond just aesthetic appeal. Here’s a detailed look at why enthusiasts choose to tint their truck windows:

Incorporating window tint into your OBS truck modification not only enhances its style but also delivers functional benefits that amplify both comfort and safety.

What features defined the iconic Ford F-Series OBS trucks from different generations?

The Ford F-Series OBS (Old Body Style) trucks hold a special place among enthusiasts, with notable characteristics defining each generation. Let’s delve into the distinctive features that set these models apart.

This generation harkens back to a bygone era with its classic appeal. Key elements include:

Built on the sturdy foundation of their predecessors, these trucks showcased:

Engine power and efficiency also saw enhancements during this period, staying consistent with former options while offering better performance.

The final OBS Ford trucks stayed true to their roots with:

A blend of heritage and subtle evolution, these trucks captured a unique status by balancing classic OBS cues with modern updates.

What are some common modifications made to OBS trucks?

Since acquiring in July 2017, a myriad of maintenance and modifications have been undertaken to keep it in top shape and enhance its performance. Here’s a detailed breakdown of the work done:

Modifications

Suspension Upgrade

Enhancing the ride dynamics, a Ridetech 4/6 suspension drop kit paired with single adjustable shocks was installed to lower the vehicle. This modification not only improves handling but gives the truck a sleek, aggressive stance.

Door Enhancements

Rebuilt door hinges, added new weather-stripping, and replaced damaged lock rod and door handle clips. These enhancements improve both functionality and aesthetics, ensuring the doors operate smoothly and complement the truck’s new look.

Paint and Body

A custom paint job can dramatically transform the truck’s appearance. Options range from restoring the original color to opting for a high-gloss or matte finish. Such changes can breathe new life into the vehicle, making it stand out on the road.

Lighting Upgrades

New headlights and taillights, especially those utilizing LED technology, offer improved visibility and a modern touch. This modification, combined with a custom grille, creates a striking front-end appearance.

Exhaust System

Chrome-plated exhaust tips are considered essential for many enthusiasts, and a complete exhaust overhaul can enhance both power and sound, adding to the truck’s character and performance.

Interior Customization

Custom seat upholstery and updated dashboard elements allow owners to personalize their truck’s interior. While some prefer original or refurbished conditions, these changes can make the space uniquely theirs.

Tire and Wheel Modifications

Installing oversized all-terrain tires on standard-sized wheels is a popular choice for those looking to enhance the rugged look of a lifted OBS truck. This gives the vehicle an imposing presence and complements the raised suspension.

How did the Chevrolet and GMC C/K platform contribute to the popularity of OBS trucks?

These trucks are not just cherished for their nostalgic value but also for the practical and innovative improvements they introduced. The combination of visual appeal and mechanical advancements makes them highly sought after by both collectors and enthusiasts. Whether for restoration projects or daily use, the OBS Chevys offer a blend of classic design and forward-thinking engineering.

The fourth-generation C/K platform, known as GMT400, laid the groundwork for some of the most beloved OBS models. This robust platform was the backbone for a range of vehicles, including:

These models shared a design that defined an era, bringing a unique mix of functionality and style that continues to attract attention today. While Chevrolet used the C/K nomenclature, GMC opted for the Sierra name for its full-size pickups, each contributing to the platform’s versatility.

Originally crafted as full-size pickup trucks and chassis cabs, the GMT400 platform expanded into the realm of full-size SUVs, demonstrating its adaptability. This evolution was key to its lasting popularity as it managed to capture the spirit of the times while offering something uniquely timeless.

When the GMT800 platform succeeded the GMT400, it didn’t quite capture the hearts of enthusiasts, which only heightened the allure of the old-school OBS look. This enduring appeal underscores how the C/K platform’s blend of classic aesthetics and innovative engineering continues to captivate and inspire.

Share Link