Travis Noack

.

August 06, 2021

.

Department

Travis Noack

.

August 06, 2021

.

Department

A DRIVER. Every custom truck enthusiast must have one. The driver is the truck that gets mobbed on the daily work commute and usually gets put through the paces on the weekend hauling the “show truck” around. The driver is never left alone for long, however. It always starts out innocent enough with a drop kit or airbag suspension setup, wheels and tires, and maybe some upgraded audio and simple exterior bolt-ons, but that only lasts so long. Pretty soon, the custom truck freak’s desire to take the build further and further takes over, and what was once the driver becomes yet another show truck. So much for self-restraint!

Mike Barcia out of Tampa, Florida, bought a driver back in January 2001 to tow his full custom Isuzu show truck. The driver came to him in the form of a trade where Mike gave up the title to his bagged ’90 C3500 and some cash for the ’96 four-door that would eventually become No Compromize.

Mike Barcia out of Tampa, Florida, bought a driver back in January 2001 to tow his full custom Isuzu show truck. The driver came to him in the form of a trade where Mike gave up the title to his bagged ’90 C3500 and some cash for the ’96 four-door that would eventually become No Compromize.

After a weekend of de-grampifying the OBS Crew, Mike set about getting it on the ground. Set up with full air-ride suspension, the truck’s stock black paint eventually gave way to a full color change with a crisp and clean two-tone with traditional flames heating up the beltline coupled with billet interior accents, ear pounding audio and deep detail under the hood. It didn’t take long before the driver became another show truck. So, Mike decided to take the dually off the road and show circuit and build the most radical custom 1-ton on the planet. The Isuzu was sidelined and the dually became the popular girl getting all of the love and attention.

After a weekend of de-grampifying the OBS Crew, Mike set about getting it on the ground. Set up with full air-ride suspension, the truck’s stock black paint eventually gave way to a full color change with a crisp and clean two-tone with traditional flames heating up the beltline coupled with billet interior accents, ear pounding audio and deep detail under the hood. It didn’t take long before the driver became another show truck. So, Mike decided to take the dually off the road and show circuit and build the most radical custom 1-ton on the planet. The Isuzu was sidelined and the dually became the popular girl getting all of the love and attention.

It was February 2003 when Mike and friend and fellow Negative Camber club member Robbie Taylor tore the truck down to perform a traditional 4-inch body drop on it. After the rockers were kissing the Florida asphalt, the truck looked cool but Mike thought, “It’ll just be another bagged and bodied dually with nice paint and a stock frame under it.” So, the decision was made to go for broke and have a full custom chassis built. Also being a fan and regular attendee of ISCA World of Wheels car shows where the best of best show up to compete, Mike knew that if he wanted to play on that level with the truck, then he had to bring his A game.

It was February 2003 when Mike and friend and fellow Negative Camber club member Robbie Taylor tore the truck down to perform a traditional 4-inch body drop on it. After the rockers were kissing the Florida asphalt, the truck looked cool but Mike thought, “It’ll just be another bagged and bodied dually with nice paint and a stock frame under it.” So, the decision was made to go for broke and have a full custom chassis built. Also being a fan and regular attendee of ISCA World of Wheels car shows where the best of best show up to compete, Mike knew that if he wanted to play on that level with the truck, then he had to bring his A game.

Enter Jimmy Graham of Jimmy’s Rod N Customs in Edgewater, Florida. Jimmy hand built and fabricated a oneoff custom chassis equipped with a custom built four-link rear suspension. The leadingedge underpinnings feature custom front suspension and shock hoops built from scratch. Not only is the chassis of No Compromize a work of fabrication and design art, but the depth of detail is unmatched.

Enter Jimmy Graham of Jimmy’s Rod N Customs in Edgewater, Florida. Jimmy hand built and fabricated a oneoff custom chassis equipped with a custom built four-link rear suspension. The leadingedge underpinnings feature custom front suspension and shock hoops built from scratch. Not only is the chassis of No Compromize a work of fabrication and design art, but the depth of detail is unmatched.

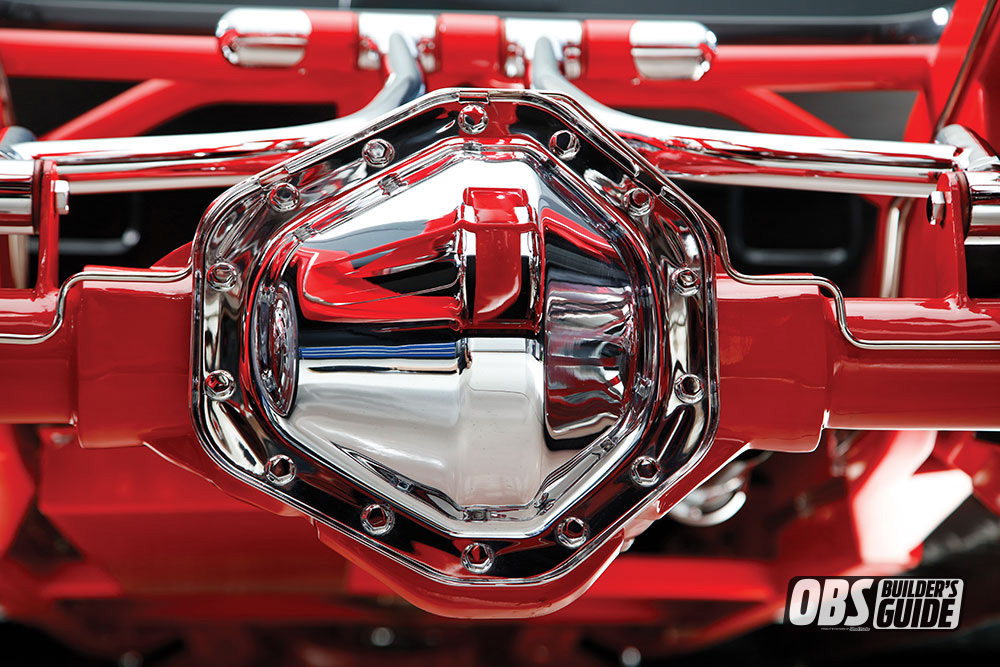

After Jimmy finished fabbing up the ultimate bones and suspension, Mike took special care to grind smooth all unnecessary roughness, such as the factory ridges on top of the rear differential where the axle tubes meet the pumpkin. Mike and Gerald Ashe welded up all of the seams and grinded all the welds baby butt smooth. Friend and fellow NC club member David “Double D” Dekorver bodyworked the frame before Chris Bareswilt covered the chassis and suspension components in Euro Red. The frame and suspension were painted as opposed to powdercoated for a superior finish, and then Mike wet sanded and polished to perfection.

After Jimmy finished fabbing up the ultimate bones and suspension, Mike took special care to grind smooth all unnecessary roughness, such as the factory ridges on top of the rear differential where the axle tubes meet the pumpkin. Mike and Gerald Ashe welded up all of the seams and grinded all the welds baby butt smooth. Friend and fellow NC club member David “Double D” Dekorver bodyworked the frame before Chris Bareswilt covered the chassis and suspension components in Euro Red. The frame and suspension were painted as opposed to powdercoated for a superior finish, and then Mike wet sanded and polished to perfection.

To keep things extra clean and smooth, all of the wiring was run through the frame rails, the air compressors were plumbed into the chassis tubing, and all of the chromed stainless bolts were clocked the same direction for that extra touch of ISCA detail. Polished stainless hard lines handle fluid transfer to the brakes and transmission, while a fully polished 3-inch stainless exhaust system built by Jimmy Graham with one-off billet chrome plated exhaust hangers built by Tom Hingle of Billet & Acrylic Fantasies kick out the octane cocktails. Cruising juice is housed in a custom aluminum fuel cell built by Jeff Davy of Devious Customs. The factory rearend was shortened 9 inches and stuffed with shortened Franklin axles while the first set of 24-inch Raceline Ratchet polished wheels mounted on Toyo rubber. Mike even sanded the side walls down for a smooth no-letter look. For an extra touch, Mike reached out to Kennedy Brown from Fat Dog Designs in Jonesboro, Arkansas, to machine one-off billet floating logo No Compromize center caps.

To keep things extra clean and smooth, all of the wiring was run through the frame rails, the air compressors were plumbed into the chassis tubing, and all of the chromed stainless bolts were clocked the same direction for that extra touch of ISCA detail. Polished stainless hard lines handle fluid transfer to the brakes and transmission, while a fully polished 3-inch stainless exhaust system built by Jimmy Graham with one-off billet chrome plated exhaust hangers built by Tom Hingle of Billet & Acrylic Fantasies kick out the octane cocktails. Cruising juice is housed in a custom aluminum fuel cell built by Jeff Davy of Devious Customs. The factory rearend was shortened 9 inches and stuffed with shortened Franklin axles while the first set of 24-inch Raceline Ratchet polished wheels mounted on Toyo rubber. Mike even sanded the side walls down for a smooth no-letter look. For an extra touch, Mike reached out to Kennedy Brown from Fat Dog Designs in Jonesboro, Arkansas, to machine one-off billet floating logo No Compromize center caps.

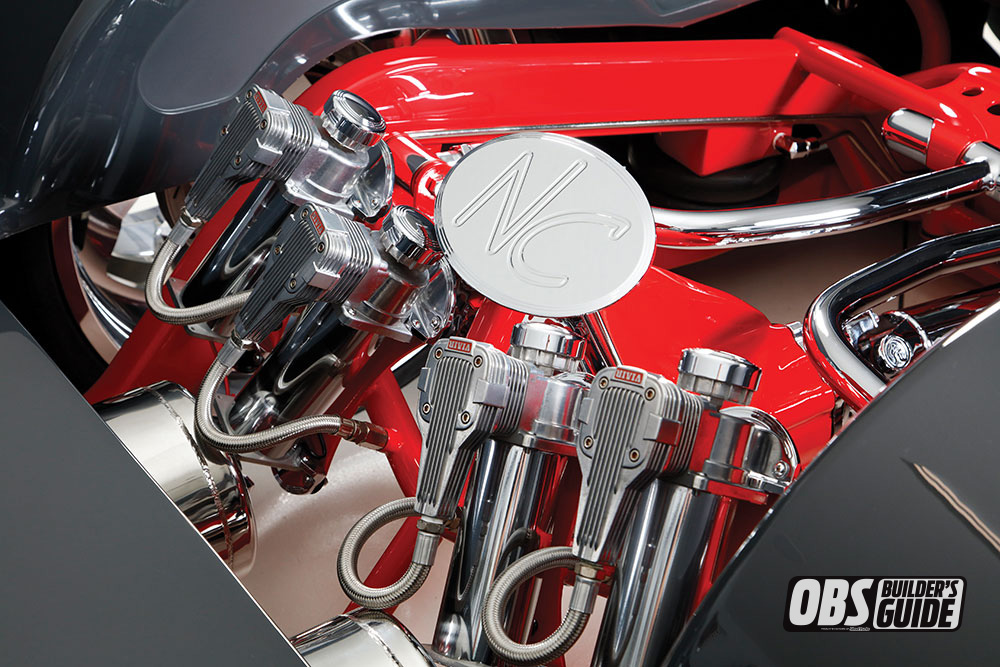

The truck comes to a halt with one-off billet 4-piston calipers and custom slotted and drilled rotors by Aerospace Engineering. Slam Specialties Slam Bags get the meticulously detailed underpinnings on the ground while air management from Accuair sends lift and drop commands from Mike’s itchy trigger fingers. Viair compressors re-supply the tanks.

The truck comes to a halt with one-off billet 4-piston calipers and custom slotted and drilled rotors by Aerospace Engineering. Slam Specialties Slam Bags get the meticulously detailed underpinnings on the ground while air management from Accuair sends lift and drop commands from Mike’s itchy trigger fingers. Viair compressors re-supply the tanks.

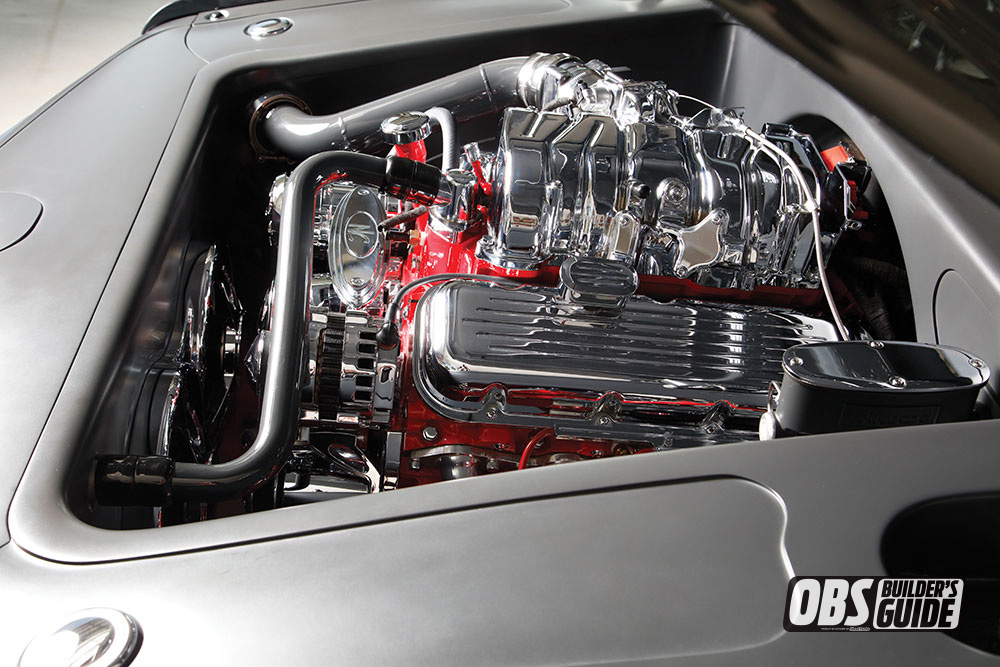

The factory big block, while mechanically stock, has a bit more bite with a March Pulley Set, Edelbrock Headers and 3-inch custom built stainless exhaust. Making the most noise under the hood is the deep detail, including the smoothed block and heads, paint-matched block, and all of the chromed and polished accents. Mike wanted the world’s finest chrome, so he reached out to Steve from Advanced Plating in Tennessee to get that accomplished. Billet Specialties valve covers cap off the valve train in style, while a custom-built radiator from Performance Rod and Customs keeps the BBC’s operating temps in check. A Wilwood master cylinder kicks fluid to the custom machined calipers allowing them to bite down on the slotted and drilled rotors.

The factory big block, while mechanically stock, has a bit more bite with a March Pulley Set, Edelbrock Headers and 3-inch custom built stainless exhaust. Making the most noise under the hood is the deep detail, including the smoothed block and heads, paint-matched block, and all of the chromed and polished accents. Mike wanted the world’s finest chrome, so he reached out to Steve from Advanced Plating in Tennessee to get that accomplished. Billet Specialties valve covers cap off the valve train in style, while a custom-built radiator from Performance Rod and Customs keeps the BBC’s operating temps in check. A Wilwood master cylinder kicks fluid to the custom machined calipers allowing them to bite down on the slotted and drilled rotors.

When building a truck of this caliber, getting it this low and expecting it to compete and win on the extremely competitive indoor show circuit, you have to pull out all of the stops. Modifications lead to more modifications to achieve the right fit, the right look, the right form and most importantly the right function! Not only does No Compromize have a detailed to the nines, full-custom chassis, but the envelope was deeply modified as well, demanding a mountain of metal work from the firewall forward.

When building a truck of this caliber, getting it this low and expecting it to compete and win on the extremely competitive indoor show circuit, you have to pull out all of the stops. Modifications lead to more modifications to achieve the right fit, the right look, the right form and most importantly the right function! Not only does No Compromize have a detailed to the nines, full-custom chassis, but the envelope was deeply modified as well, demanding a mountain of metal work from the firewall forward.

Blending classic CK lines with more modern Silverado styling, Mike opted to go with a ‘06 Chevy cat-eye front end. Sounds simple, right? But this mod combined with Mike’s obsession to go over the top turned into a five-year fabrication adventure just to make it seamless. Jimmy’s Rod ‘N’ Custom knocked it out of the park again with hammer bending all of the edges for a clean, smooth look. The front fenders were sectioned and lengthened in the front to make them flush with the ’06 Silverado bumper. On the backside, the ’06 fender is joined with the ’96 fender, and the wheel opening had to be cut, sectioned and massaged to make the lines flow proportionately. Moving up, the hood was lengthened on the backside by 10 inches and the windshield wiper cowl area was removed. The side curves of the hood were cut off so that when the hood was opened a clean fender line was achieved. The hood top body lines were then rebuilt and moved in 2 inches per side. The bottom side of the hood was hand built with a bead-rolled insert added for a smooth look and to gain clearance between the top of the intake and the base of the hood. The ’06 Silverado bumper top was chromed and the lower half sectioned and extended by Gerald Ashe so the bottom sat flush with the tarmac when the truck is laid out.

Blending classic CK lines with more modern Silverado styling, Mike opted to go with a ‘06 Chevy cat-eye front end. Sounds simple, right? But this mod combined with Mike’s obsession to go over the top turned into a five-year fabrication adventure just to make it seamless. Jimmy’s Rod ‘N’ Custom knocked it out of the park again with hammer bending all of the edges for a clean, smooth look. The front fenders were sectioned and lengthened in the front to make them flush with the ’06 Silverado bumper. On the backside, the ’06 fender is joined with the ’96 fender, and the wheel opening had to be cut, sectioned and massaged to make the lines flow proportionately. Moving up, the hood was lengthened on the backside by 10 inches and the windshield wiper cowl area was removed. The side curves of the hood were cut off so that when the hood was opened a clean fender line was achieved. The hood top body lines were then rebuilt and moved in 2 inches per side. The bottom side of the hood was hand built with a bead-rolled insert added for a smooth look and to gain clearance between the top of the intake and the base of the hood. The ’06 Silverado bumper top was chromed and the lower half sectioned and extended by Gerald Ashe so the bottom sat flush with the tarmac when the truck is laid out.

Even before paint was laid down, the engine compartment alone was a work of art in and of itself, with a custom bead-rolled firewall, custom core support and core support bead-rolled sheetmetal cover and bead-rolled fender wells. The radiator and power steering caps were all frenched into the sheetmetal work as well as the hood hinge pockets. To take it one step further, Mike wanted custom billet hood hinges, but he had no clue what he was getting himself into. After commissioning four different machine shops and delaying the build for over a year, Bobby McCurdy finally saved the day. Bobby designed and cut a set of one-off custom billet hood hinges like no other. The truck is basically a highend turn table street rod with a bed on it.

Even before paint was laid down, the engine compartment alone was a work of art in and of itself, with a custom bead-rolled firewall, custom core support and core support bead-rolled sheetmetal cover and bead-rolled fender wells. The radiator and power steering caps were all frenched into the sheetmetal work as well as the hood hinge pockets. To take it one step further, Mike wanted custom billet hood hinges, but he had no clue what he was getting himself into. After commissioning four different machine shops and delaying the build for over a year, Bobby McCurdy finally saved the day. Bobby designed and cut a set of one-off custom billet hood hinges like no other. The truck is basically a highend turn table street rod with a bed on it.

After Jimmy finished the work on the front clip and the engine compartment, it was time to get the cab and bed slick and smooth. Starting with the bed, the fuel door, stake pockets, tailgate handle and taillights were all shaved. A motorcycle style fuel cap was added to the top of the bed rail while one-off custom taillights by Greening Auto were frenched in for stylish stopping. A custom roll pan was built, and the dually fenders were raised 2 inches so the 24-inch Raceline would tuck. Jimmy fabricated new bead-rolled sheetmetal to the front outside bulkhead of the bed, and the factory dually fender marker lights were shaved in favor of custom one off machined replacement. Jimmy kept the tools burning by fabricating a push-button tailgate handle on the inside of the tailgate, rounding all four corners of the inside of the bed, building bead-rolled interior sheetmetal inserts inside the inner bed sides, and building widened bead-rolled inner wheel tubs. It didn’t stop there. The welder kept on blazing with a custom raised and smoothed bed floor panel, both top and bottom, smooth sheetmetal on the inside of the tailgate and bead-rolled billet oval No Compromize insert into the tailgate.

After Jimmy finished the work on the front clip and the engine compartment, it was time to get the cab and bed slick and smooth. Starting with the bed, the fuel door, stake pockets, tailgate handle and taillights were all shaved. A motorcycle style fuel cap was added to the top of the bed rail while one-off custom taillights by Greening Auto were frenched in for stylish stopping. A custom roll pan was built, and the dually fenders were raised 2 inches so the 24-inch Raceline would tuck. Jimmy fabricated new bead-rolled sheetmetal to the front outside bulkhead of the bed, and the factory dually fender marker lights were shaved in favor of custom one off machined replacement. Jimmy kept the tools burning by fabricating a push-button tailgate handle on the inside of the tailgate, rounding all four corners of the inside of the bed, building bead-rolled interior sheetmetal inserts inside the inner bed sides, and building widened bead-rolled inner wheel tubs. It didn’t stop there. The welder kept on blazing with a custom raised and smoothed bed floor panel, both top and bottom, smooth sheetmetal on the inside of the tailgate and bead-rolled billet oval No Compromize insert into the tailgate.

Ever since the truck came off the road and was torn down in ’03, the color of choice for the modified metal was to be red. When it came time for the metal work to be body worked and covered in color, Mike delivered the truck to Justin and Eli Griffin at Twin States Rod Shop in Meridian, Mississippi. Once the truck was arrow straight, smooth and ready for color, it was time for the booth and the ultimate decision on color. Since the chassis was already red and Mike wanted it to stand out, it was decided that the body better be an opposing color. BASF RM products were custom mixed to come up with the custom color nicknamed “SEMA Gray,” and the truck was coated from nose to tail and roof to rocker and the liquid art buried in RM Glamour clear coat.

Ever since the truck came off the road and was torn down in ’03, the color of choice for the modified metal was to be red. When it came time for the metal work to be body worked and covered in color, Mike delivered the truck to Justin and Eli Griffin at Twin States Rod Shop in Meridian, Mississippi. Once the truck was arrow straight, smooth and ready for color, it was time for the booth and the ultimate decision on color. Since the chassis was already red and Mike wanted it to stand out, it was decided that the body better be an opposing color. BASF RM products were custom mixed to come up with the custom color nicknamed “SEMA Gray,” and the truck was coated from nose to tail and roof to rocker and the liquid art buried in RM Glamour clear coat.

Completion of the metal work, body work and paint led to wiring before the truck was delivered to the upholstery and audio shop for threads and sounds. Justin and Eli Griffin installed a Painless Performance wiring harness to connect all of the electrical dots and a custom motor wire harness from Tempe Speed & Performance to get the bigblock cranking.

Completion of the metal work, body work and paint led to wiring before the truck was delivered to the upholstery and audio shop for threads and sounds. Justin and Eli Griffin installed a Painless Performance wiring harness to connect all of the electrical dots and a custom motor wire harness from Tempe Speed & Performance to get the bigblock cranking.

No head turning, jaw dropping and awardwinning custom show truck is complete without a double throw down interior and some tunes to pummel ear drums. Aaron Markwell, Jesse Johannesen and the team of Innerworx in Sarasota, Florida, got down on the cabin of No Compromize with the entire interior inner structure built out of ABS plastic and then cut, shaped, layered and routered out to perfection. Innerworx built the custom dash, door panels, center console, overhead console and the seats. A total of 11 hides of Relicate Napa saddle leather were used to wrap the full custom interior. Mushroom Versaweave textile carpet covers the cab floor. Complementing the supple leather and smooth street rod sculpted styling of the threads is a Flaming River steering column topped by a custom machined 15-inch billet steering wheel. Vintage Air climate control keeps show cruising temps in check while Classic Instruments gauges provide accurate reporting on the big blocks behavioral patterns. Further accenting the cruising chamber are a variety of billet dress-up items from Clayton Machine Works. To finish off the interior, Mike had Jeff Bertrand of J&B Microfinish in Pontiac, Illinois, machine custom billet seat recliner handles to match the door handles, while Tony Pasquini of Automods in Sarasota, Florida, performed the interior leather laser engraving NC logos throughout. Tom Hingle of Billet and Acrylic Fantasies in Vero Beach, Florida, designed and machined more than 100 unique custom billet parts placed carefully and strategically throughout the build to add class and detail at every turn. A keen eye will note the “NC” engraved throughout the billet accents signifying two things—the truck’s name, No Compromize, and Mike’s truck club, Negative Camber.

No head turning, jaw dropping and awardwinning custom show truck is complete without a double throw down interior and some tunes to pummel ear drums. Aaron Markwell, Jesse Johannesen and the team of Innerworx in Sarasota, Florida, got down on the cabin of No Compromize with the entire interior inner structure built out of ABS plastic and then cut, shaped, layered and routered out to perfection. Innerworx built the custom dash, door panels, center console, overhead console and the seats. A total of 11 hides of Relicate Napa saddle leather were used to wrap the full custom interior. Mushroom Versaweave textile carpet covers the cab floor. Complementing the supple leather and smooth street rod sculpted styling of the threads is a Flaming River steering column topped by a custom machined 15-inch billet steering wheel. Vintage Air climate control keeps show cruising temps in check while Classic Instruments gauges provide accurate reporting on the big blocks behavioral patterns. Further accenting the cruising chamber are a variety of billet dress-up items from Clayton Machine Works. To finish off the interior, Mike had Jeff Bertrand of J&B Microfinish in Pontiac, Illinois, machine custom billet seat recliner handles to match the door handles, while Tony Pasquini of Automods in Sarasota, Florida, performed the interior leather laser engraving NC logos throughout. Tom Hingle of Billet and Acrylic Fantasies in Vero Beach, Florida, designed and machined more than 100 unique custom billet parts placed carefully and strategically throughout the build to add class and detail at every turn. A keen eye will note the “NC” engraved throughout the billet accents signifying two things—the truck’s name, No Compromize, and Mike’s truck club, Negative Camber.

For cruising beats, Mike went with all Sony components featuring three-way speakers up front, two 10-inch subwoofers in the center console and a sixchanel Bluetooth amplifier with DSP sending the signals.

For cruising beats, Mike went with all Sony components featuring three-way speakers up front, two 10-inch subwoofers in the center console and a sixchanel Bluetooth amplifier with DSP sending the signals.

No Compromize was a 15-year journey in the making from the time Mike tore it down until the day it rolled into the SEMA Show in November 2018. His commitment to the level and quality of the build is self-evident in the finished product. Mike is thankful for the help and support of his wife, Heather, and daughters Madison and Brooke Barcia for allowing him to pursue his dream. Mike would also like to extend his deepest appreciation for the hard work and dedication of the build team, including Justin Griffin, Eli Griffin, Gauge Griffin, Jimmy Graham, Aaron Markwell, Jesse Johannesen, Chris Bareswilt, Gerald Ashe, David Dekorver, Robbie Taylor, Efrain Ramos, Tony Pasquini, Cody Holmes, Chris Douglass, Joe Griswold, Alex Madrigal, Kennedy Brown, Bobby McCurdy, Jeff Bertrand, Andre Brown, Chris Rawlins, Matty Barkley, Anthony DeMichael, Chuck Scheer, Bryan Perreault, Danny Terneus and CJ Fayet. Bad ass trucks, family and friends— what it’s all about!

TRUCK SPECS

Mike Barcia

1996 Chevy C3500 Dually

Tampa, Florida

Negative Camber

Chassis/Suspension

Engine/Drivetrain/Performance

Wheels/Tires Brakes

Body /Paint

Interior

Miscellaneous Custom Tricks

Share Link